A cold bending equipment and method for manufacturing U-shaped bar

A U-shaped, cold-state technology, which is applied in the field of cold-state bending equipment for manufacturing U-shaped rods, can solve the problems of metal material structure changes, low bending control precision, and unsuitable use in occasions with high material performance requirements, and achieves guaranteed The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

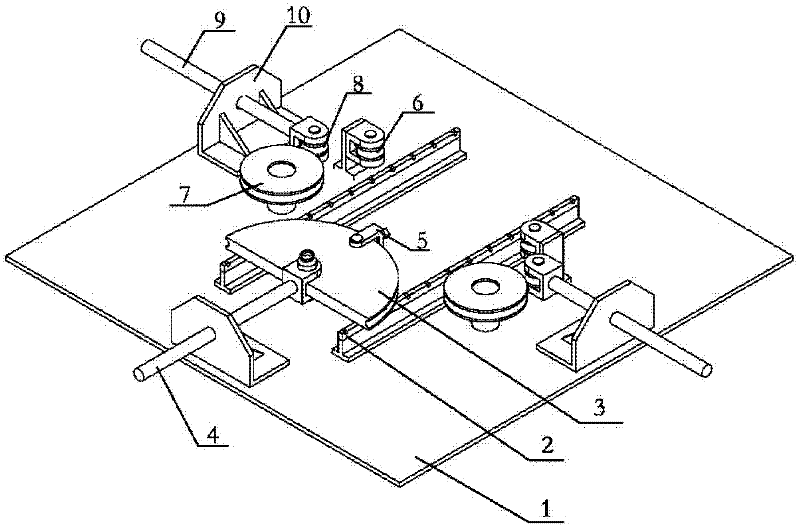

[0030]A steel bar with a diameter of 30mm is provided below, and the U section is bent into a semicircle with a radius of 363mm. An embodiment of the cold bending equipment for manufacturing U-shaped rods.

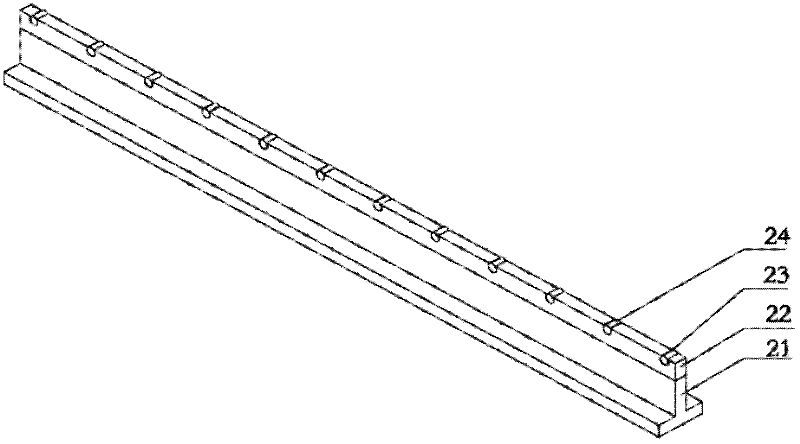

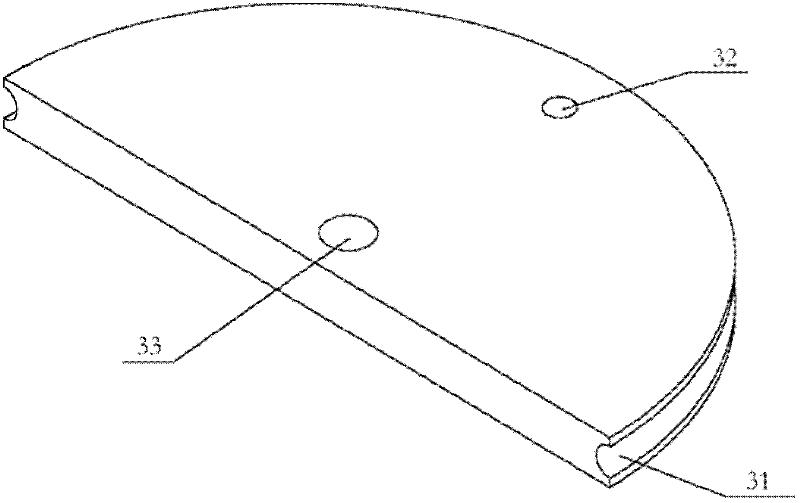

[0031] The distance between two parallel guide rails is 500mm, and the width of the guide rails is 20mm. On the guide rails, rollers with a diameter of 10mm are equidistant at 100mm intervals; the mold is pushed forward to a semicircle with a radius of 363mm and a thickness of 50mm. For a groove with a radius of 16mm, the center of the groove on the cross section is 1mm away from the arc edge of the positively pushing mold, that is, the depth of the groove on the forwardly pushing mold is 15mm. The grooves of pads in other lateral guide pulleys, lateral push pulleys and steel bar fixtures are also provided with the same. The diameter of the small lateral guide pulleys on both sides is 100mm, and the diameter of the large lateral guide pulleys is 300mm. The distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com