Numerical control universal swinging mechanism

A vertical and horizontal technology, applied in the direction of mechanical equipment, gear transmission, lighting and heating equipment, etc., can solve problems such as non-universal swing, and achieve the effects of digital control, precise movement, and flexible and complex waterscape modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

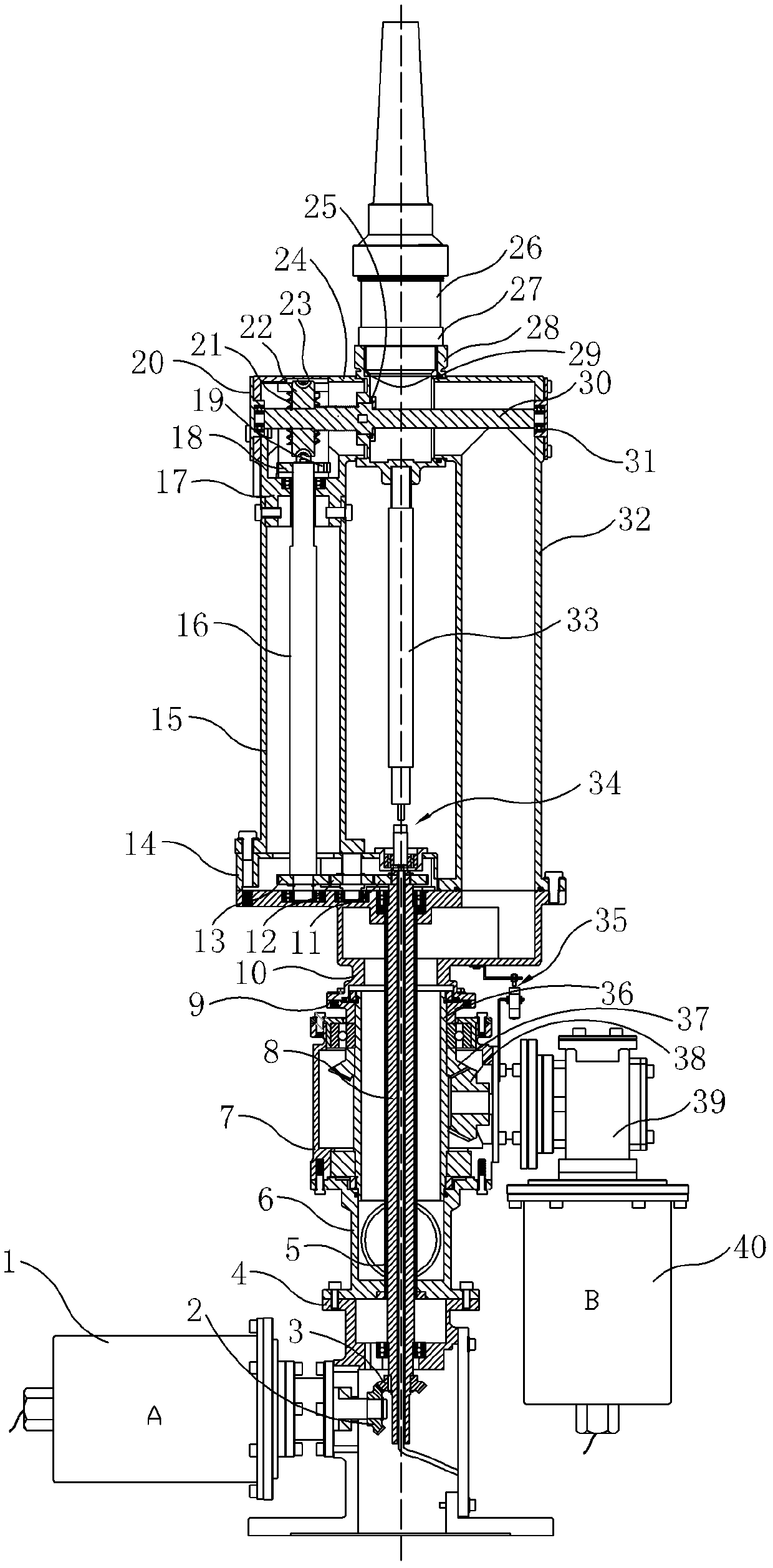

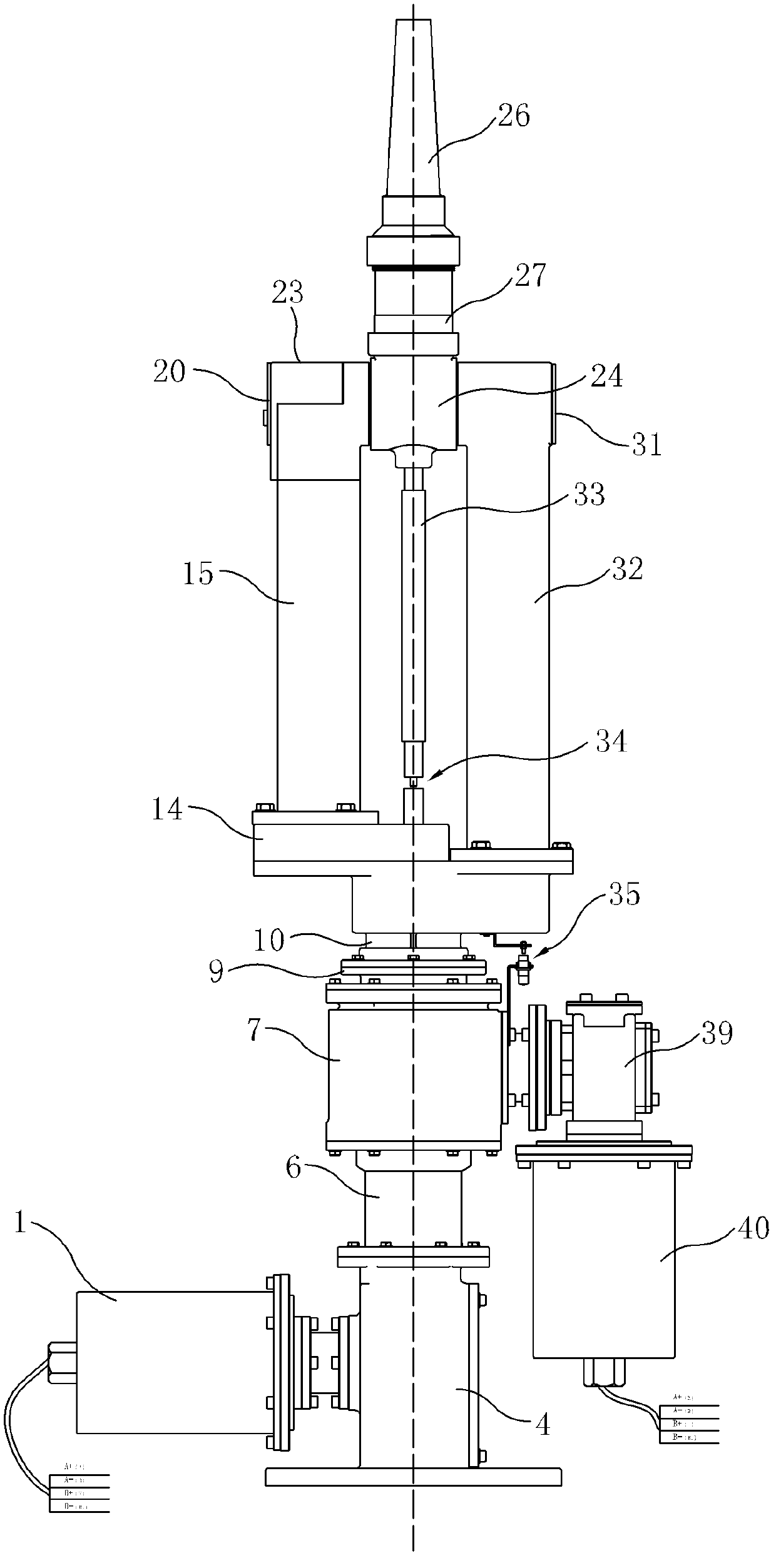

