Patents

Literature

36results about How to "Easy clutch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

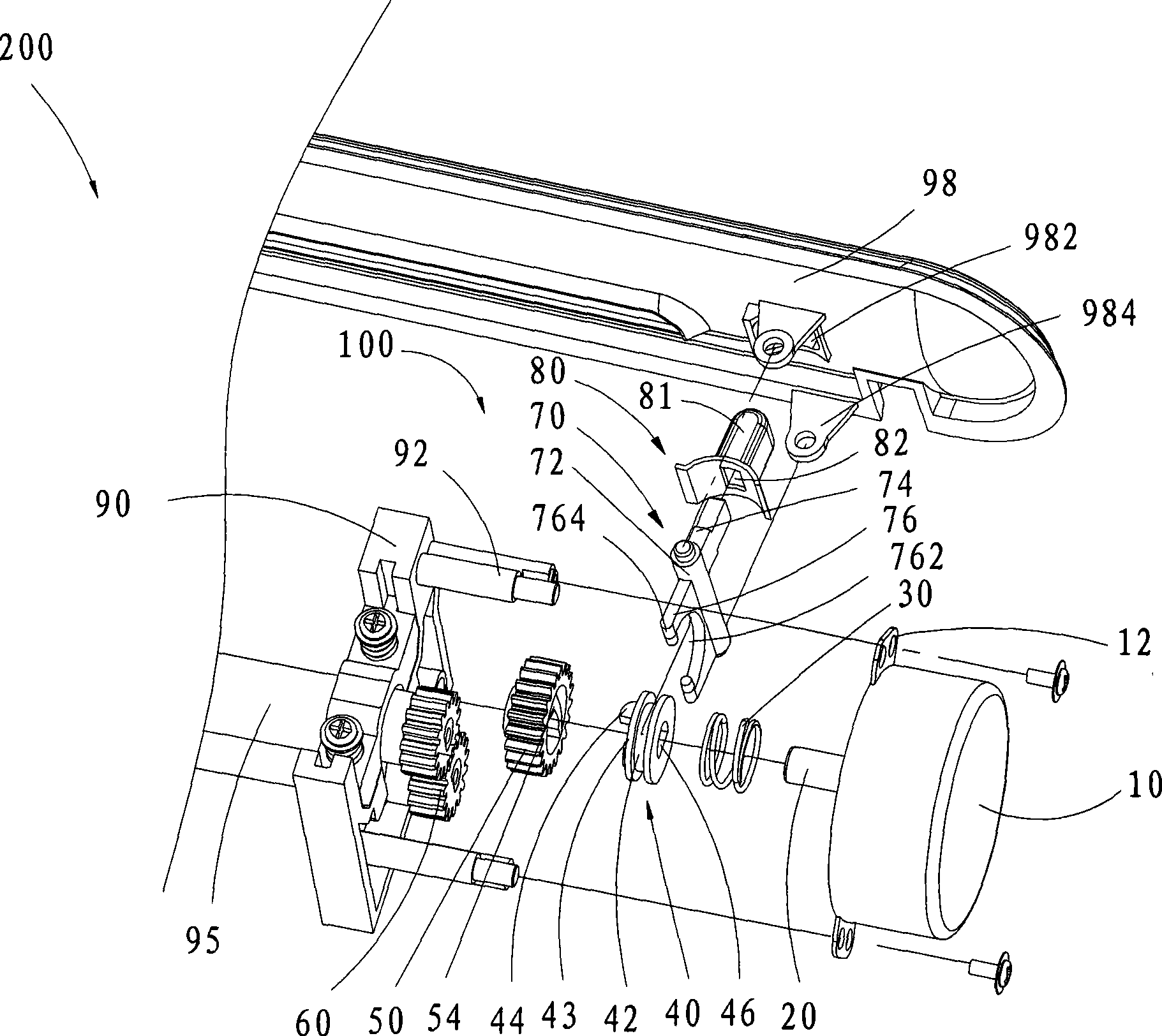

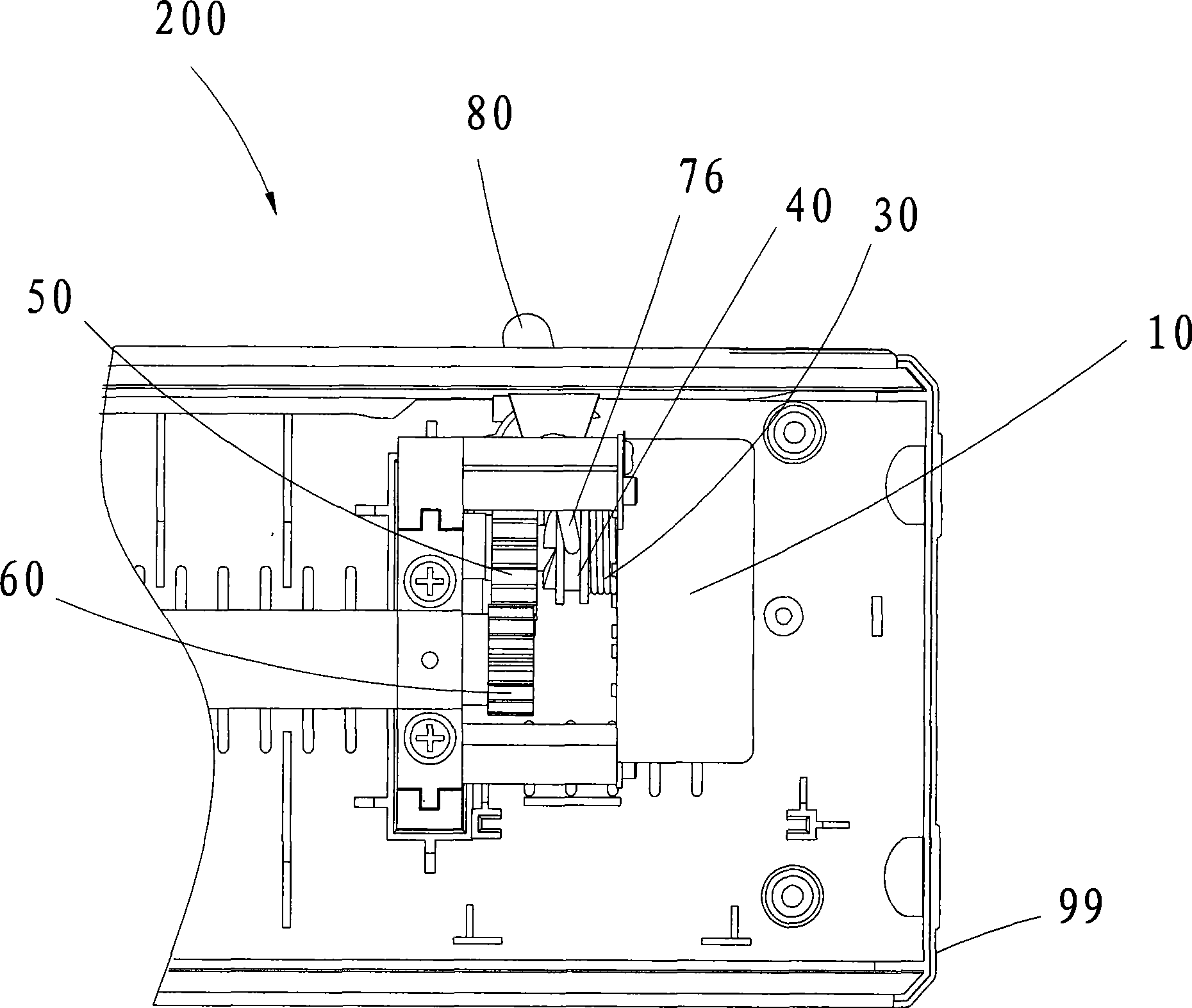

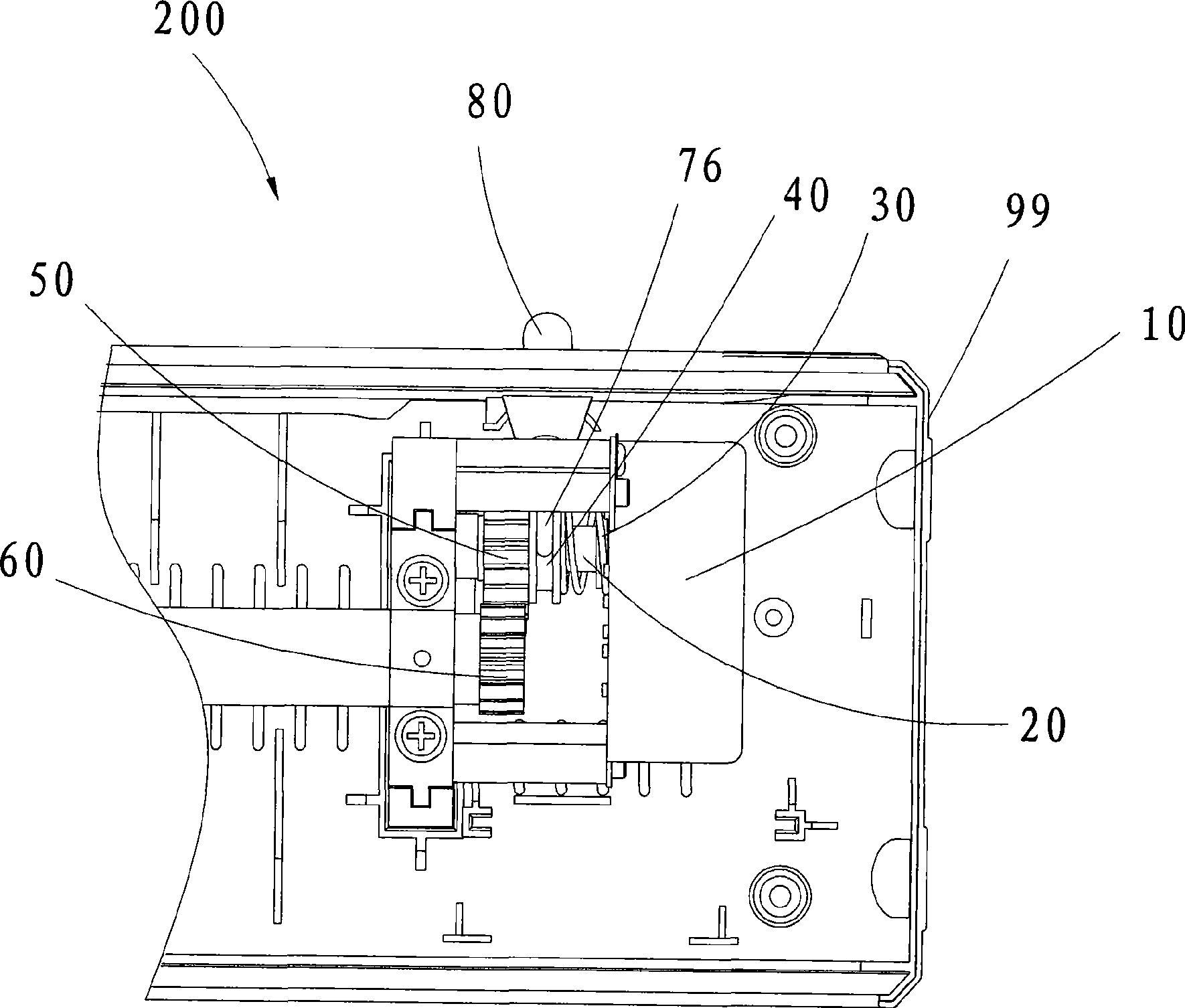

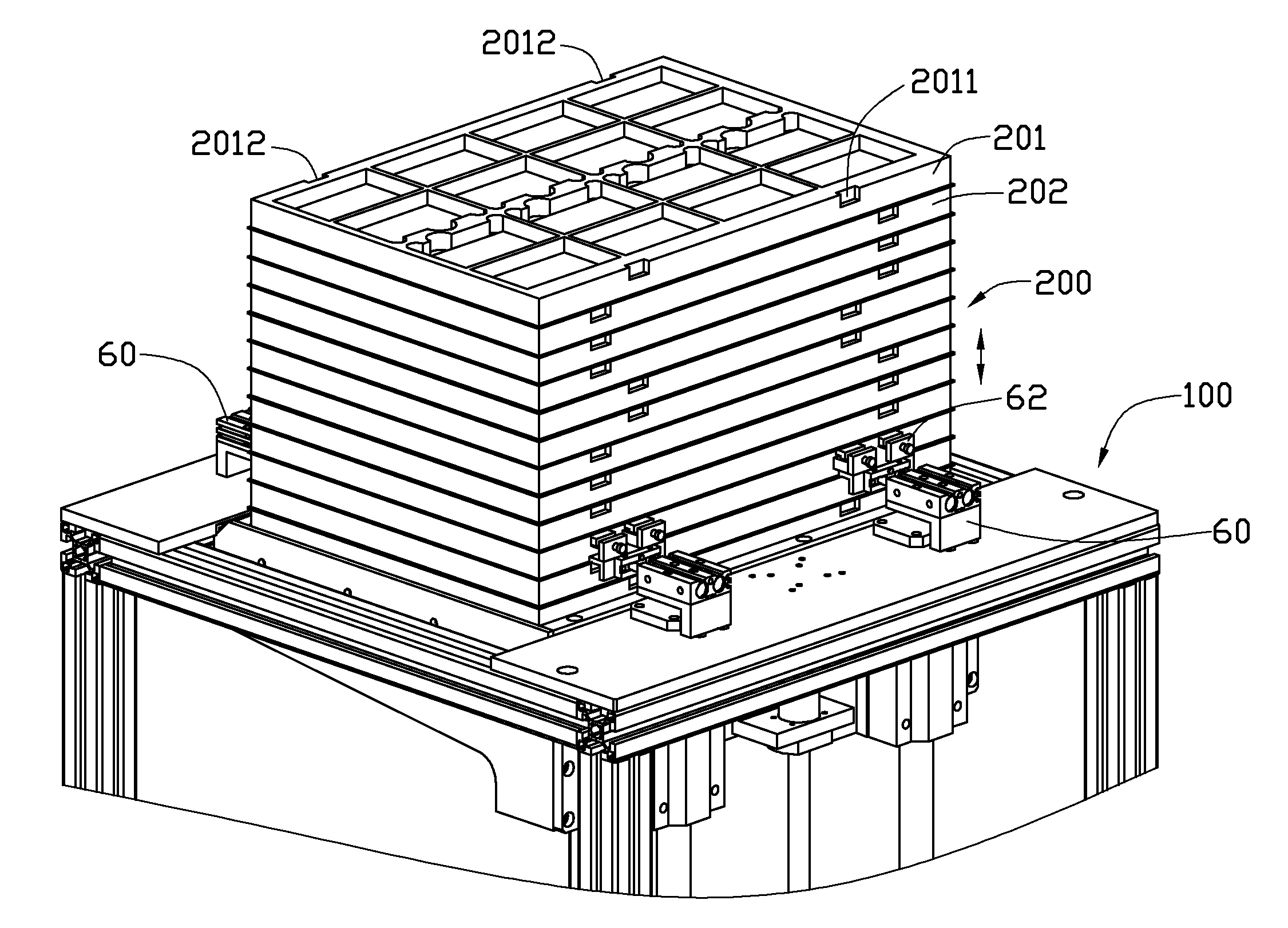

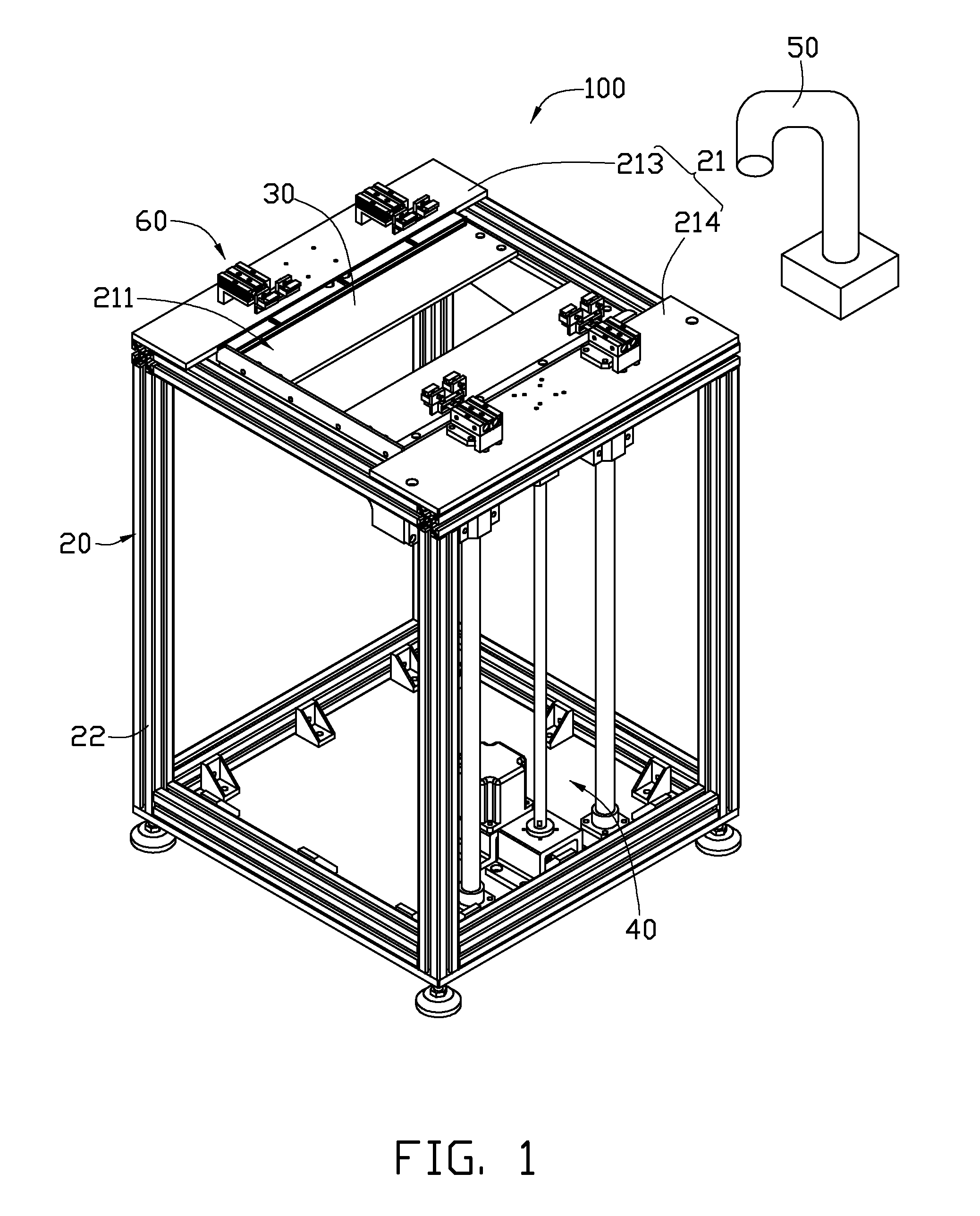

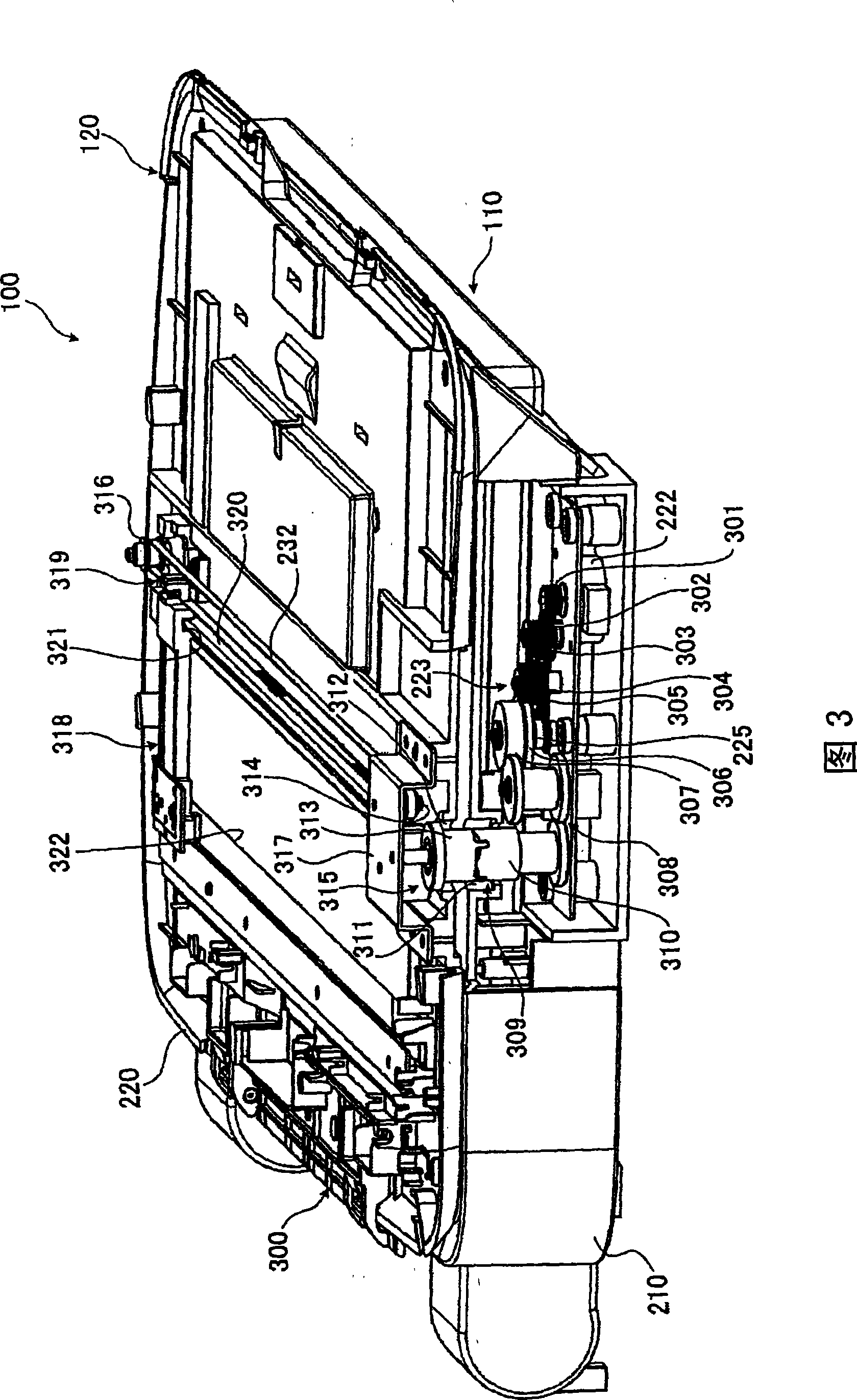

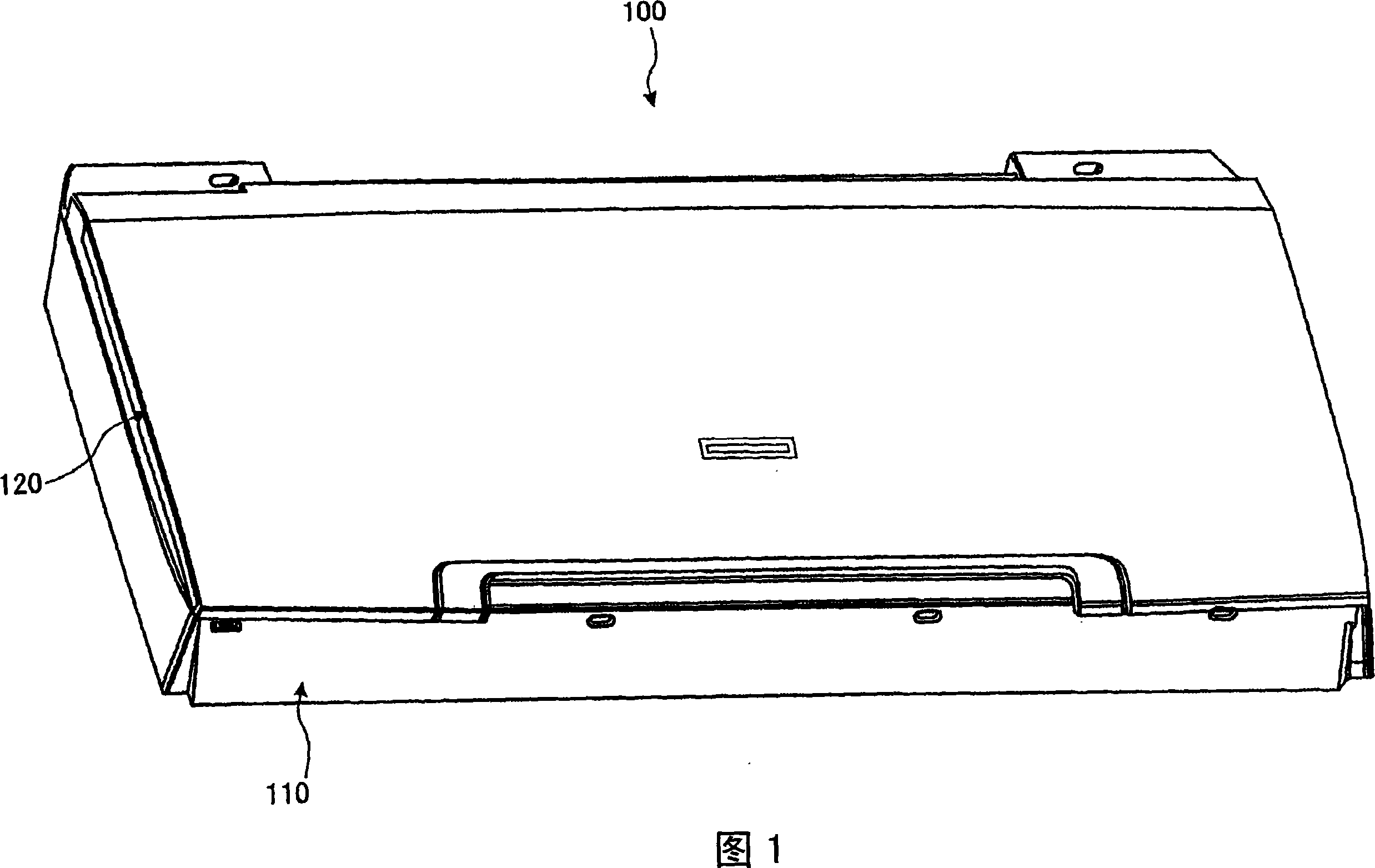

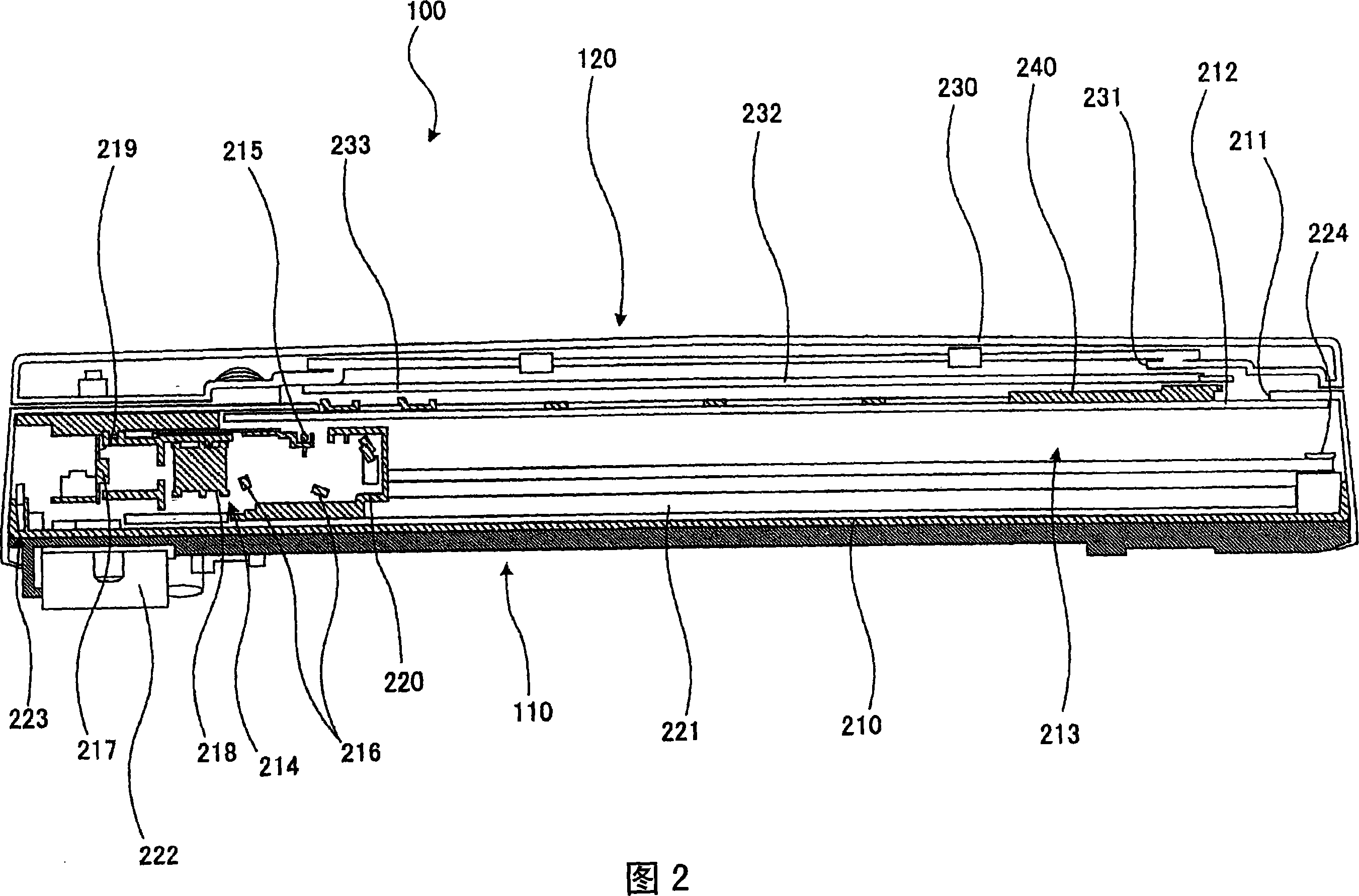

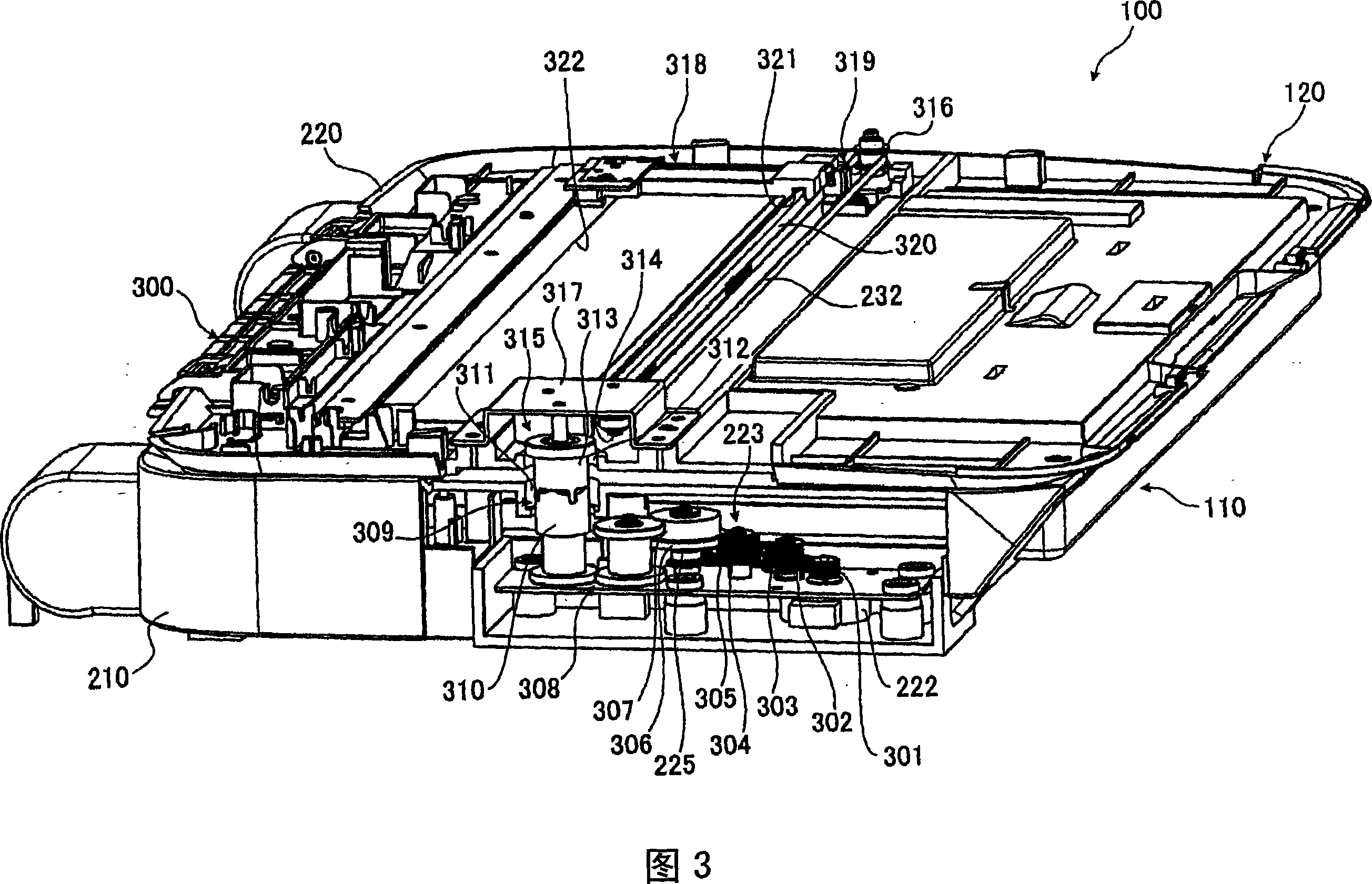

Component feeding device

InactiveUS20110286829A1Easy clutchStacking articlesDe-stacking articlesEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

