Method and device for unfolding steel ball surface based on multi-image sensor

An image sensor and sensor technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of randomness and complexity of the full coverage image on the steel ball surface, cannot guarantee complete coverage of the steel ball surface, cannot achieve full coverage, etc. Achieve the effects of avoiding complex mechanical structure, reducing difficulty and cost, and simplifying mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method and device for unfolding the steel ball surface based on the multi-image sensor of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

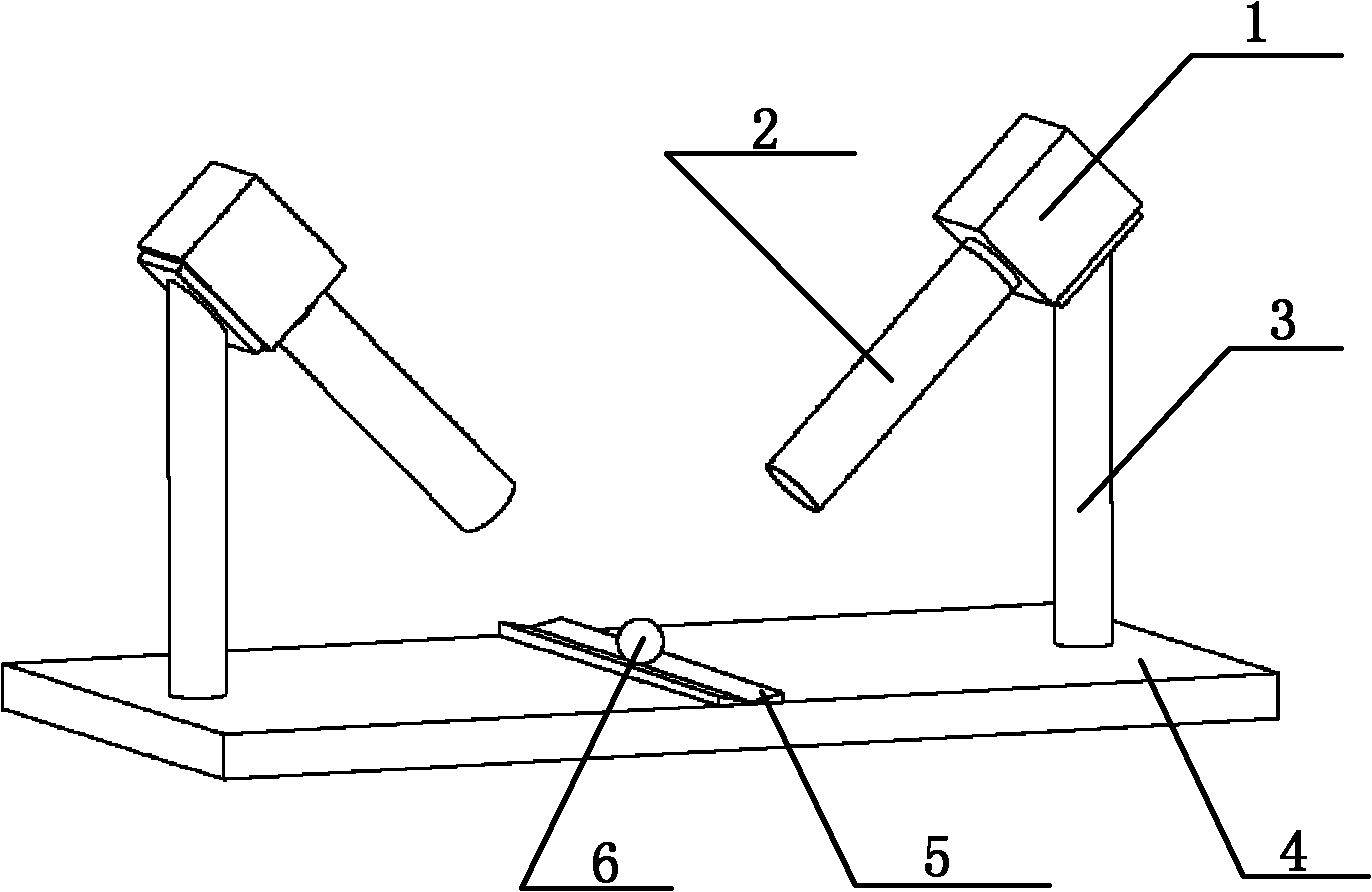

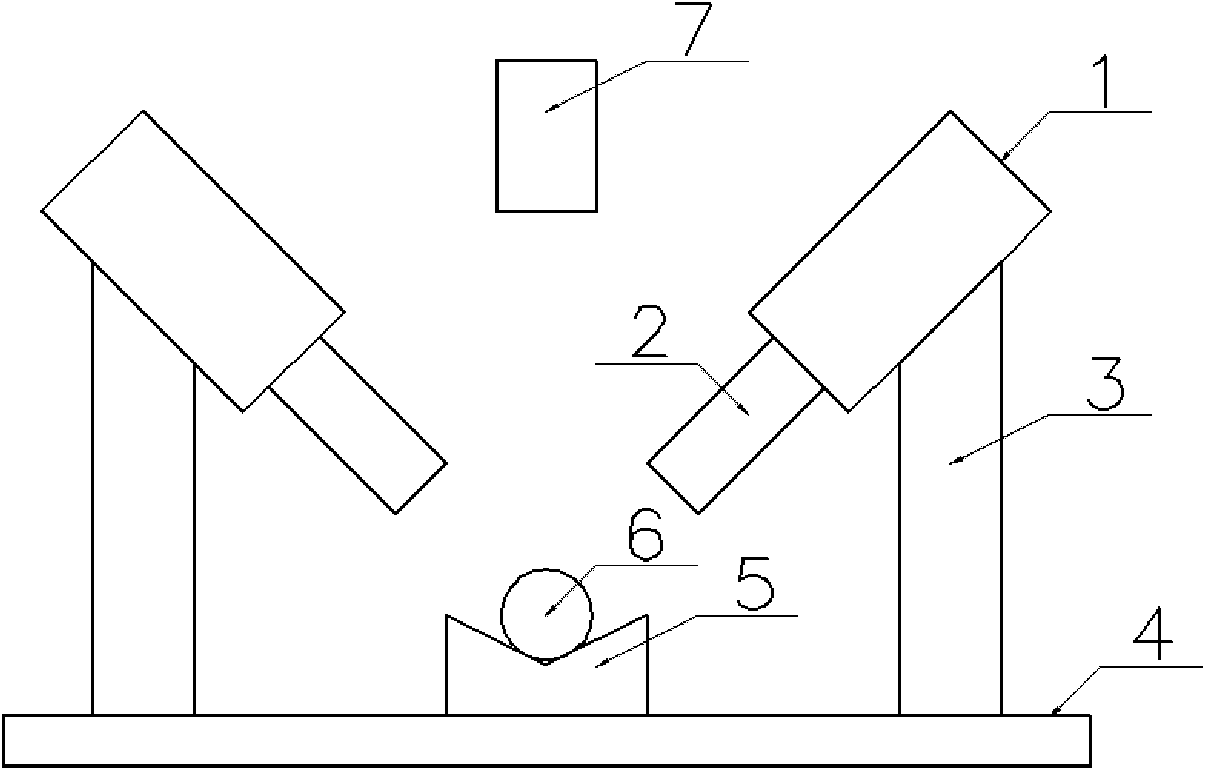

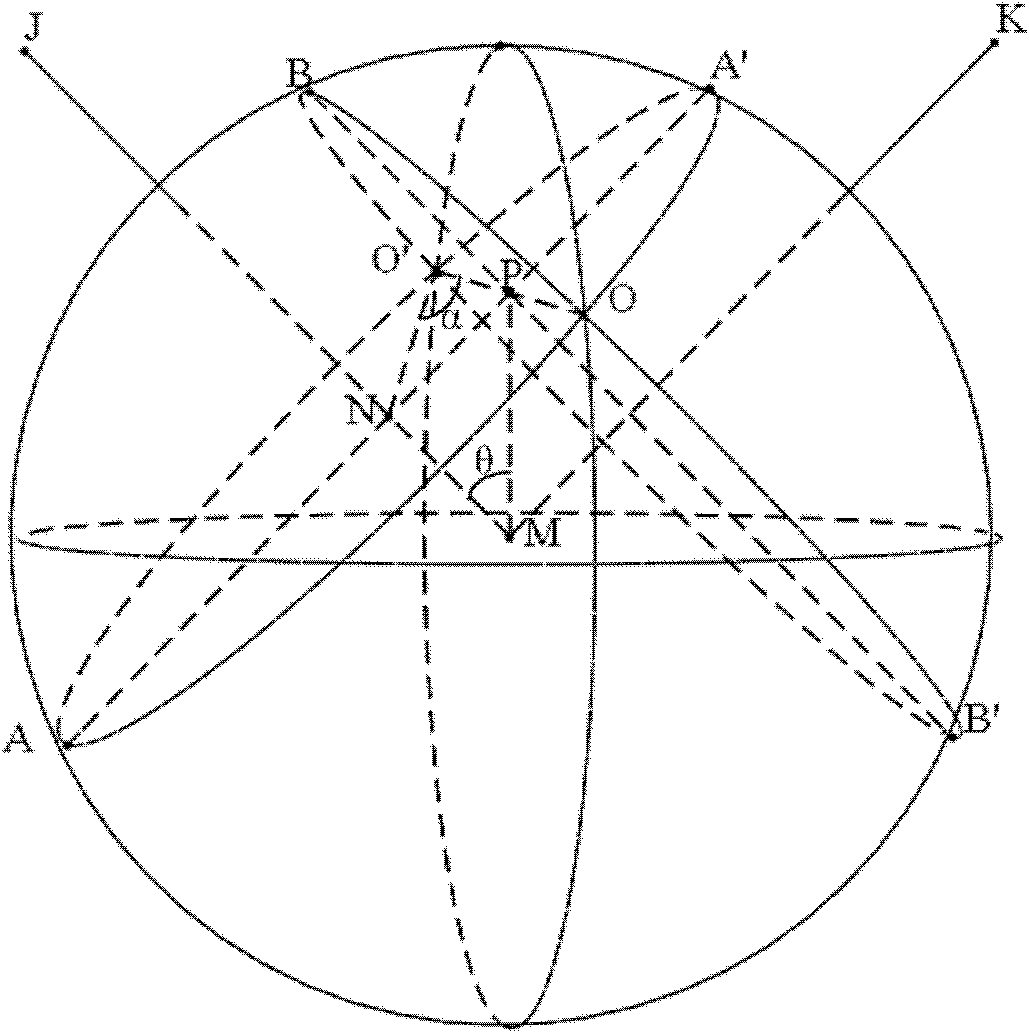

[0030] The steel ball surface unfolding method based on the multi-image sensor of the present invention is to set a linear guide rail formed by a groove, and the groove is a V-shaped groove. The linear guide rail has a gradient that enables the steel ball to be tested to perform a pure rolling motion forward along the linear guide rail by gravity, and two image sensors that are symmetrical and of the same structure are respectively arranged obliquely above the axis of the linear guide rail. The corresponding two image sensor parameters and the two lens optical parameters are respectively adjusted to be consistent, so as to obtain a symmetrical and equal-sized spherical crown surface, and a light source is arranged above the linear guide rail. Set the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com