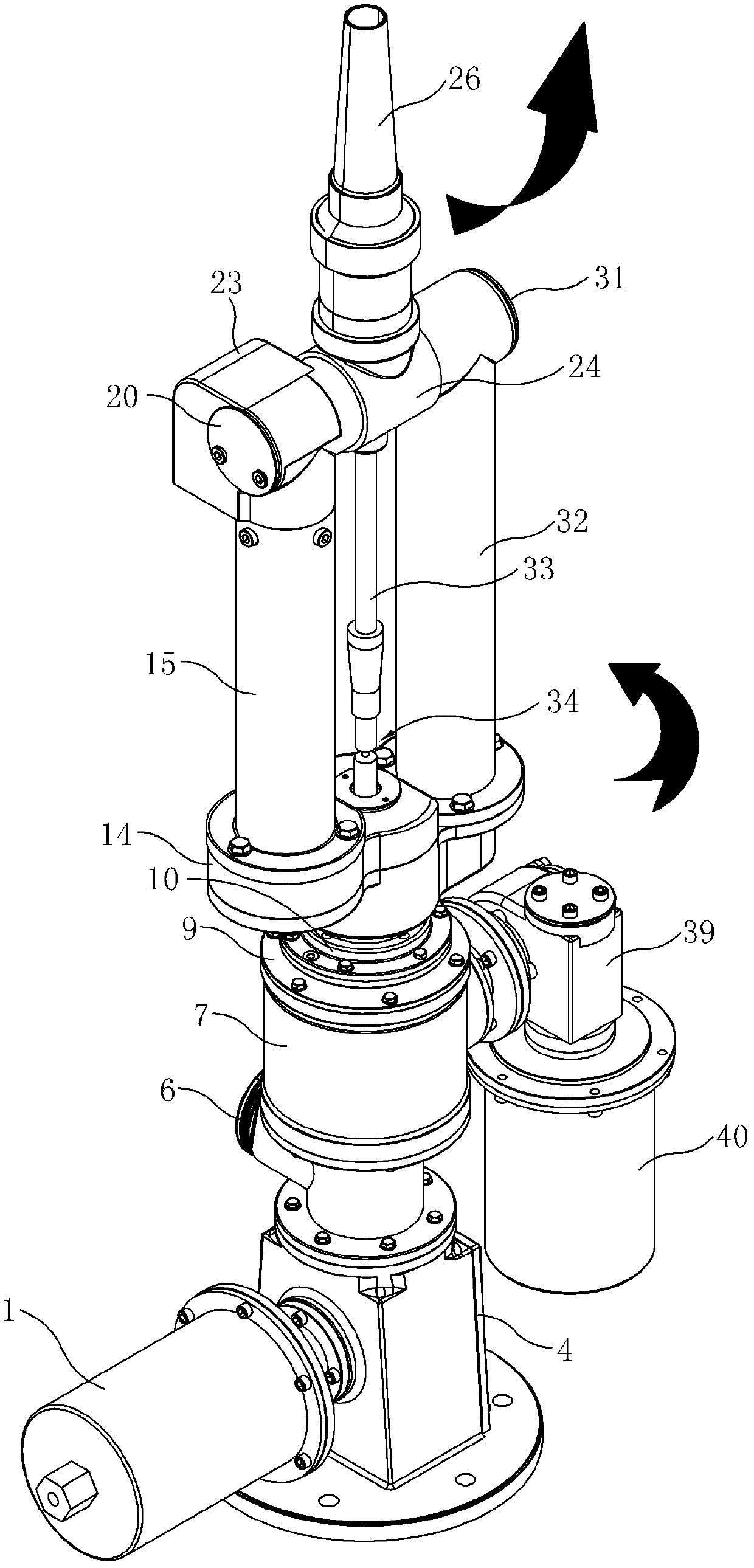

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] Such as Figure 1 to Figure 5 As shown, the design scheme of the specific embodiment of the present invention is to use two precision stepping motors, the stepping motor A1 drives the nozzle to rotate in the vertical direction through the gear, the worm 21, and the worm wheel 22, and the stepping motor B40 drives the nozzle through the reduction gear and the gear Rotate in the horizontal direction, so that the spray head (or lamp head) installed on the movable joint 28 can swing universally in three-dimensional space. In addition, in order to prevent out-of-synchronization of precision stepping motor control, the phenomenon of inconsistent nozzle operation in the digital control universal swing mechanism for multiple musical fountains occurs; each precision stepping motor is equipped with an origin detection device. Its mechanical struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com