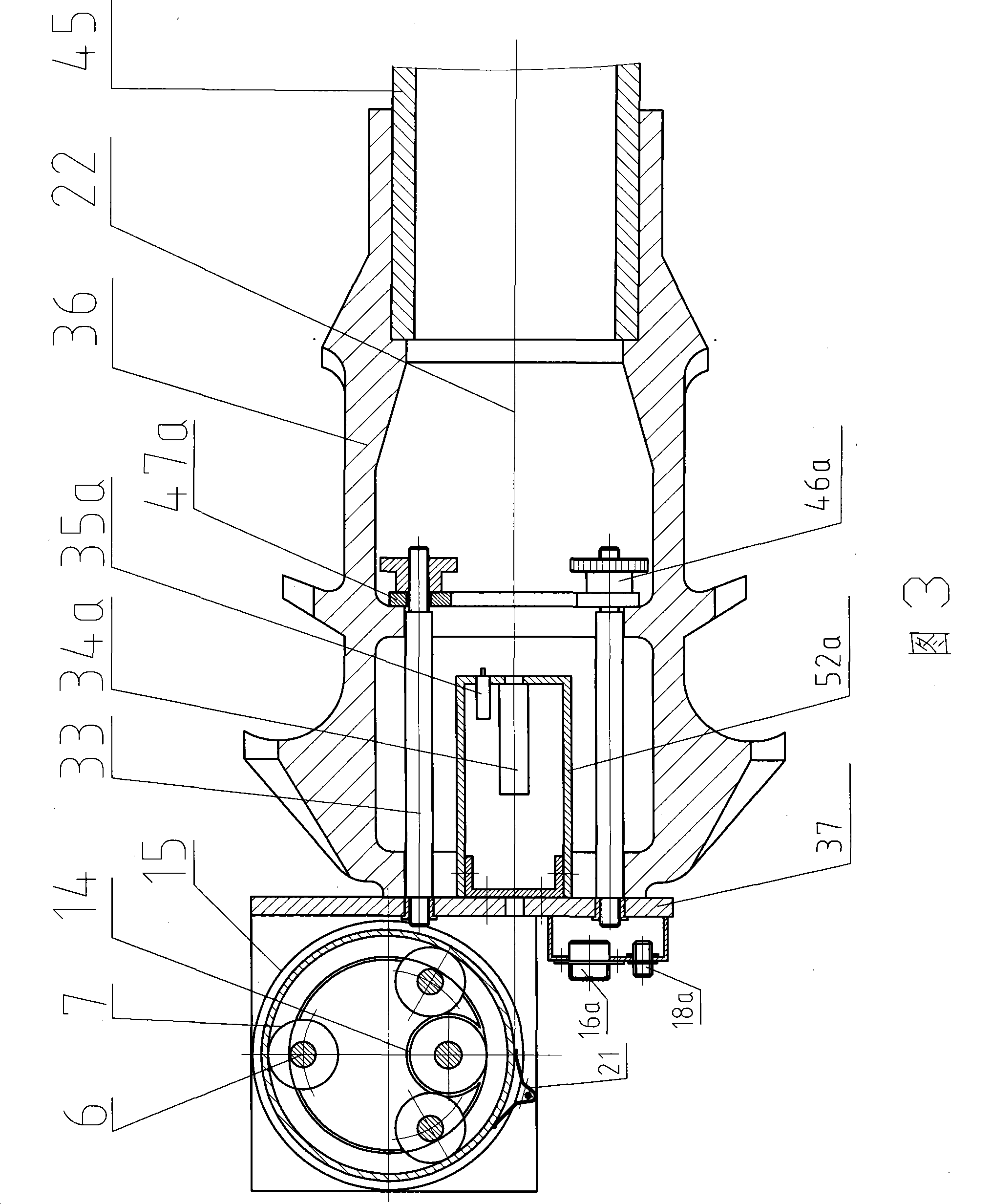

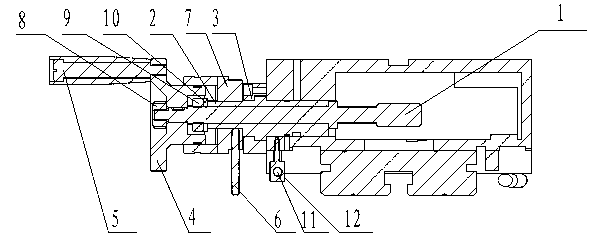

Multifunctional automatic gun wiping machine

A multi-functional automatic gun cleaner comprises drive motors, an automatic controller and a cleaning body; transmission mechanisms, a front gun cleaner bracket and a rear gun cleaner bracket are arranged between the cleaning body and the drive motors; the front end of each gun cleaner bracket is provided with a gun cleaner bracket positioning structure matched with the two ports of the gun barrel, while the drive motor is fixed at the rear end of each gun cleaner bracket; the transmission mechanisms are arranged between the cleaning body and the two motors; each transmission mechanism comprises an electromagnetic clutch which connects the drive motor with a pull-rope drum, and a gear deceleration mechanism; the electromagnetic clutch comprises a pull-in end, a sliding end and a fixed end; the pull-in end of the electromagnetic clutch is fixed on the output shaft of the drive motor; the fixed end of the electromagnetic clutch is fixedly connected with a main shaft; and the main shaft is fixedly connected with the gear deceleration mechanism. The multi-functional automatic gun cleaner is suitable for the gun tubes of any caliber, or can be used to remove and clean the grease stain, rust and fouling in civil pipes.

Owner:济南海鹰机电制造有限公司

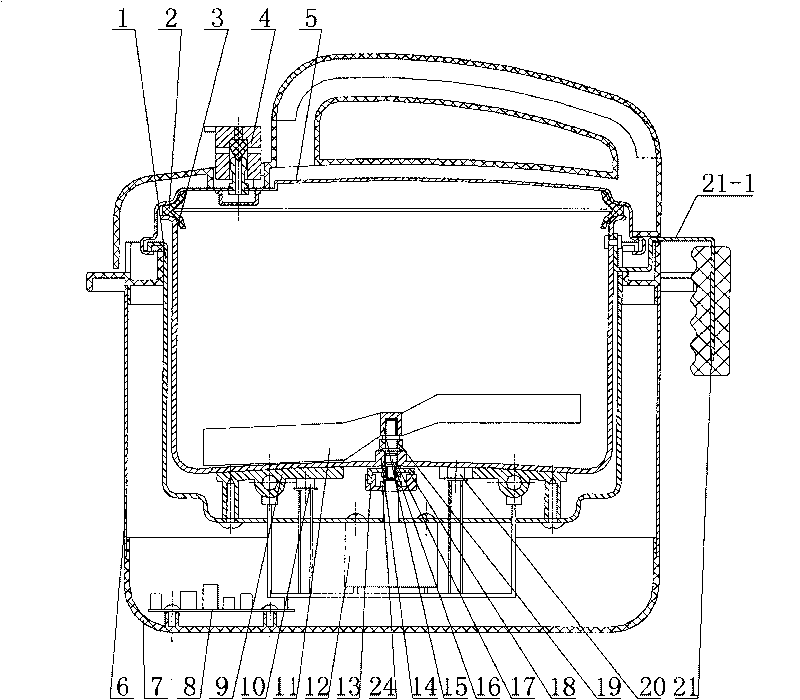

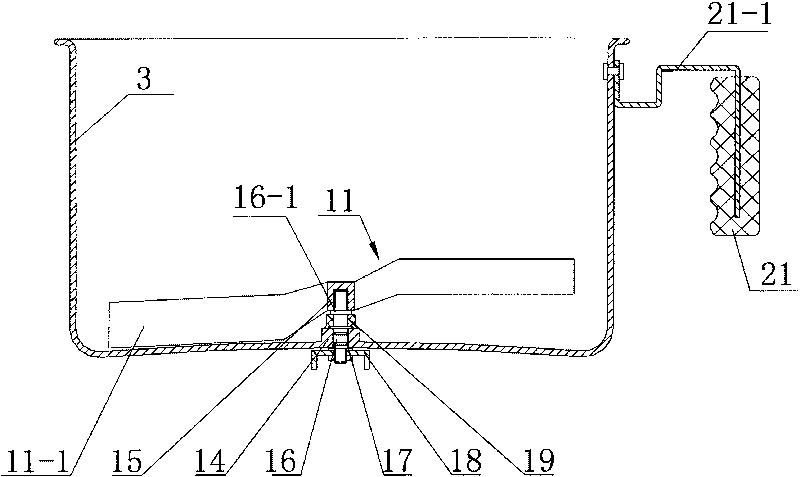

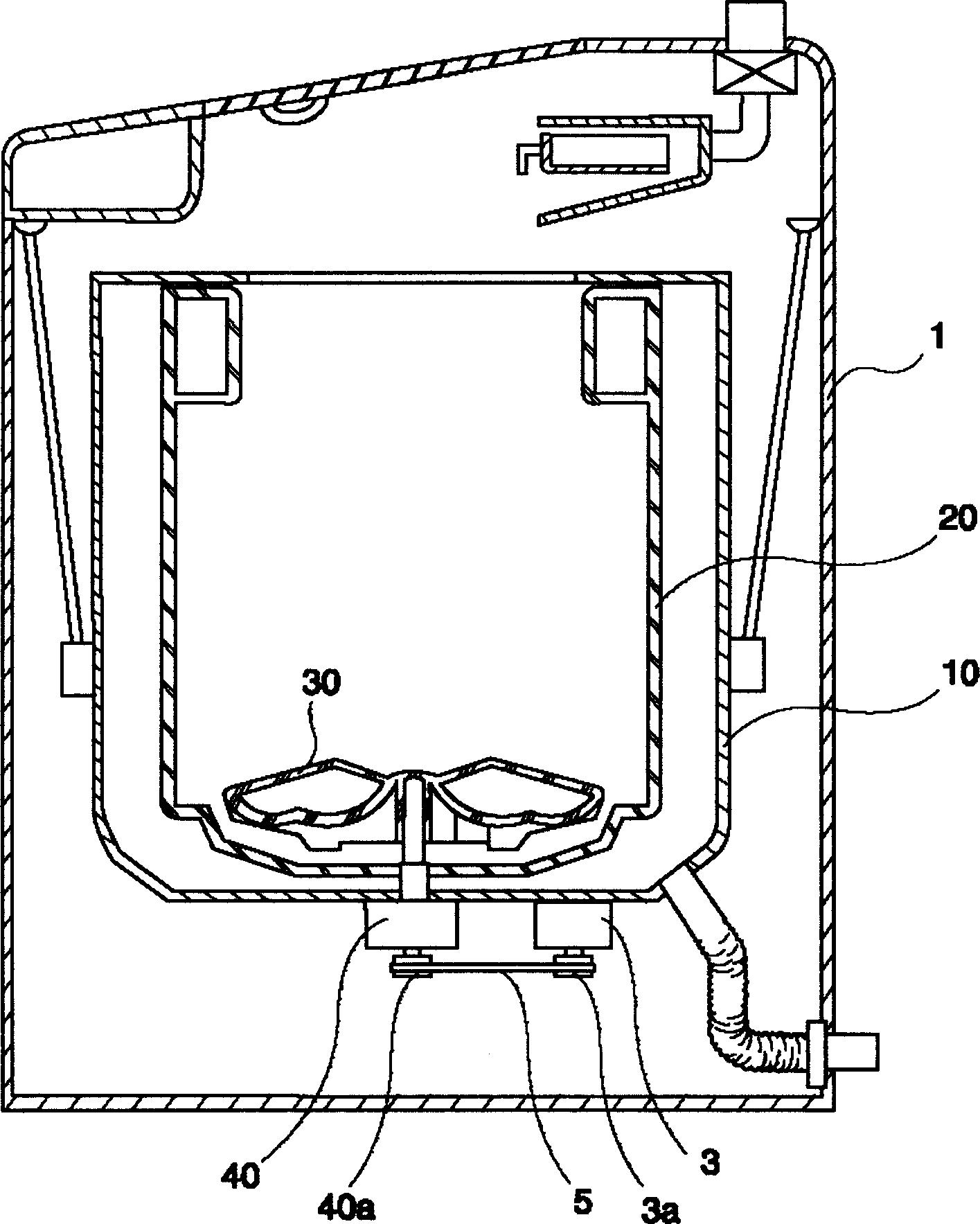

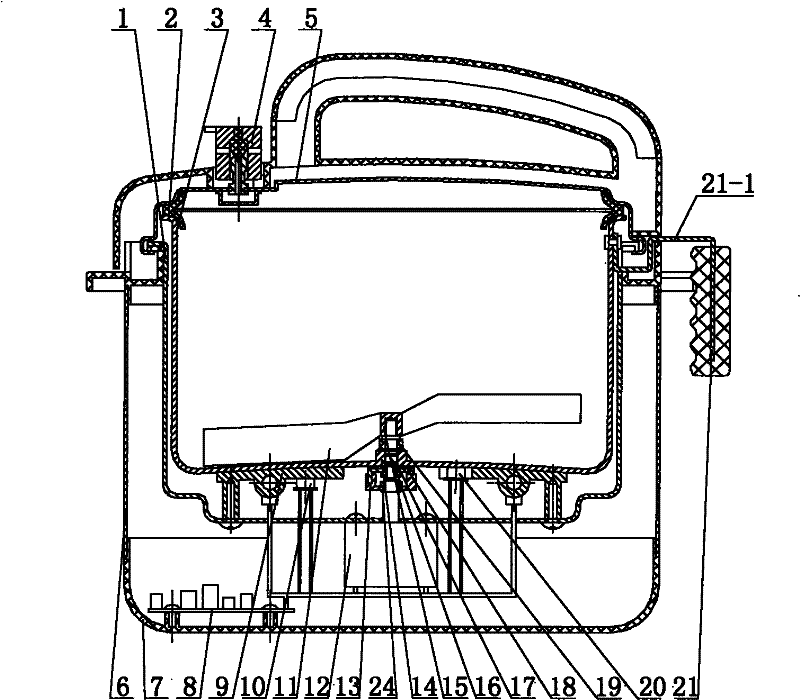

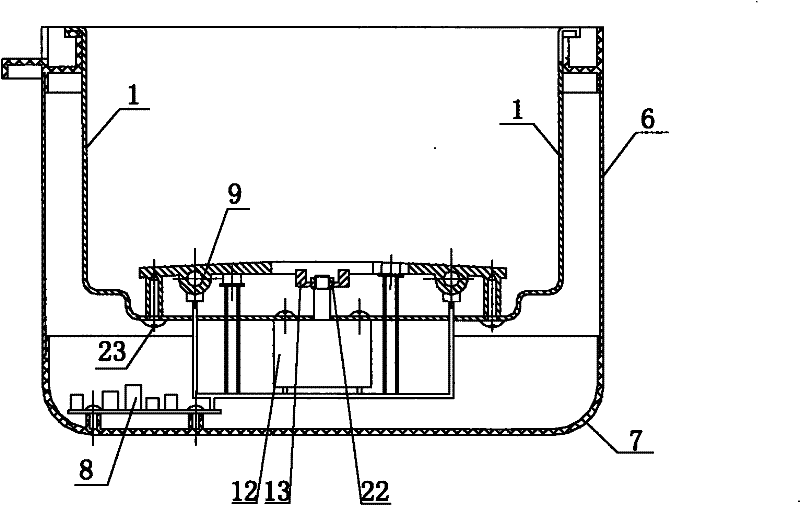

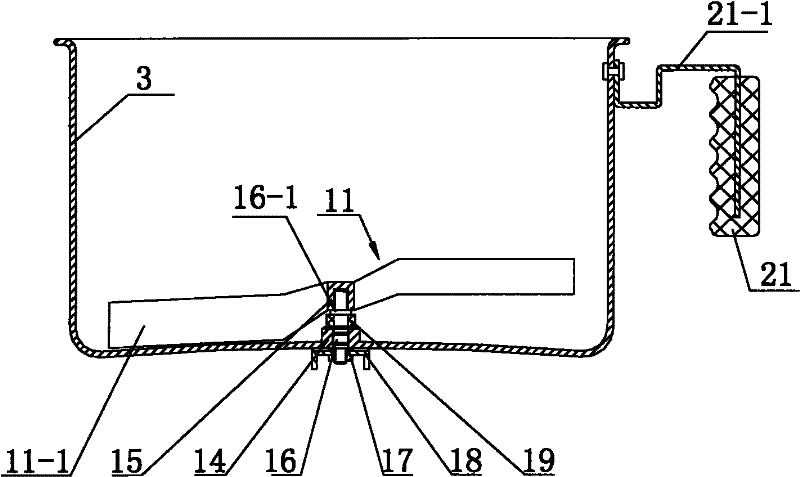

Electric pressure cooker

The invention provides an electric pressure cooker which can solve the problems caused by arranging an electrical motor on the cover of the cooker in the prior art. The technical scheme is as follows: the electric pressure cooker comprises an inner pot, an outer pot, a shell, a heating plate, the electrical motor and a stirrer, wherein the electrical motor is arranged in the lower part of the outer bottom surface of the inner pot, the motor shaft is connected with a main driving disc, the inner bottom surface of the inner pot is provided with a drive shaft sleeve, the inside of the drive shaft sleeve is provided with a drive shaft, the stirrer is fixedly connected with the upper end of the drive shaft through a stirrer sleeve, the lower end of the drive shaft passes through the bottom surface of the inner pot and is fixedly connected with an auxiliary driving disc, and the main driving disc and the auxiliary driving disc constitute a clutch. As the electrical motor and the motor shaft are arranged in the lower cavity of the outer bottom surface of the inner pot, the weight of the cover of the cooker is reduced, when the cover is opened, the motor shaft and a stirring blade are not needed to take out so as to avoid the phenomenon of taking soup or rice along with the motor shaft and the stirring blade out of the cooker, reduce the space occupied by the cover and ensure to conveniently and hygienically place the cover.

Owner:崔美娟

Rewinding mechanism for rechecking machine

The invention provides a rewinding mechanism for a rechecking machine. The rewinding mechanism is characterized by comprising a rack, a transverse arranged U-shaped positioning groove, a power mechanism and a rotating shaft mechanism, wherein an output shaft of the power mechanism is provided with a clutch; the rotating shaft mechanism comprises a paper tube rotating shaft main body, a bearing connecting shaft, a bearing component and a transmission shaft with clutching teeth on the outer surface; the bearing component comprises a tubular bearing pedestal and a bearing; the bearing connectingshaft is connected to the bearing in a penetration manner; the transverse arranged U-shaped positioning groove is connected to a set screw in a penetration manner; the clutch comprises a movable sleeve which rotates along with the output shaft and can move forwards and backwards; and transmission teeth engaged with the clutching teeth on the transmission shaft are arranged in the inner cavity of the movable sleeve. Compared with the prior art, the rewinding mechanism has the advantages of being capable of substantially lowering noise and causing rechecking environments to be friendly.

Owner:GUANGDONG TIANAN NEW MATERIAL

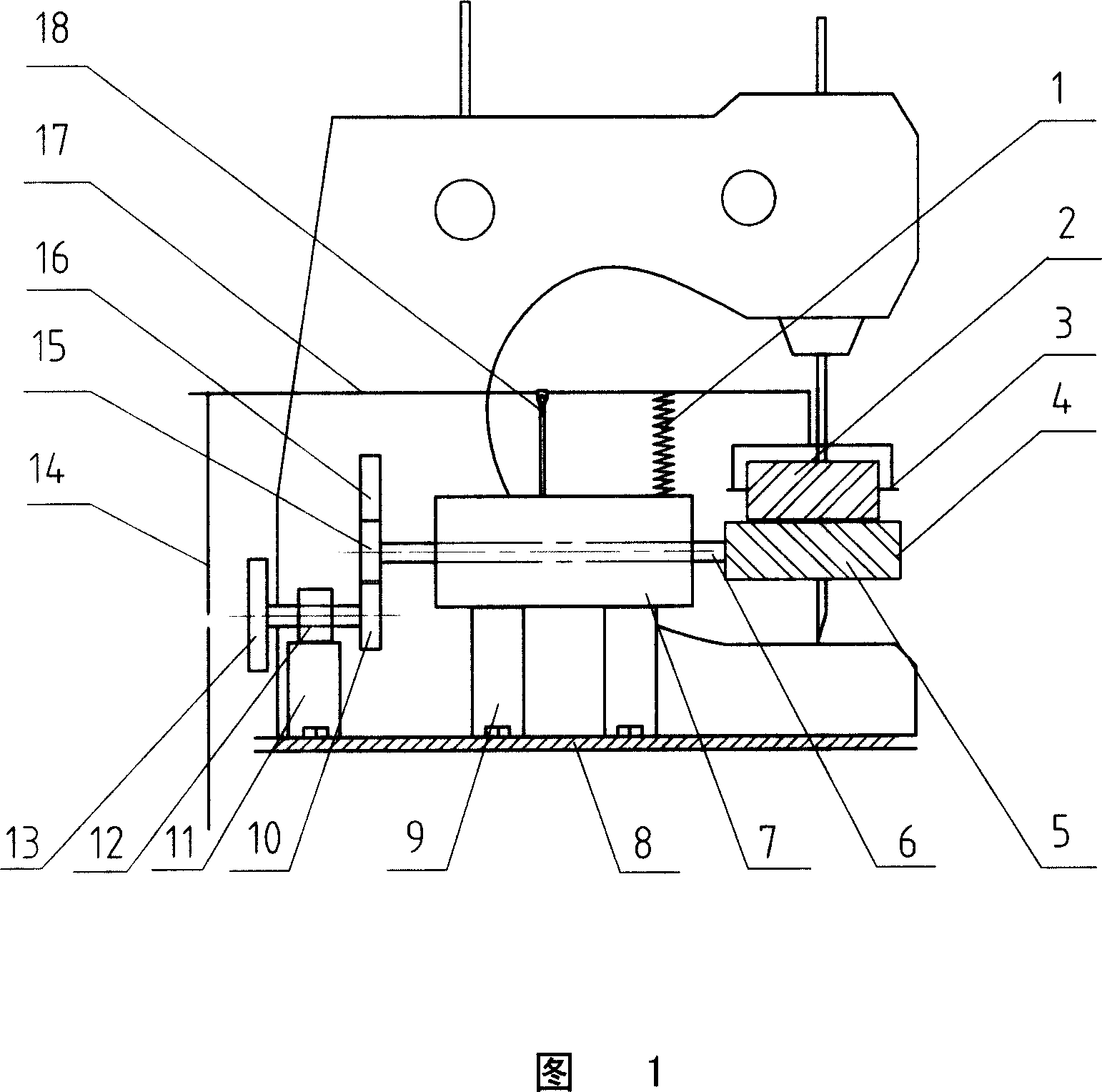

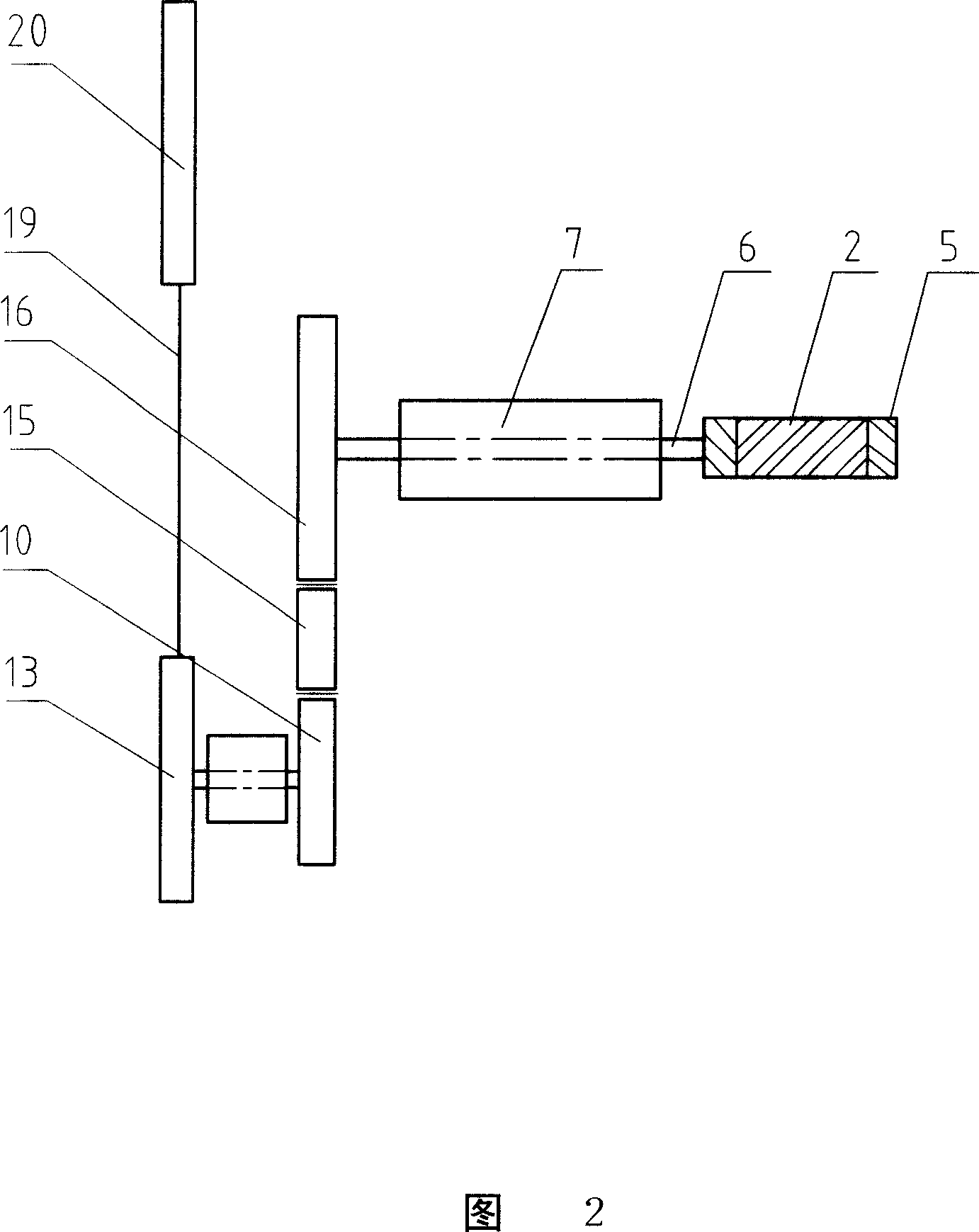

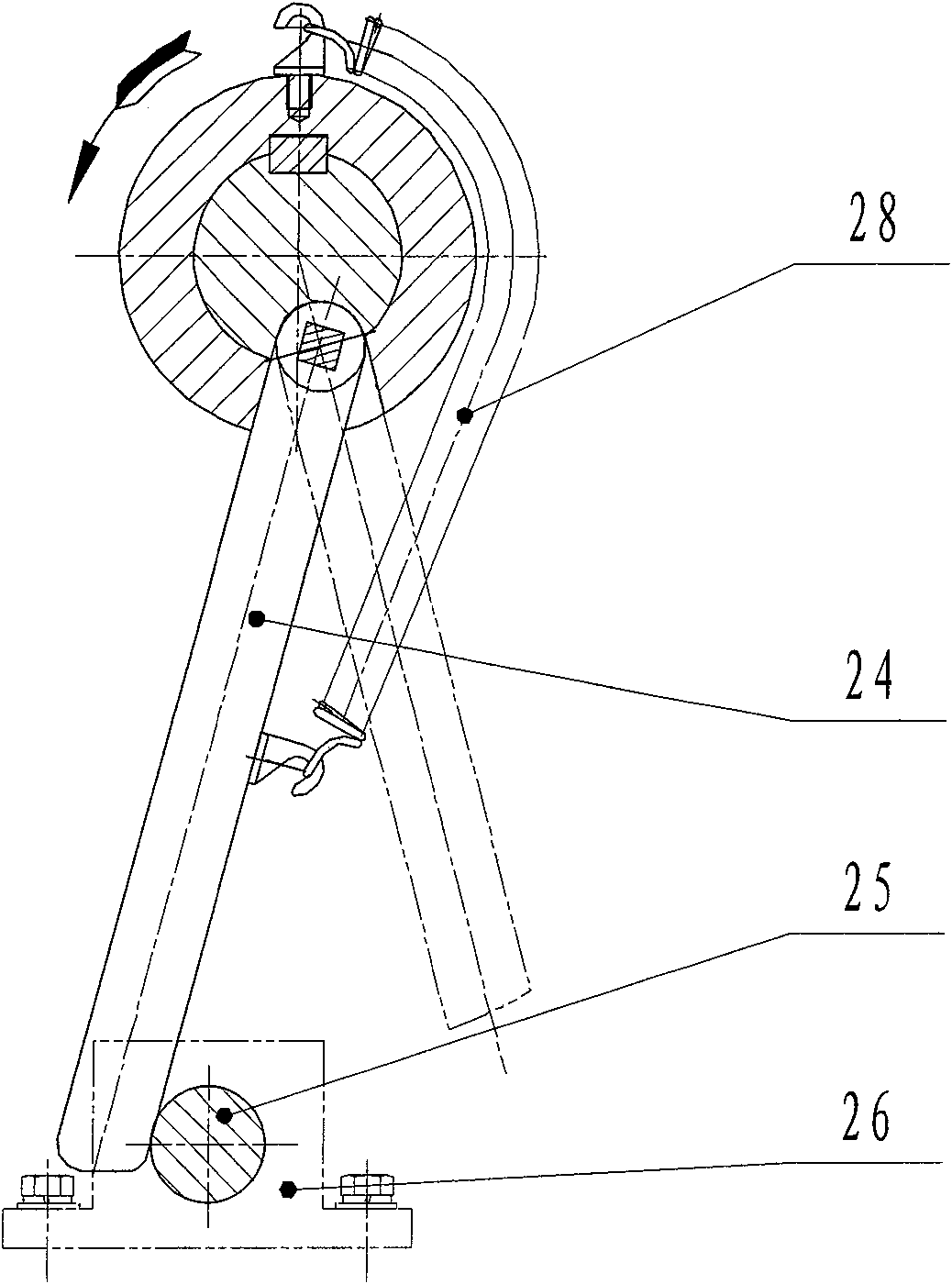

Fabric synchronizing tractor of industrial sewing machine

InactiveCN101074519ATroubleshoot synchronous traction issuesCorrect and maintain sewing directionWork-feeding meansJoystickClutch control

This invention discloses one synchronous traction device of industrial sewing machines fabric, it includes stent installed on the table and driving wheel of machine heads, the point is that install one follower wheel with transmission gears at the back of driving wheel, the follower wheel is connected with driving wheel by belt; one shaft is installed at one side of the gear of driven wheel, at one side of the shaft install a differential gear and an active roller at the other side, the steering Gear is installed between the gear of driven wheel and differential gear, the two gear in between match; one support bar is installed on the double-bearing, its top connect with one connecting rod, at one side the connecting rod connect without fix with clutch control rod, at the other side it connect with friction roll by pin, in order to make the friction roll work closely with active roll one tension spring is installed between the double-bearing and connecting rod. This invention has the traits of new structure, reasonable design, good synchronous effect, it not only improves the quality of sewing fabric, but also lowered the cost of production and widely to be installed to use in the industrial sewing machines of flake sewing fabric.

