Burner for suspension roaster and application thereof

A suspension roasting furnace and main combustion technology, applied in furnaces, burners, combustion methods, etc., can solve the problems of large amount of high-temperature pollutants and insufficient fuel combustion, etc., to reduce local high-temperature areas, reduce generation, and stabilize burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

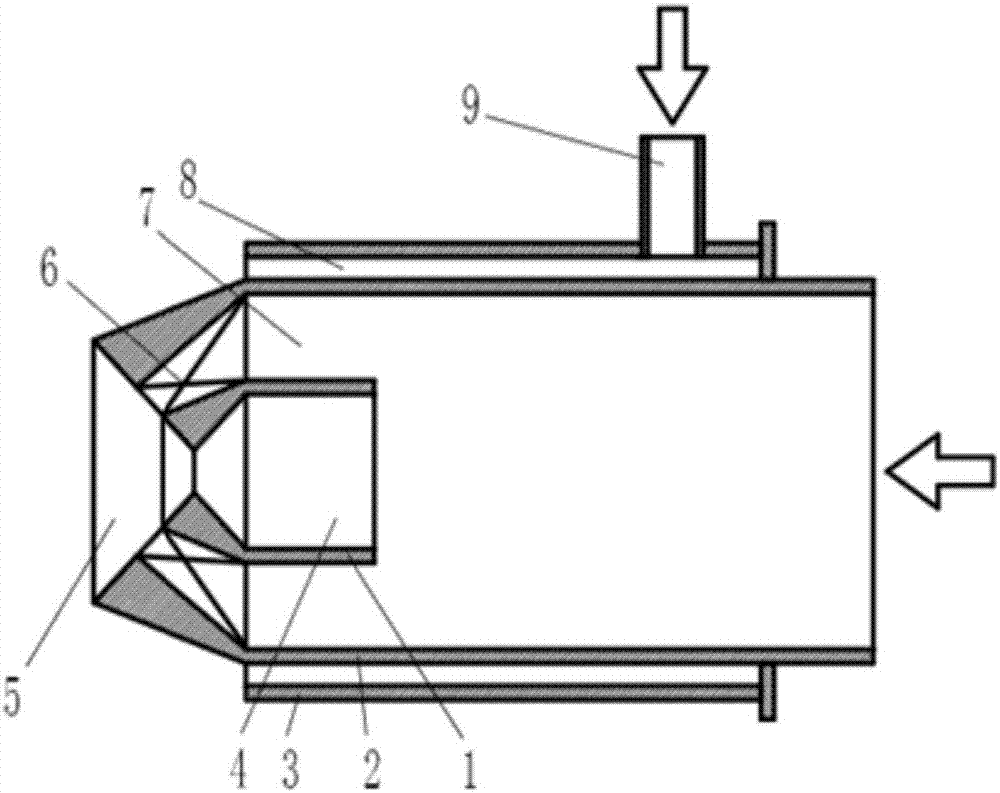

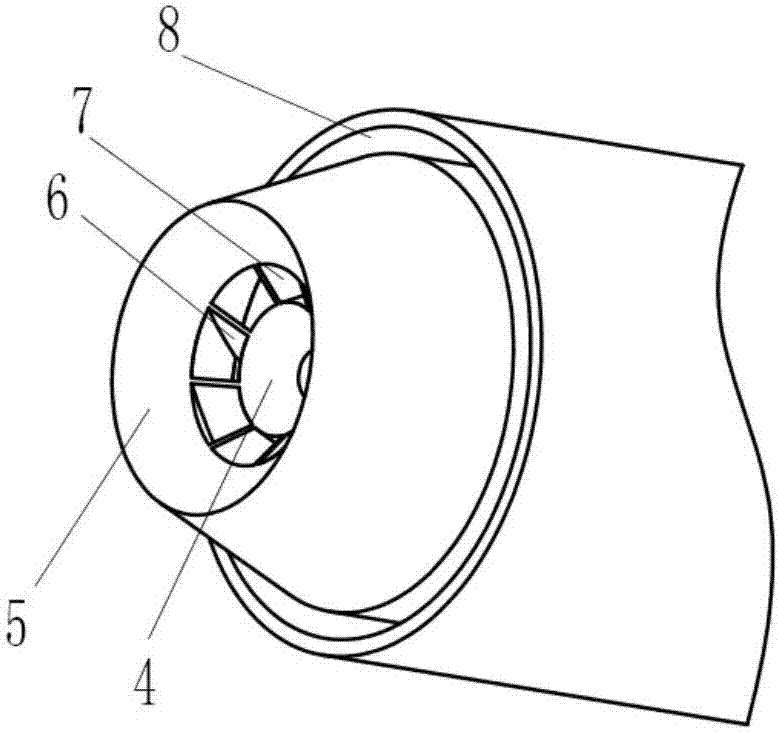

[0037] Such as figure 1 with figure 2 As shown, a burner for a suspension roaster includes a center pipe 1 and a gas sleeve 2, the gas sleeve 2 is set outside the center pipe 1, and the center pipe 1 has a central direct current A gas channel 4, a swirl gas channel 7 is defined between the outer wall of the central tube 1 and the inner wall of the gas casing 2, and the swirl gas channel 7 includes a straight section and an inclined section sequentially arranged along the gas flow direction, The straight section is parallel to the central axis of the central pipe 1 , the inclined section is inclined inwardly relative to the central axis of the central pipe 1 , and a swirling device is arranged in the swirling gas channel 7 .

