Automatic production line of solar sectional material

An automated production line and solar profile technology, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of excessive manual processes, low production efficiency, uneven products, etc., to reduce production costs, reduce labor costs, installation and Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

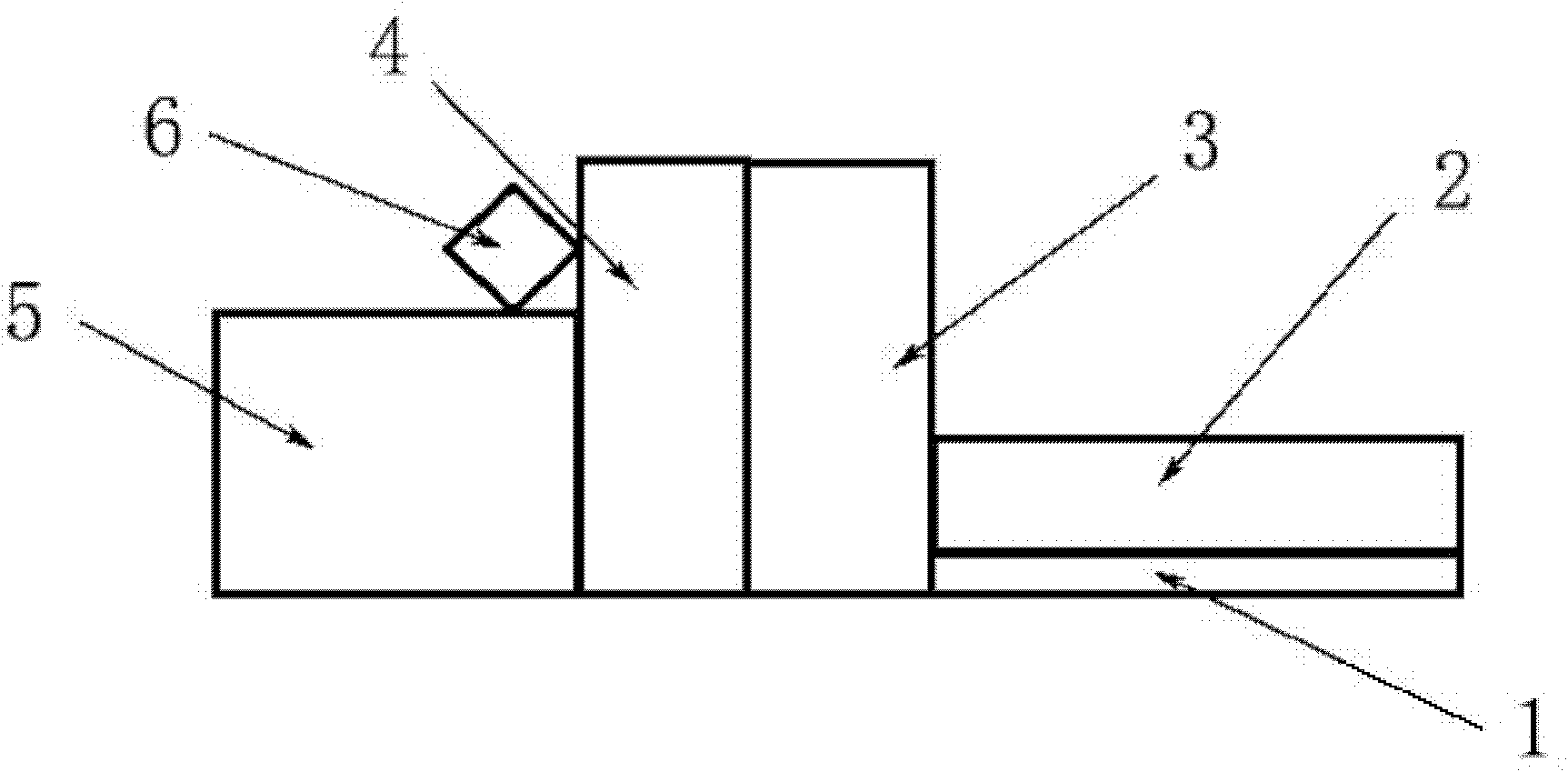

[0032] Such as figure 1 As shown, the solar profile automatic production line of the present invention is composed of a feeding support part 1, a feeding and conveying part 2, a tape pasting part 3, a punching part 4, a bending part 5 and a control cabinet 6.

