A fully automatic calibrator and calibration method thereof

A calibration method and technology of calibrators, applied in instruments, measuring devices, measuring electrical variables, etc., can solve problems such as inflexibility and low efficiency of calibration methods, achieve flexible instrument calibration, reduce investment in personnel and equipment, and simplify instrument calibration. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

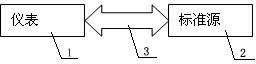

[0014] Such as figure 1 As shown, a kind of full-automatic calibrator of the present invention, it comprises instrument 1, standard source 2 and RS-485 bus 3, instrument 1 is connected with standard source 2 through RS-485 bus 3, and instrument 1 is as host computer, to standard source 2 Send the command.

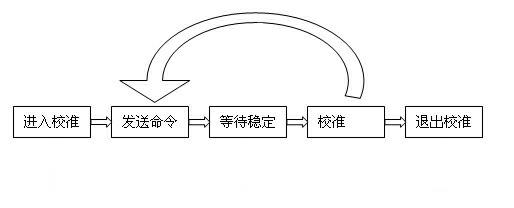

[0015] Such as figure 2 As shown, the calibration method of a fully automatic calibrator of the present invention includes the following steps: (a), enter calibration: make the instrument enter the calibration state by operating the instrument, and the subsequent steps are all completed automatically; (b), send the command: The instrument sends a command to let the standard source output a signal; (c), wait for stability: the instrument sends a judgment command to judge whether the output of the standard source is stable; (d), calibrate: the instrument starts to calibrate; (e), repeat steps (b) to (d) Until all points are calibrated; (f), Exit Calibration: Exit the instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com