[0038] The central pipe 1 provided inside the gas bushing divides the incoming gas into two parts: the central direct flow gas and the swirling flow gas. The direct-flow gas and the swirling gas premixed have strong penetrating power and diffusion abil...

Embodiment 2

[0040] Such as figure 1 with figure 2As shown, a burner for a suspension roaster, its structure is different from that of Example 1 in that: the swirl device is located in the inclined section of the swirl gas channel 7, so that the gas flows through the swirl When the gas channel is 7, a certain swirl intensity is obtained, so this part of the gas has a strong diffusion ability after being sprayed out from the burner, and can be fully mixed with the supporting gas.

Embodiment 3

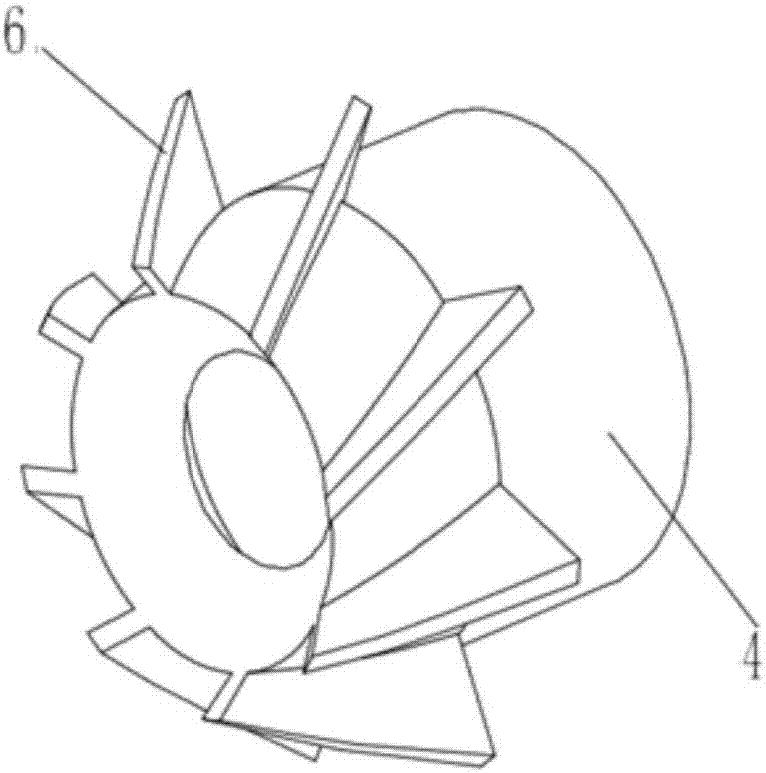

[0042] Such as image 3 As shown, a burner for a suspension roaster, its structure is different from that of Example 2 in that: the swirl device is a swirl sheet 6, and the swirl sheet 6 is connected to the outer wall of the central tube 1 Fixed connection, and the swirl plate 6 is inclined in the same direction relative to the central axis of the gas sleeve 2, the swirl plate 6 changes the flow state of the gas in the swirl gas channel, and enhances the swirl of this part of the gas Intensity, thereby promoting the mixing of gas and supporting gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com