[0033] Such as figure 1 The shown feeding support part 1, tape sticking part 3, punching part 4, and bending part 5 are connected in sequence, the feeding support part 1 and the feeding conveying part 2 are connected together side by side, and the control cabinet 6 is placed in the punching part 4 and the bending part 5, and connect with each part of the whole production line through lines.

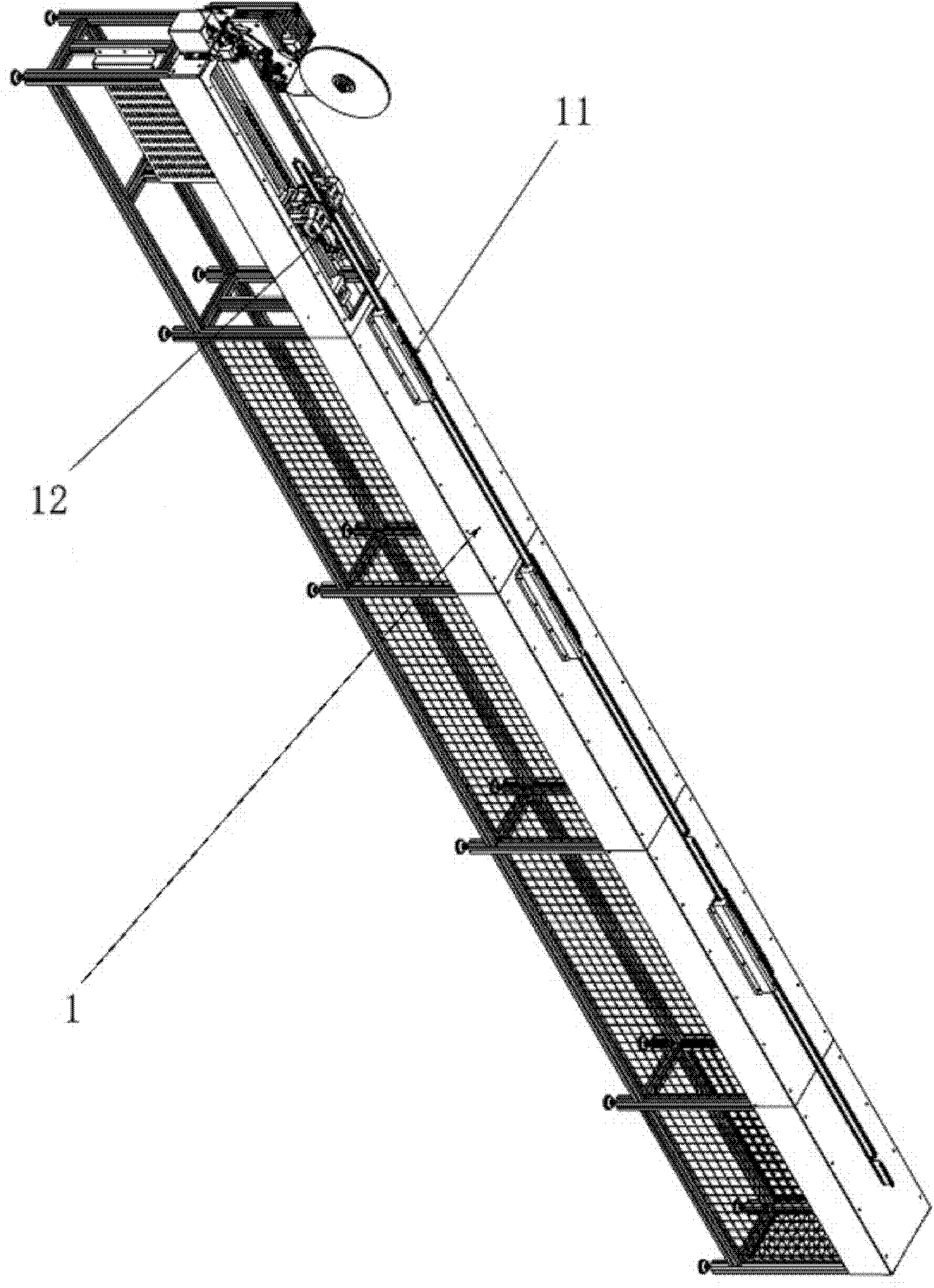