Owner:刘青

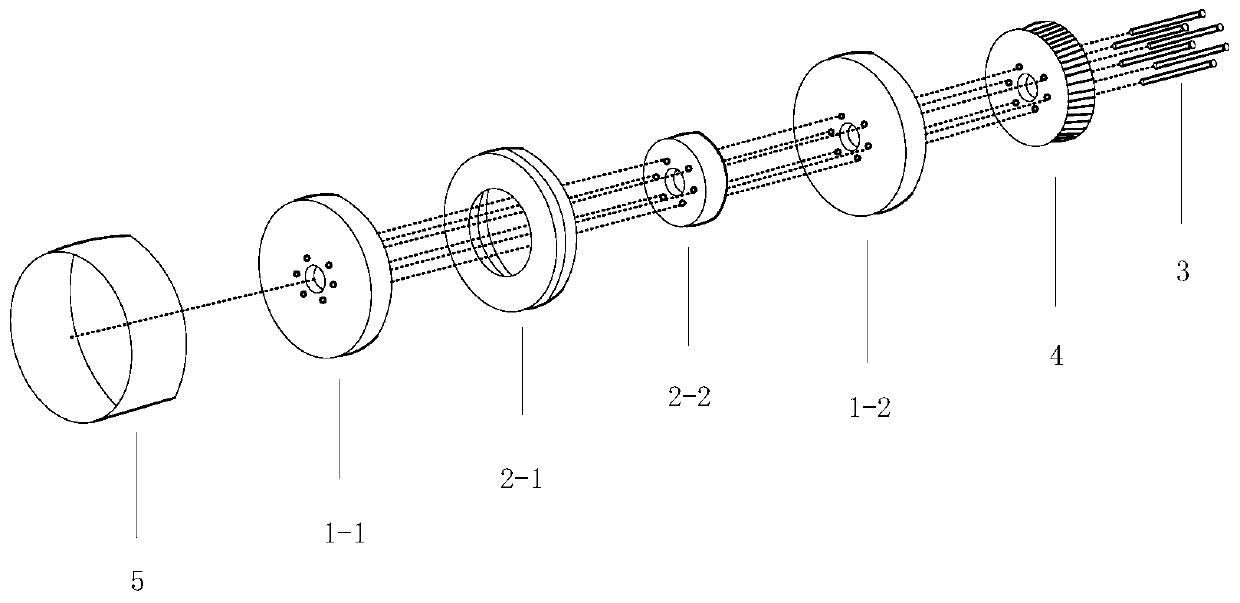

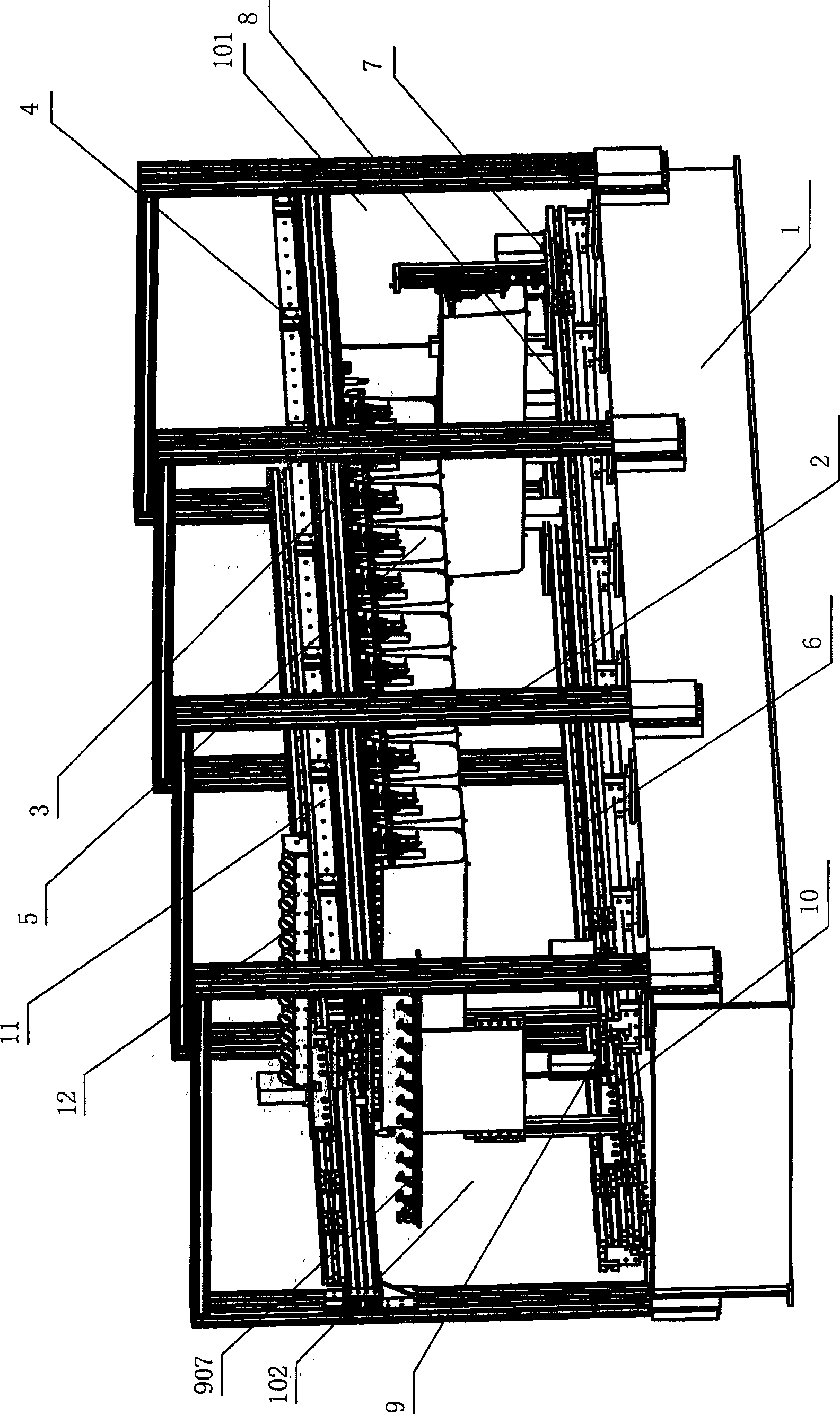

An exhaust blower for fluorescent lamp production

InactiveCN101217088AAchieve continuous exhaust processingEasy clutchTube/lamp vessels exhaustionFixed frameFluorescence

The invention discloses an exhaust machine for the production of fluorescent tubes, including a base and a fixed frame, the invention is characterized in that one end of the base is an upper pipe mouth, the other end is a lower pipe mouth, the upper part of the fixed frame is provided with a fixed board, a plurality of rows of mercury gun groups are arranged on the fixed board, each mercury gun group is composed of a plurality of mercury guns which are arranged side by side, a plurality of drying ovens which are corresponding to the mercury guns and have upward openings are arranged from the upper pipe mouth to the lower pipe mouth, drying oven fixed devices are arranged between the fixed board and the drying ovens, a first transmission guide track group which is arranged below the fixed board and a second transmission guide track group which is arranged above the fixed board are arranged between the upper pipe mouth and the lower pipe mouth; a drying oven ascending and descending device, an upper pipe device and a lower pipe device which can move along the first transmission guide track group are arranged on the first transmission guide track group, the second transmission guide track group is provided with a mercury filling device which can move along the second transmission guide track group, and the invention has the advantage that the exhaust machine can simultaneously realize the continuous exhaust processing of a plurality of lamp tubes under the situation of non-mobile processing working position.

Owner:ZHEJIANG YANKON GROUP

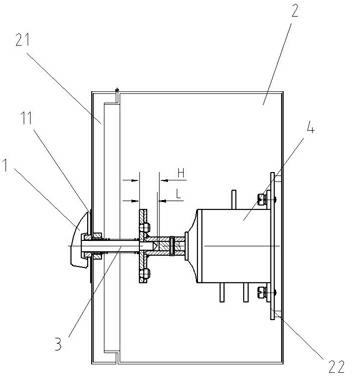

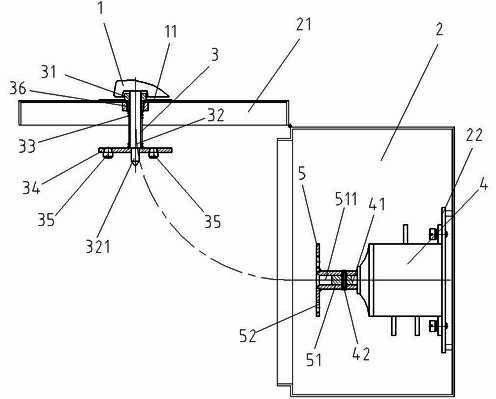

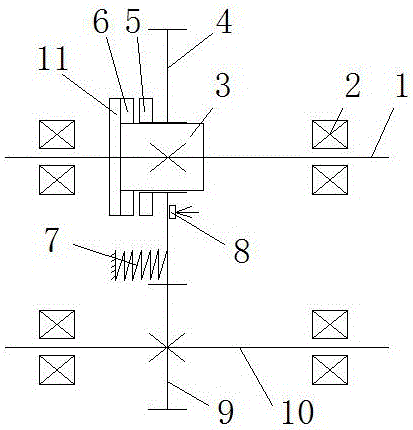

Combination switch control clutch device of power distribution cabinet

The invention discloses an operating clutch device of a power distribution cabinet combined switch, which comprises an operating handle, a clutch mechanism, and a turntable connected with a combined switch. The clutch mechanism comprises a guide sleeve, a guide rod, a compression spring, a shifting fork disc and a pair of positioning pins, wherein the guide sleeve is fixed on the door panel of a power distribution cabinet through a fixing nut, the guide rod penetrates through the guide sleeve, one end of the guide rod is fixedly connected with the operating handle and the other end of the guide rod is fixedly connected with the shifting fork disc; and the pair of positioning pins is respectively fixed on the shifting fork disc, the compression spring is movably sheathed on the guide rod, a shaft sleeve on one side of the turntable is fixedly connected with the rotating shaft of the combined switch, the inner hole of the shaft sleeve is matched with the other end of the guide rod and a pair of positioning pin holes which are matched with the heads of the pair of positioning pins are arranged on the surface of the turntable. The operating clutch device of the power distribution cabinet combined switch has a compact structure, is simple to operate and is reliable to work. When circular motion for opening and closing is carried out under the situation that the repeatability precision and the rigidness of the door panel of the power distribution cabinet are poor, the operating clutch device can be engaged and disengaged easily.

Owner:镇江四洋柴油机制造有限公司

Engaging and disengaging gear and gluing machine using the same

The invention discloses a clutch device and a laminating machine using the clutch device. The laminating machine also comprises a laminating roll and a laminating roll support, the laminating roll support is provided with a motor fixing column, a motor is fixed with the motor fixing column of the laminating roll support, the clutch device comprises the motor, a motor output shaft, an elastic part, an end face clutch and a radial clutch, the elastic part, the end face clutch and the radial clutch are orderly sleeved on the motor output shaft, the motor output shaft is in transmission connection with the laminating roll through the radial clutch between the motor and the laminating roll support, wherein the side surface of the end face clutch is provided with a groove, the clutch device also comprises a clutch wrench for pushing the radial clutch, and the clutch wrench is partially accommodated in the groove to push the radial clutch to slide along the motor output shaft. The clutch device and the laminating machine using the clutch device have the advantages of simple structure and easy realization of disengagement and engagement.

Owner:SHENZHEN QIXIN GRP LLC

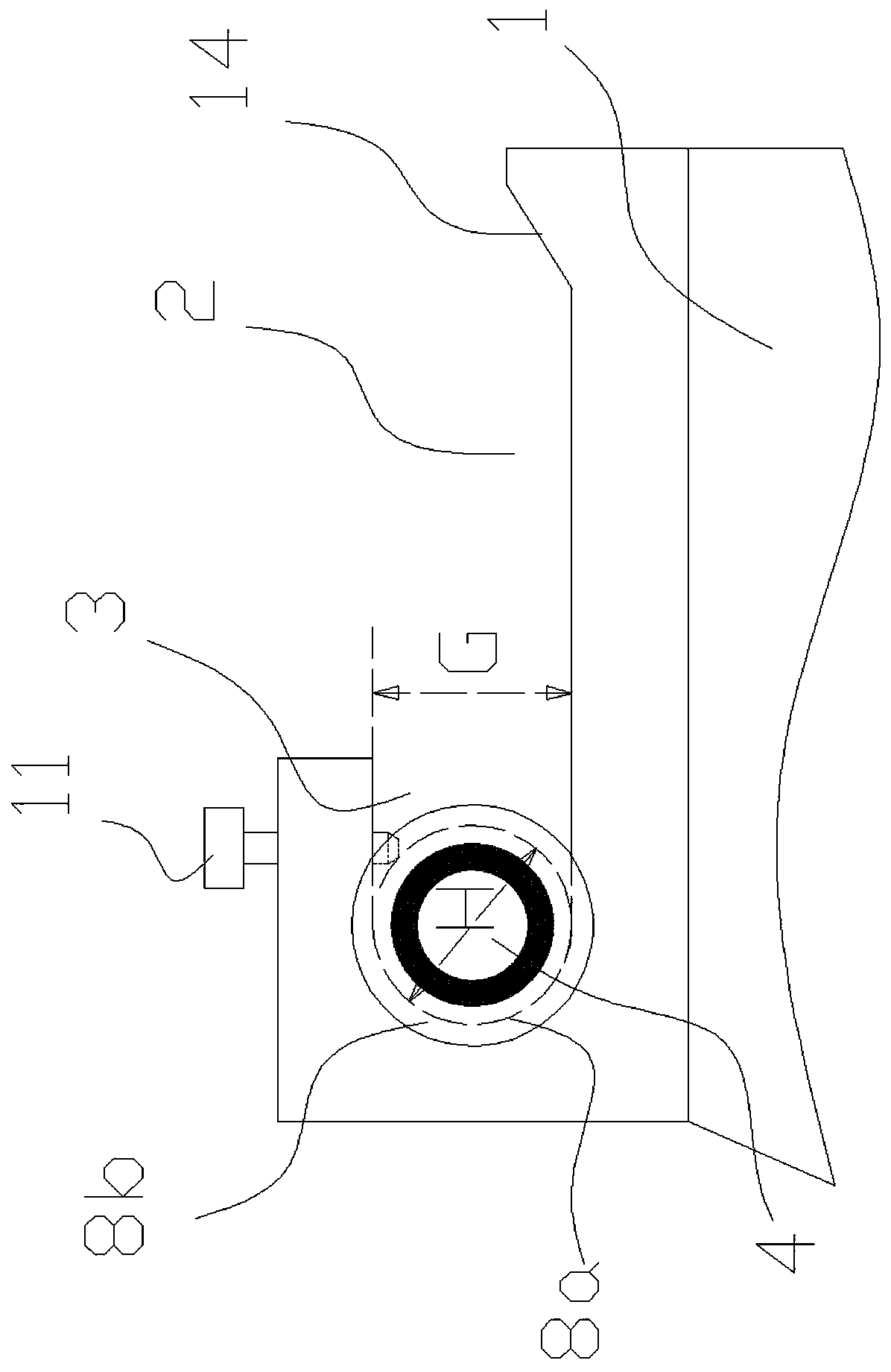

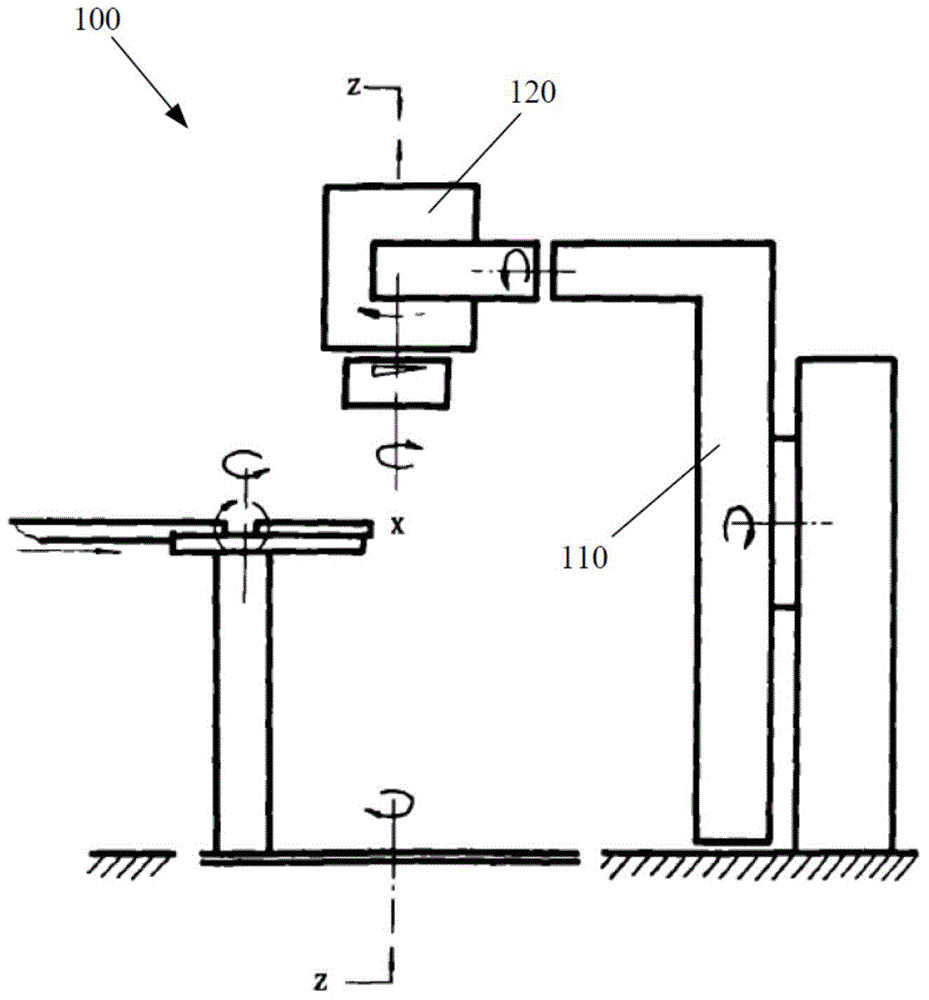

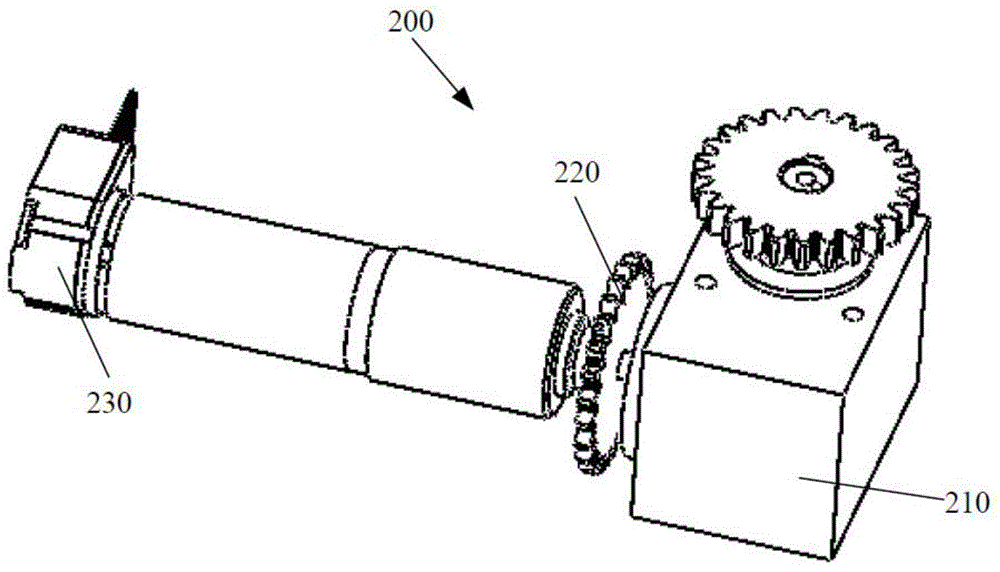

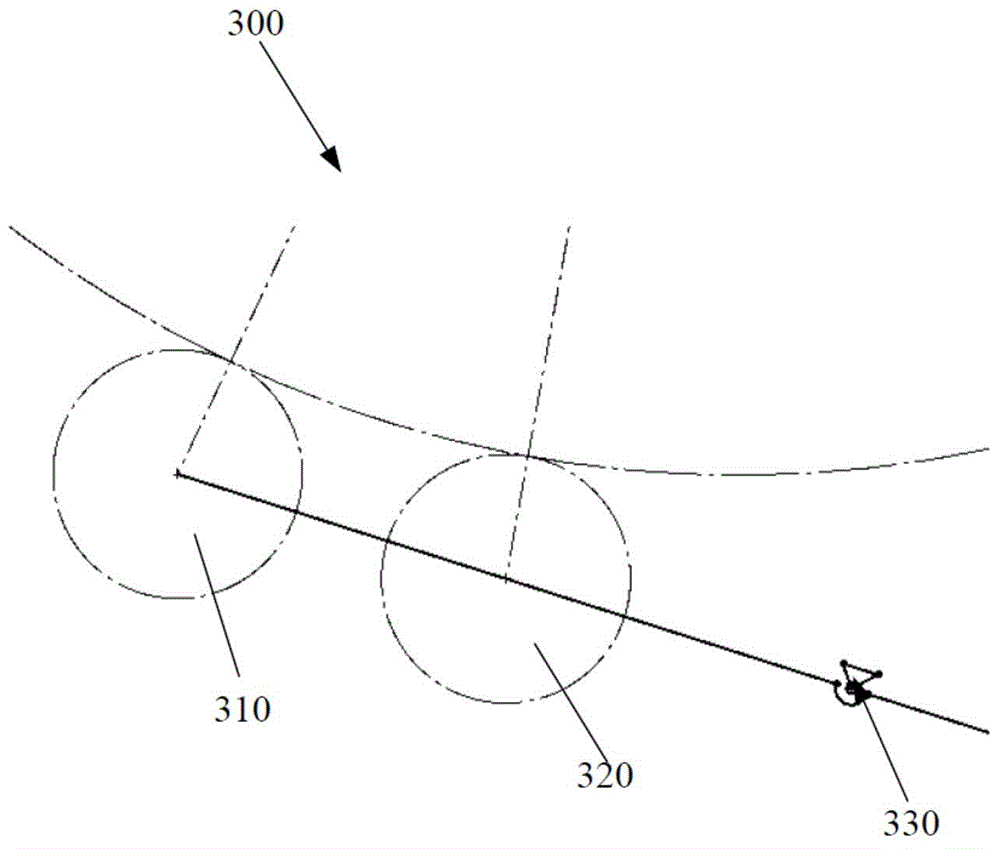

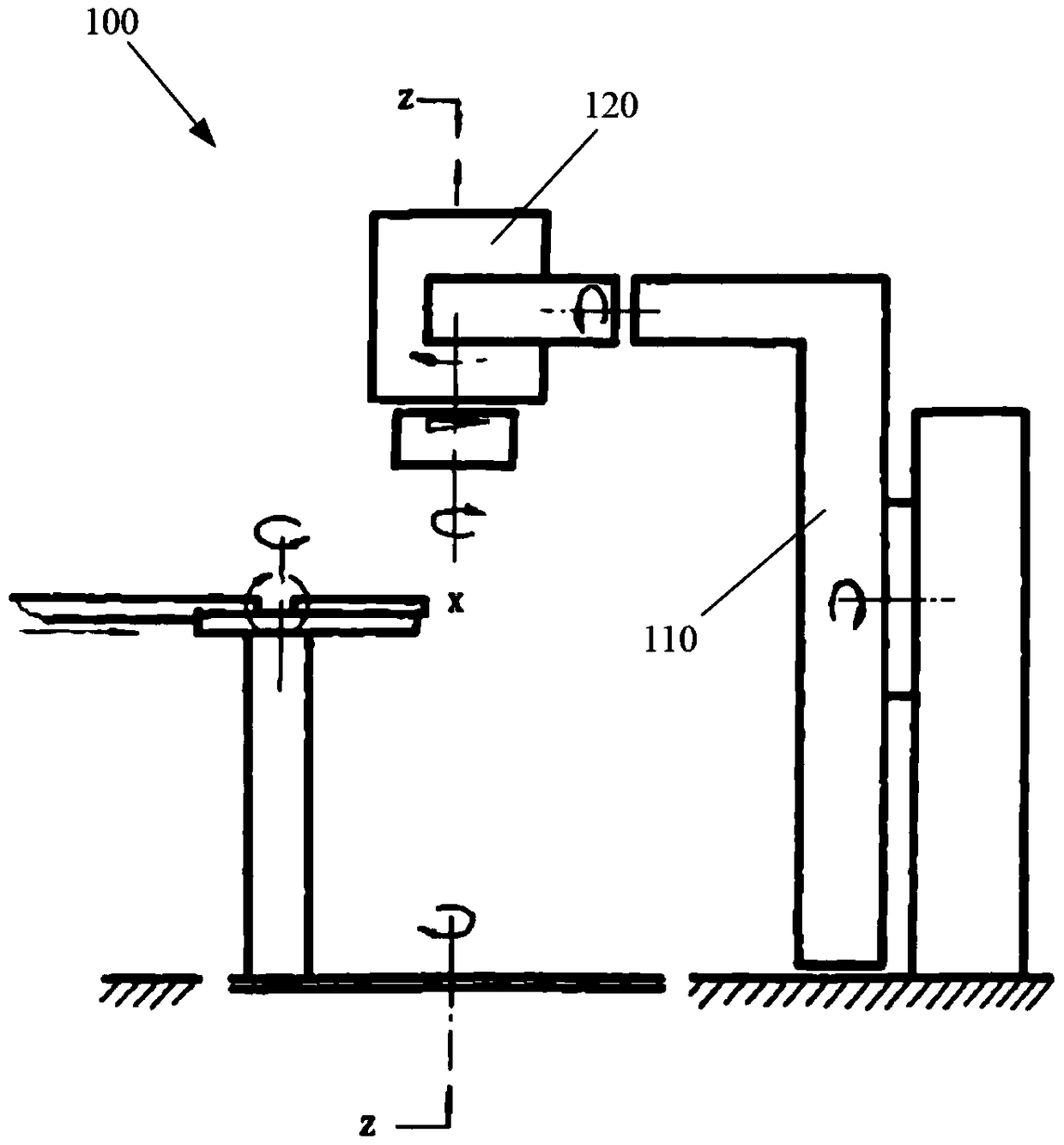

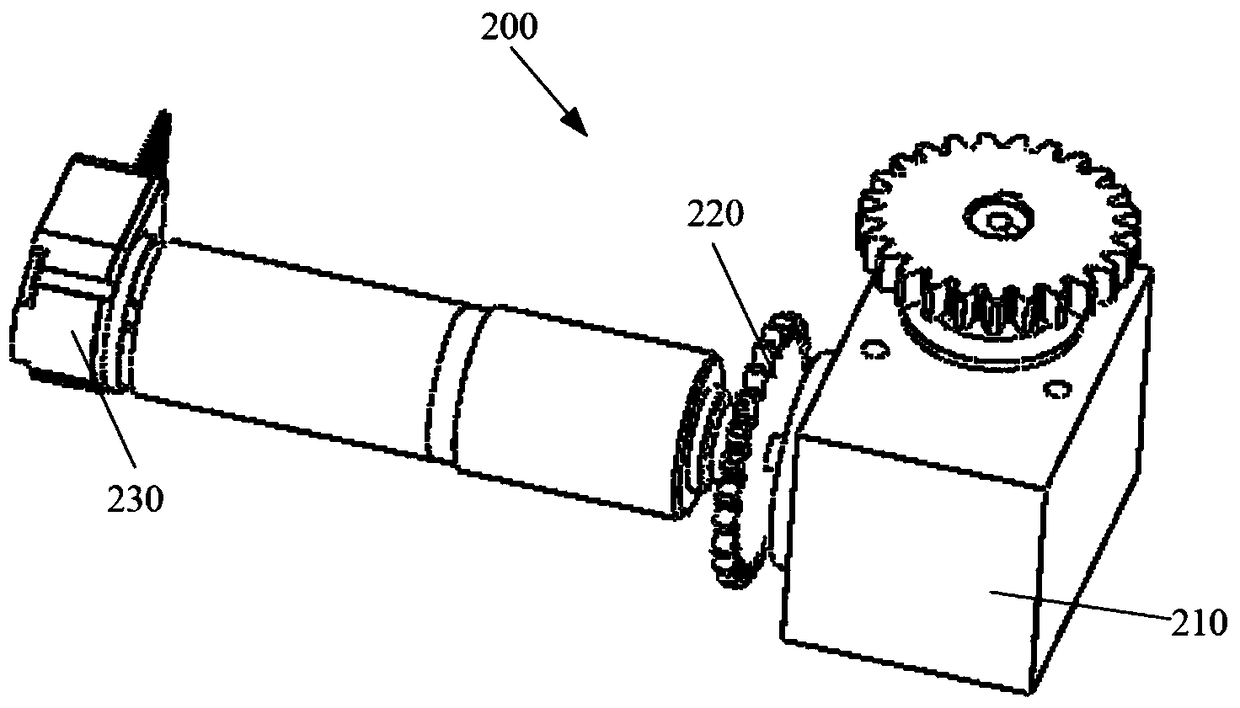

Gear clutch mechanism and radiotherapy equipment including same

ActiveCN105987091AGood locking functionEasy clutchInterengaging clutchesX-ray/gamma-ray/particle-irradiation therapyClutchEngineering

