Rewinding mechanism for rechecking machine

A re-inspection machine and frame technology, applied in the field of winding technology, can solve the problems of difficult meshing operation, influence of re-inspection environment, connection can not be too precise, etc., to improve rewinding efficiency, improve re-inspection environment, transmission high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

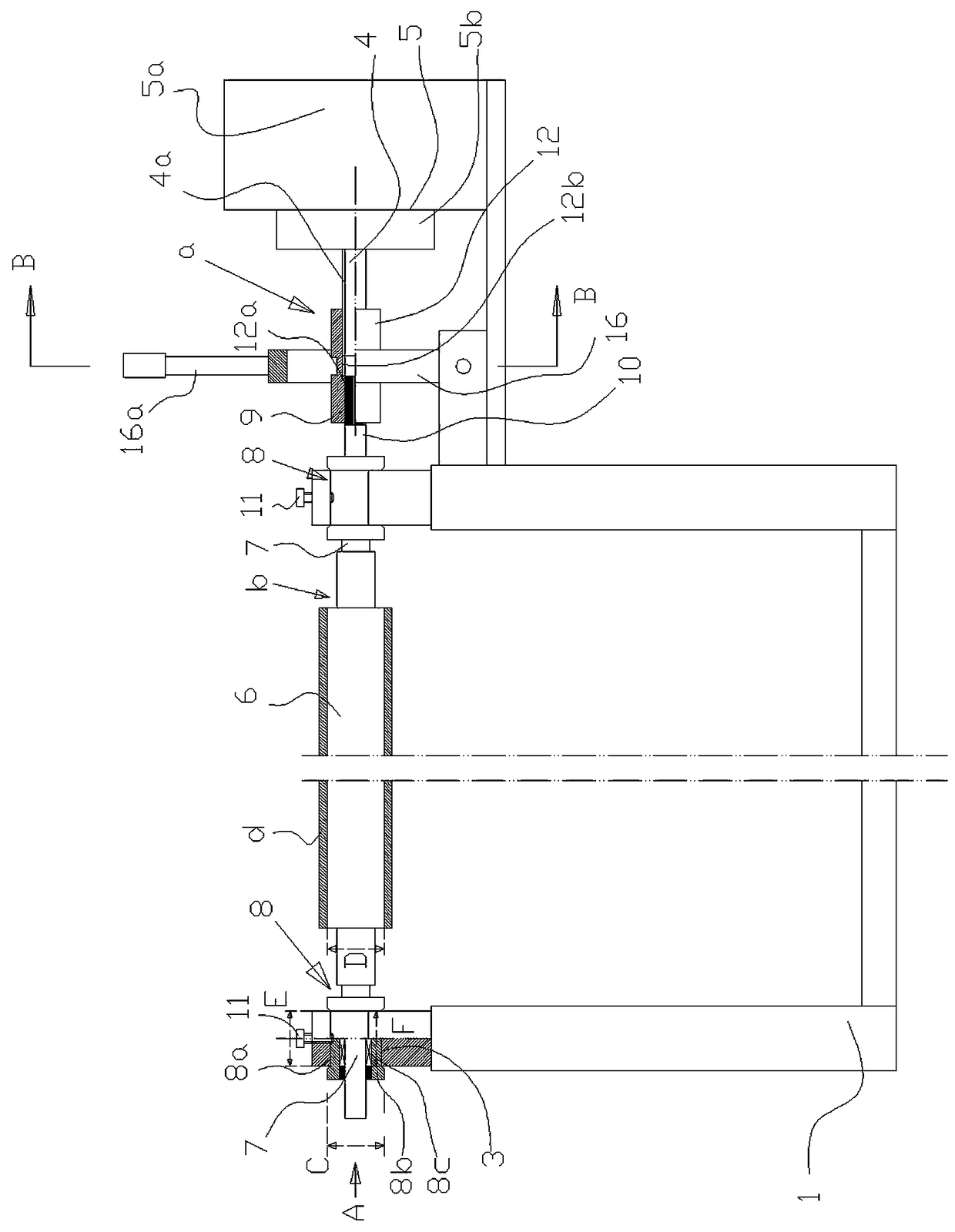

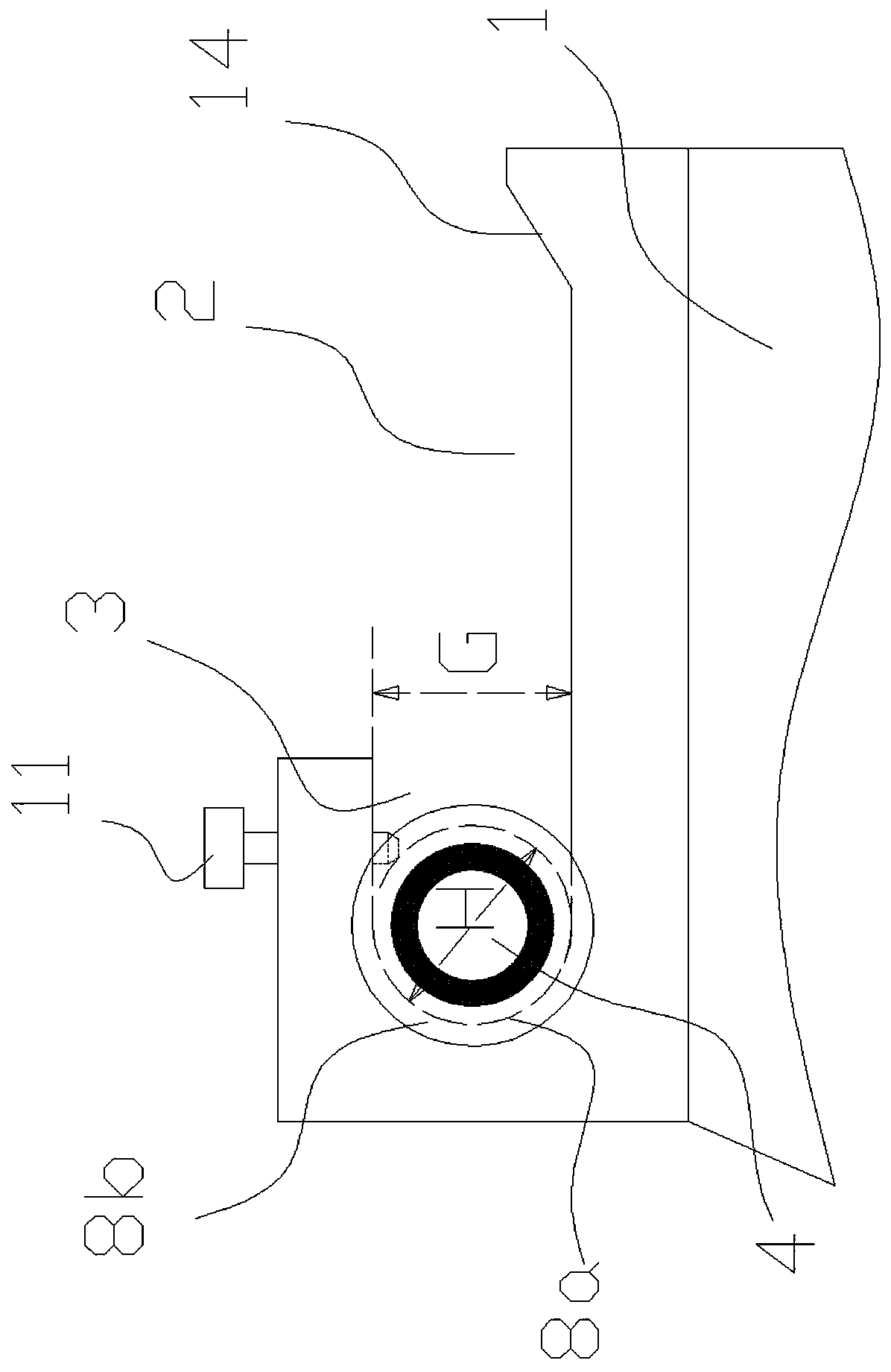

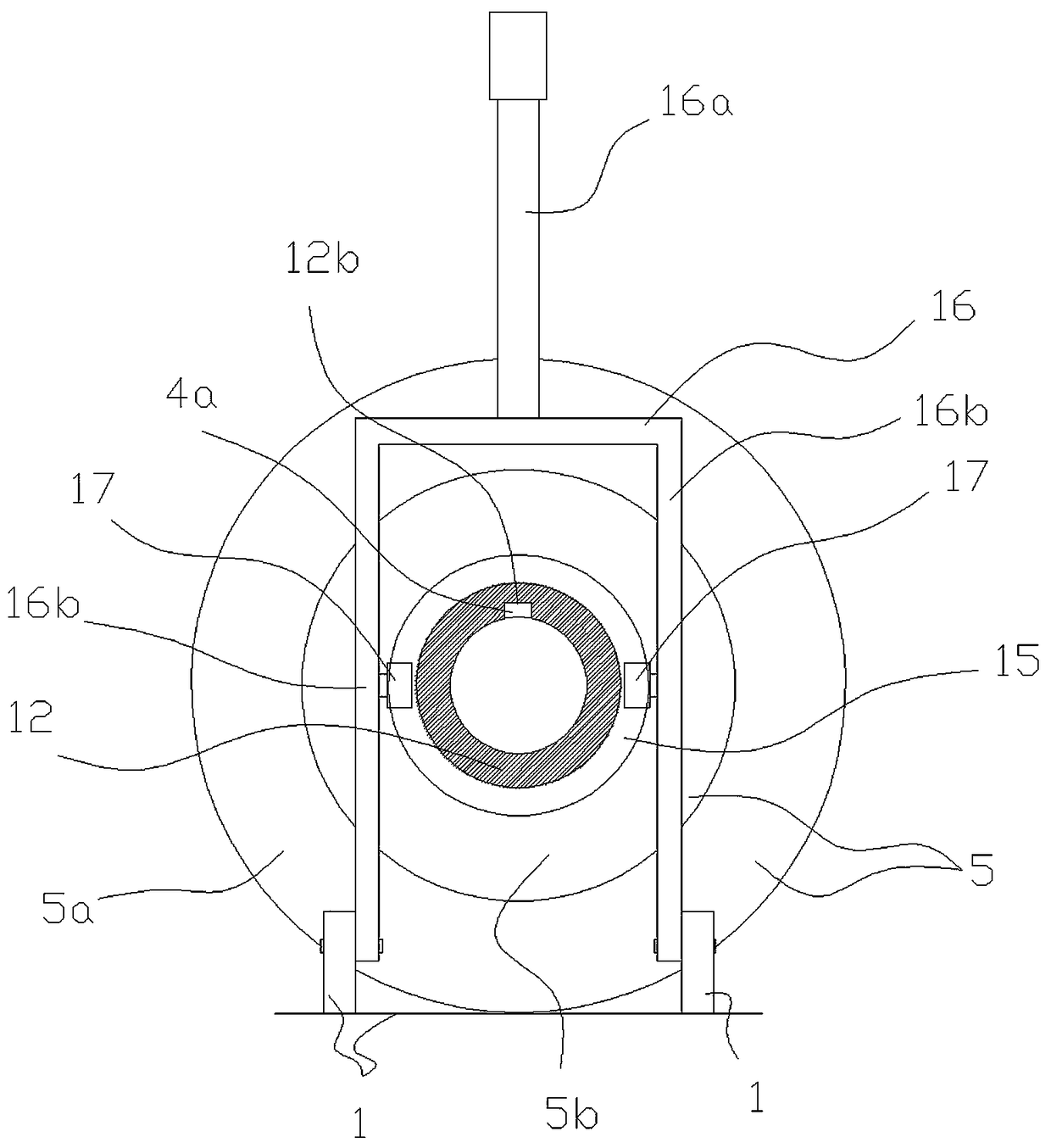

[0012] The present invention will be further described in detail with reference to the accompanying drawings and embodiments:

[0013] Such as figure 1 As shown, the present invention includes a frame 1, a horizontal U-shaped positioning slot 3 with inlets 2 arranged on both sides of the frame 1, and a horizontal U-shaped positioning slot 3 arranged at one end of the frame 1 and facing the horizontal U-shaped positioning slot 3. The output shaft 4 has a power mechanism 5 with a clutch a (including a motor 5a, a deceleration mechanism 5b), a rotating shaft mechanism b, such as figure 1 As shown, the rotating shaft mechanism b includes a paper drum rotating shaft body 6 for sleeved paper drum d, a bearing connecting shaft 7 arranged at both ends of the paper drum rotating shaft body 6, a bearing member 8 arranged on the bearing connecting shaft 7, and One of the bearings is connected to the drive shaft 10 with clutch teeth 9 on the outer surface of the end of the shaft 7, such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com