A thermal porosimetry method for determining the pore structure of cement-based materials

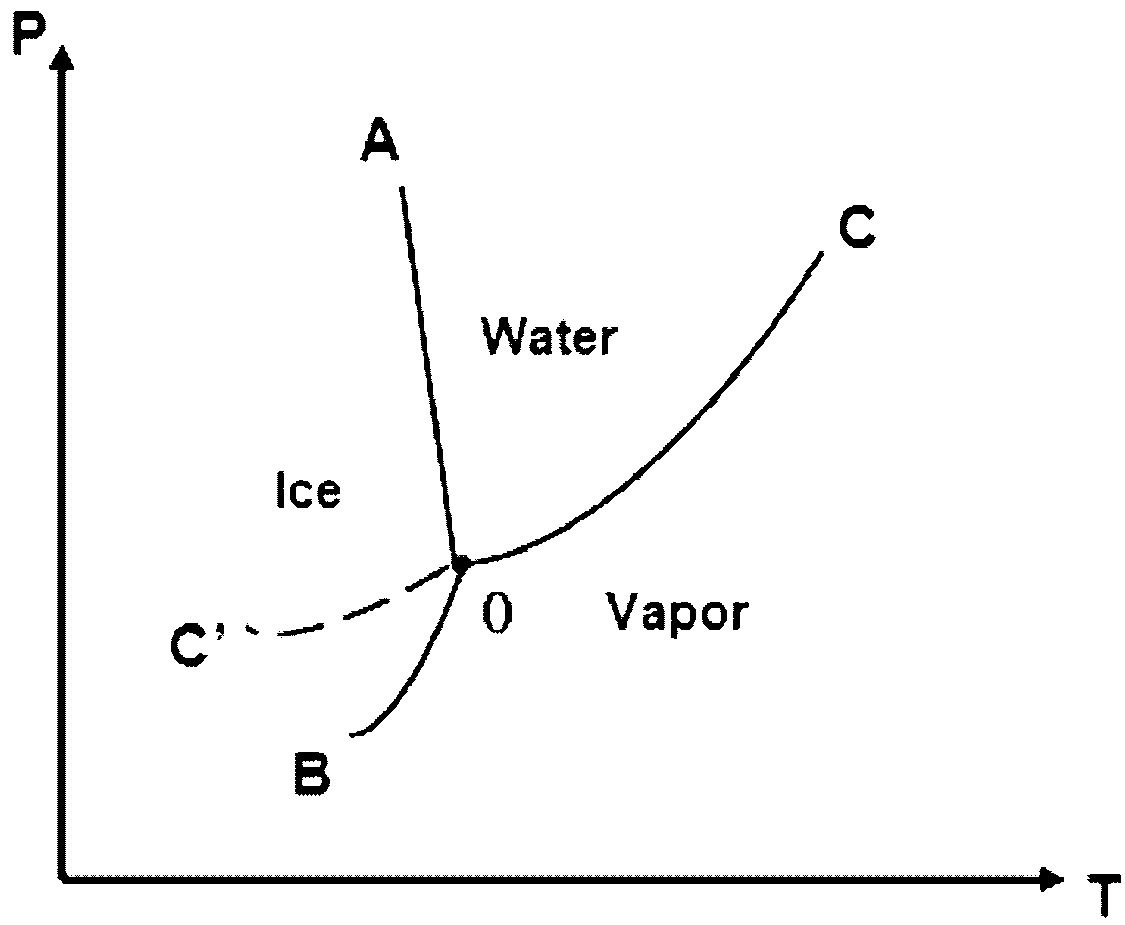

A technology of cement-based material and pore structure, which is applied in the direction of material thermal development, suspension and porous material analysis, measurement device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