The invention provides a gear clutch mechanism and radiotherapy equipment including the same. The gear clutch mechanism is mounted at a base and comprises a driven gear, a guiding component, a mounting plate, a driving gear and a pushing assembly, wherein the driven gear is rotatably fixed to the base; the guiding component is fixed on the base; the mounting plate is supported by the guiding component in a sliding manner; the driving gear is rotatably fixed to the mounting plate; the pushing assembly is used for pushing the mounting plate to slide along the guiding component, and when the pushing assembly pushes the mounting plate to slide close to the driven gear, the driving gear moves close to the driven gear until being mutually meshed with the driven gear; and when the pushing assembly pushes the mounting plate to slide away from the driven gear, the driving gear moves far from the driven gear until being mutually separated from the driven gear. The gear clutch mechanism adopts a special cam structure, so that the clutching of the gear in the radial direction can be conveniently realized. By adjusting the profile of the cam, a relatively large dead angle can be formed, and a good locking function can be realized.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

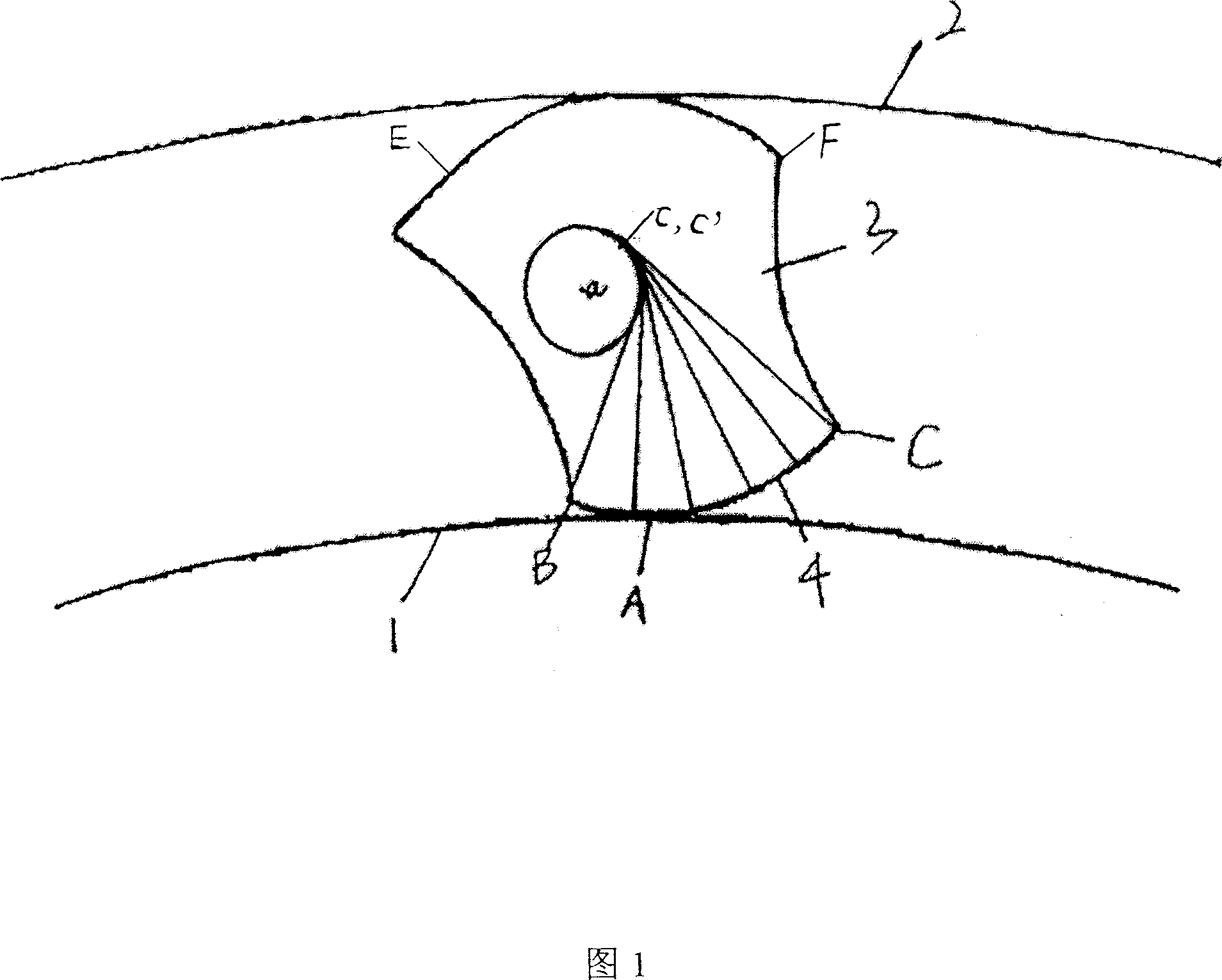

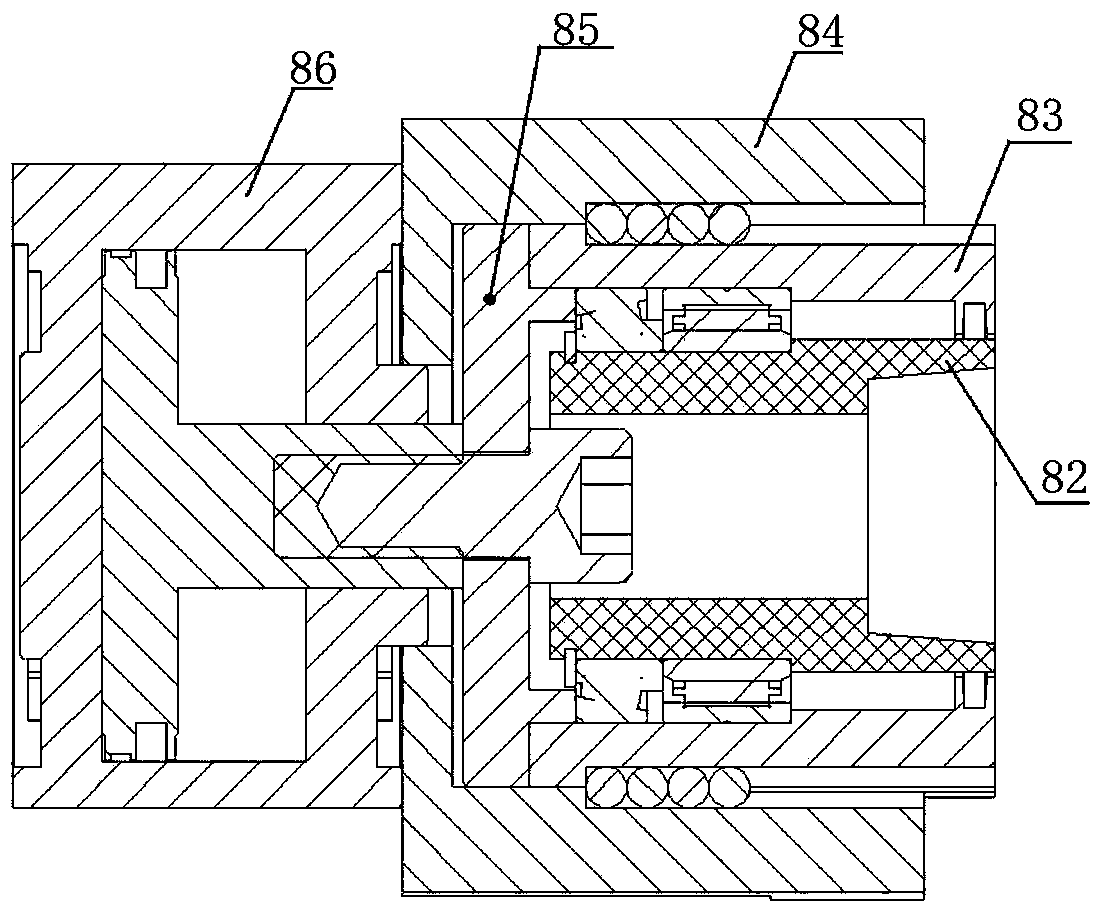

Wedge block for one-way clutch

InactiveCN101021234AExtended service lifeImprove use reliabilityFreewheel clutchesCarrying capacityLoad carrying

The present invention discloses a wedge-shaped block for one-way clutch. The invented wedge-shaped block is set between inner ring and outer ring of one-way clutch, the contact face of the described wedge-shaped block and inner ring and outer ring of said one-way clutch adopts involute curved face, so that when the clutch is worked, the curvature of said working face can be enlarged with the increment of load, the working face contact area also can be enlarged, therefore it can raise load-carrying capacity.

Owner:陈仙鹏 +1

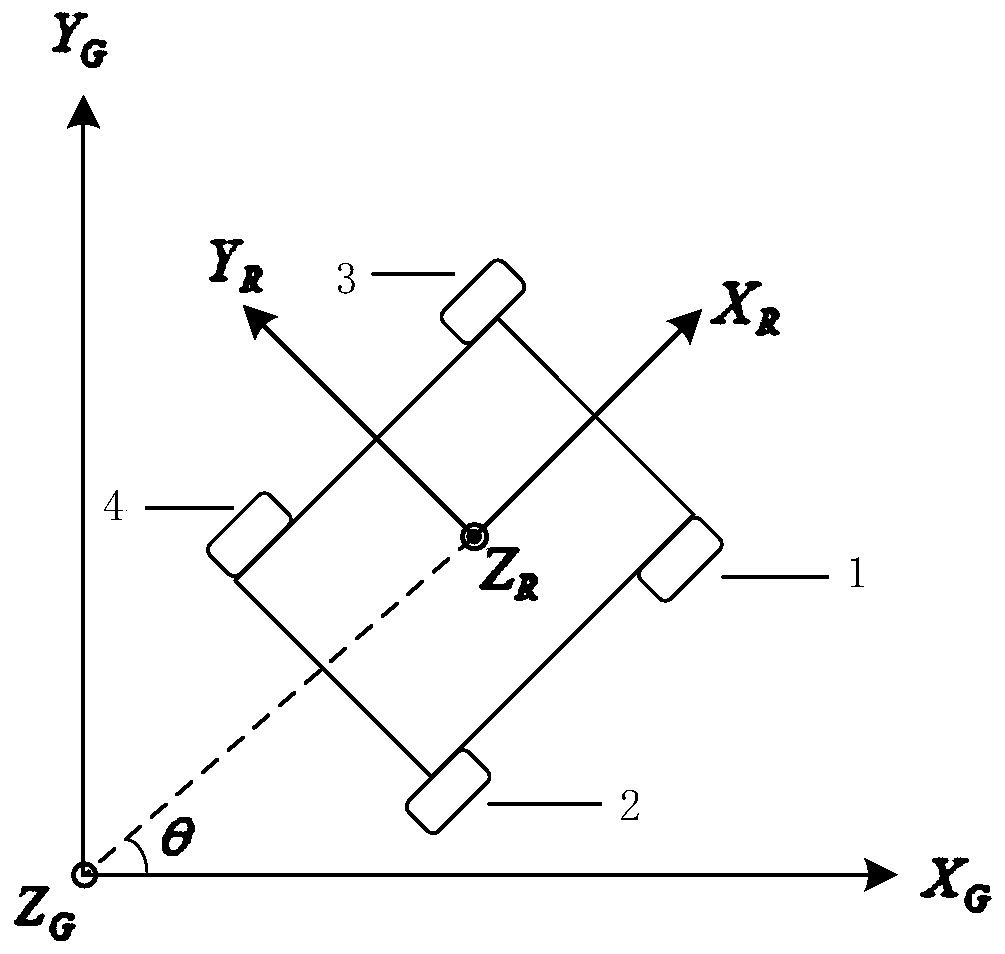

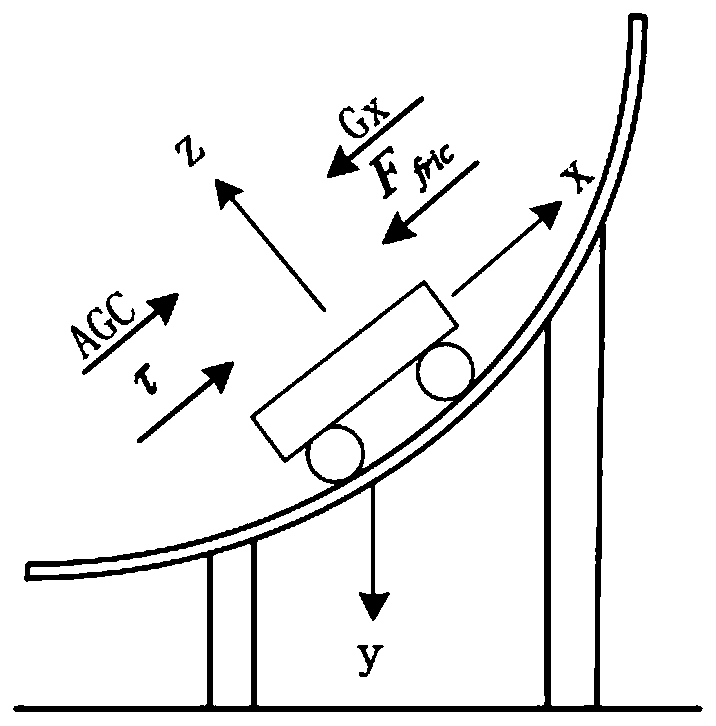

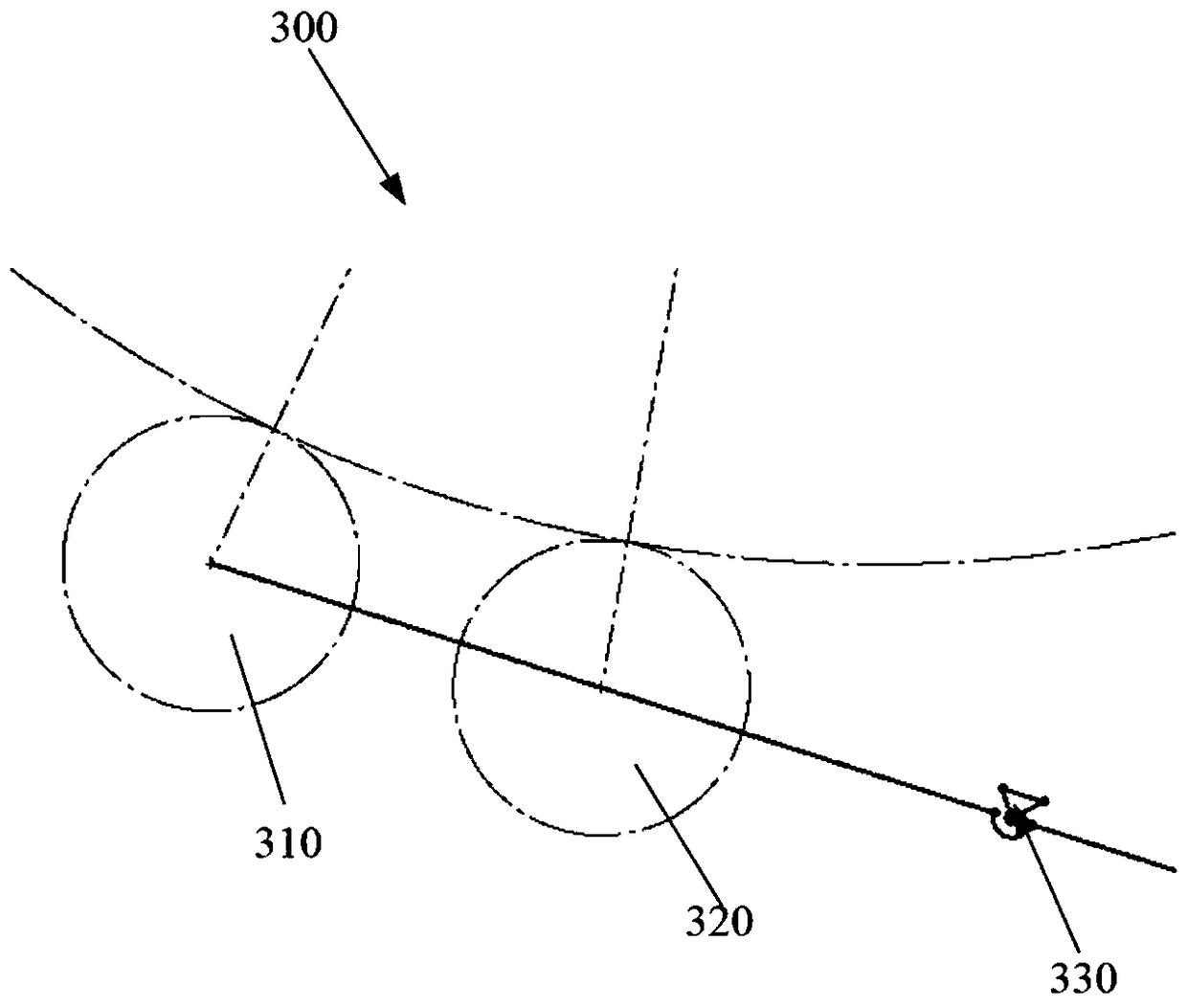

Wall-climbing robot and active adhesion control method thereof

ActiveCN109720431AAvoid stickingPrevent fallingWheelsVehiclesAnti jammingCounter propagation neural network

A wall-climbing robot is provided with four magnetic wheels. Each magnetic wheel is composed of an annular rubidium magnet, a steel disc and a hub. Each annular rubidium magnet and the corresponding steel disc form a nested structure, the wall-climbing robot is applied to the active adhesion control field of a flaw detection wall-climbing robot of a large spherical storage tank, a magnetic adhesive force active control strategy is used, a counter-propagation neural network is adopted, and automatic real-time monitoring and magnetic adhesive force control are achieved through an active adhesioncontrol method. The wall-climbing robot is simple in structure, convenient to operate, high in accuracy and high in anti-jamming capability.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Constant mesh gear speed change device

The invention discloses a constant mesh gear speed change device and relates to a gear speed changer. According to the constant mesh gear speed change device, driven gears are fixedly arranged on a driven shaft, and fixed sleeves are fixedly arranged on a driving shaft; one ends of the fixed sleeves are provided with clutch ratchets of the fixed sleeves, and sleeve bodies of the fixed sleeves are sleeved with driving gears; the end surfaces of the driving gears are provided with clutch pawls of the driving gears, and the driving gears and the driven gears are in a constant mesh state; and the clutch pawls of the driving gears and the clutch ratchets of the fixed sleeves are in a constant separating state under the action of a spring; at the moment, the driving shaft is rotated, the driving gears are not rotated, and the driven gears and the driven shaft are not rotated either; a shifting fork is pushed under the action of external force, the clutch pawls of the driving gears and the clutch ratchets of the fixed sleeves are in a constant mesh state, at the moment, the driving shaft rotates and drives the driving gears to rotate, and the driven gears and the driven shaft are rotated too. The constant mesh gear speed change device is small and exquisite in structure, separating and meshing are easy, gear breaking is avoided, and achieving of a miniature gearbox of a bicycle center shaft is facilitated.

