Engaging and disengaging gear and gluing machine using the same

A clutch device, glue machine technology, applied in the direction of lamination device, control lamination, lamination, etc., can solve the problems of heavy motor, laborious use, etc., to achieve the effect of easy clutching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

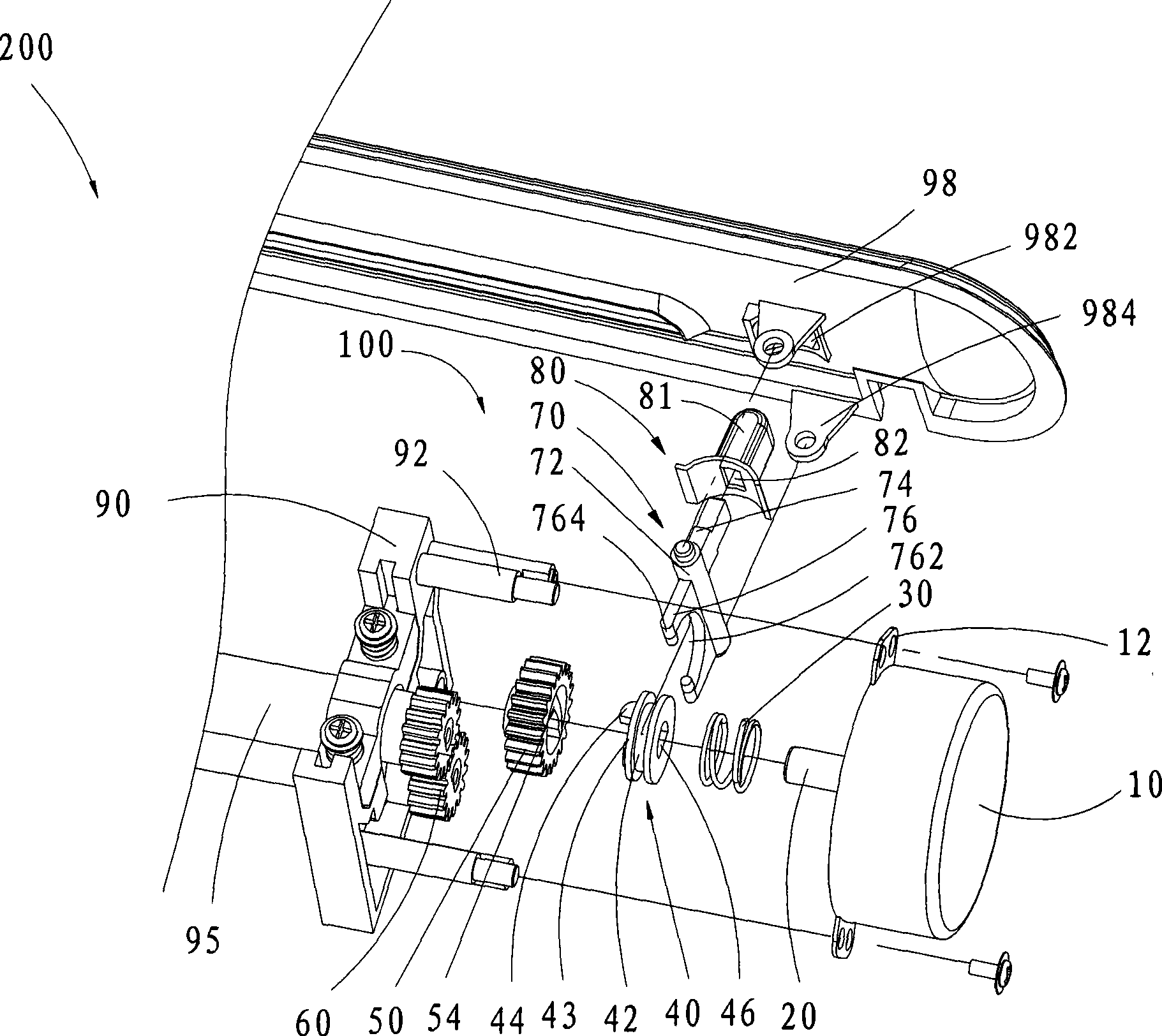

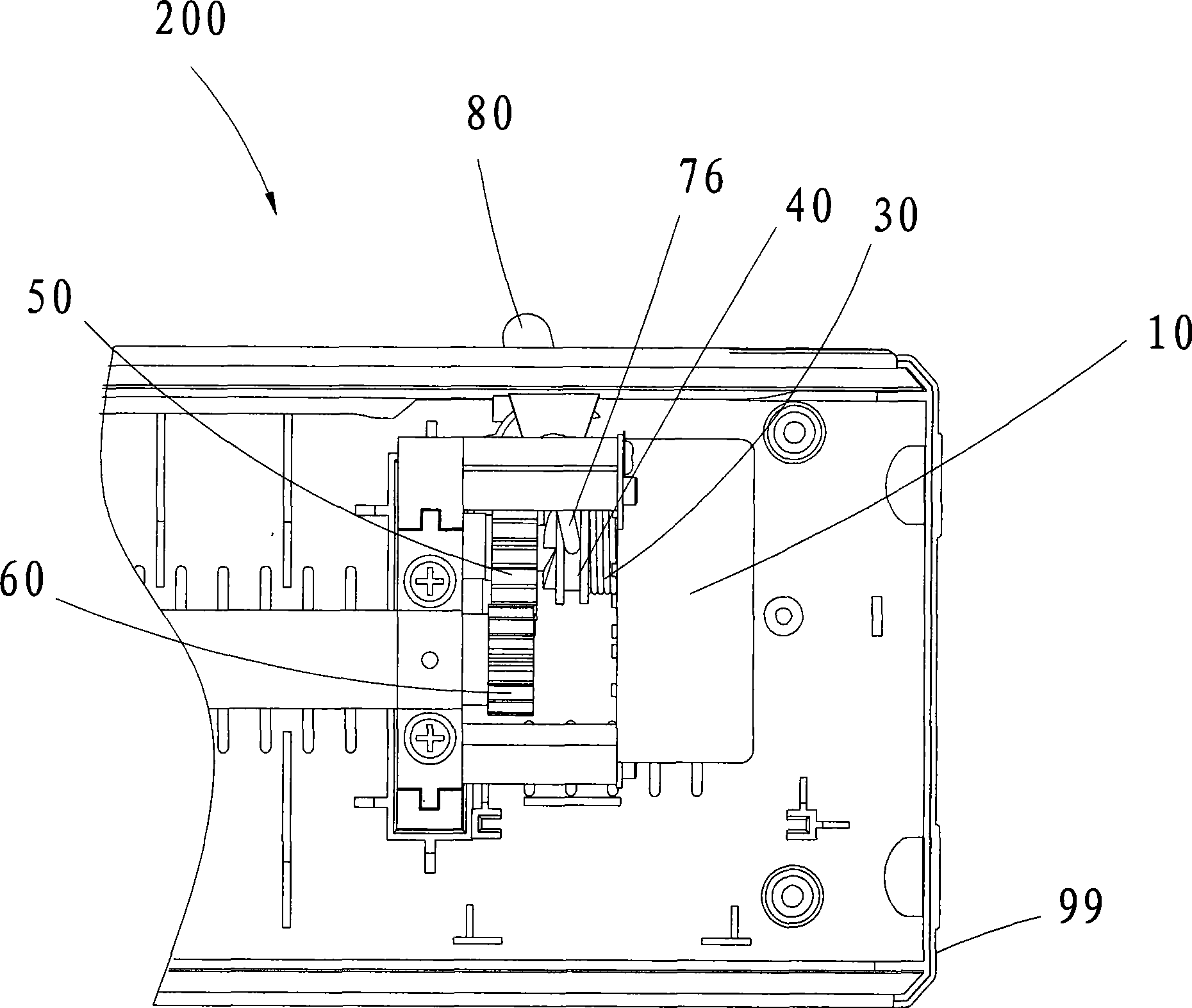

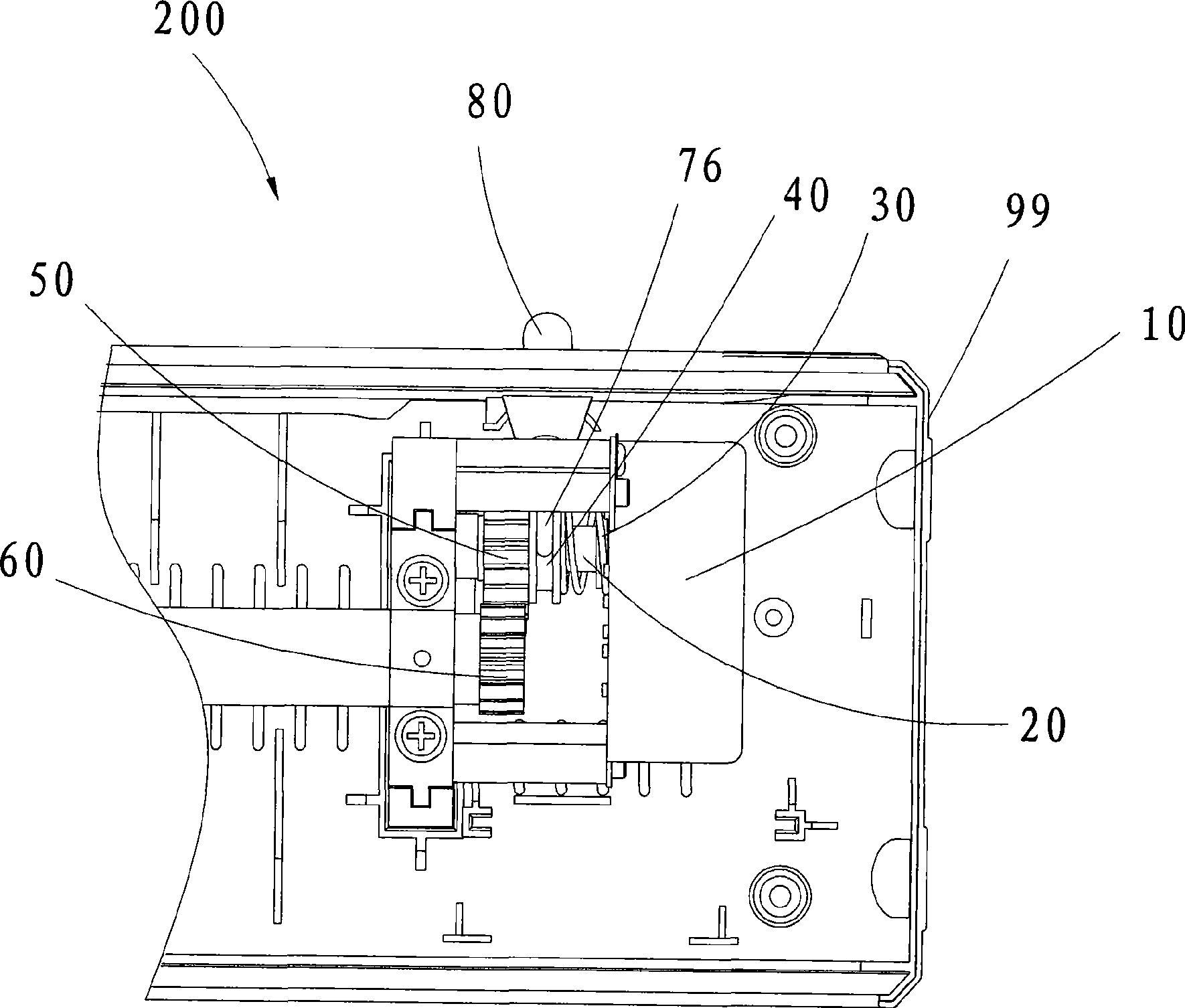

[0015] The clutch device of the present invention can be widely used in various office equipments. Such as figure 1 As shown, the clutch device of the present invention and the gluing machine using the clutch device propose an embodiment. The clutch device 100 of this embodiment is applied in the gluing machine 200. The clutch device 100 includes a motor 10, a motor output shaft 20, an elastic member 30, a radial clutch 40, an end face clutch 50, a clutch wrench 70 and a clutch wrench set 80. Laminating machine 200 also includes gear set 60, crossing rubber roller support 90, crossing rubber roller 95, rear cover 98 and lower cover 99 (see figure 2 ).

[0016] One end surface of the motor 10 extends radially outwards with two mounting pieces 12 for mounting on the rubber roller bracket 90 . The motor output shaft 20 is a non-circular flat shaft extending from one end of the motor 10 and can be driven by the motor 10 to rotate.

[0017] The elastic member 30 is a compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com