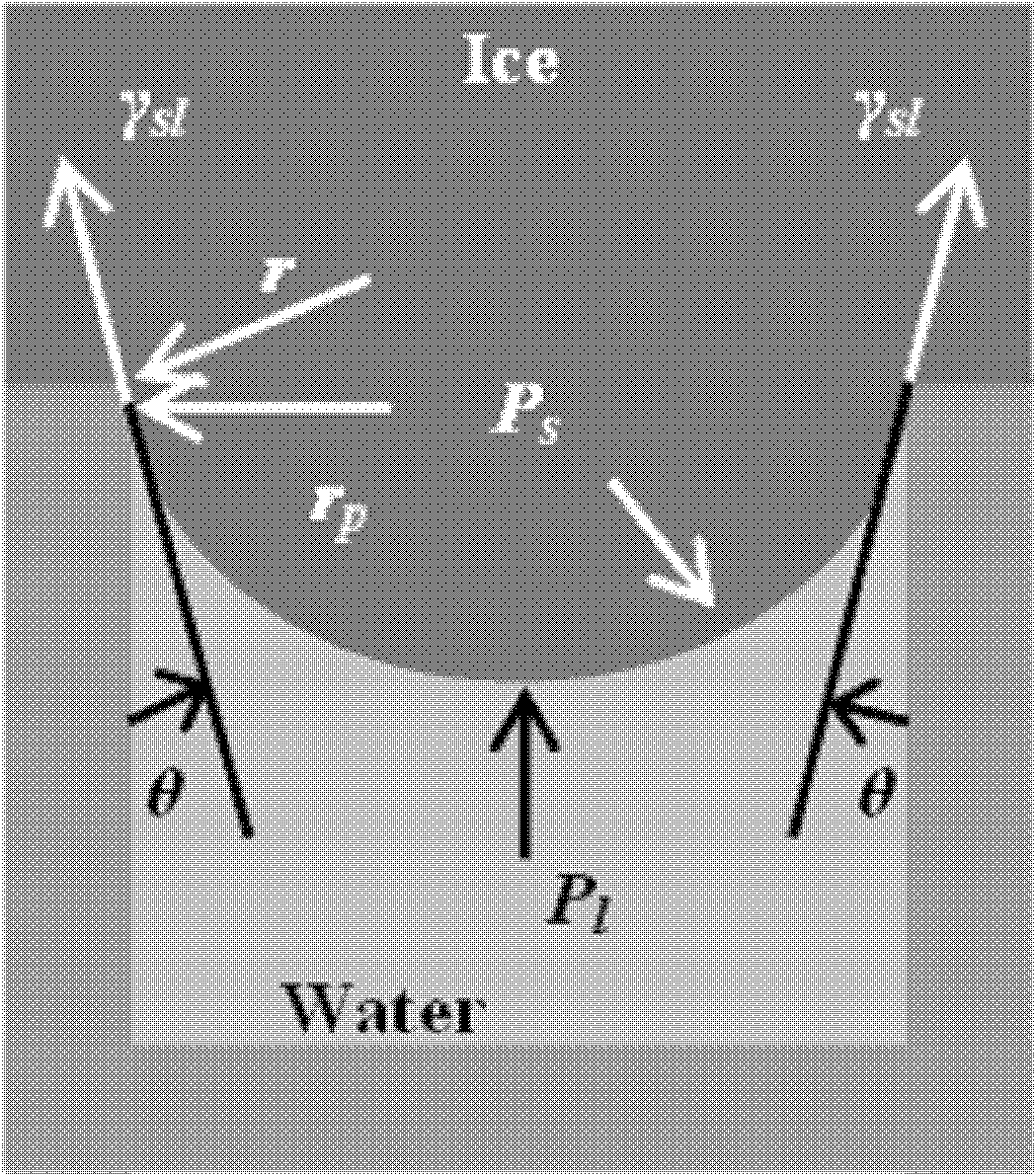

Method used

Image

Examples

Embodiment 1

[0067] In this embodiment, the cement stone with a water-cement ratio of 0.6 is an example:

[0068] (1) The sample is first made into a sheet, so that it can be put into the DSC aluminum crucible of the differential scanning calorimeter;

[0069] (2) Put it in a drying oven at 60°C and dry it to constant weight, and weigh it in m d =8.71mg; Determination of the total volume V of the cement-based material sample 样 =18.47mm 3 ;

[0070] (3) Then put the sample into deionized water, and place it in a crucible after vacuum water saturation treatment to wait for DSC test. In order to make the experimental data more accurate, it is necessary to drop kerosene on the sample, and then seal the crucible;

[0071] (4) Set the experimental conditions for the DSC test, wherein the sample temperature T of the DSC test is controlled at -40°C to +5°C, and the temperature rise and fall rates are both 0.3°C / min. In this way, the data of the sample temperature T and the corresponding heat ...

Embodiment 2

[0093] In this embodiment, the cement stone with a water-cement ratio of 0.6 is an example:

[0094](1) The sample is first made into a sheet, so that it can be put into the DSC aluminum crucible of the differential scanning calorimeter;

[0095] (2) Put it in a drying oven at 60°C and dry it to constant weight, and weigh it in m d =8.80mg; Determination of the total volume V of the cement-based material sample 样 =18.48mm 3 ;

[0096] (3) Then put the sample into deionized water, and place it in a crucible after vacuum water saturation treatment to wait for DSC test. In order to make the experimental data more accurate, it is necessary to drop kerosene on the sample, and then seal the crucible;

[0097] (4) Set the experimental conditions for the DSC test, wherein the sample temperature T of the DSC test is controlled at -40°C to +0°C, and the temperature rise and fall rates are both 3°C / min. The data of the sample temperature T and the corresponding heat flow P are thus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com