Wedge block for one-way clutch

A one-way clutch and wedge block technology, applied in one-way clutches, clutches, mechanical equipment, etc., can solve the problems of large wear, low reliability and weak bearing capacity of the wedge block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

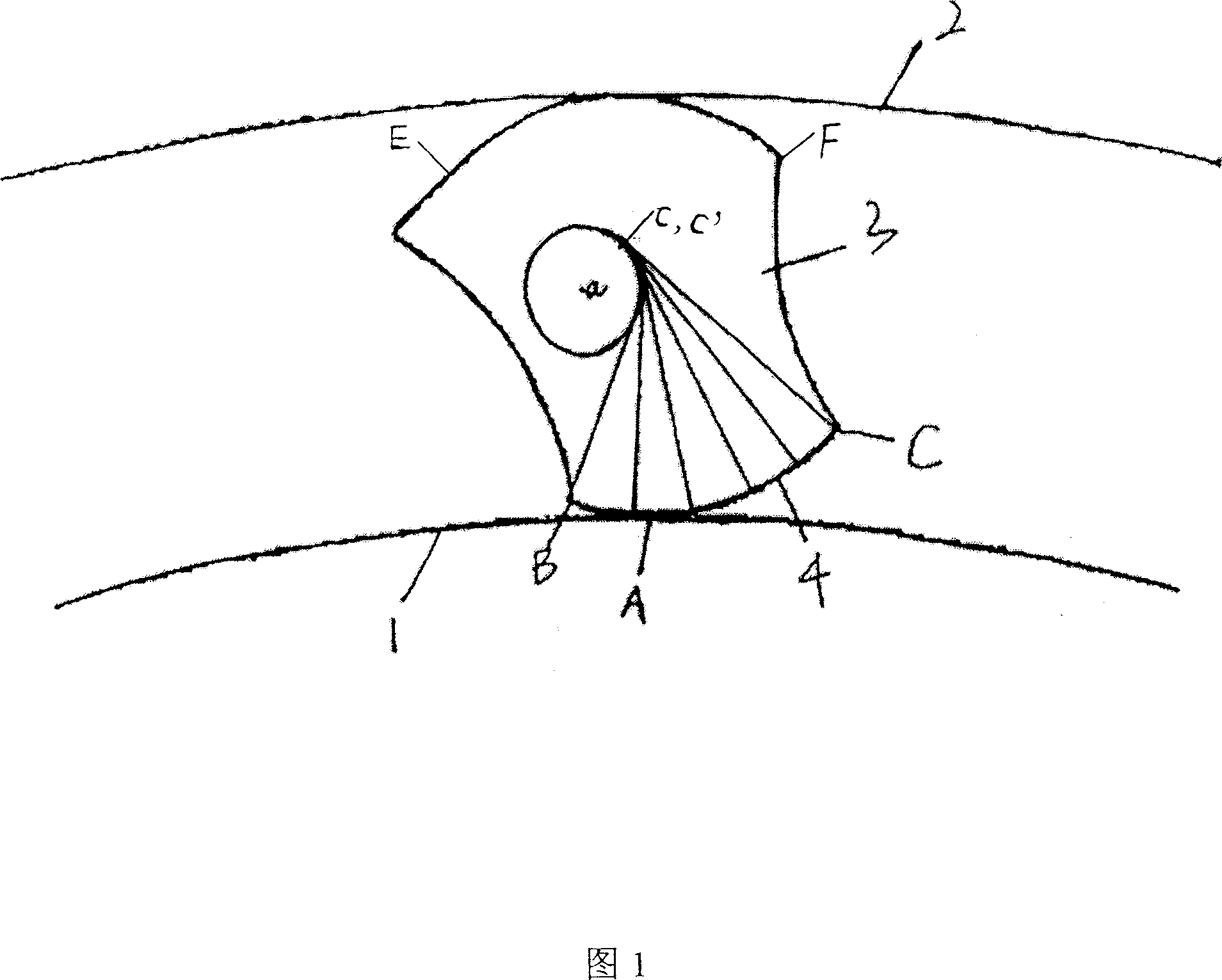

[0007] As shown in Figure 1, the wedge block 3 of the present invention is arranged between the outer ring 1 and the inner ring 2 of the one-way clutch, and the contact surface with the inner ring 1 is A, and the lower end of the wedge block 3 and the one-way clutch The contact surface A adopts an involute 4 curved surface. In the figure, a is the center of the circle, point c coincides with point c', the involute 4 is centered at a, point c is fixed, and point c' passes through when it stretches outward A segment of trajectory BC in the route of . In this way, on the one hand, the curvature on the BC surface gradually increases from B to C, and on the other hand, the curvature center of each point on the BC surface also changes along the circular track of the base circle a, while maintaining the same circle center or curvature center of the upper surface EF The eccentric distance is basically unchanged, so as to ensure that the pressure angle during work is basically unchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com