Worm member for rotary working table

A technology of rotary table and worm rod, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc. It can solve the problems of limited bearing capacity, affecting the accuracy of the whole machine, and the inability to guarantee the accuracy of the axial runout of the rotary table. To achieve the effect of firm fixation and convenient clutch adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below through specific embodiments. It should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some modifications and improvements can also be made, and these should also be regarded as belonging to the present invention. protection scope of the invention.

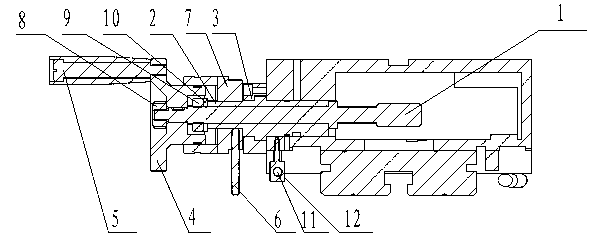

[0015] The rotary table drives the turbine of the turbine assembly to rotate through the worm of the worm assembly, thereby driving the rotation of the working table. Worm member of the present invention such as figure 1 As shown, the worm member includes a worm 1, a worm sleeve 2, a worm sleeve fixing seat 3, a hand wheel 4, a handle 5, a clutch disc puller 6 and a clutch disc 7; the worm 1 is provided with a worm sleeve 2 The worm cover 2 is fixed on the worm cover holder 3; the hand wheel 4 is fixed on the worm 1; the hand wheel 4 is connected with the handle 5; superior. The hand wheel 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com