A Mechanical Grain On-line Sampler

A sampler and mechanical technology, applied in the direction of sampling devices, etc., can solve the problems of inability to control the drying process in real time, poor adaptability, and failure to solve online sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

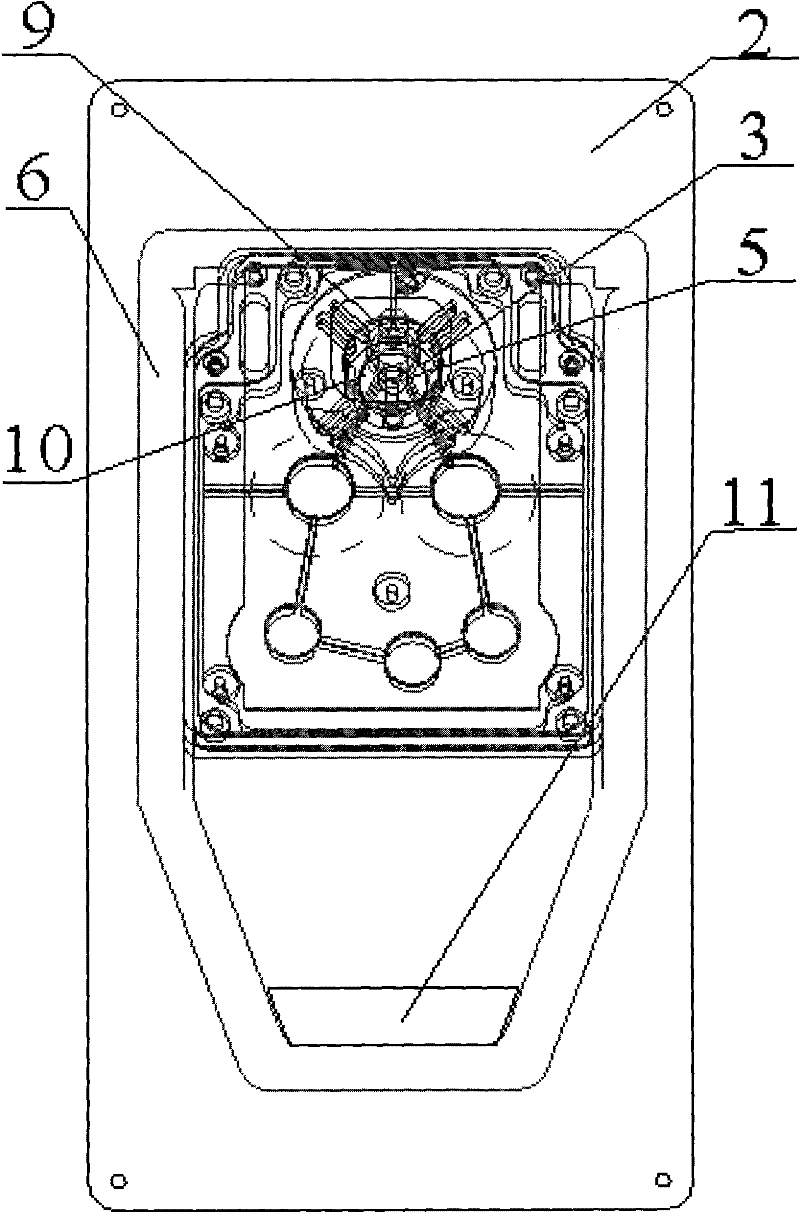

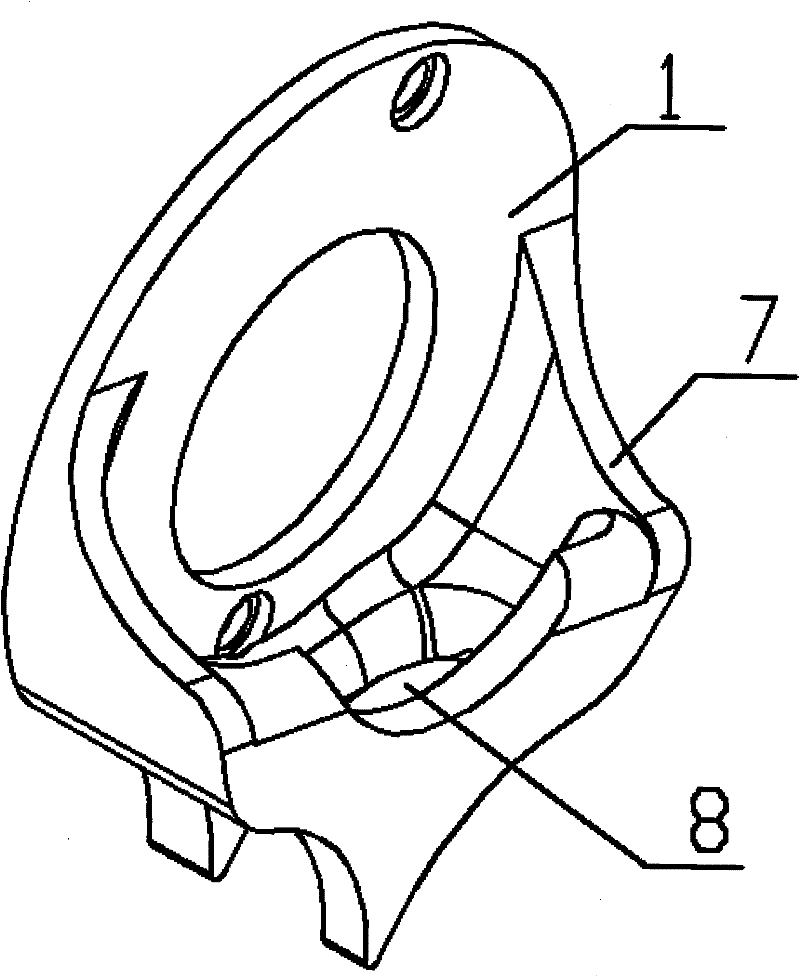

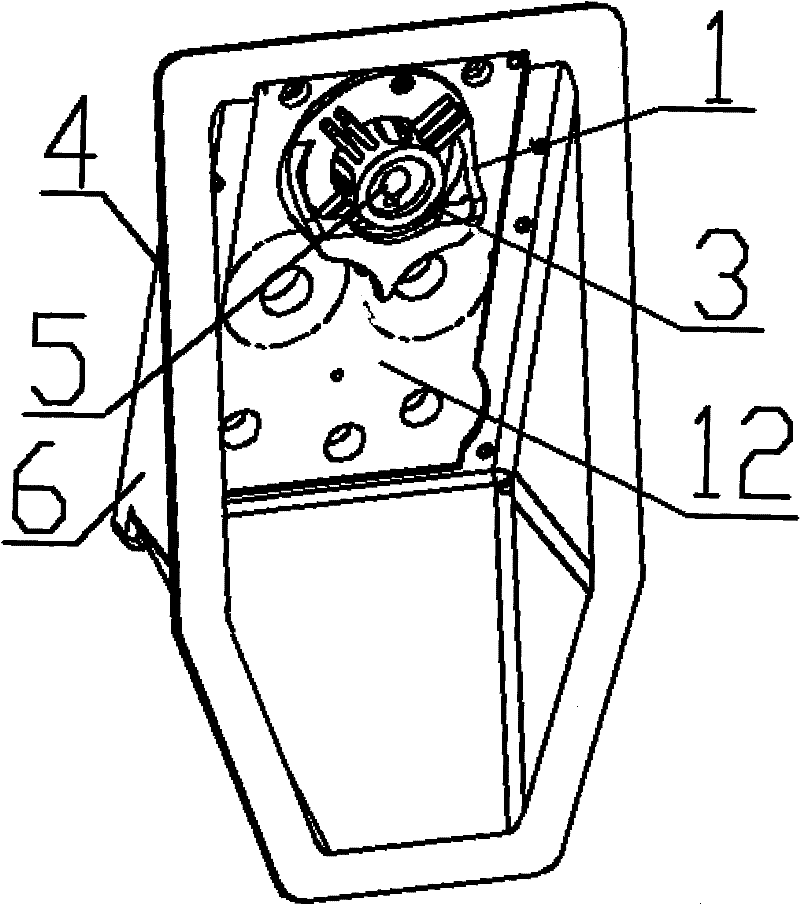

[0019] Such as figure 1 As shown, the assembled grain on-line sampler is directly installed on the machine wall of the hoist, and the grain splashed in the hoist will rush down from the semi-elliptical through hole 10 to the seed hole 9 and the corresponding hole 9 of the receiving hole wheel 3. Between the adjacent two rows of brushes, the detector is turned on, and the drive shaft 5 drives the receiving hole wheel 3 to rotate. At this time, it is on the upper part of the receiving hole wheel 3, and the seed hole 9 sandwiched between the two rows of brushes receives the grain. Along with hole wheel turns out drier or hoist together and enters detection room, when rotating to the position of seed guide plate 7 of moving seed protector 1, hairbrush touches seed guide plate 7 and makes redundant seeds on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com