A coding machine base with an annular groove

A ring groove and coding machine technology, which is applied in printing, stamping, etc., can solve problems such as structural dislocation, inconsistent actions, and inaccurate dimensions, and achieve the effect of reasonable design, overcoming unreasonable design, and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

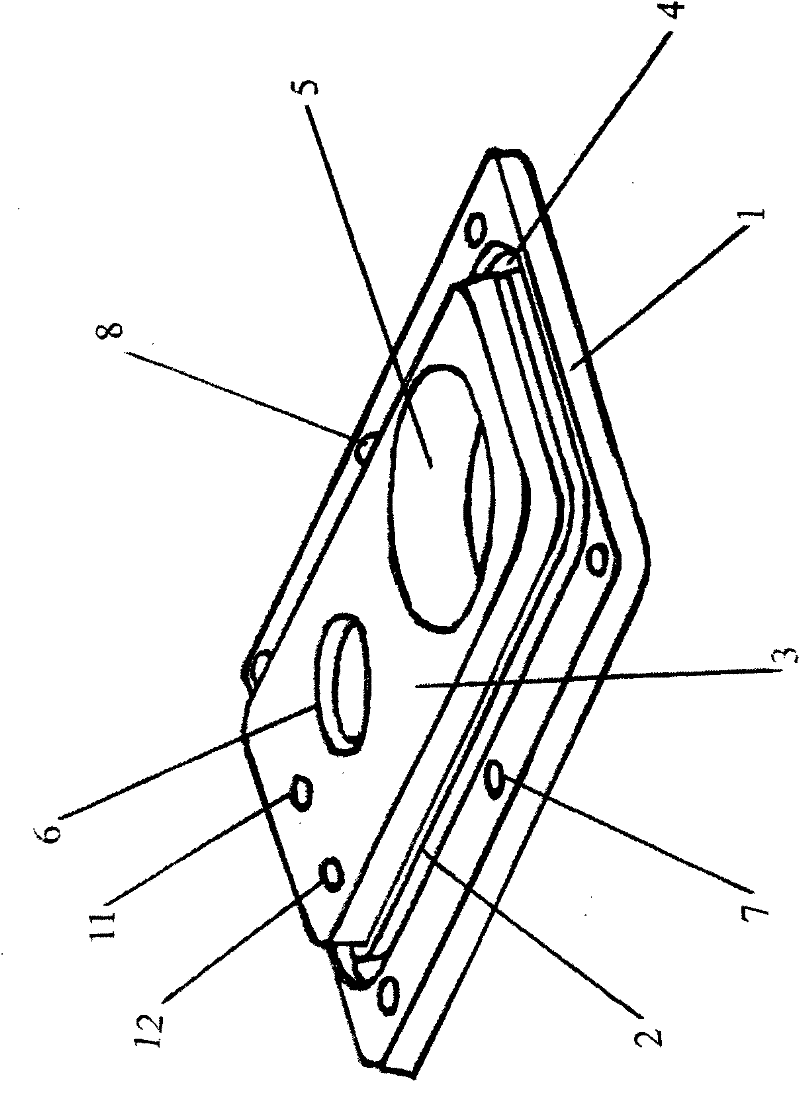

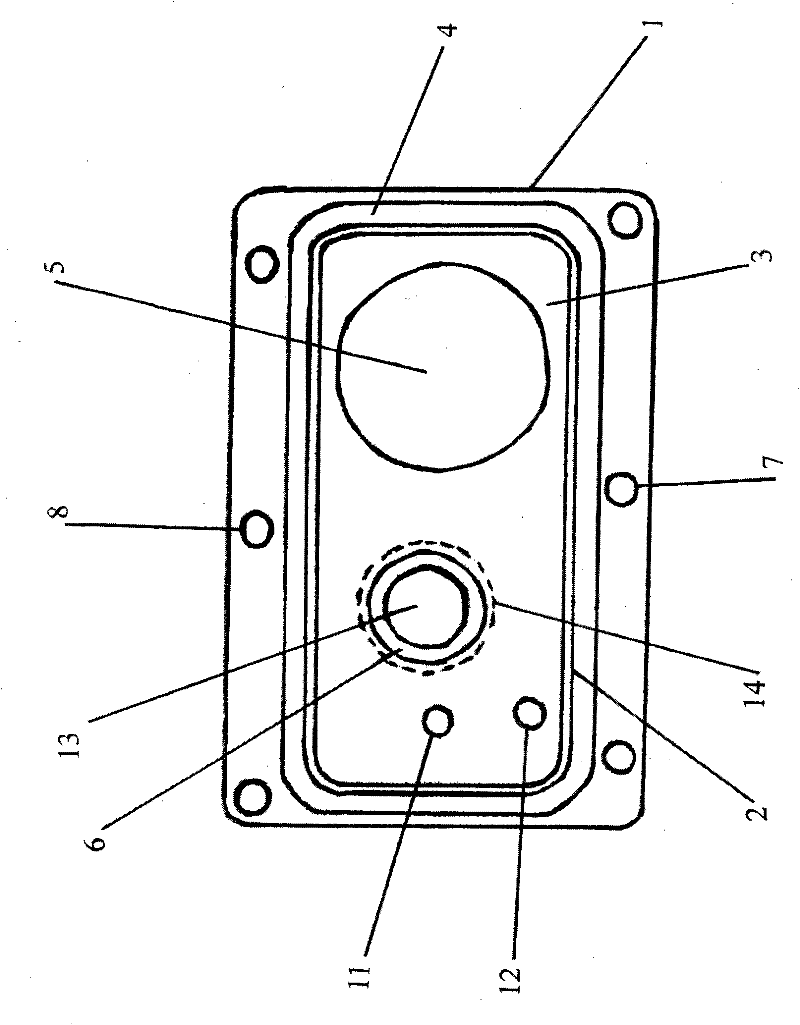

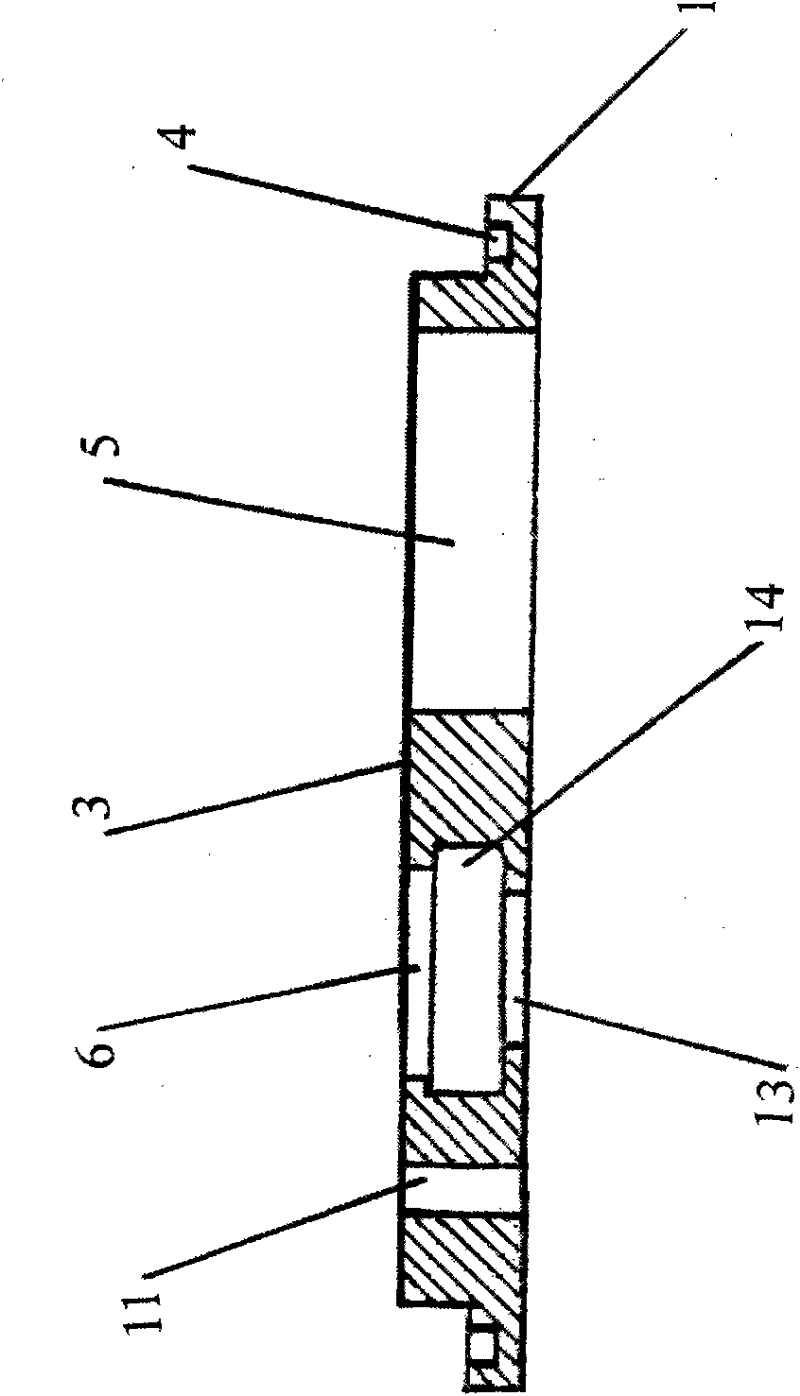

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011]A coding machine base with an annular groove, including a base plate, a groove and a hole, characterized in that the base plate 1 is a rectangular parallelepiped metal plate, the left and right lengths of the base plate 1 are 95.25mm, and the front, The rear width is 61.9252mm, and the upper and lower heights are 3.9624mm; the base plate 1 has six sides, left, right, front, rear, upper and lower, and the left, right, front and rear corners of the base plate 1 are Small rounded corners, the radius of the four small rounded corners is 3.9624mm; there is an annular groove 4 on the top of the base plate 1, the annular groove 4 is a groove with a four-sided shape, and the depth of the annular groove 4 is 2.032mm mm, the width of the annular groove 4 is 1.1938mm, the annular groove 4 is surrounded by the outer ring edge and the inner ring edge, the annular groove 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com