Operating clutch device of power distribution cabinet combined switch

A combination switch and clutch device technology, applied in the field of power transmission and distribution, can solve problems such as poor rigidity and strength, unsafe operation switches, and enlarged cabinet dimensions, and achieve effective clutching, convenient use, and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

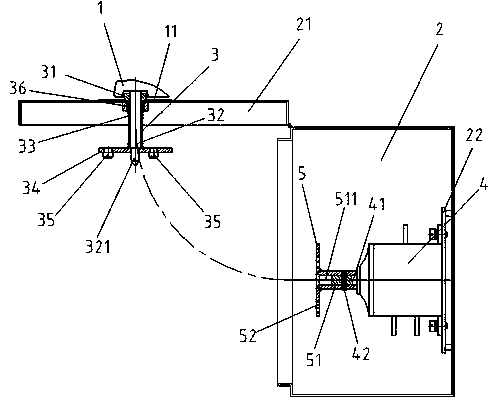

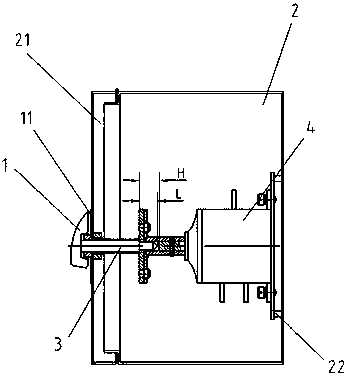

[0017] This example figure 1 , figure 2 As shown, it includes an operating handle 1 arranged outside the door panel 21 of the power distribution cabinet, a clutch mechanism 3 arranged in the power distribution cabinet 2 and connected to the operating handle 1, and a turntable 5 connected to the combined switch 4 fixed in the power distribution cabinet. The combined switch 4 is fixed on the box wall of the distribution cabinet 2 through the fixing plate 22, and the switch nameplate 11 for indicating the working state of the switch is provided on the door panel 21 of the distribution cabinet at the lower side of the operating handle 1.

[0018] The clutch mechanism 3 includes a guide sleeve 31, a guide rod 32, a compression spring 33, a shift fork plate 34, and a pair of positioning pins 35. The guide sleeve 31 is fixed on the door panel 21 of the power distribution cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com