An exhaust blower for fluorescent lamp production

A fluorescent tube and exhaust machine technology, applied in the direction of electric tube/lamp exhaust, etc., can solve the problems of reduced vacuum degree, increased lamp manufacturing speed, and inability to do it at the same time at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

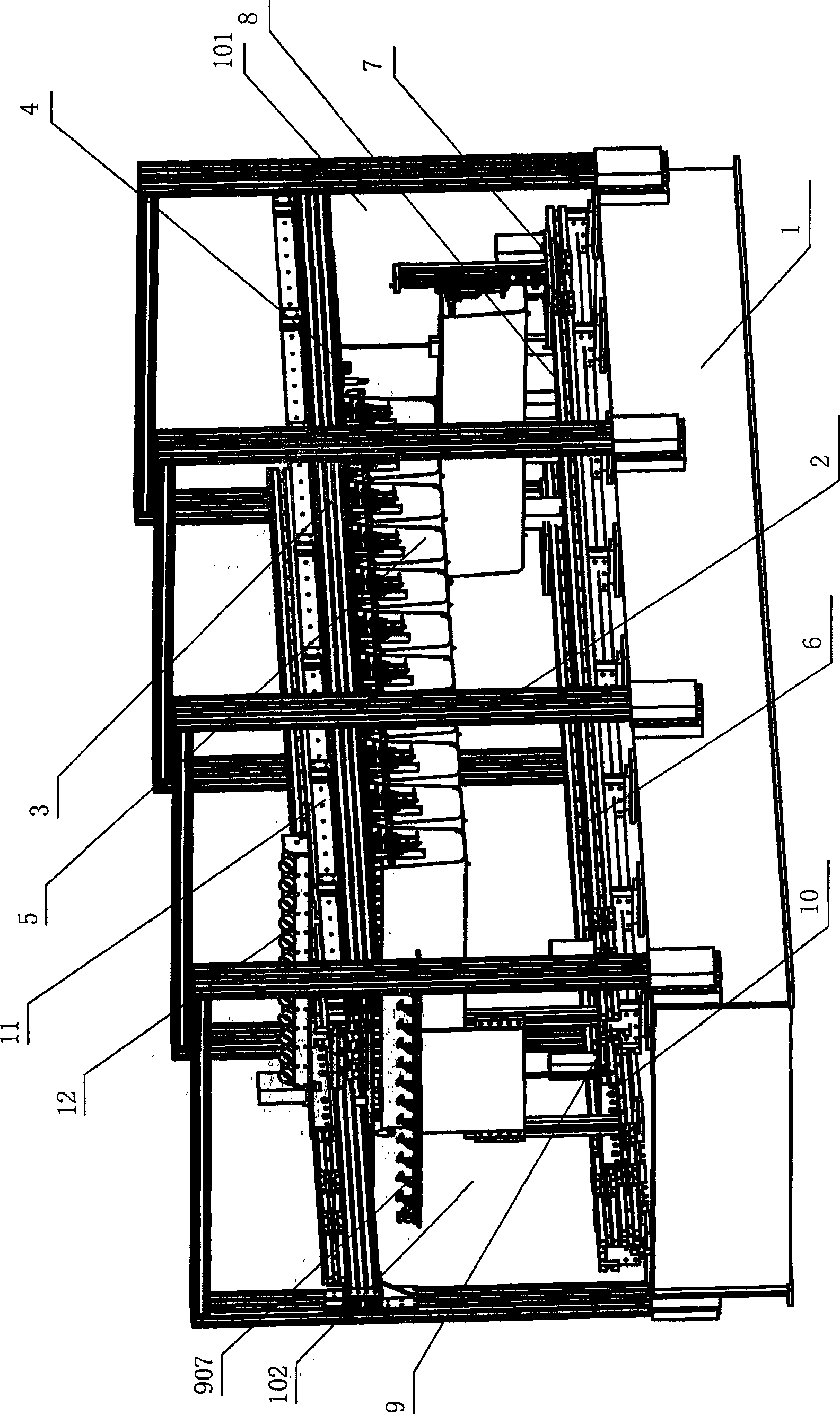

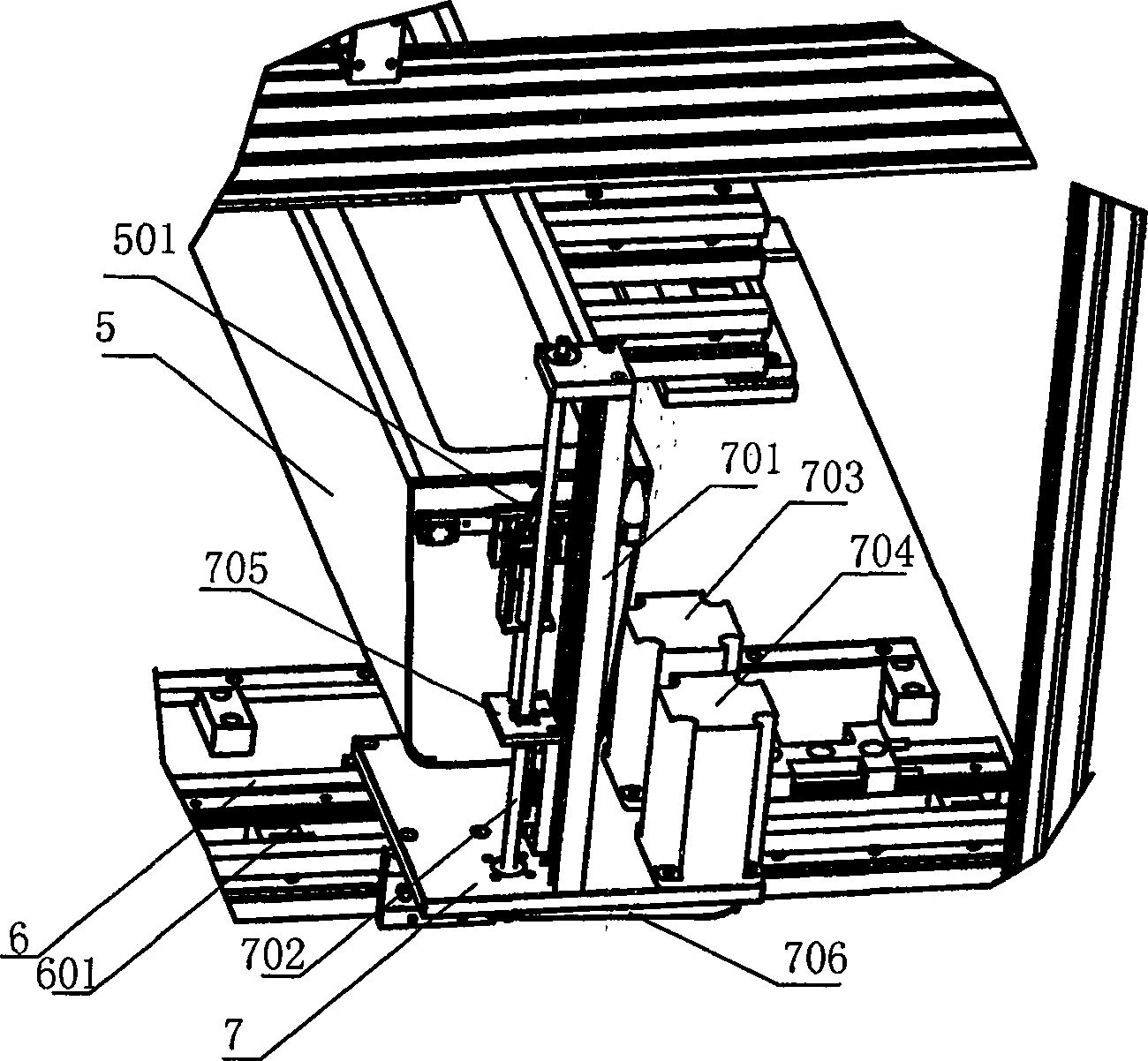

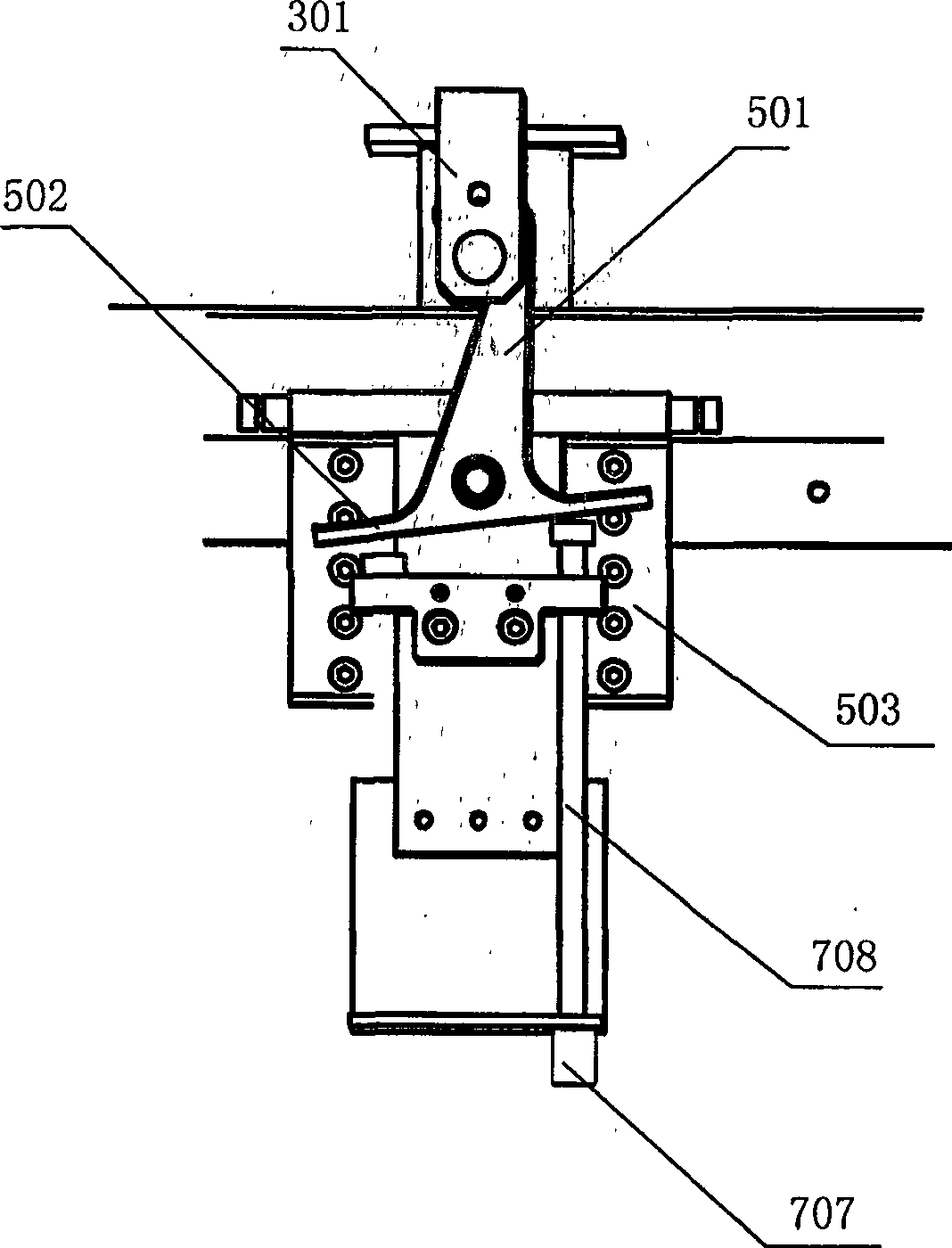

[0023]As shown in the figure, an exhaust machine for the production of fluorescent lamps includes a base 1 and a fixing frame arranged on the base 1. One end of the base 1 is an upper nozzle 101, and the other end of the base is a lower nozzle 102. The upper part of the fixed frame 2 is provided with a fixed plate 3, and the fixed plate 3 is provided with multiple rows of mercury gun groups composed of a plurality of mercury guns 4 arranged side by side, and a plurality of openings are arranged from the upper nozzle 101 to the lower nozzle 102. The oven 5 corresponding to the mercury gun group, between the upper nozzle 101 and the lower nozzle 102, two first transfer guide rails 6 and a second transfer guide rail 10 are arranged in parallel, the first transfer guide rail 6 and the second transfer guide rail 10 is arranged below the fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com