Automatic curling machine

A wire winding machine, automatic technology, applied in the direction of conveying filament-like materials, sending objects, thin material processing, etc., can solve the problems of difficult collection of aluminum wire, easy to pollute the environment of the processing workshop, etc., to achieve a clean environment, reliable centering, work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] This embodiment provides an automatic aluminum wire winding machine used in the turning process of aluminum non-stick pans, which can automatically wind and collect the aluminum wires generated in the turning process of aluminum non-stick pans, with high collection efficiency and no excess consumption. manpower to ensure the cleanliness of the processing workshop.

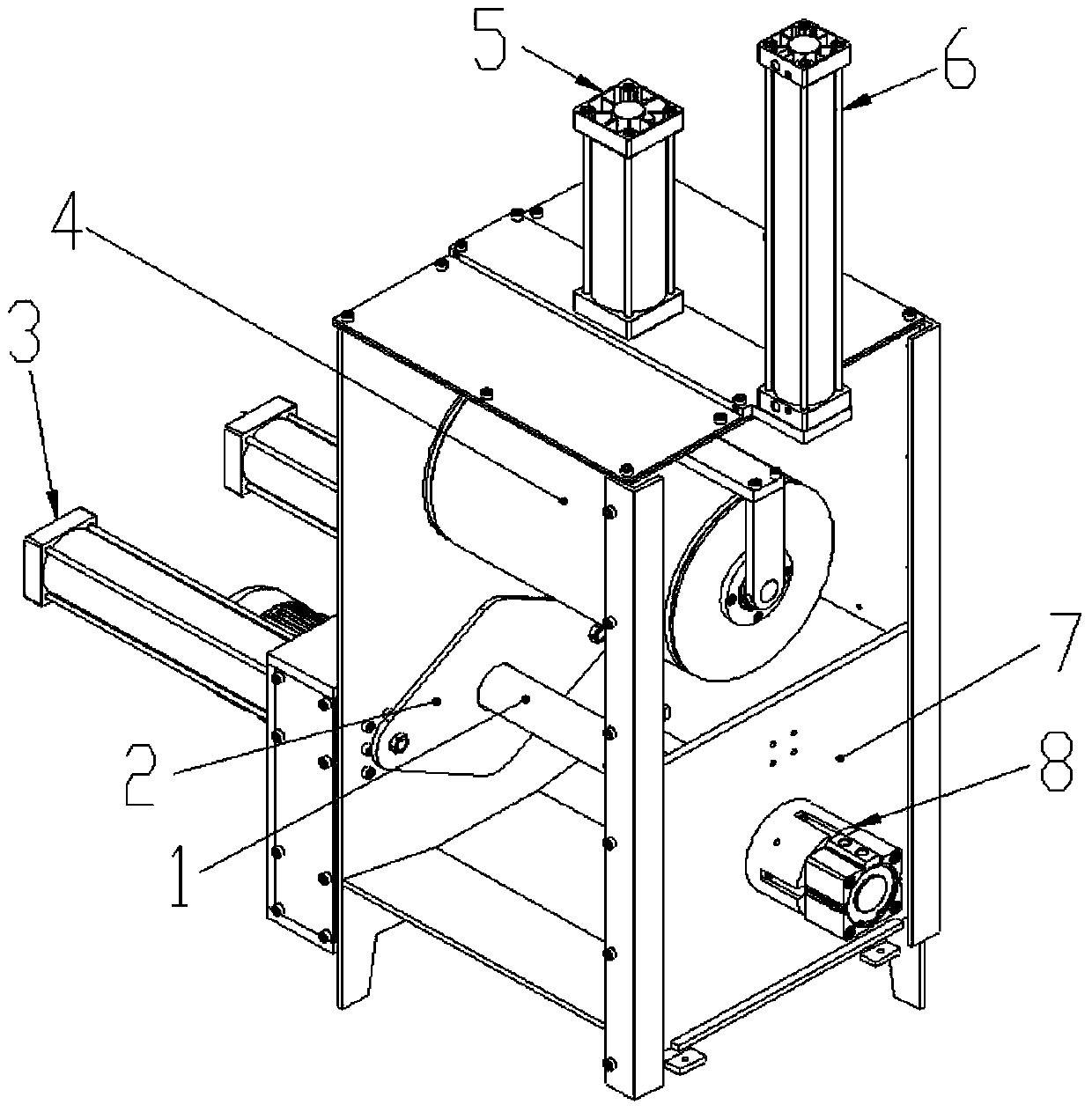

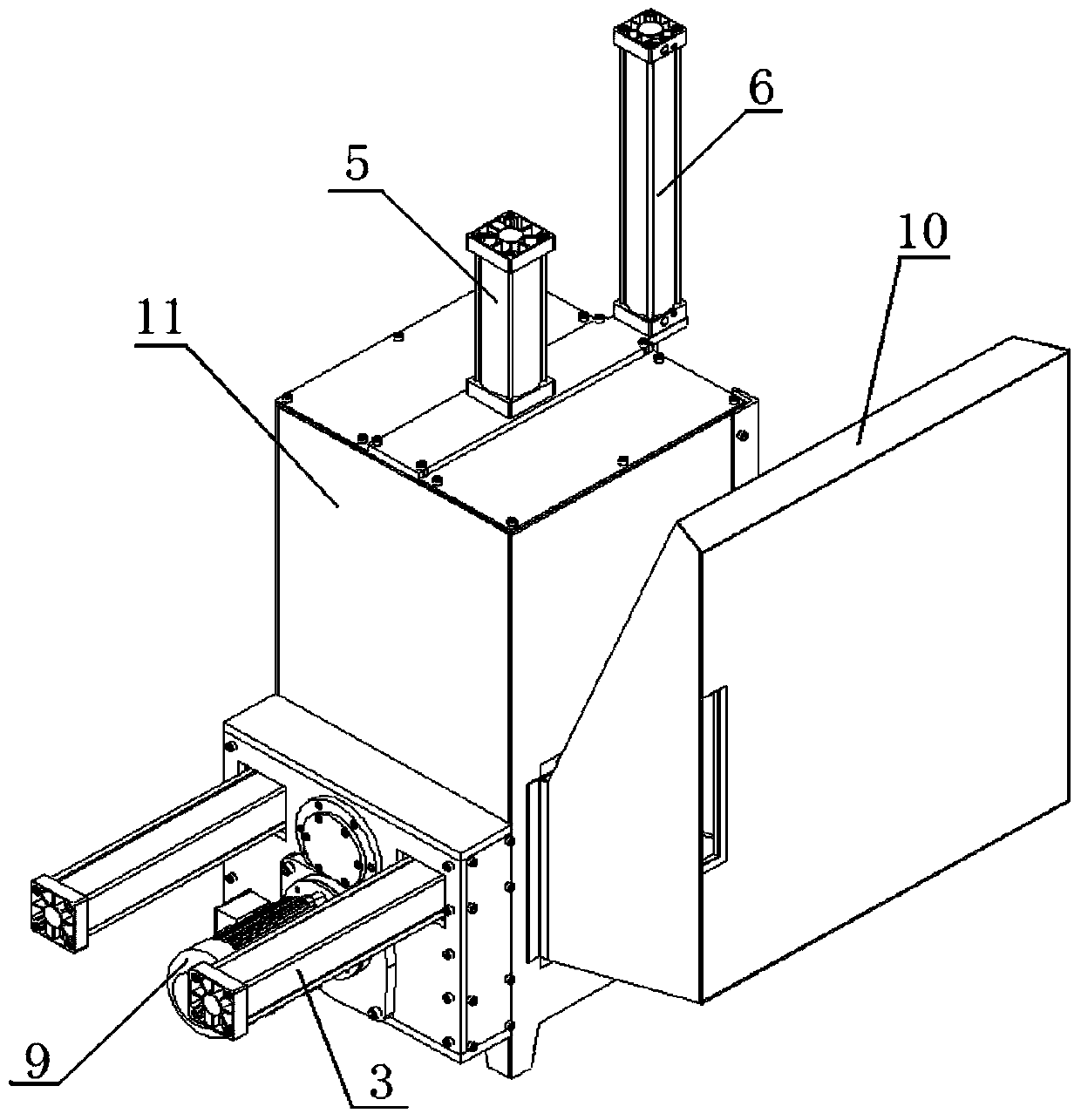

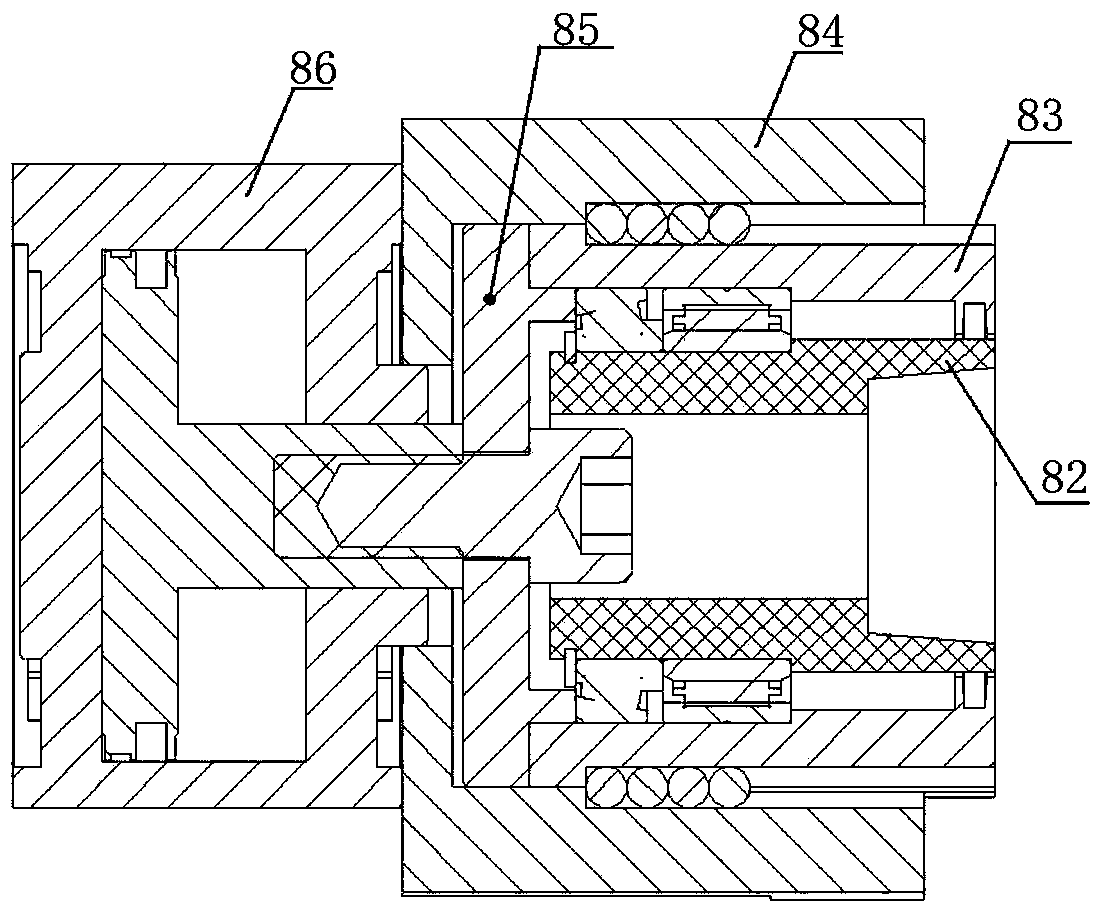

[0021] The overall structure of the winding machine is as follows: figure 1 As shown, it includes a winding shaft 1, a pusher plate 2, a pusher cylinder 3, a pressure wheel 4, a pressure wheel control cylinder 5, a discharge door control cylinder 6, a discharge door 7, a centering device 8, a reduction motor 9, Feeding cover 10 and casing 11. Among them, the winding shaft 1 is a tapered structure, and its connection relationship is: the box body 11 provides support and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com