Owner:石幸运

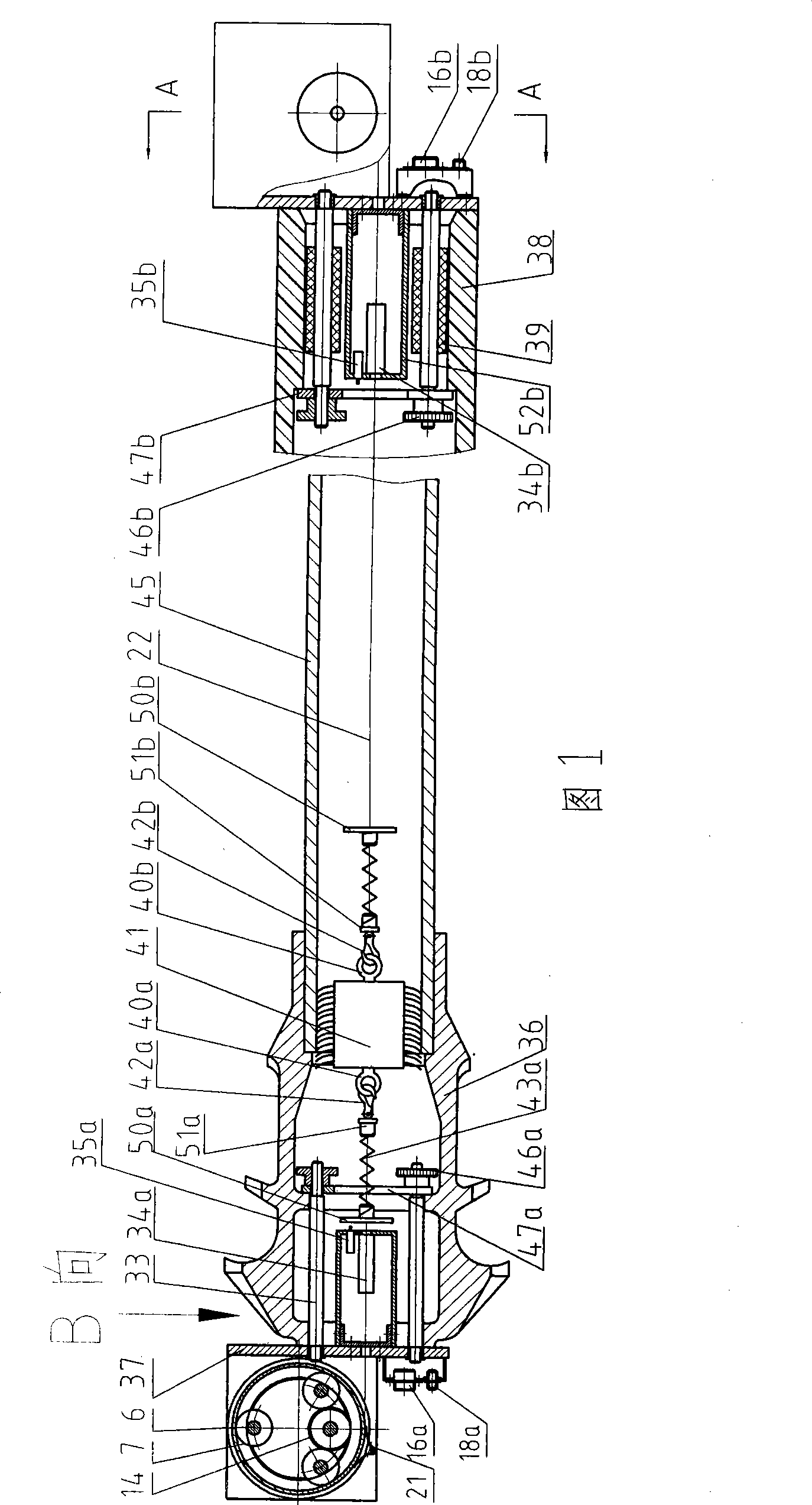

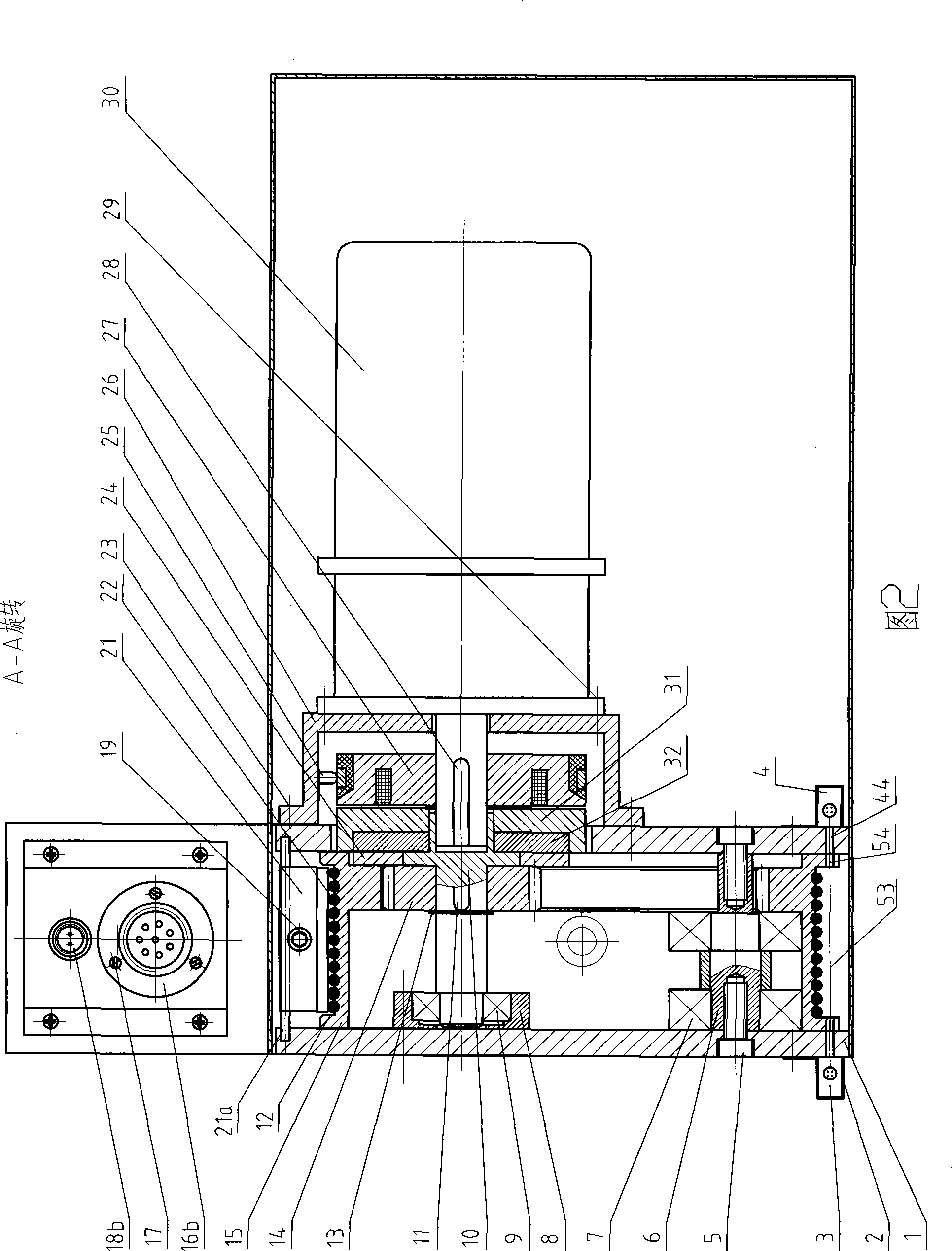

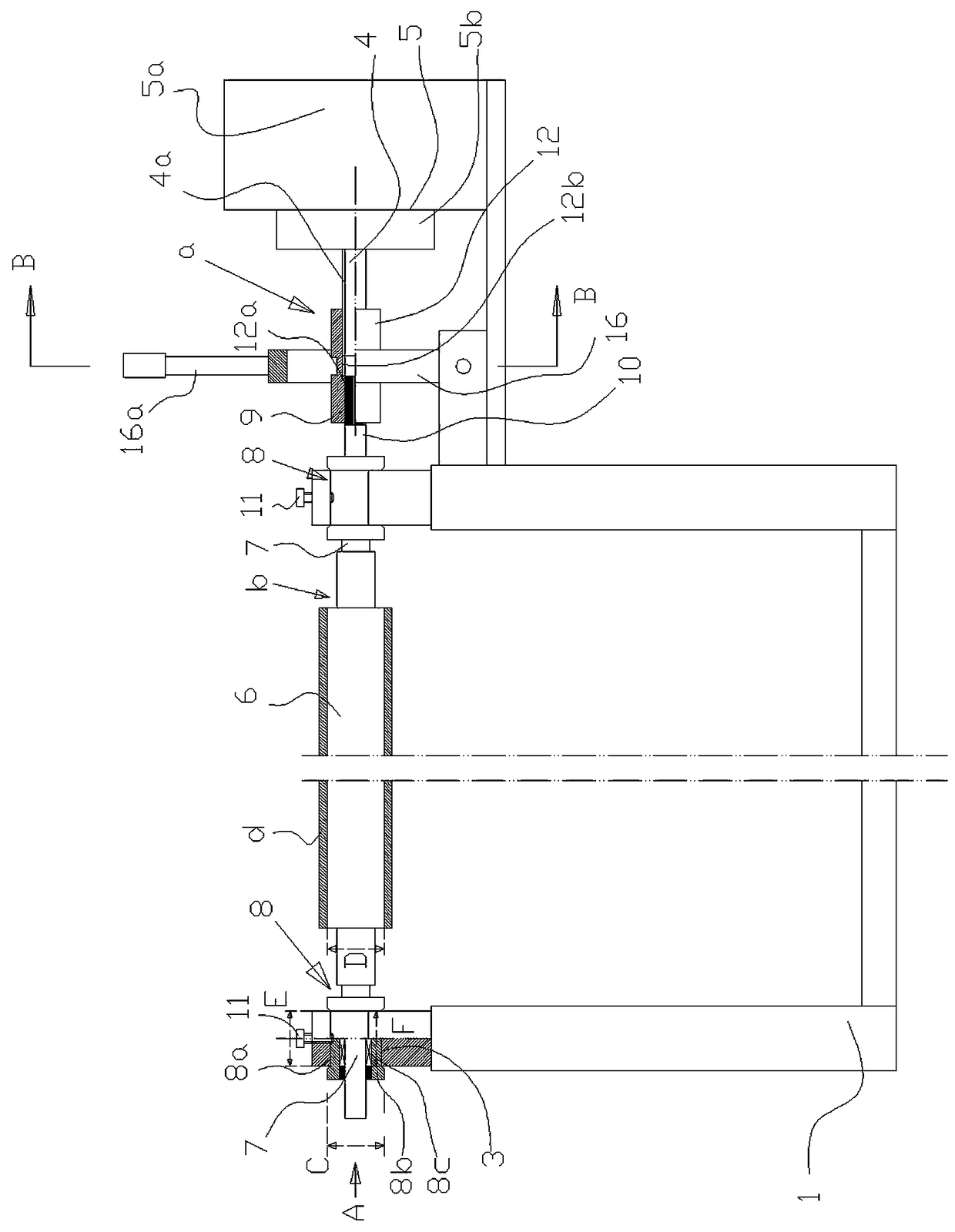

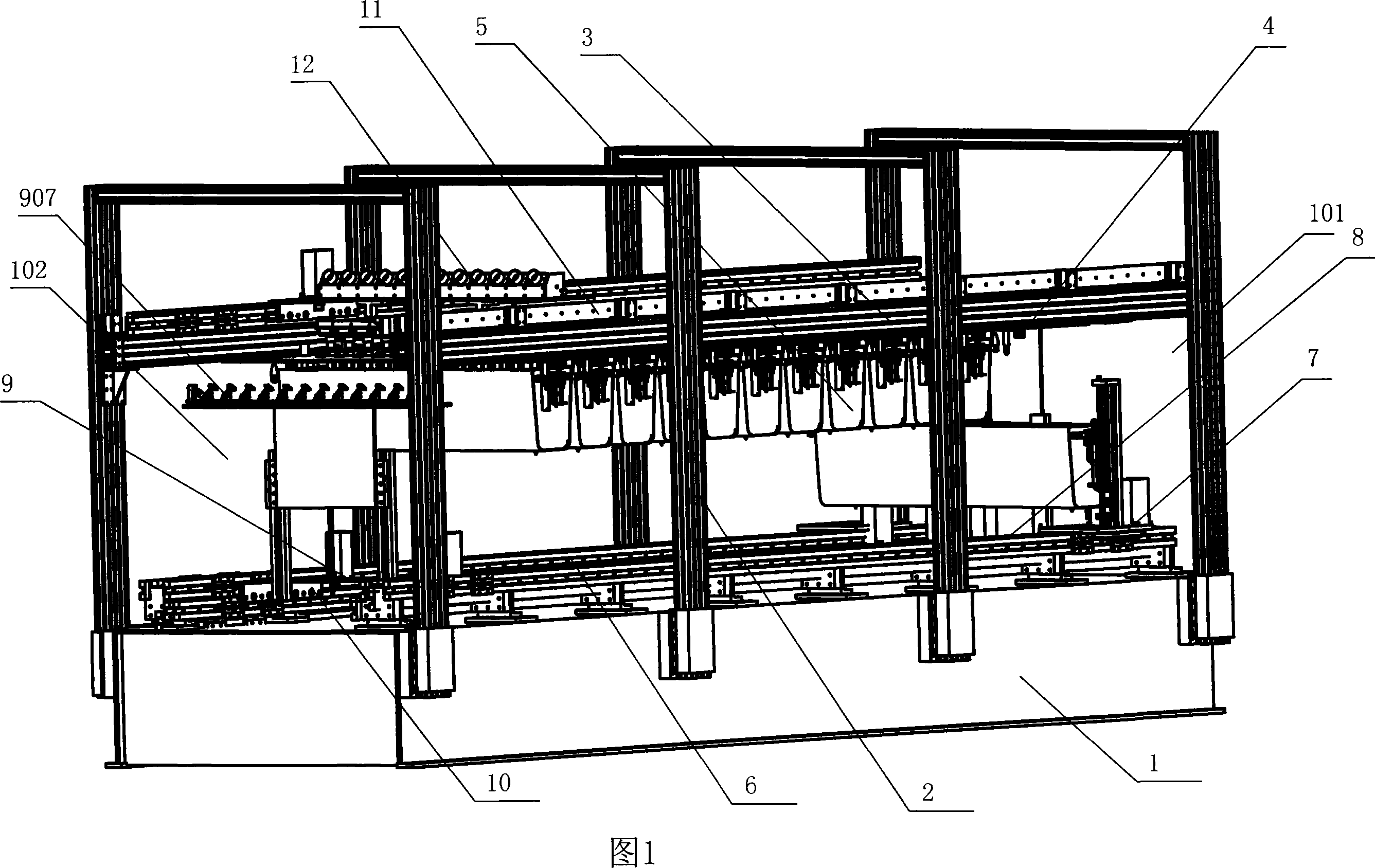

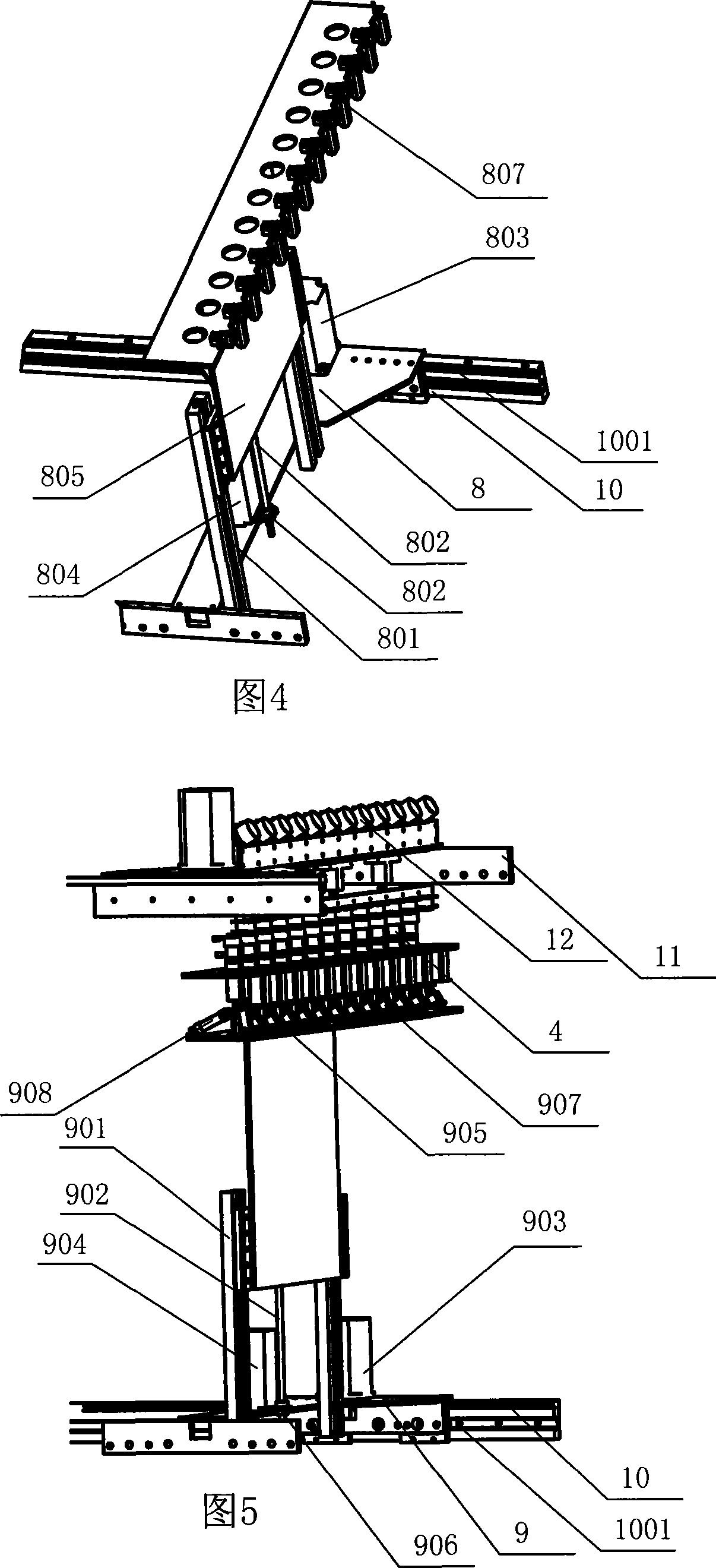

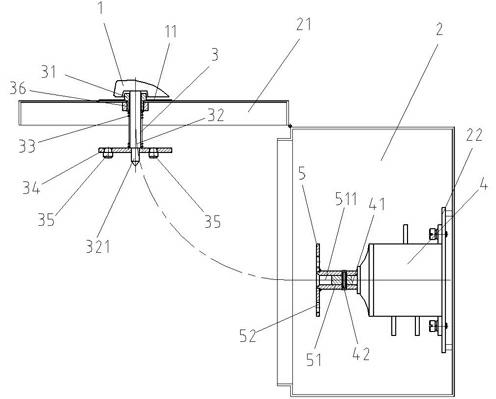

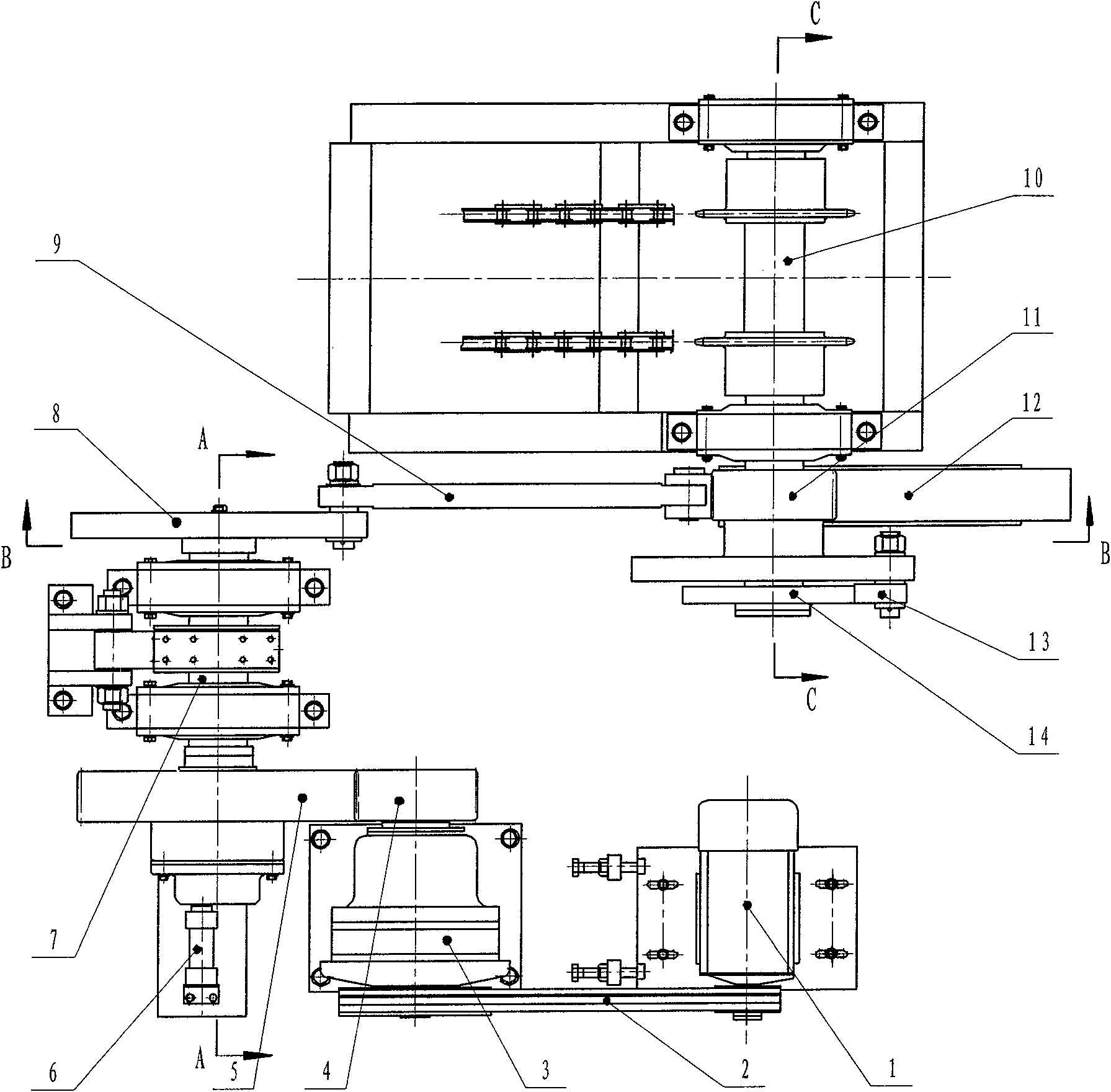

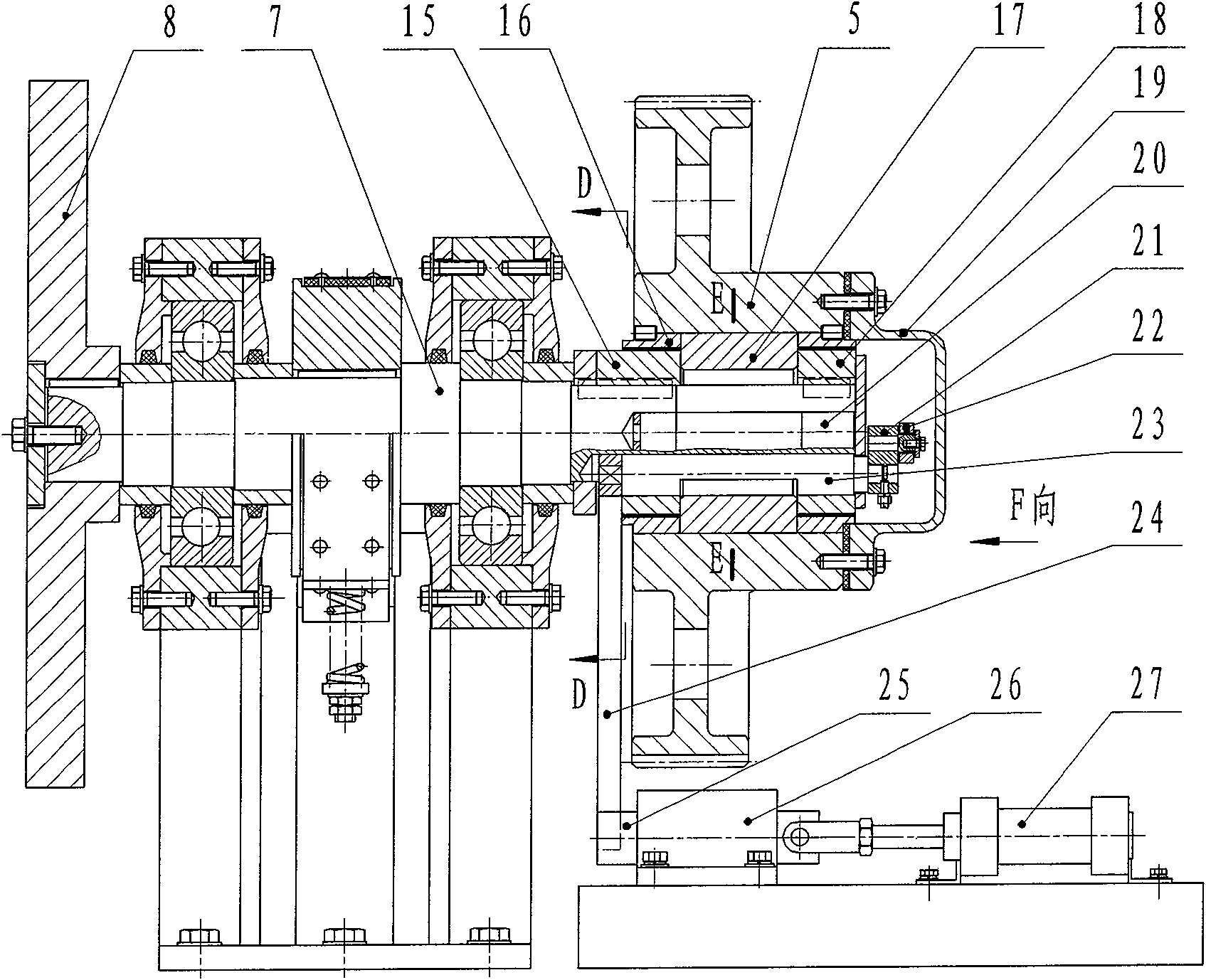

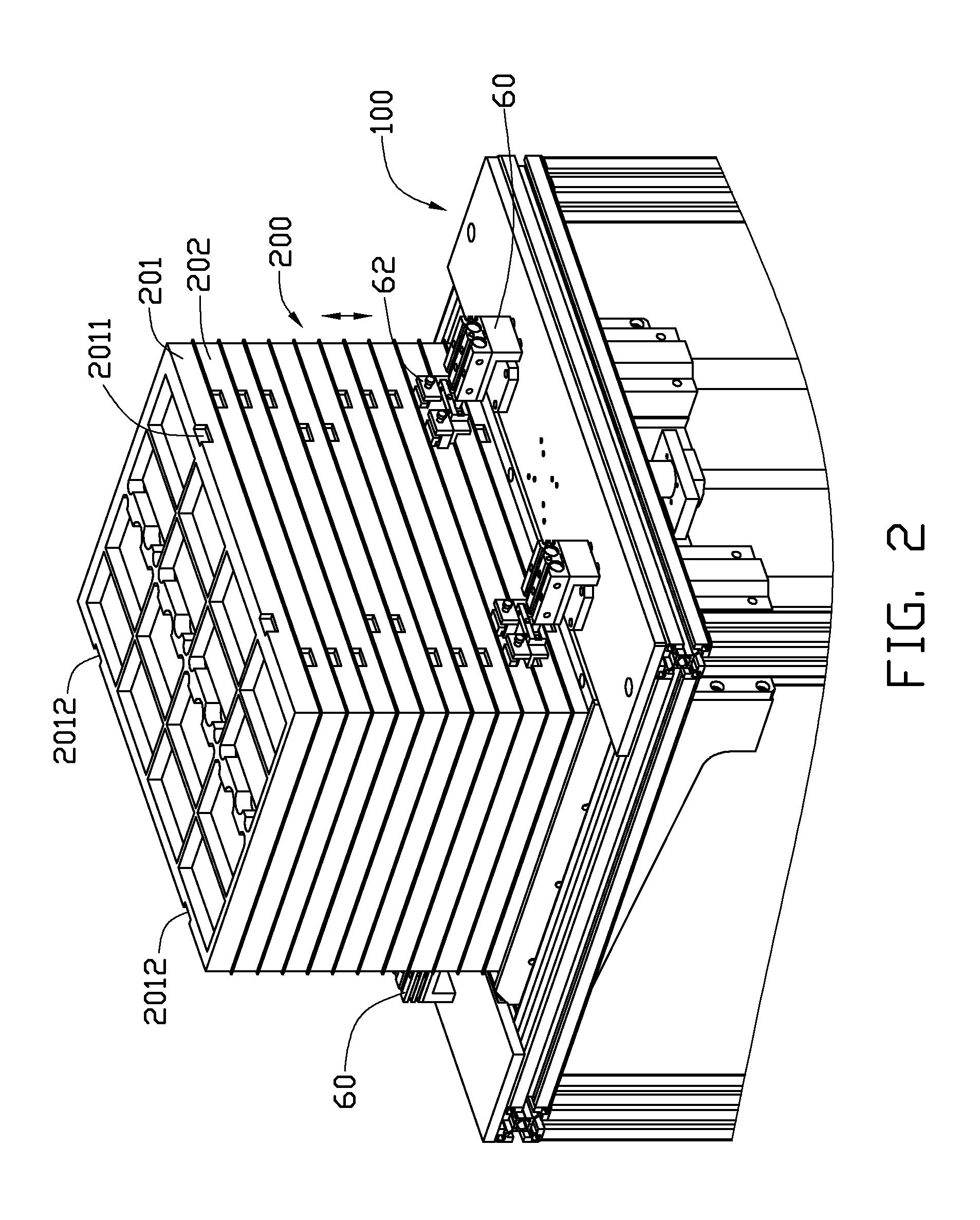

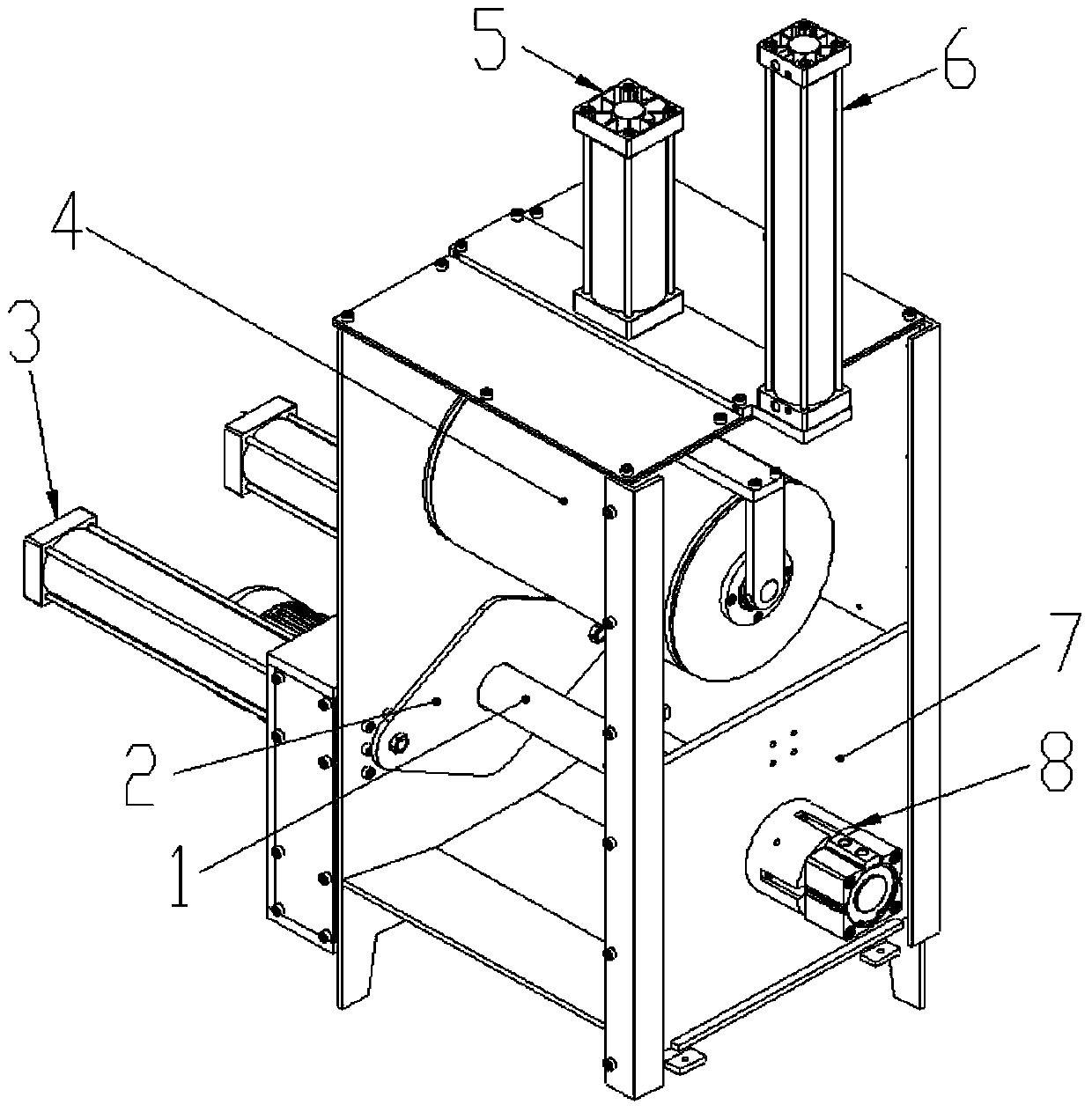

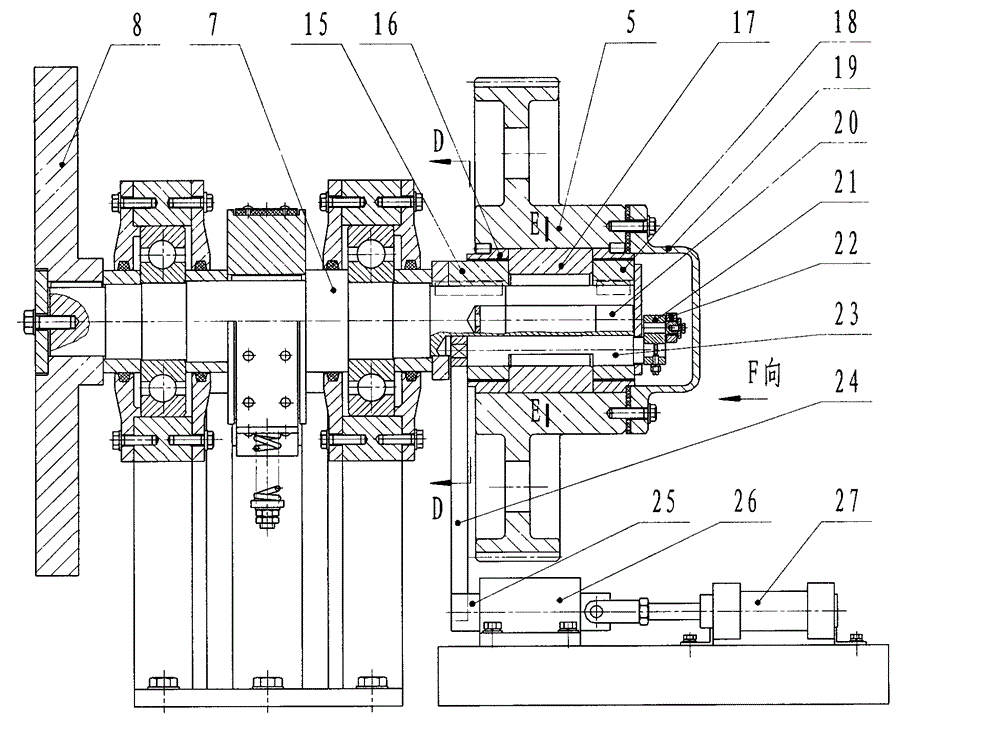

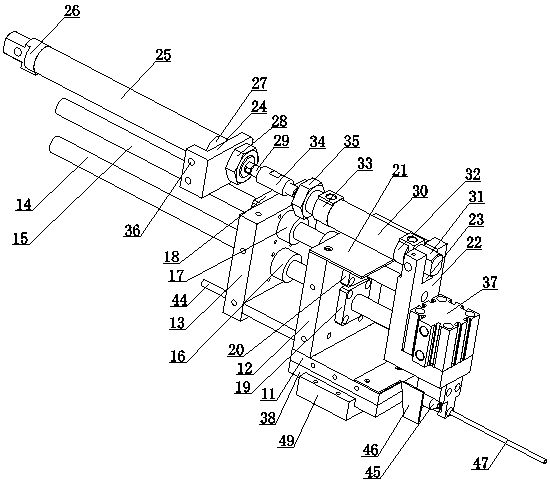

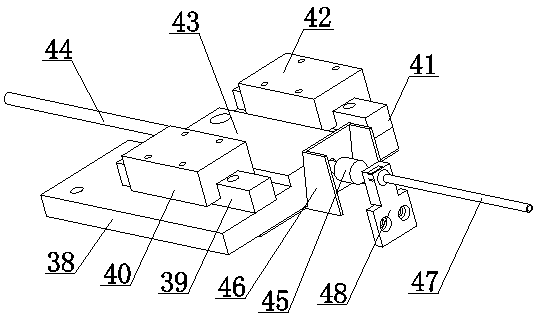

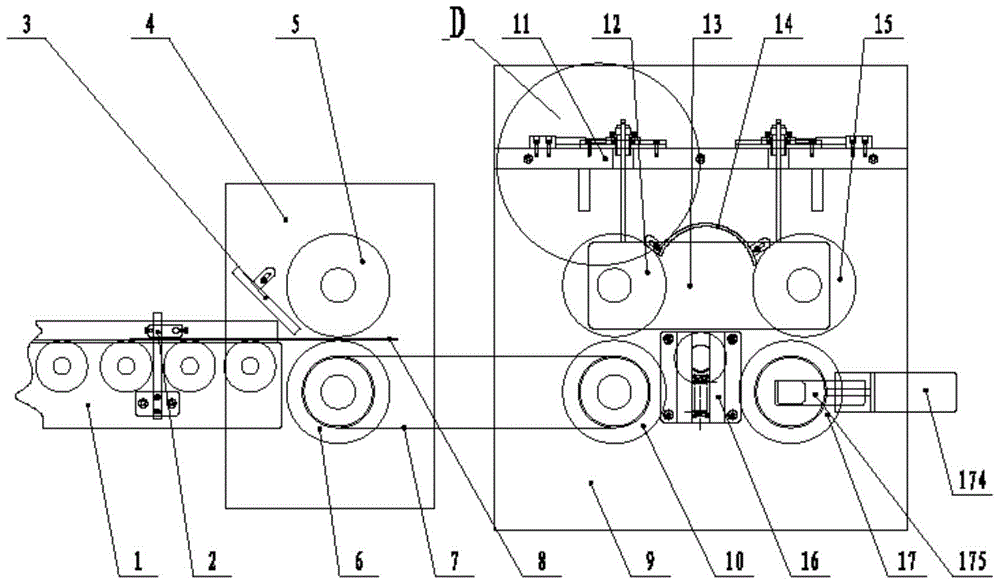

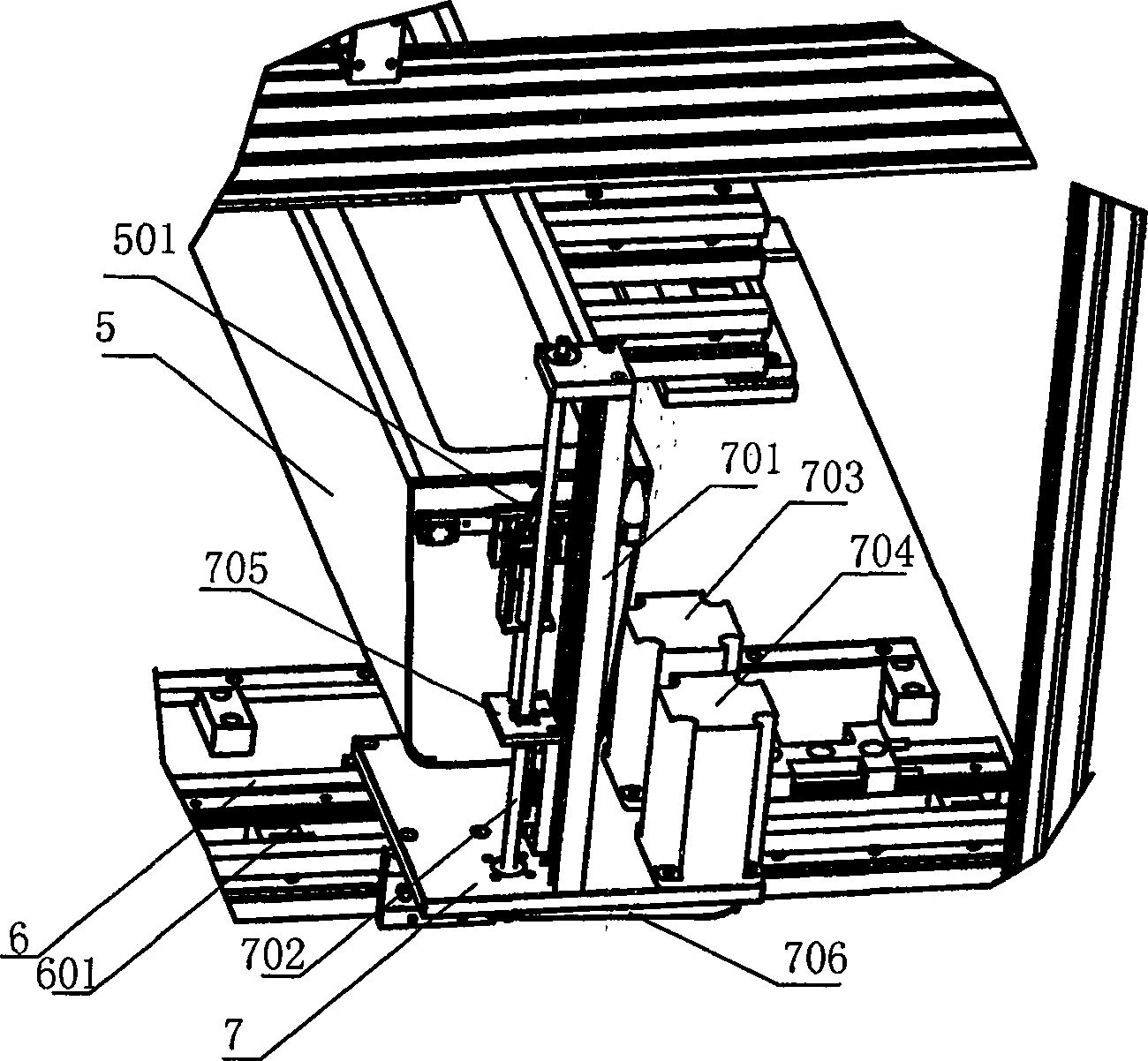

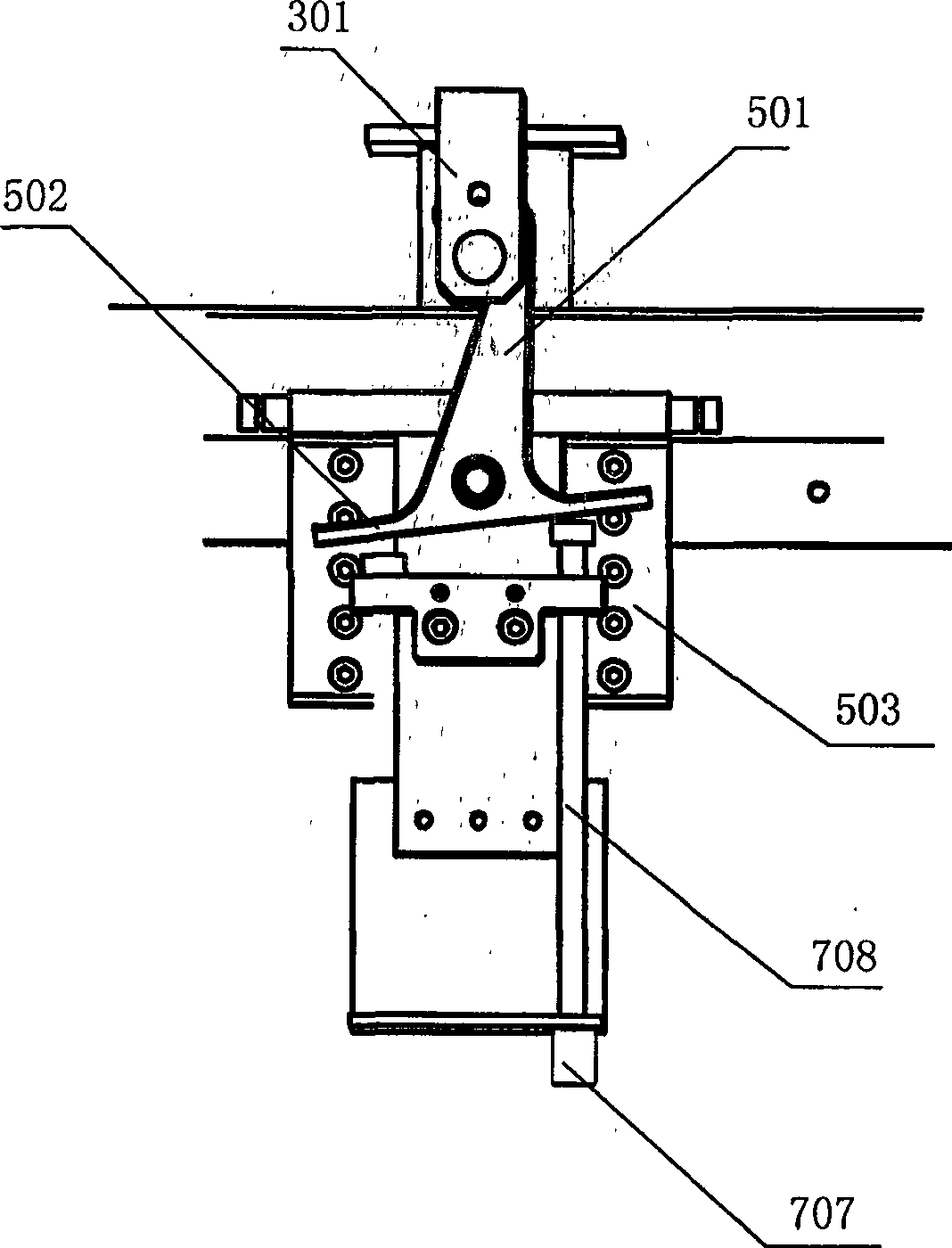

Workpiece step conveying driving system

InactiveCN101665186AReliable clutchEasy clutchConveyorsFluid actuated clutchesThree levelProduction line

The invention relates to a workpiece step conveying driving system which can realize a step conveying function, which is applied to the field of workpiece step conveying production in a large automatic production line, can overcome and make up the defects of a prior conveying technology on the multistation, long distance and heavy load conveying capacity, sufficiently ensure the requirements on step precision as well as reliability and stability of running and flexibly control the step working rhythm on site. The system comprises a power-driving part, double rotor clutch devices and a driven part, wherein the power-driving part takes a motor as a power source and can meet the requirements on step rhythm and production efficiency through three-level speed reduction; the driven part can achieve the step driving function, stop accumulated errors and ensure the step precision and the running stability through the function combination of a slider-crank mechanism, a rack and spur gear mechanism and a ratchet-and-pawl mechanism; and the rotor clutch devices realize rigid joint and separation of the driving part and the driven part of the system through double rotors and ensure the requirements on reliable use and precision.

