Tension pay-off device for wire rope

The technology of a pay-off device and a wire rope is applied in the field of the pay-off device, which can solve the problems of unstable tension and the like, and achieve the effects of convenient installation and regulation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

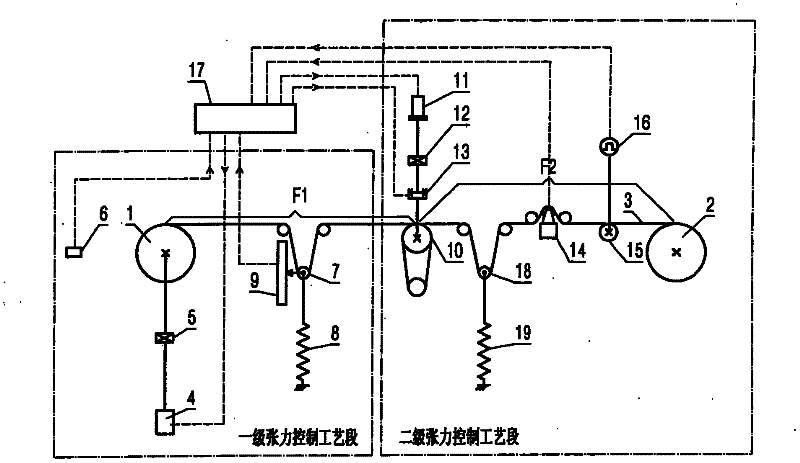

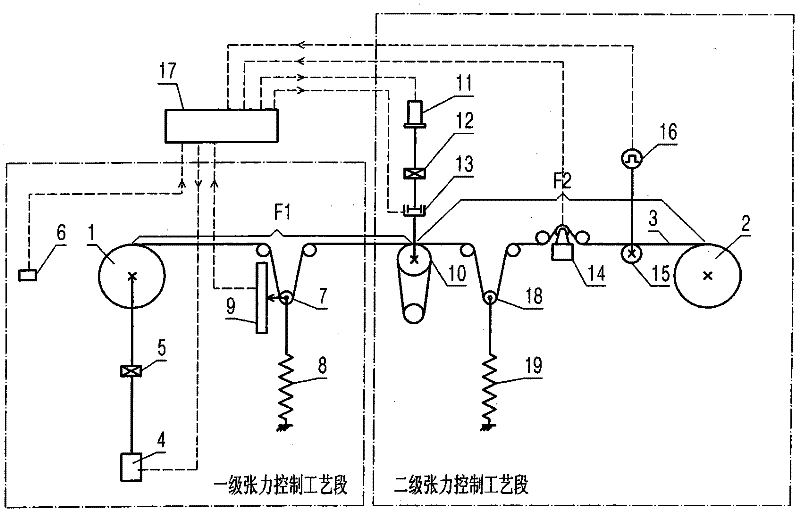

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention includes a pay-off reel 1 and a take-up reel 2 and a wire rope 3 wound on the pay-off reel 1 and the take-up reel 2 respectively, wherein the take-up reel 2 winds the wire rope 3 at a certain speed On the driving wheel thereon, a primary tension F1 is produced on the wire rope 3 behind the pay-off reel 1, and a secondary tension F2 is generated on the wire rope 3 before the take-up reel 2; the pay-off reel 1 The wheel shaft is provided with a first-stage pay-off power mechanism 4 that controls the primary tension F1 of the wire rope through torque or speed; on the wire rope 3 in front of the pay-off reel 1, there is a coil that can control the wire rope through the output torque or speed. Secondary pay-off wheel set 10 with secondary tension F2.

[0016] The first-level pay-off power mechanism 4 is at least composed of a speed-adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com