A boom machine that drives the translation of the reel

A technology of boom machine and driving machine, which is applied in the direction of clockwork mechanism and hoisting device, which can solve the problems of slipping out of the chute, danger, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

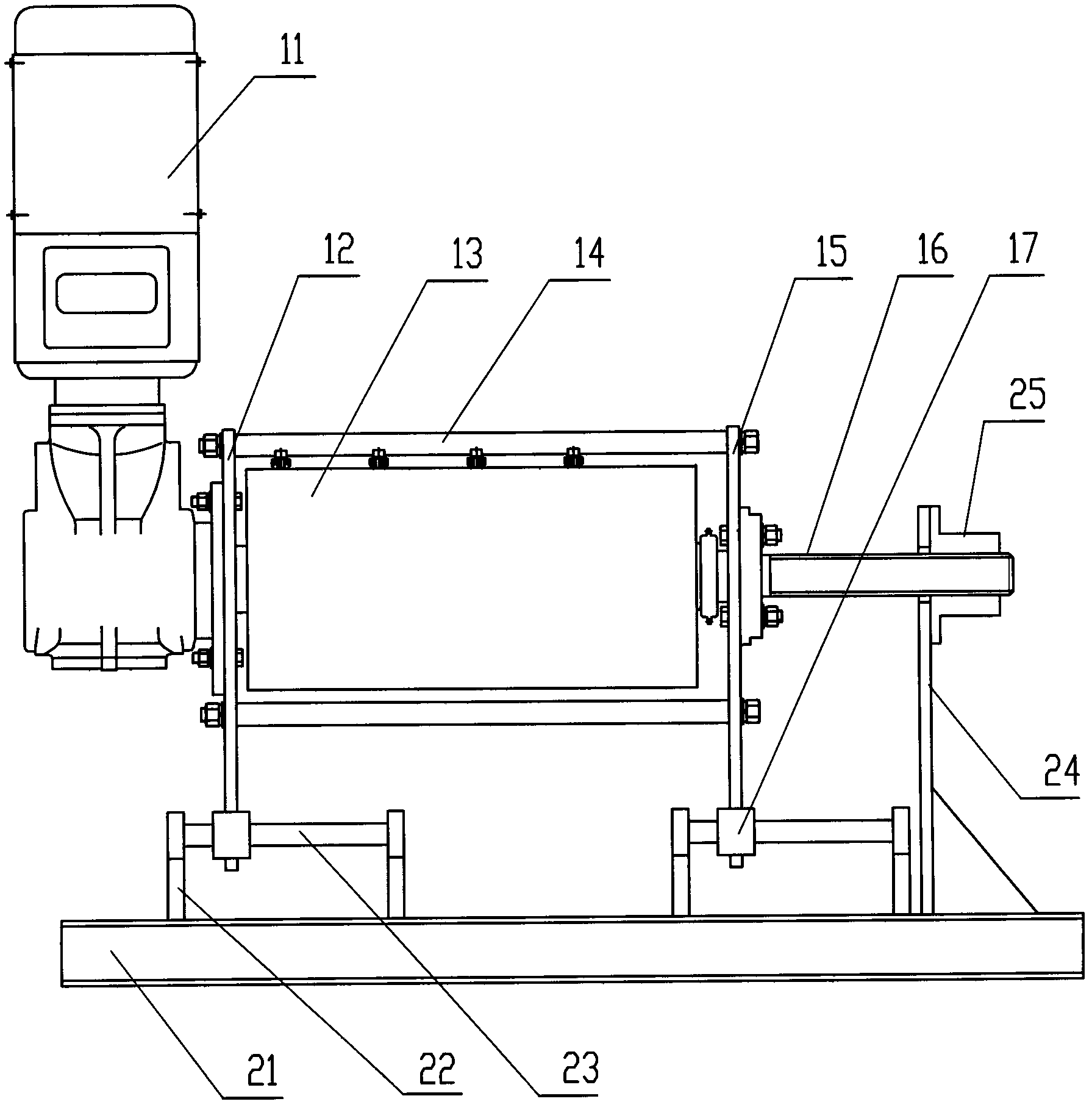

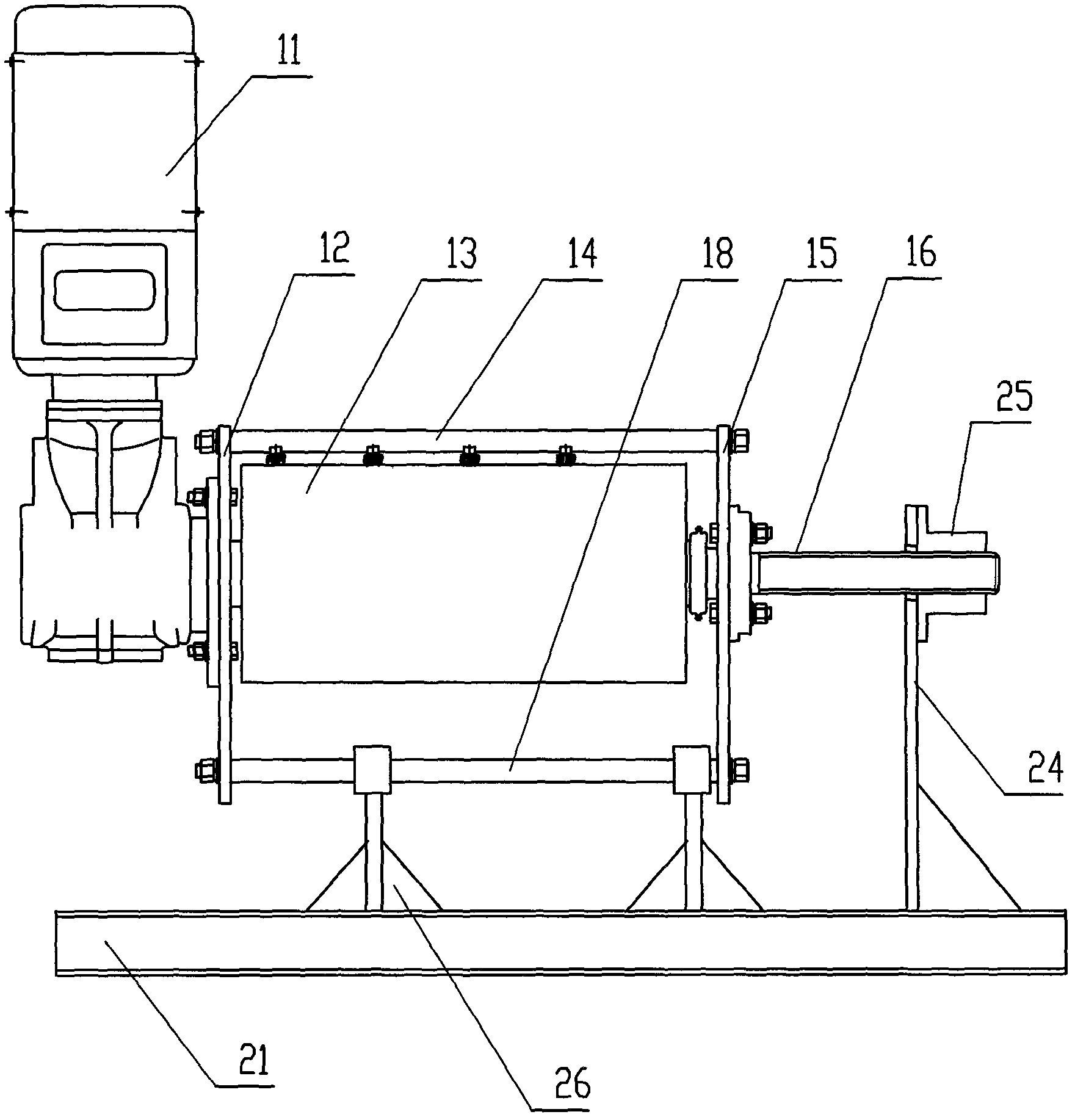

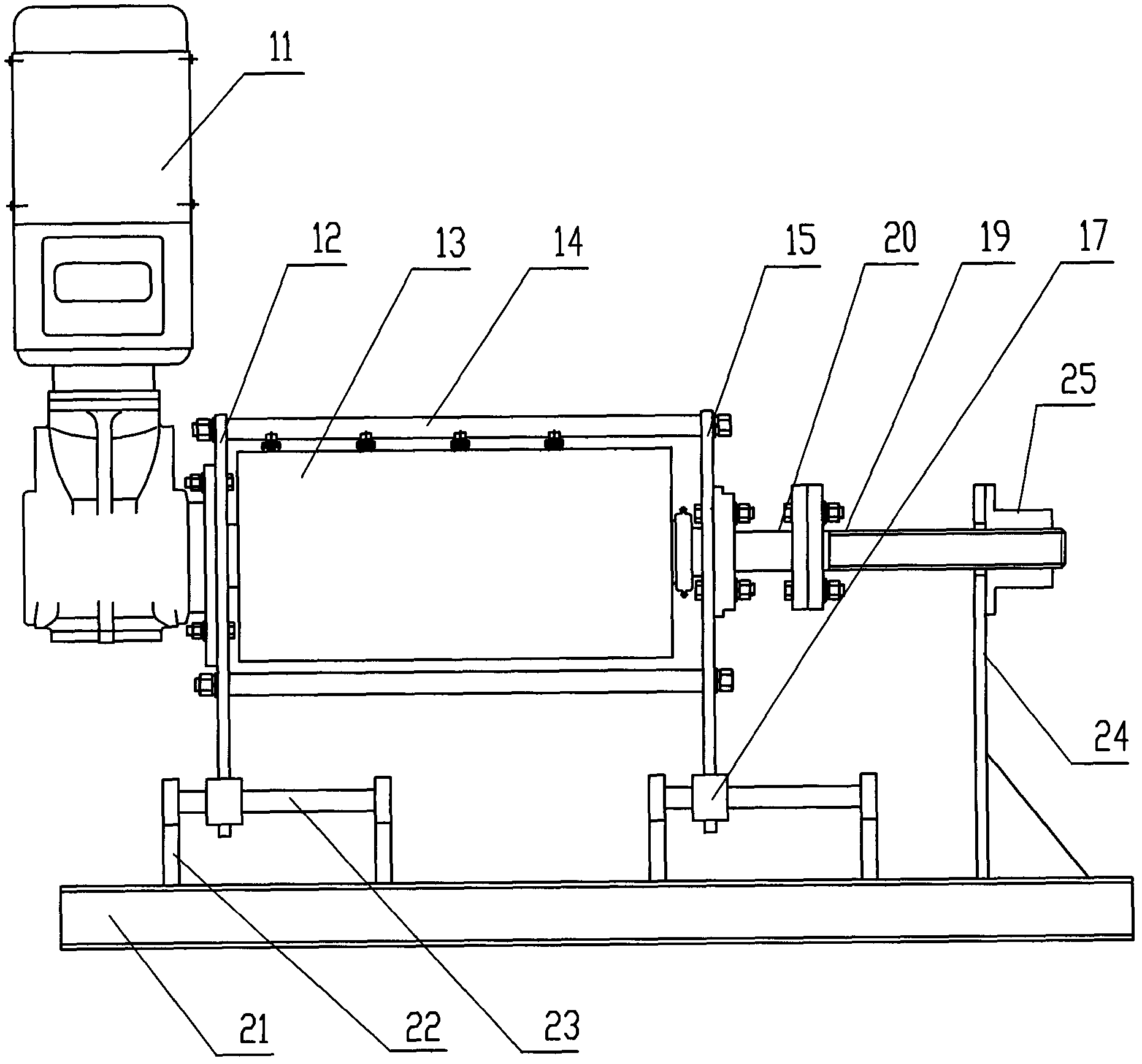

[0020] figure 1 The present invention uses the screw reel shaft (16) to pull the movable part of the boom machine driver to move, and sets the slide bar (23) on the base (21) to ensure that the sling (03) keeps the original position downward from the pulley (02). Schematic diagram of the structure in the vertical state.

[0021] figure 1 Among them, the screw drum shaft (16) is driven by a motor and a reducer (11), and the front drum support plate (15) and the rear drum support plate (12) support the screw drum shaft (16) and The drum (13) is provided with a sliding sleeve mechanism (17) at the lower part of the front drum support plate (15) and the rear drum support plate (12); the above structures 11-17 form the movable part of the boom machine driver The base (21) is provided with a slide bar support plate (22) to support the slide bar (23), and the linear bearing in the sliding sleeve mechanism (17) slides along the slide bar (23); There is a base support plate (24), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com