Owner:CHANGCHUN EQUIP TECH RES INST

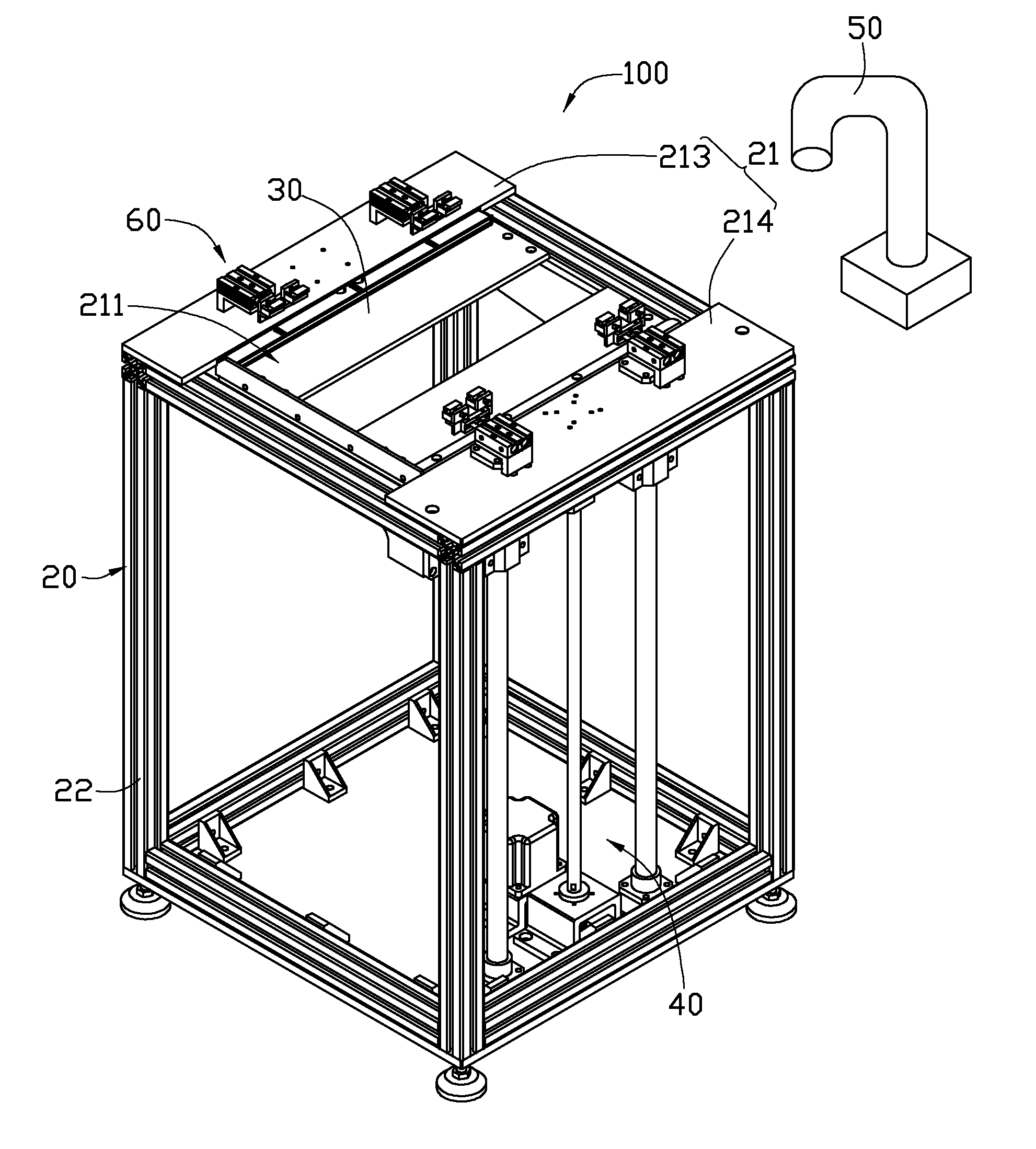

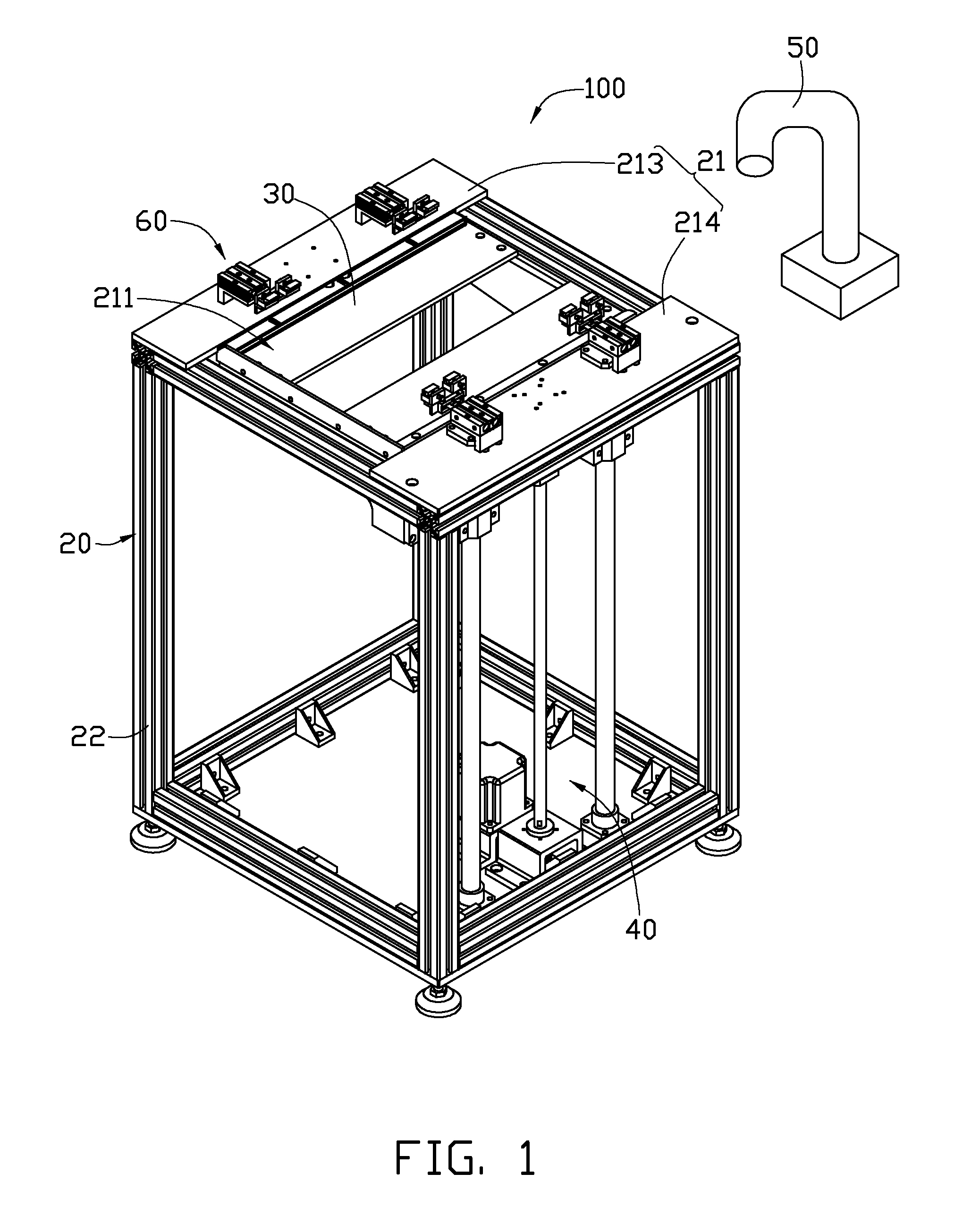

Component feeding device

InactiveUS8534985B2Easy clutchStacking articlesDe-stacking articlesEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

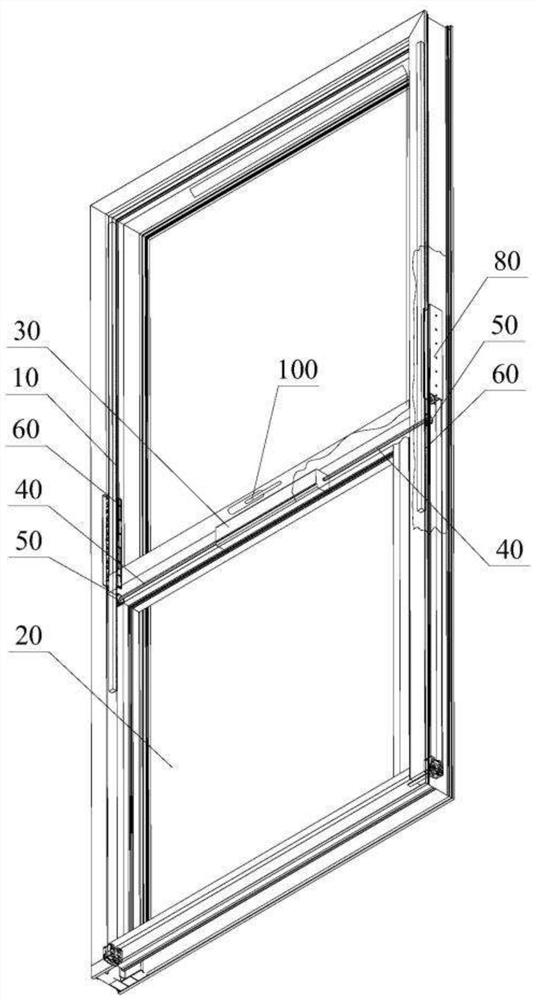

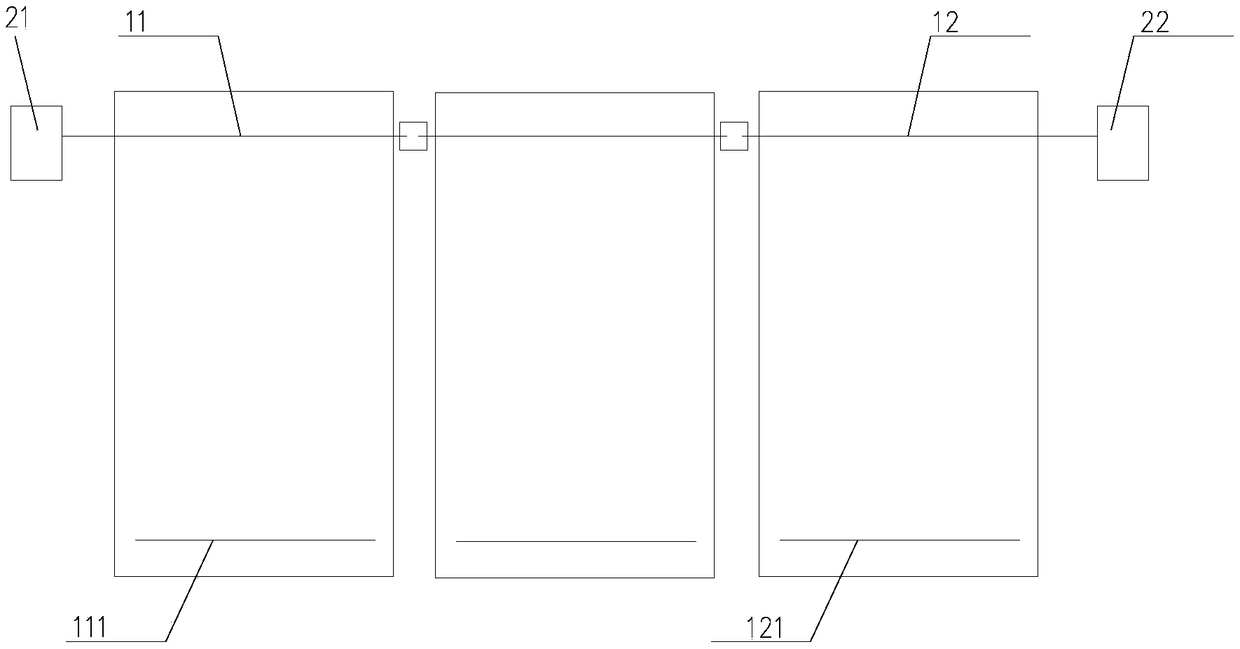

Electric lifting door and window

ActiveCN113944403ARealize free liftingSmooth motionMan-operated mechanismWindows/door improvementSash windowElectric machine

The invention relates to the technical field of doors and windows, and particularly relates to an electric lifting door and window. The electric lifting door and window comprises a window frame / door frame and a movable window sash capable of sliding up and down along the window frame / door frame. A driving device is provided with a transmission shaft driven by a lifting motor. The transmission shaft is horizontally arranged, and the two ends of the transmission shaft extend out of the two opposite side faces of the movable window sash correspondingly and are each fixedly provided with a gear. Racks are fixedly arranged on the left inner side wall and the right inner side wall of the window frame / door frame correspondingly. The gears are engaged with the racks. Along with rotation of the lifting motor, under the interaction of the gears and the racks, the movable window sash is driven to slide up and down along a sliding rail on the inner side face of the window frame / door frame, and accordingly the movable window sash is opened or closed. According to the electric lifting door and window, the transmission shaft is driven by the lifting motor to extend out in two directions, the movable window sash is driven to slide up and down in cooperation with the gears and the racks, movement is stable, friction force is small, simpleness and high efficiency are achieved, movement is flexible, the clamping stagnation delay phenomenon is avoided, the occupied space is small, and cost is saved.

Owner:GUANGZHOU HAODI DOOR & WINDOW

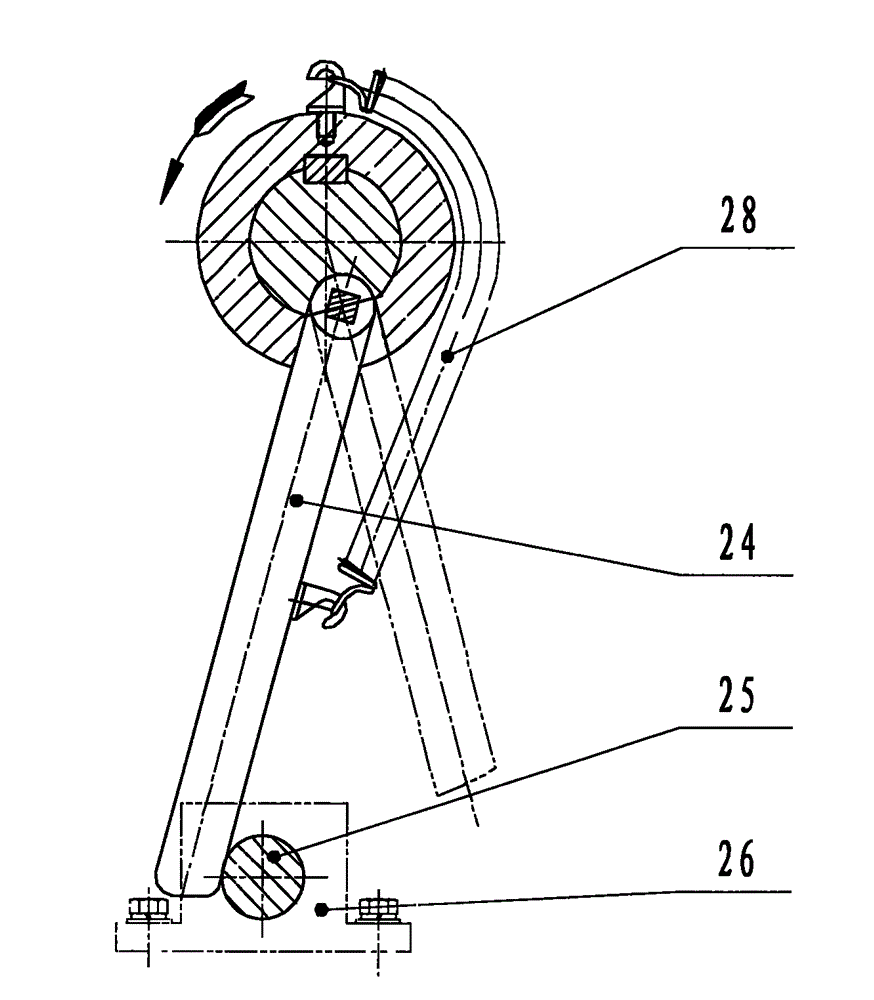

Automatic curling machine

ActiveCN103723571ASmall footprintImprove cleanlinessFilament handlingArticle deliveryMetallic materialsEngineering

The invention discloses an automatic curling machine capable of automatically collecting filamentous scraps produced in the process of turning flexible metal materials, efficiently without consuming excess manpower. The automatic curling machine comprises a curling shaft, a push plate, push cylinders, a press roller, a press roller control cylinder, a discharge door control cylinder, a discharge door, a centering device, a reducer motor, a feed cover, and a box. The curling shaft is rotated to wind the filamentous scraps onto the curling shaft so that curling is achieved. The reducer motor powers the curling shaft. The push plate is used for pushing out the curled filamentous scraps from the curling shaft. The push cylinders power the push plate. The press roller is used for compressing the filamentous scraps on the curling shaft during the curling process, and the size of the filamentous scraps is decreased. The press wheel control cylinder is used for adjusting pressure of the press roller. The centering device is used for balancing stress of the curling shaft so as to guarantee that the curling shaft operates reliably. The feed cover is used for guiding the filamentous scraps to smoothly enter the box.

Owner:COCABA COOKWARE MFR

Workpiece step conveying driving system

InactiveCN101665186BReliable clutchEasy clutchConveyorsFluid actuated clutchesThree levelProduction line

Owner:CHANGCHUN EQUIP TECH RES INST

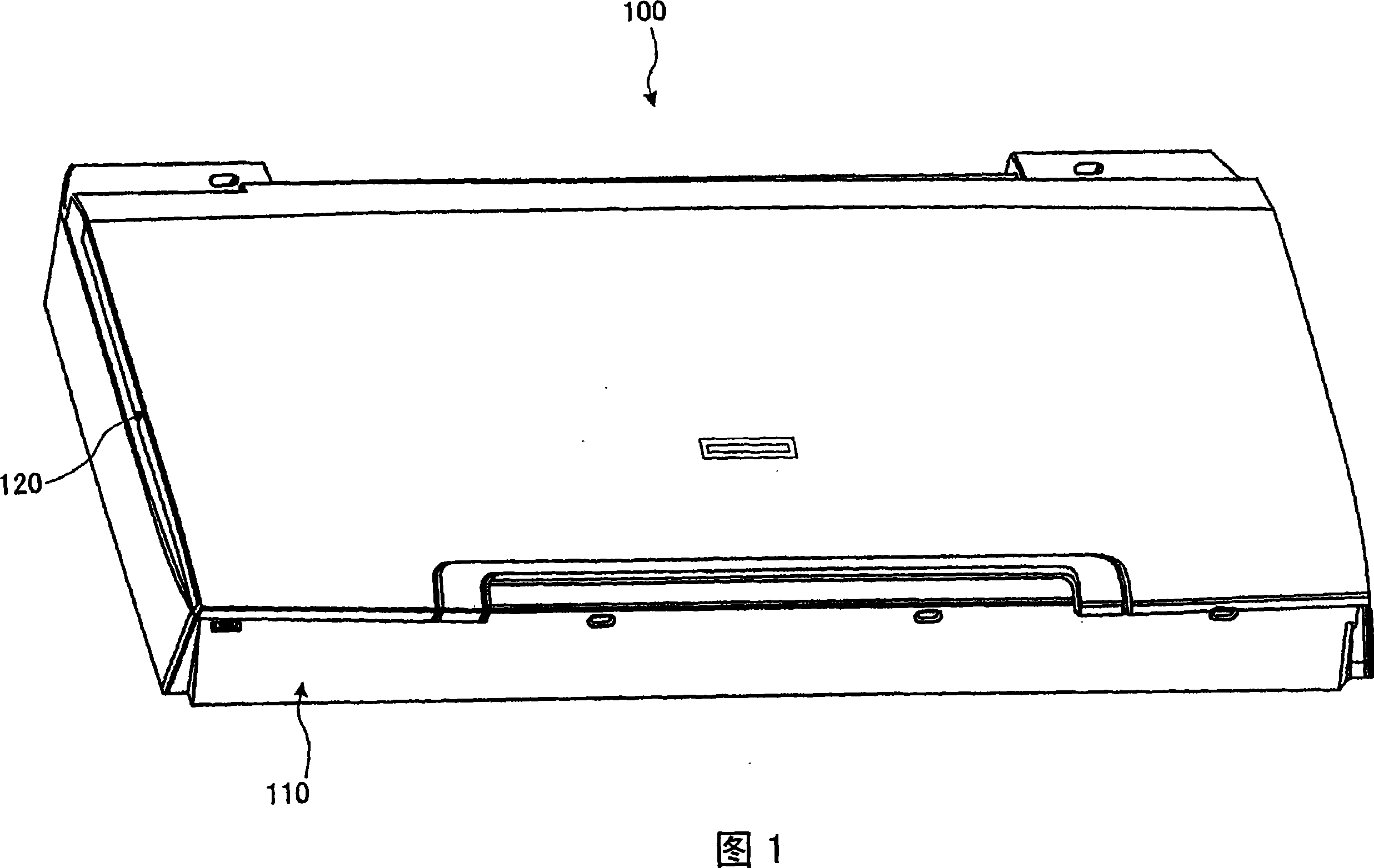

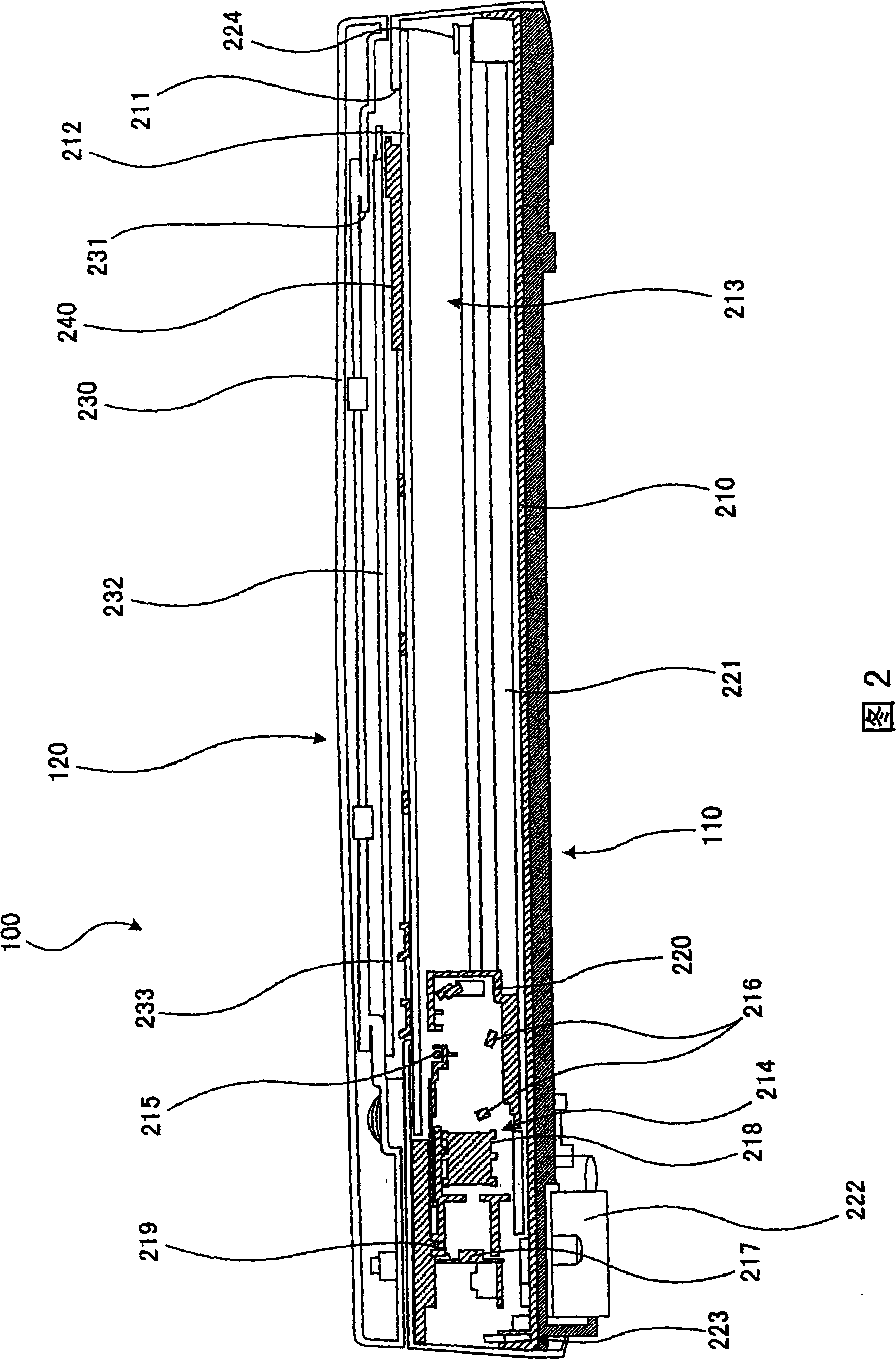

Image reading apparatus and multi-function machine

InactiveCN101052087BEasy clutchReduce the burden onPictoral communicationMedicineComputer graphics (images)

An image reading apparatus has a light source and an image capturing device disposed to face each other with a document table interposed therebetween. The image reading apparatus includes: an image capturing device moving mechanism, operable to perform a moving operation for moving the image capturing device in a scanning direction; and a light source moving mechanism, operable to move the light source in the first direction with the movement operation performed by the image capturing device moving mechanism.

Owner:SEIKO EPSON CORP

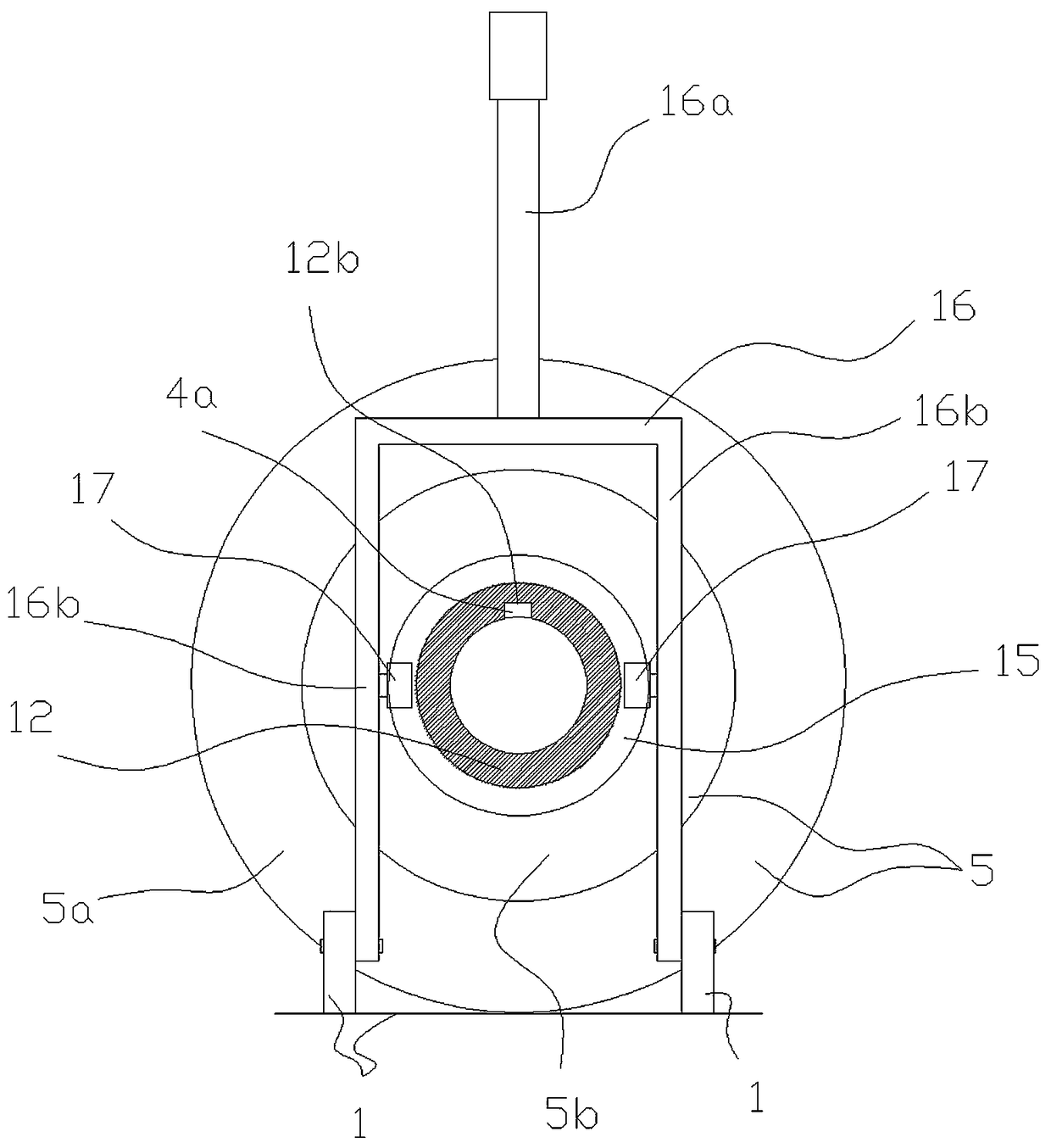

Separation and reunion automatic control mechanism of spring machine clutch

The invention relates to the field of spring machines, in particular to a separation and reunion automatic control mechanism of a spring machine clutch. The mechanism comprises a box body, a lever, an L-shaped shifting fork, a movable semi clutch, a fixed semi clutch, a clutch shaft and a compression spring. The movable semi clutch and the fixed semi clutch are arranged on the clutch shaft, and the compression spring is further arranged between the box body and the movable semi clutch. The shifting fork is arranged on the box body, the shifting fork is arranged on the box body, the end portion of the shifting fork in the box body is connected with the lever in intersection mode and located above the lever, and the end portion of the shifting fork outside the box body is connected with the movable semi clutch in sleeve mode. Users can lift the lever to enable the shifting fork to deviate the movable semi clutch from the fixed semi clutch. By means of the scheme, the shifting fork enables the movable semi clutch to deviate from the fixed semi clutch, and the compression spring enables the movable semi clutch to be restored, and high-performance separation and reunion can be achieved.

