Anti-coking burner for pulverized coal boiler and boiler installed with the burner

A pulverized coal boiler and burner technology, which is applied in the direction of burning powder fuel burners, burners, and burning with multiple fuels, and can solve the problems of rising exhaust gas temperature, boiler failure to reach normal output, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

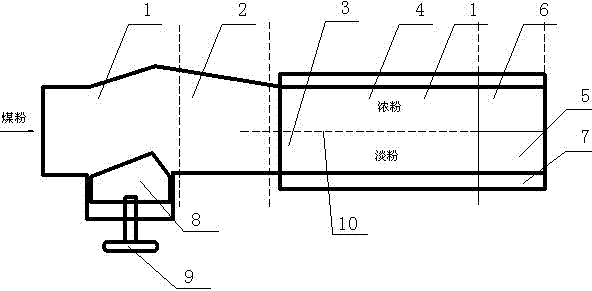

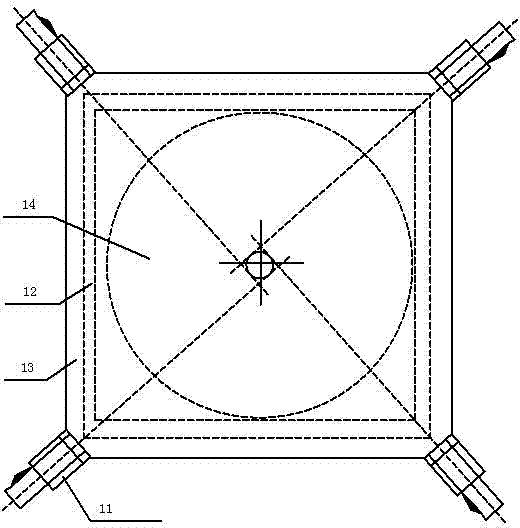

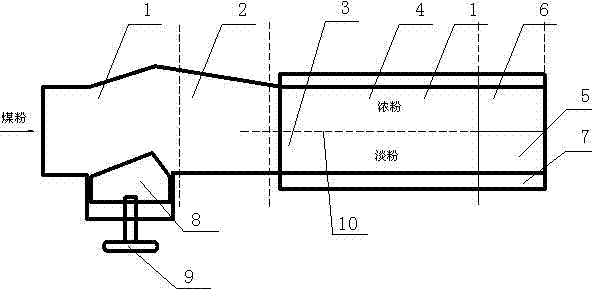

[0013] Such as figure 1 As shown, the pulverized coal boiler anti-coking burner of the present invention mainly includes a burner casing and a pulverized coal flow channel in the casing, and a pulverized coal separator 1 and a buffer zone 2 are arranged in sequence along the pulverized coal flow direction in the pulverized coal flow channel , the light powder passage 3 and the thick powder passage 4 parallel to each other and separated, and the light powder nozzle 5 and the thick powder nozzle 6 corresponding to the thick and light powder passages; a perimeter air duct is provided on the outer edge of the thick and light powder passages 7. A regulator is also provided on the wall of the flow channel in the pulverized coal separator, and the regulator includes a separation block 8 that can move radially along the flow channel, and an adjustment hand wheel 9 connected with the separation block and located outside the burner casing. Between the light powder passage 3 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com