Integral pouring molding method for burner of regenerative heating furnace

A technology of integral pouring and forming method, applied in lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of large maintenance and replacement construction, long construction period, short service life of heating furnace burners, etc., and shorten the maintenance project. Quantity, shortening of construction period, and overcoming the effect of long period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation steps of molding method of the present invention are:

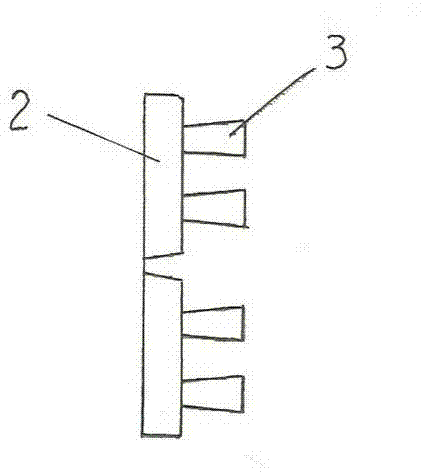

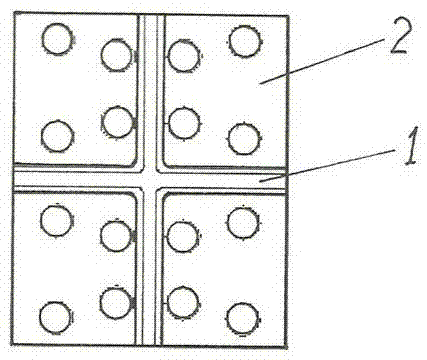

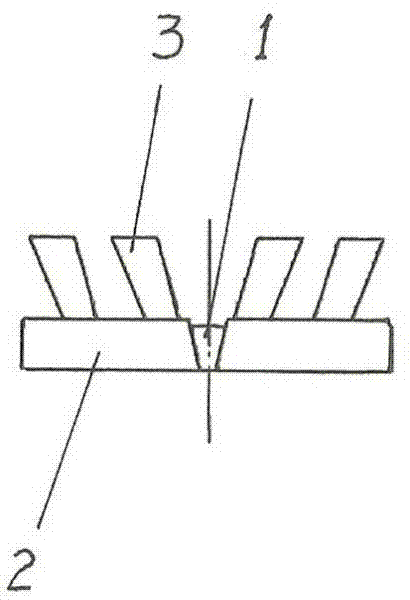

[0026] 1. According to figure 1 , figure 2 For the structure shown, the cross ribs and burner nozzle molds are made respectively. Among them, the cross rib 1 is a cross-shaped support frame used to support the mold of the burner nozzle, that is, it is placed in the outlet of the burner heat storage box, and the outlet of the heat storage box is divided into four equal parts. Each part Place a burner nozzle mold. The burner spout mold is formed on a rectangular mold base plate 2 with four spout models 3 protruding outward from the plate surface of the mold base plate. The nozzle model 3 on the mold base plate 2 is preferably made into a horizontal oblique cone ( image 3 ), that is, the spout model 3 is inclined to one side in the horizontal direction. Such as Figure 5 As shown, the layout of the nozzle mold of the burner is to make the nozzle model 3 tilt outward along the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com