Owner:SHAOXING JIADU SPRING MACHINE

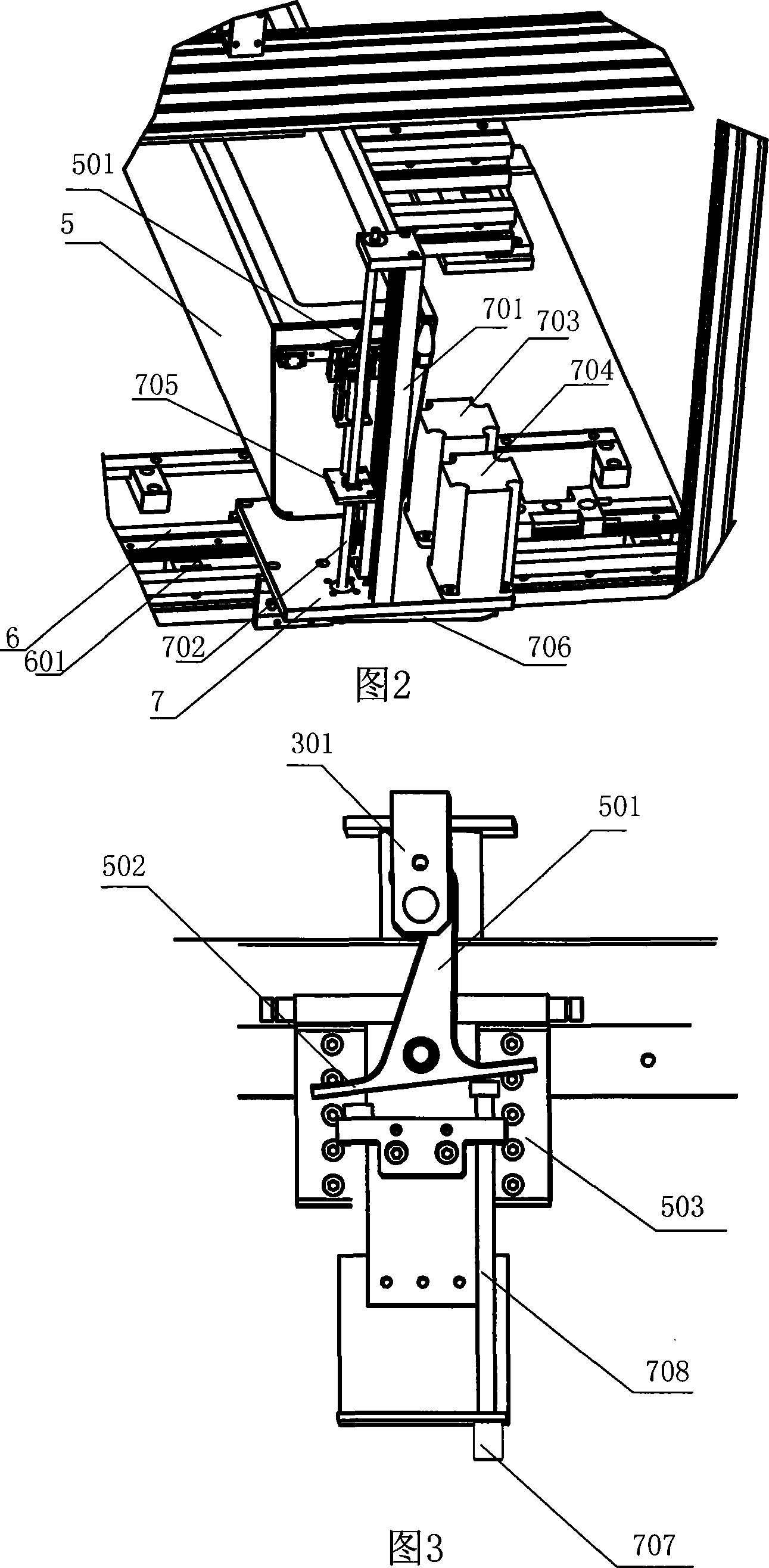

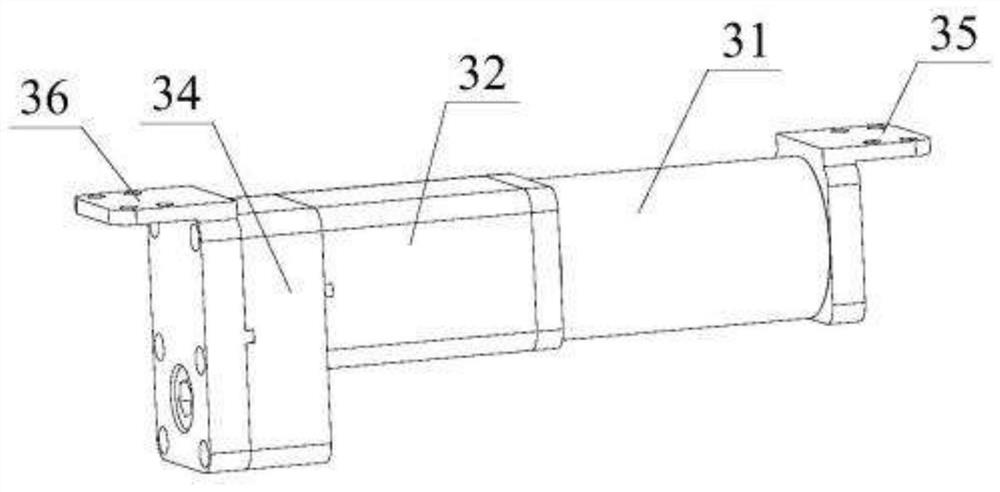

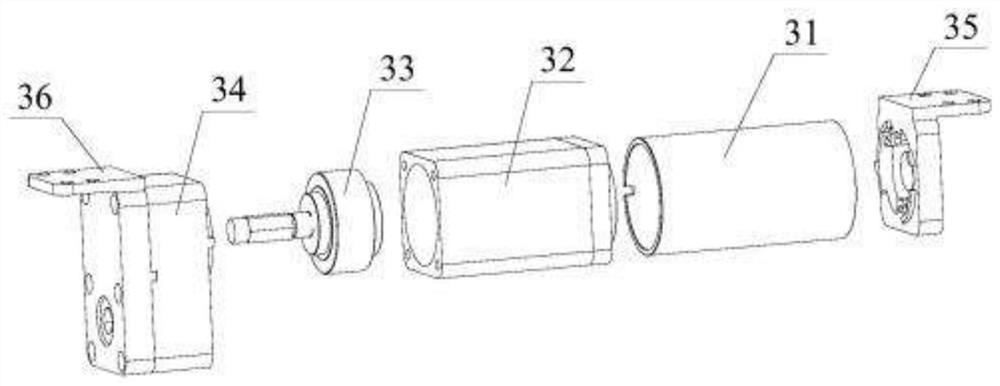

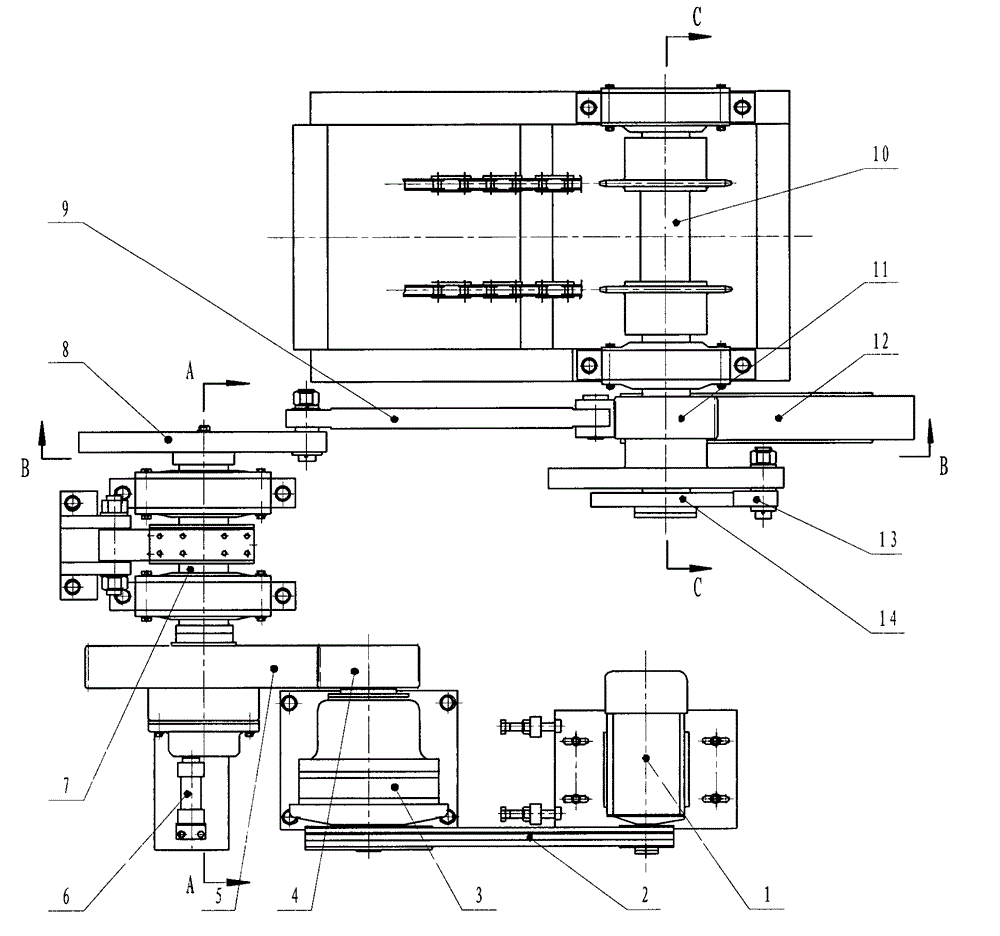

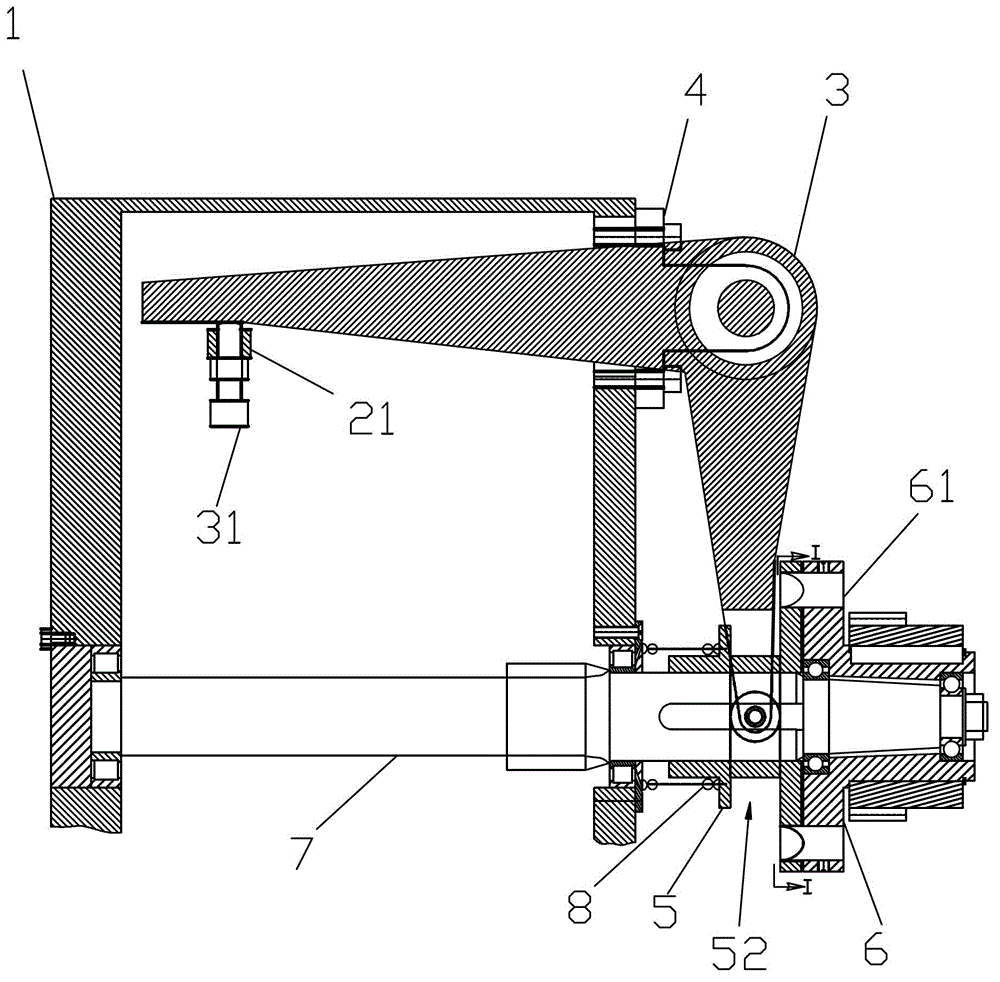

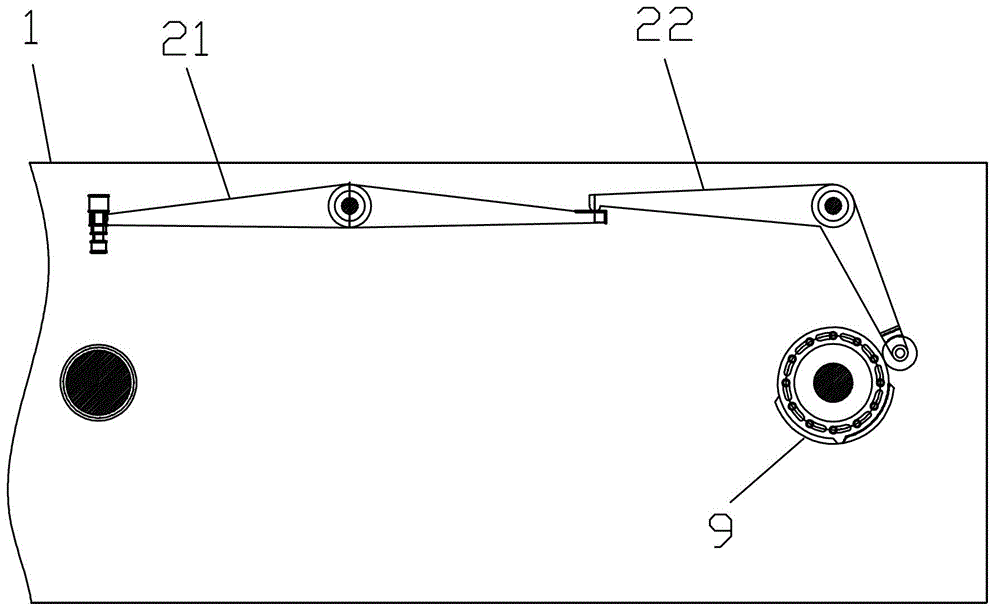

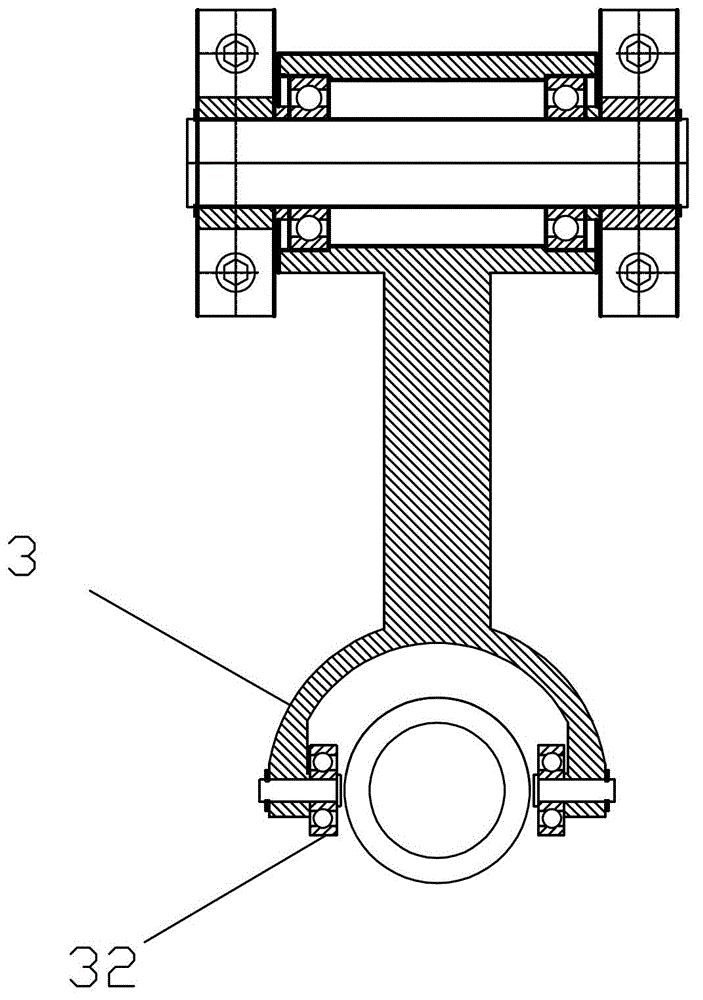

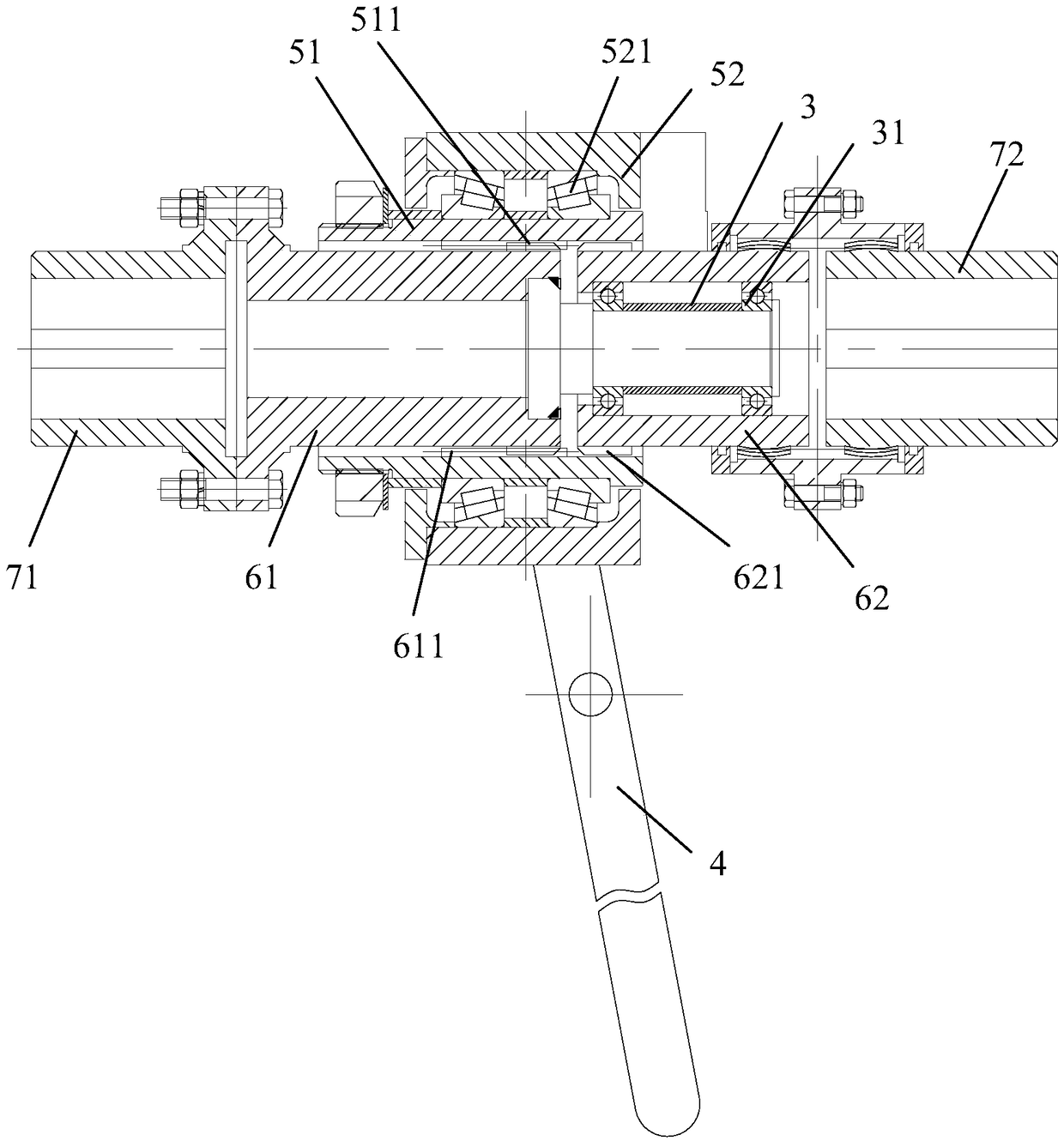

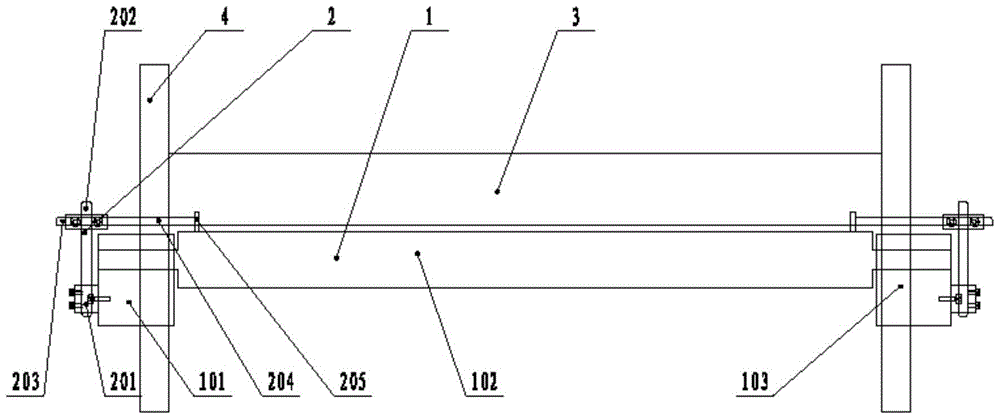

A mechanical clutch device for a drive shaft

ActiveCN106641200BGreat power driveGuaranteed coaxialityInterengaging clutchesGearing detailsCouplingDrive shaft

The invention discloses a mechanical type separation-and-union device for transmission shafts. The separation-and-union device is arranged between the transmission shafts of adjacent transmission platforms and comprises a first gear sleeve half (61), a second gear sleeve half (62) and a separation-and-union assembly. The first gear sleeve half (61) is connected with the first transmission shaft on the transmission platform arranged at one side through a coupling half (71), and the first transmission shaft drives the first gear sleeve half (61) to rotate. The second gear sleeve half (62) is arranged beside the first gear sleeve half (61) and connected with the second transmission shaft on the second transmission platform arranged at the other side through a crown-gear coupling (72), and the second transmission shaft drives the second gear sleeve half (62) to rotate. The separation-and-union assembly is arranged outside the first gear sleeve half (61) and the second gear sleeve half (62) and controlled to be connected with and separated from the first gear sleeve half (61) and the second gear sleeve half (62) so that the transmission platforms arranged at the two sides can be driven by the first transmission shaft and the second transmission shaft to perform synchronous movement or separate movement. According to the mechanical type separation-and-union device, the transmission shafts on the transmission platforms are connected or separated, and the effect that multiple transmission platforms are driven can be achieved.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

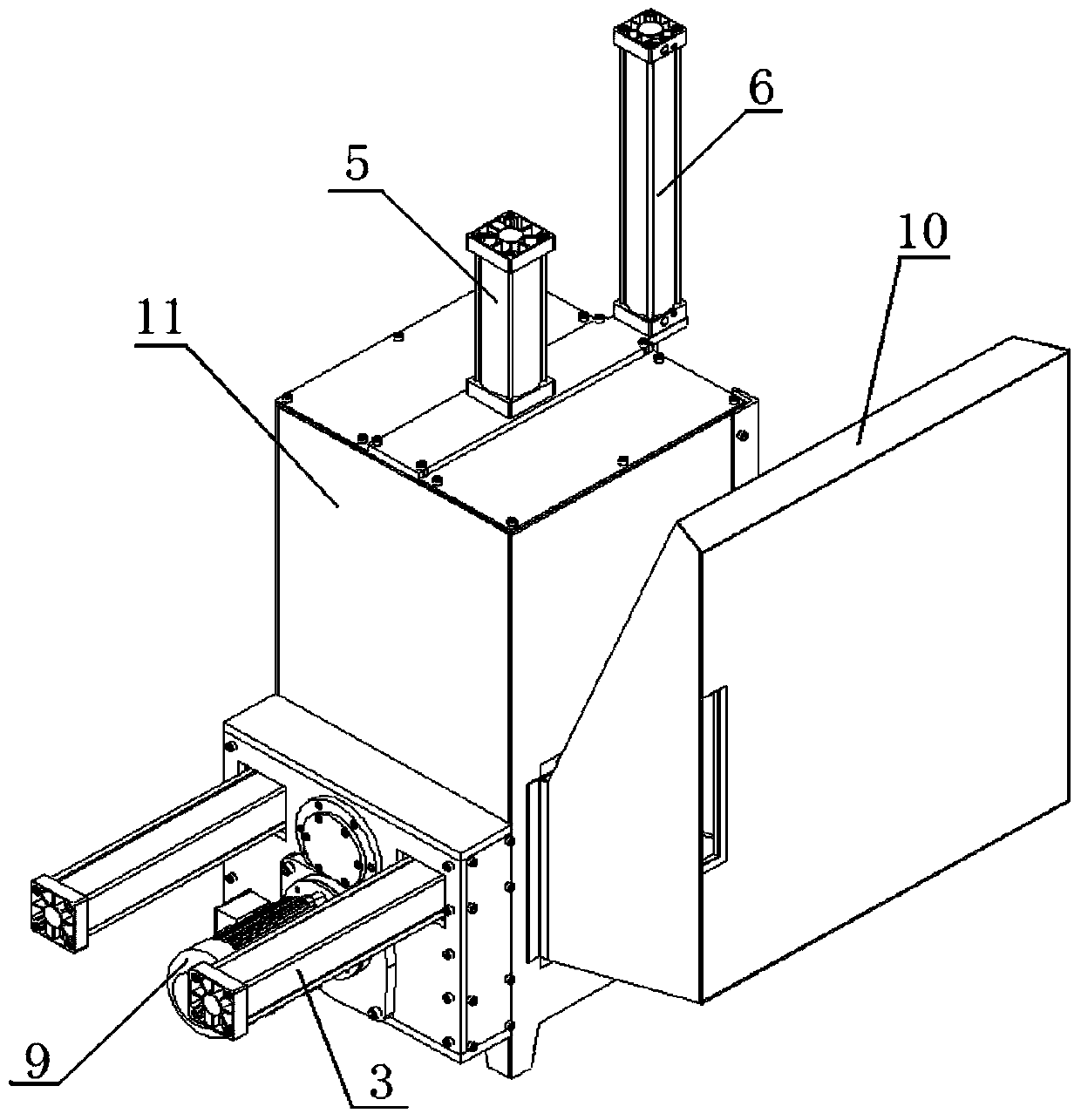

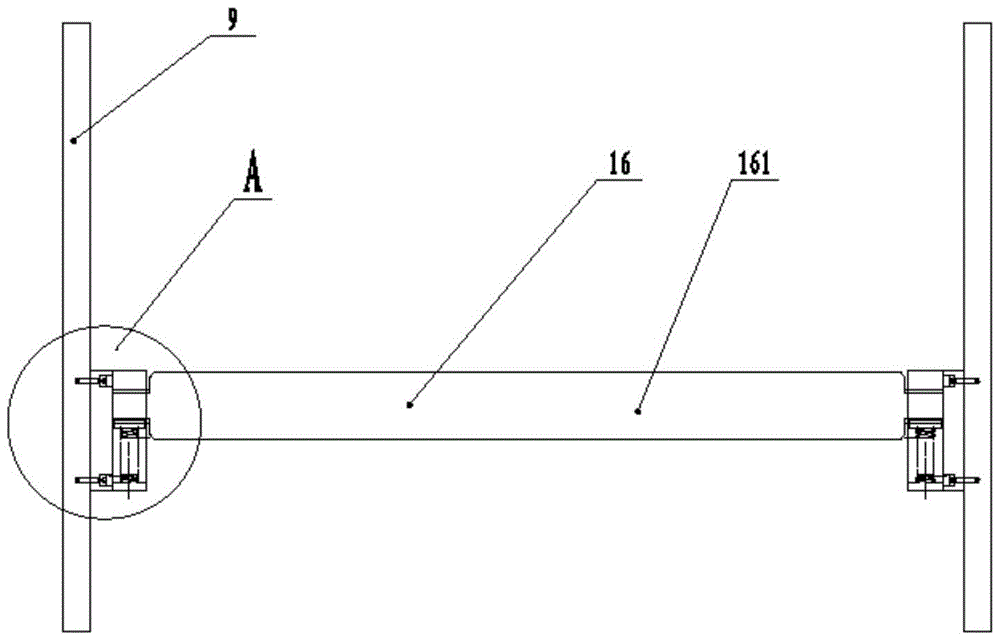

Clutch self-control traction device for pre-coating type film laminating machine

InactiveCN107618128AEasy clutchConvenience Traction ControlOther domestic articlesHydraulic cylinderEngineering

The invention discloses a clutch self-control traction device for a pre-coating type film laminating machine. The clutch self-control traction device comprises a sliding adjusting base, a side base isarranged on the sliding adjusting base, a side plate is arranged behind the side base, movement shafts are inserted into side portions of the side base and the side plate, a movement base is arrangedat the front end of each movement shaft, a fixed block is arranged at the top of the side plate, a hydraulic cylinder is arranged at the back of the fixed block, a piston rod is arranged at the frontof the hydraulic cylinder, a movement barrel is arranged at the end of the piston rod, and a clamped connection column is arranged at the front end of the movement barrel and is clamped into a positioning groove; each movement base is provided with a fixed shell, a traction mechanism is arranged at the front portion of the sliding adjusting base and comprises a positioning base, and a protrudingbase is arranged on the movement base; and a pneumatic pipe is inserted into the protruding base, and a traction roller is arranged at the front end of the pneumatic pipe. According to the clutch self-control traction device, the traction roller can conveniently conduct traction control over a thin film conveyed through the pre-coating type film laminating machine, clutch operation is convenient,and thin film traction operation efficiency is high.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

Worm member for rotary working table

InactiveCN103240611AEasy clutch adjustmentFixed firmlyLarge fixed membersMechanical engineeringEngineering

The invention discloses a worm member used for a rotary working table. The worm member comprises a worm, a worm sleeve, a worm sleeve fixing seat, a hand wheel, a handle, a separation and reunion disc poking rod and a separation and reunion disc. The worm sleeve is arranged outside the worm and fixed in the worm sleeve fixing seat. The hand wheel is fixed on the worm, the handle is connected onto the hand wheel, the separation and reunion disc poking rod is arranged on the separation and reunion disc used for controlling the worm. The separation and reunion adjustment of the worm and a worm wheel is convenient. The worm member can prevent the effect on an axial gap of the worm and the worm sleeve caused by displacement of a worm locking nut and the worm sleeve due to friction between the worm locking nut and the worm sleeve in rotating of the worm. A worm sleeve locking rod has the effect of locking the worm sleeve and enables the worm and the worm sleeve to be firmly fixed.

