Device for studying the effect of vibration on precision measurement of machine tool spindles

A machine tool spindle and precision measurement technology, which is applied to the vibration displacement measurement device of the machine tool spindle, and the field of devices that analyze the impact of vibration noise on the vibration displacement measurement of the machine tool spindle, and can solve the problems of vibration isolation, failure to take into account, structural installation, and inconvenient adjustment, etc. problems, to achieve the effect of improving coupling stiffness, easy clutch adjustment, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

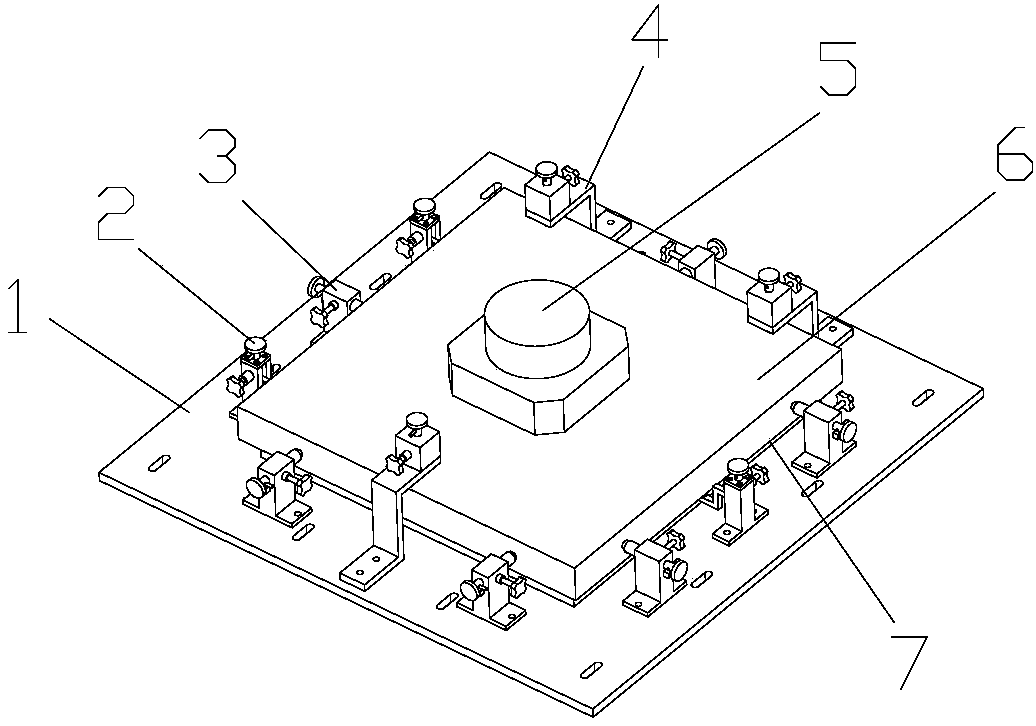

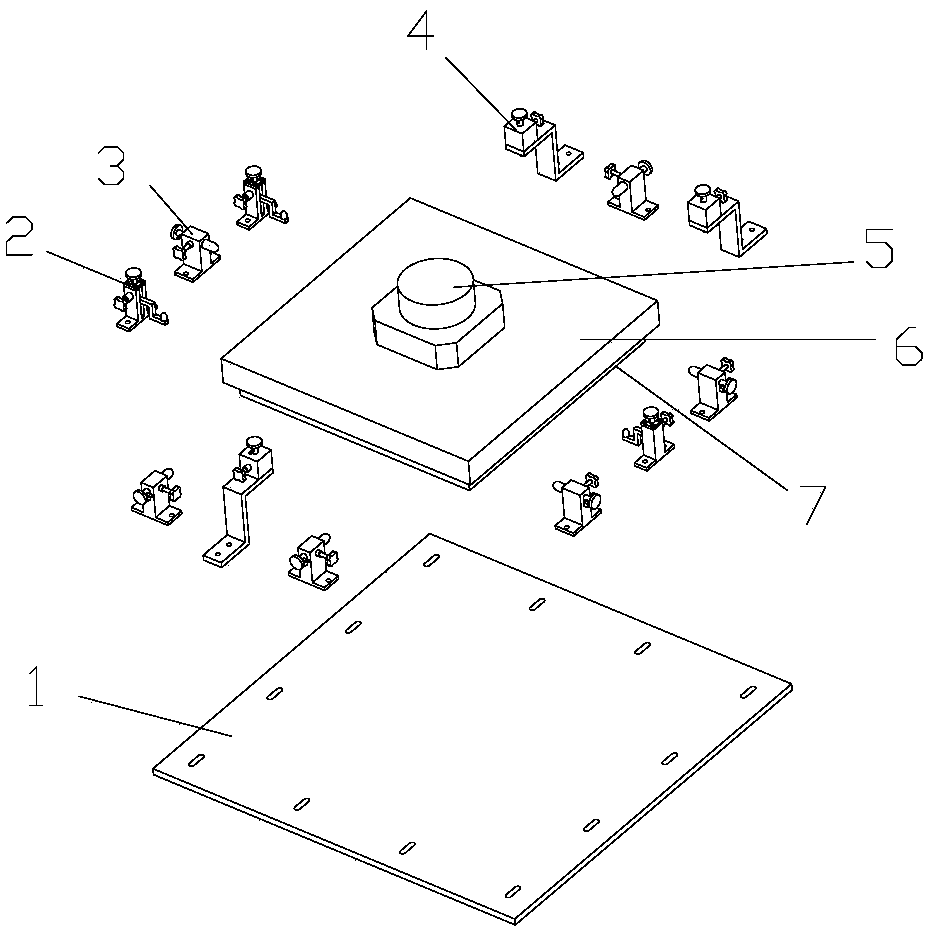

[0041] The application of the present invention to the drilling and milling machine will be described in detail below in conjunction with the accompanying