A coreless reel device for crossing the belt

A technology of crossing belt and core roll, which is applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of high price of crossing belt, poor reel effect, time-consuming processing, etc., and achieves a high degree of automation , The effect of saving cost and increasing the discharge space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

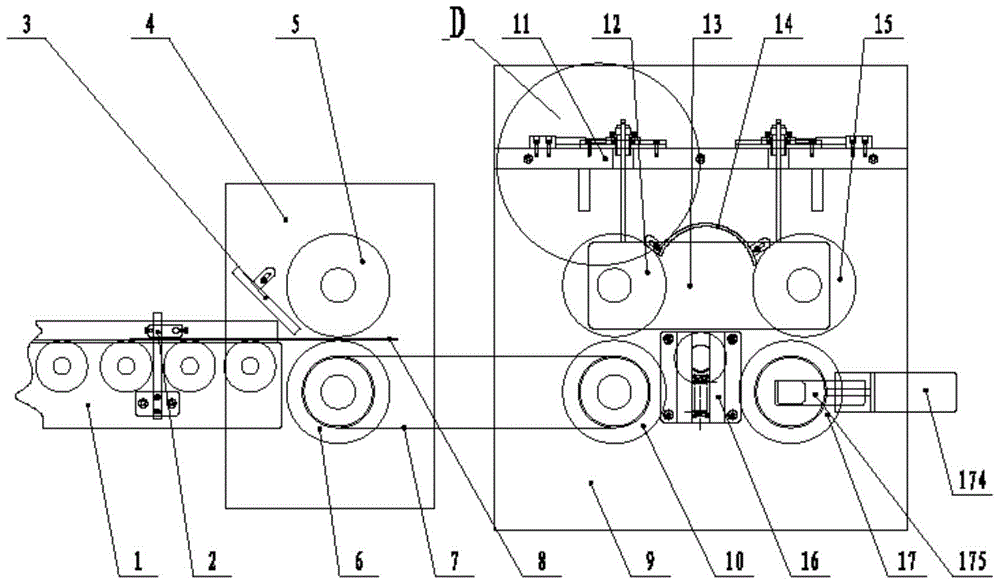

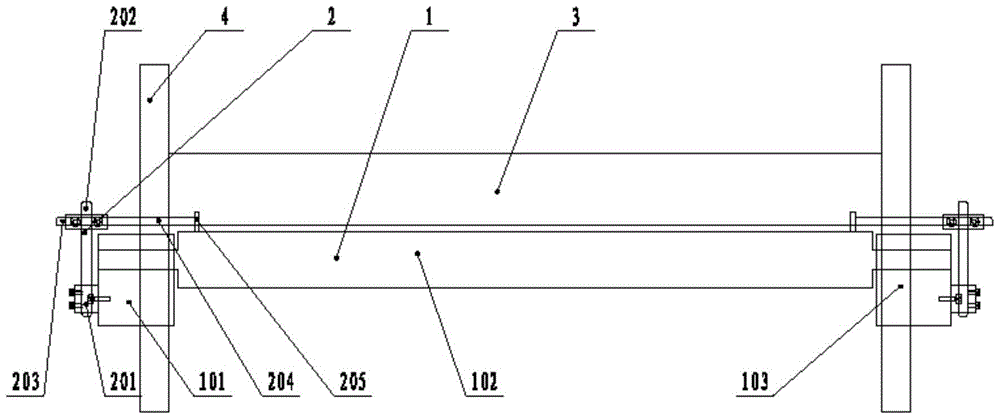

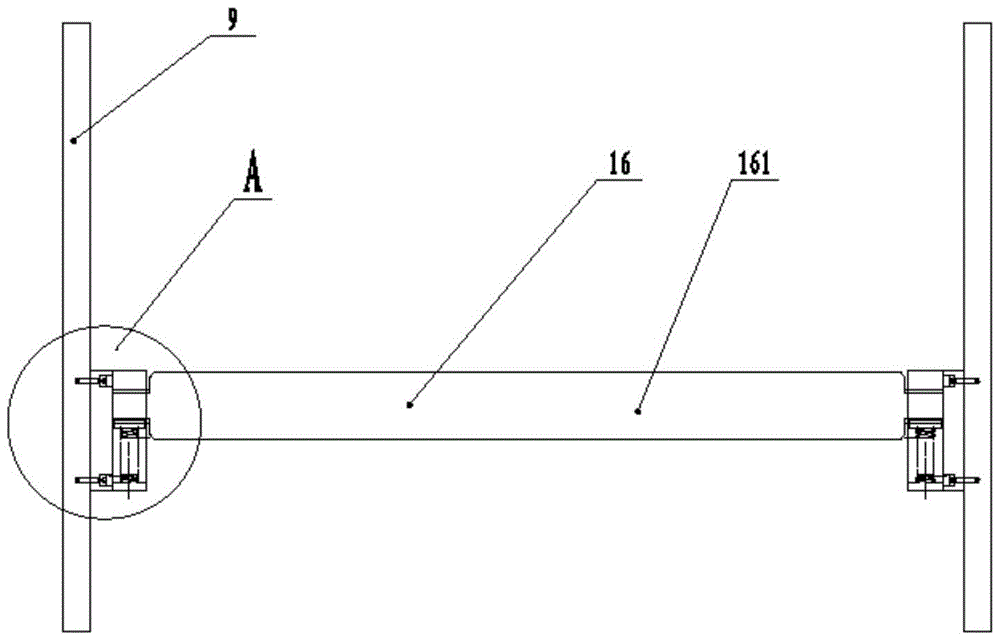

[0036] Such as figure 1 As shown, a coreless reel device for crossing a belt according to an embodiment of the present invention includes two left-right symmetrical front fenders 4 and two left-right symmetrical rear fenders 9 . A front pressure wheel 5 and a front power wheel 6 are installed between the two front baffles 4 , and the belt feeding mechanism 1 is located at the fronts of the two front baffles 4 . The pressure band cover 3 is installed on the front baffle plate 4 through the earrings through bolts, and the pressure band cover 3 forms an included angle with the horizontal plane. A belt adjustment mechanism 2 is installed on both sides of the belt feeding mechanism 1 . The rear power wheel 10 and the auxiliary power mechanism 17 are installed in parallel on the lower parts of the two tailgates 9, and the two movable mechanism bottom plates 120 are respectively fixed on the upper parts of the two tailgates 9 by bolts, and are symmetrically installed on the two mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com