Owner:GAOYOU LIBO MACHINE TOOL ACCESSORIES FACTORY

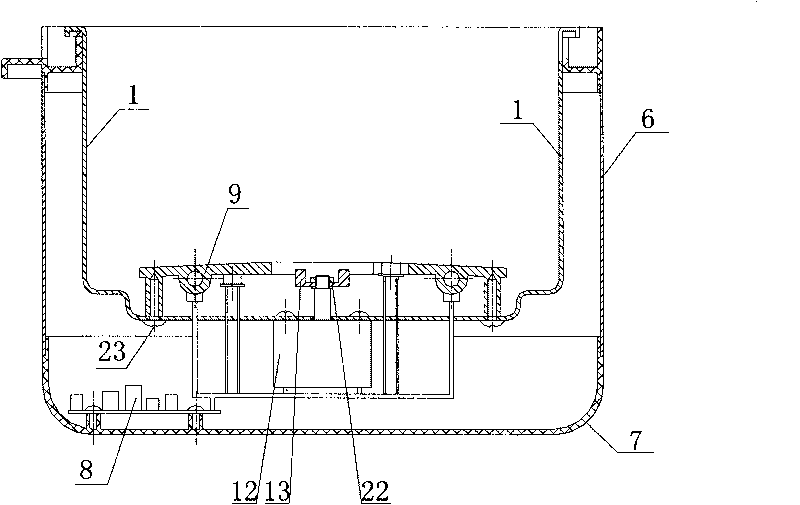

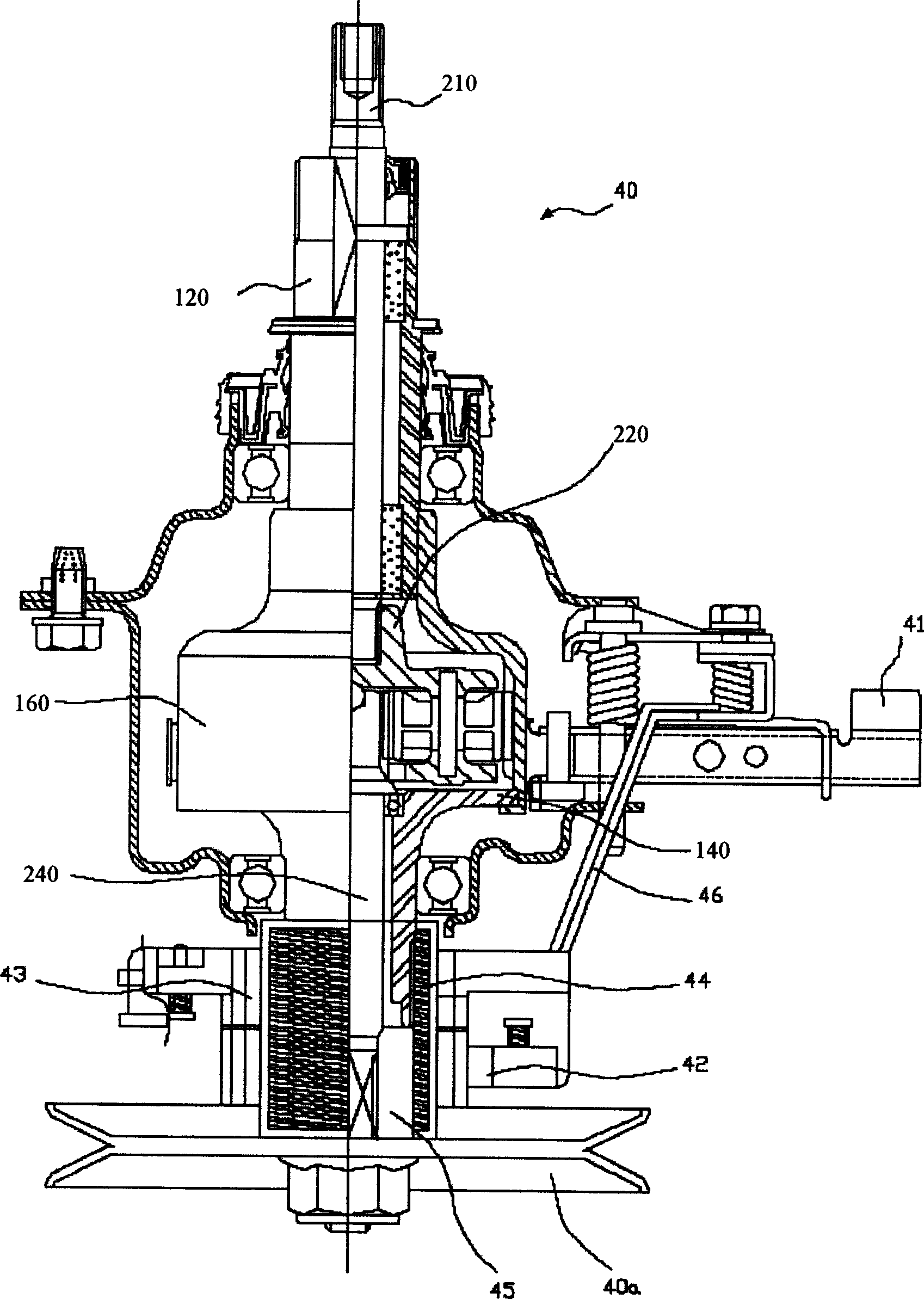

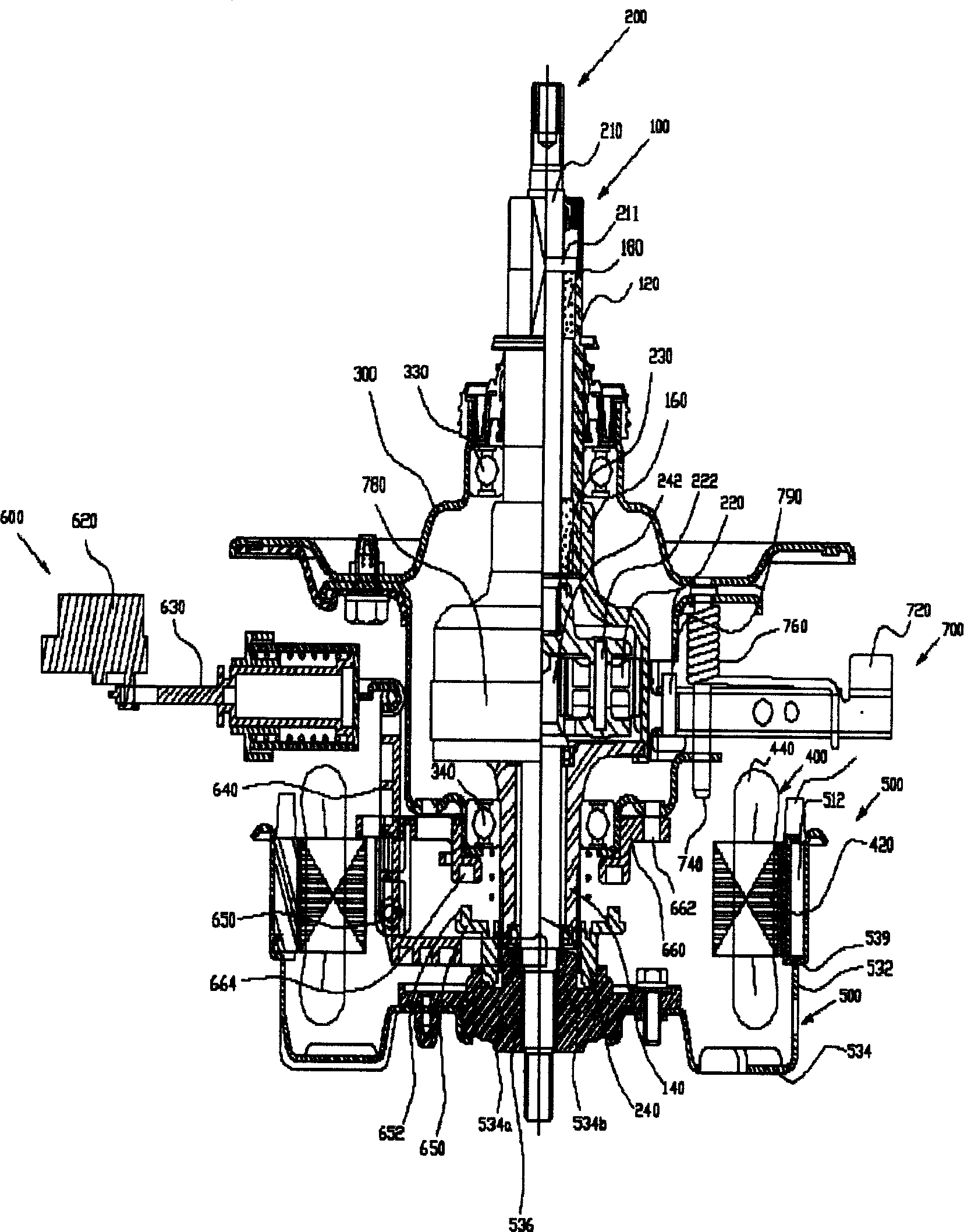

Driving device of full-automatic washing machine

InactiveCN1566488AIncrease output powerEasy transferMagnetic circuit rotating partsOther washing machinesEngineeringClutch

The invention discloses a driving device for a full-automatic washing machine, which comprises an outer barrel, a washing barrel, a washing wheel, a dewatering axis 100, a washing axis 200, a clutch housing 300, a clutch assembly 600, a stator assembly 400, a rotor 510 and a rotor frame 530. The stator assembly 400 consists of an iron core 420 and a coil 440, a combining protrusion 462 is formed above the upper mounting protrusion structure 464a, the combining protrusion is combined with the protrusion hole 662 of the clutch assembly 600. Another two driving device is also provided, one of which includes a stator assembly 400, a rotor 510 and a rotor frame 530, the stator assembly 400 comprises a iron core 420, a coil 440, an insulator 460a, 460b, 460c and upper mounting protrusion structure 464a, the upper mounting protrusion structure 464a combines with the assembling hole 424 of the iron core 420, a combining protrusion 462 is formed above the upper mounting protrusion structure 464a, and the combining protrusion 462 combines with the protrusion hole 662 of the clutch assembly 600. In the other driving device, the outer barrel is horizontally arranged in the cylinder washing machine housing.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Operating clutch device of power distribution cabinet combined switch

Owner:镇江四洋柴油机制造有限公司

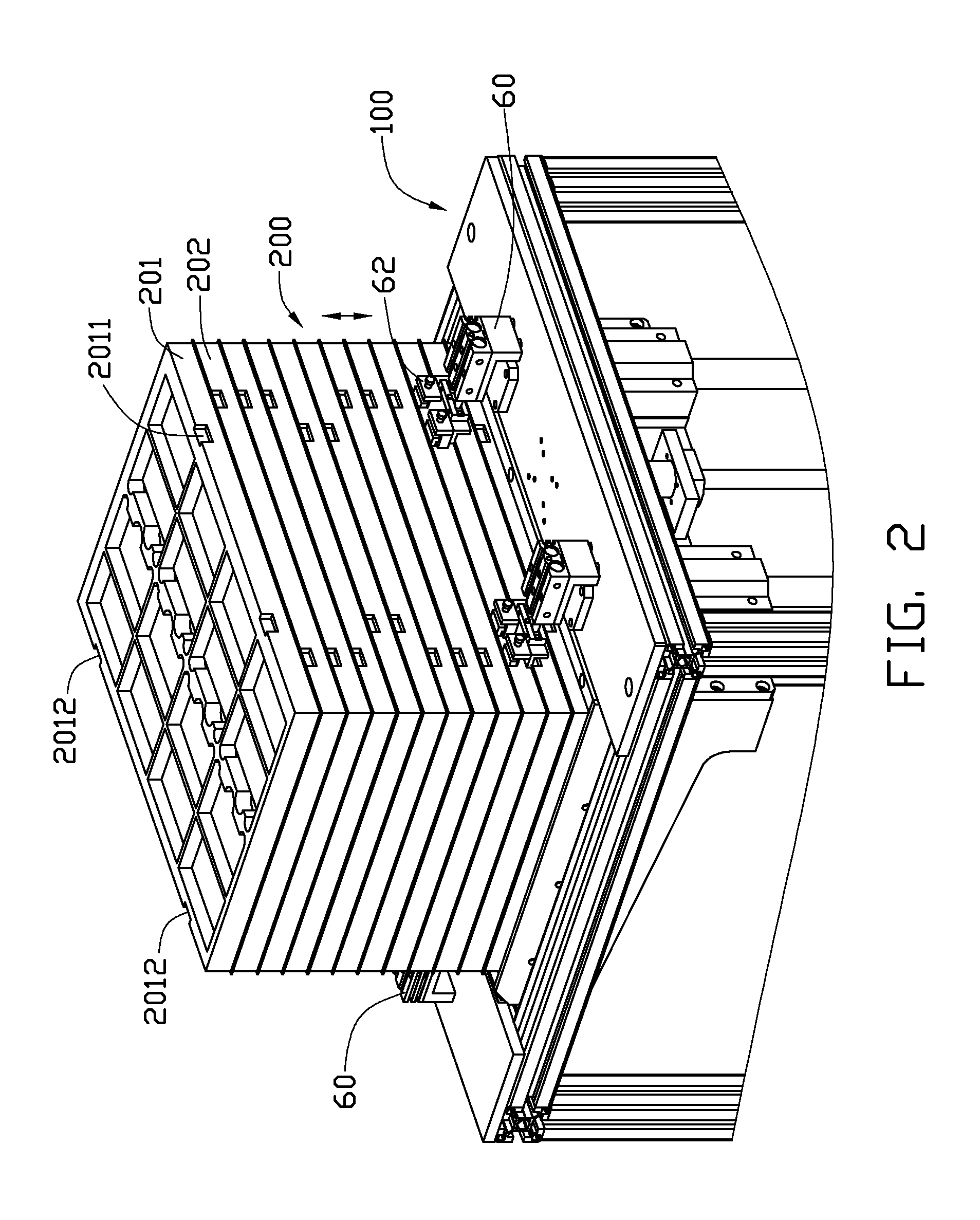

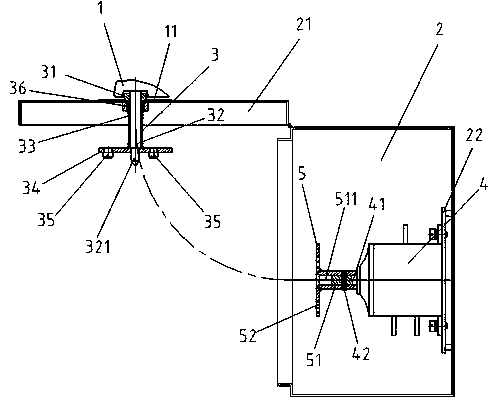

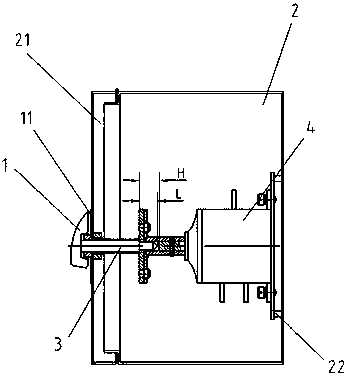

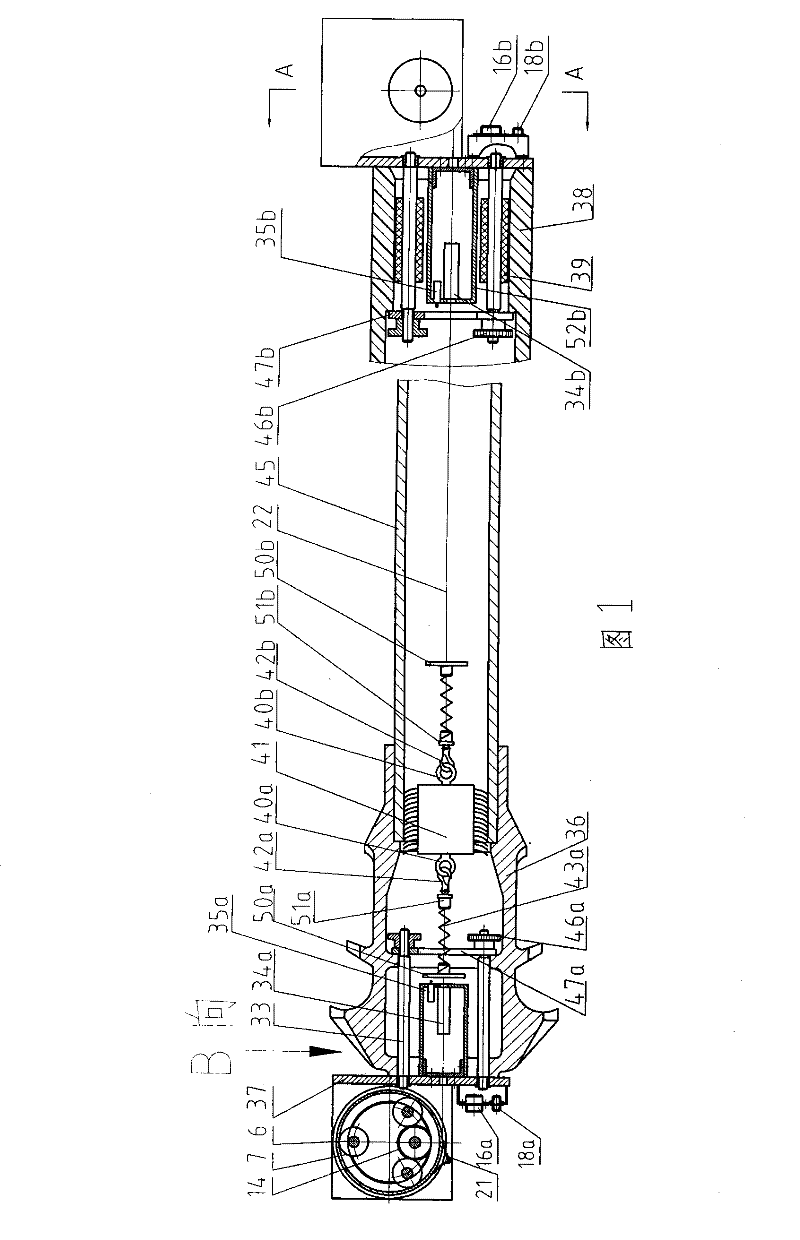

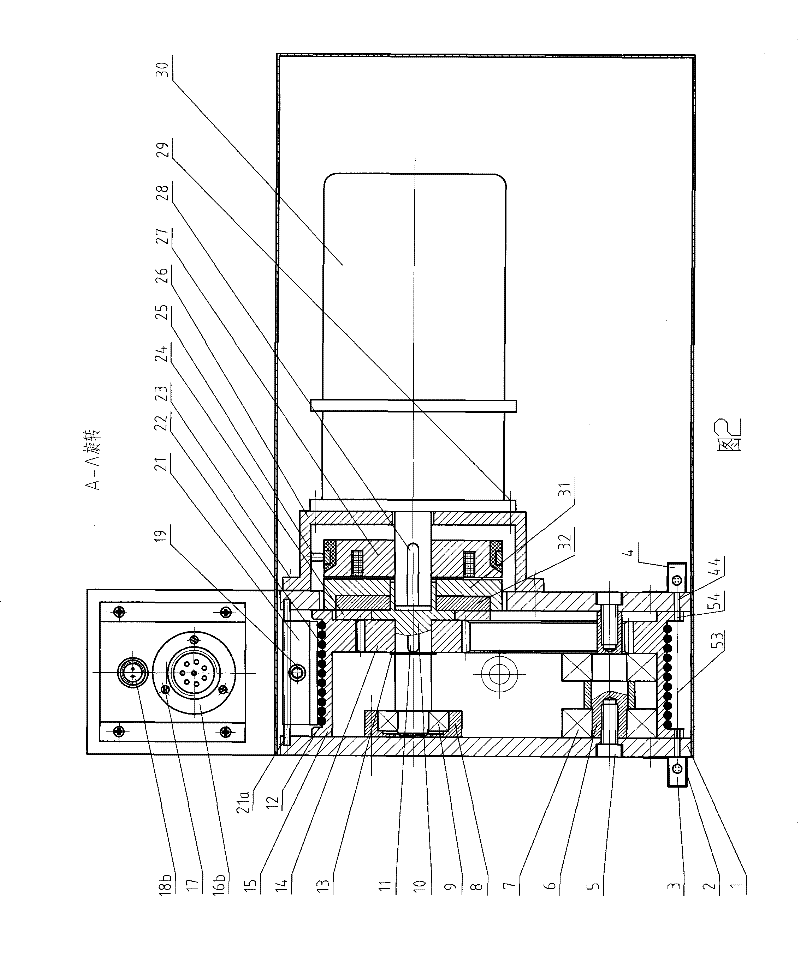

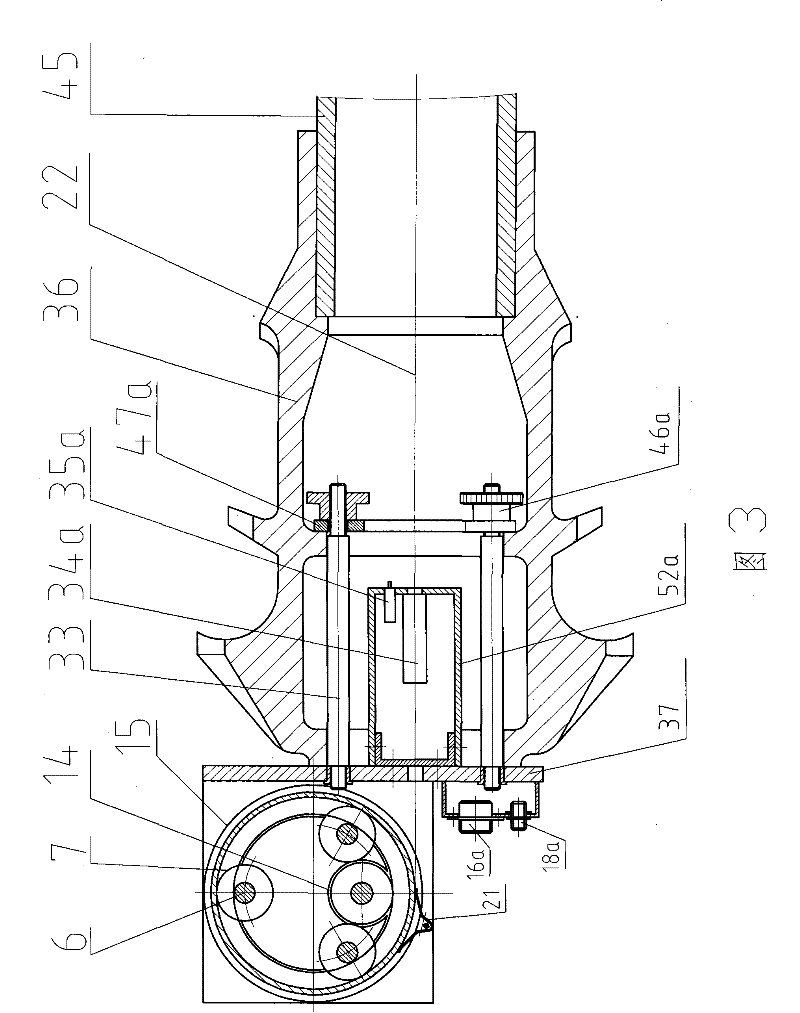

Multifunctional automatic gun wiping machine

A multi-functional automatic gun cleaner comprises drive motors, an automatic controller and a cleaning body; transmission mechanisms, a front gun cleaner bracket and a rear gun cleaner bracket are arranged between the cleaning body and the drive motors; the front end of each gun cleaner bracket is provided with a gun cleaner bracket positioning structure matched with the two ports of the gun barrel, while the drive motor is fixed at the rear end of each gun cleaner bracket; the transmission mechanisms are arranged between the cleaning body and the two motors; each transmission mechanism comprises an electromagnetic clutch which connects the drive motor with a pull-rope drum, and a gear deceleration mechanism; the electromagnetic clutch comprises a pull-in end, a sliding end and a fixed end; the pull-in end of the electromagnetic clutch is fixed on the output shaft of the drive motor; the fixed end of the electromagnetic clutch is fixedly connected with a main shaft; and the main shaft is fixedly connected with the gear deceleration mechanism. The multi-functional automatic gun cleaner is suitable for the gun tubes of any caliber, or can be used to remove and clean the grease stain, rust and fouling in civil pipes.

Owner:济南海鹰机电制造有限公司

A coreless reel device for crossing the belt

The invention relates to a core-free winding barrel device for a crossing belt. The core-free winding barrel device comprises an elastic shaft mechanism, a forming wheel and an arc-shaped forming board. The core-free winding barrel device has the beneficial effects that the elastic shaft mechanism, the forming wheel and the arc-shaped forming board are integrally used, so that the crossing belt is wound conveniently; when a barrel body of a winding barrel is enlarged, the characteristic that a moving mechanism is used for driving a rear press wheel, an arc-shaped forming board and the forming wheel to move upwards and driving an elastic shaft to move downwards is adopted, the diameter of the winding barrel can be adjusted at will, and the universality of the device is improved. The winding barrel is more stable through an auxiliary power mechanism and gear engagement is facilitated through outer engagement design of gears. Due to the fact that bearings and bearing bushes are arranged at the two ends of the auxiliary power mechanism, an auxiliary shaft can be driven by the gear B to rotate, meanwhile the power of an air cylinder is used for driving the auxiliary shaft to move horizontally along a long groove, the discharging space is enlarged, the winding barrel falls down smoothly, and automatic discharging operation is finished. The automation degree of the whole core-free winding barrel device is high, no barrel core is needed, cost is saved, and the labor intensity of operators is greatly relieved.

Owner:NINGBO SUKE ACTUACTOR CO LTD

Image reading apparatus and multi-function machine

An image reading apparatus has a light source and an image capturing device disposed to face each other with a document table interposed therebetween. The image reading apparatus includes: an image capturing device moving mechanism, operable to perform a moving operation for moving the image capturing device in a scanning direction; and a light source moving mechanism, operable to move the light source in the first direction with the movement operation performed by the image capturing device moving mechanism.

Owner:SEIKO EPSON CORP

An exhaust blower for fluorescent lamp production

InactiveCN100543909CAchieve continuous exhaust processingEasy clutchTube/lamp vessels exhaustionFluorescenceEngineering

The invention discloses an exhaust machine used for the production of fluorescent lamp tubes, which comprises a base and a fixing frame. There are multiple rows of mercury gun groups on the top, and the mercury gun group is composed of multiple mercury guns arranged side by side. From the upper nozzle to the lower nozzle, there are multiple ovens with upward openings corresponding to the mercury gun groups. Between the fixed plate and the oven An oven fixing device is arranged between the upper nozzle and the lower nozzle. The first conveying rail group below the fixed plate and the second conveying rail group above the fixed plate are arranged. Oven lifting device, upper tube device and lower tube device that can move along the first conveying guide rail group, the second conveying guide rail group is provided with a mercury injection device that can move along the second conveying guide rail group, the advantage lies in that the processing station does not move Under certain circumstances, continuous exhaust processing of multiple lamp tubes can be realized at the same time.

Owner:ZHEJIANG YANKON GROUP

Gear clutch mechanism and radiotherapy equipment including it

ActiveCN105987091BEasy clutchAdjust transmission accuracyInterengaging clutchesX-ray/gamma-ray/particle-irradiation therapyEngineeringCam

The invention provides a gear clutch mechanism and radiotherapy equipment including the same. The gear clutch mechanism is mounted at a base and comprises a driven gear, a guiding component, a mounting plate, a driving gear and a pushing assembly, wherein the driven gear is rotatably fixed to the base; the guiding component is fixed on the base; the mounting plate is supported by the guiding component in a sliding manner; the driving gear is rotatably fixed to the mounting plate; the pushing assembly is used for pushing the mounting plate to slide along the guiding component, and when the pushing assembly pushes the mounting plate to slide close to the driven gear, the driving gear moves close to the driven gear until being mutually meshed with the driven gear; and when the pushing assembly pushes the mounting plate to slide away from the driven gear, the driving gear moves far from the driven gear until being mutually separated from the driven gear. The gear clutch mechanism adopts a special cam structure, so that the clutching of the gear in the radial direction can be conveniently realized. By adjusting the profile of the cam, a relatively large dead angle can be formed, and a good locking function can be realized.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Electric pressure cooker

The invention provides an electric pressure cooker which can solve the problems caused by arranging an electrical motor on the cover of the cooker in the prior art. The technical scheme is as follows: the electric pressure cooker comprises an inner pot, an outer pot, a shell, a heating plate, the electrical motor and a stirrer, wherein the electrical motor is arranged in the lower part of the outer bottom surface of the inner pot, the motor shaft is connected with a main driving disc, the inner bottom surface of the inner pot is provided with a drive shaft sleeve, the inside of the drive shaft sleeve is provided with a drive shaft, the stirrer is fixedly connected with the upper end of the drive shaft through a stirrer sleeve, the lower end of the drive shaft passes through the bottom surface of the inner pot and is fixedly connected with an auxiliary driving disc, and the main driving disc and the auxiliary driving disc constitute a clutch. As the electrical motor and the motor shaftare arranged in the lower cavity of the outer bottom surface of the inner pot, the weight of the cover of the cooker is reduced, when the cover is opened, the motor shaft and a stirring blade are notneeded to take out so as to avoid the phenomenon of taking soup or rice along with the motor shaft and the stirring blade out of the cooker, reduce the space occupied by the cover and ensure to conveniently and hygienically place the cover.

Owner:崔美娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com