drawings. It is mainly used to isolate the influence of the vibration of the machine tool itself on the sensor in the experiment that needs to collect the vibration of the machine tool spindle or the tool displacement data, so as to ensure that the collected data is true and effective. refer to Figure 14 , Figure 15 , Figure 16 .

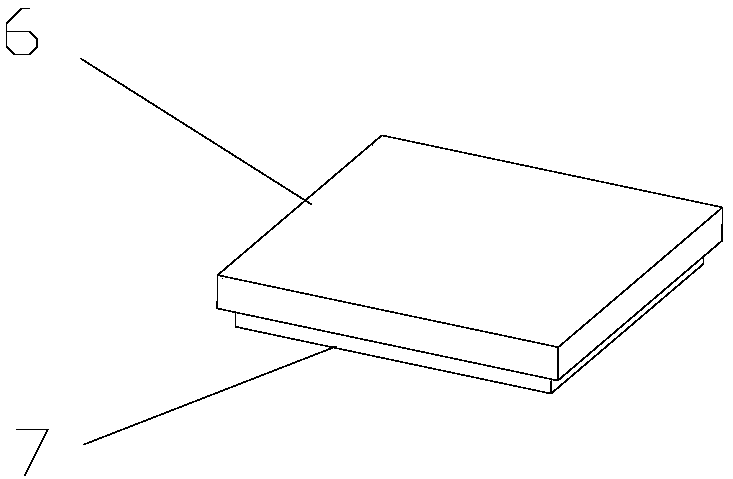

[0042] Such as figure 1 , as shown in 2, a device for studying the influence of vibration on the precision measurement of the spindle of a machine tool, including a bed base plate 1, a vibration isolation layer 7, a test table 6, an upper clutch positioning mechanism 4, a lower clutch positioning mechanism 2, and a lateral clutch positioning mechanism Mechanism 3 and positioning boss 5 etc.

[0043] The bed base plate 1 is connected with the machine tool processing table through a T-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com