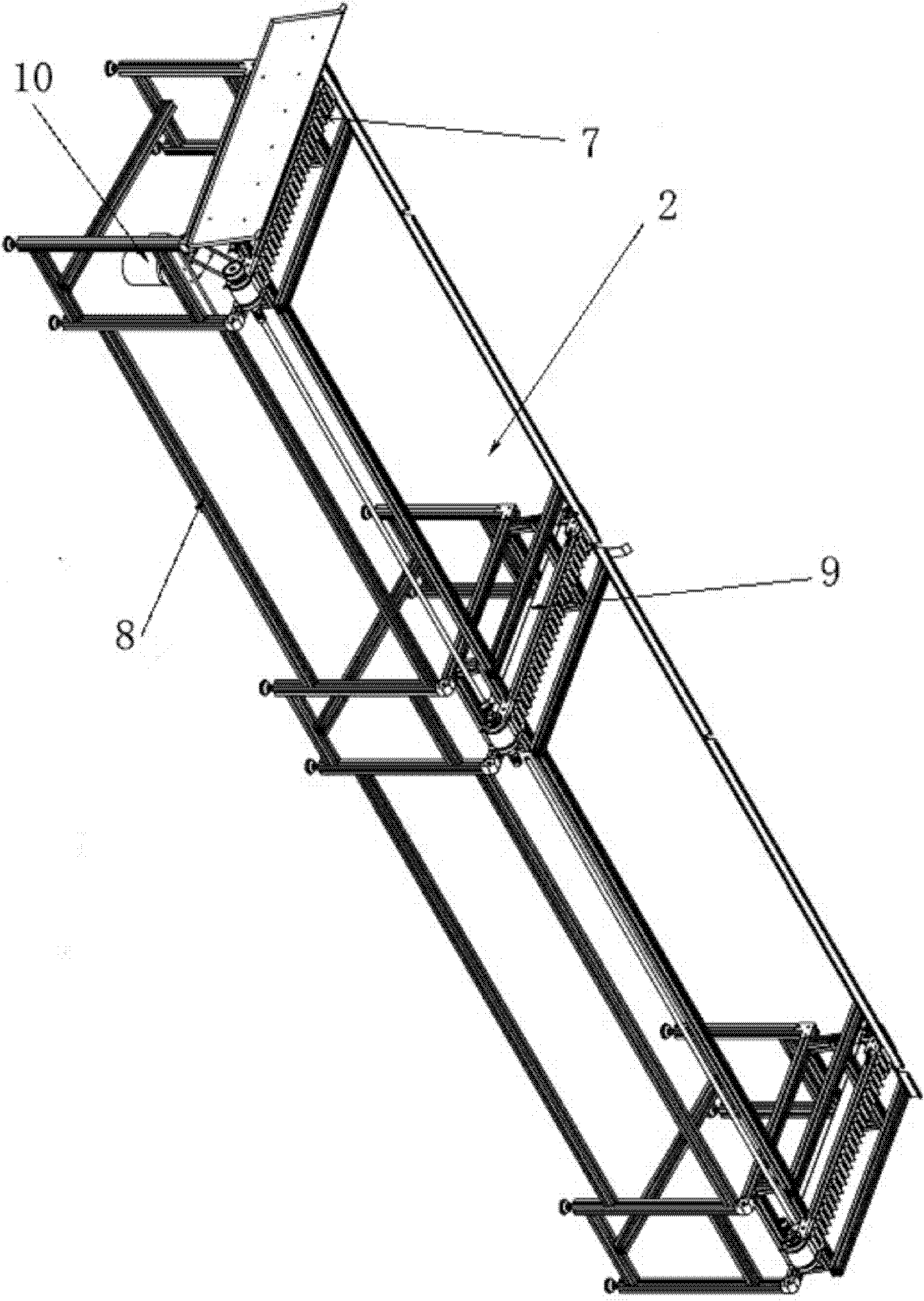

[0034] Such as figure 2 , Figure 8 As shown, the feeding support part 1 is composed of a support positioning structure 11 and a traveling device 12. The support positioning structure 11 completes the positioning of the profile, and the traveling device 12 adjusts the speed of the profile according to the 6 commands of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com