Multifunctional automatic gun wiping machine

An automatic wiping and multi-functional technology, which is applied in the direction of weapon accessories, offensive equipment, weapon cleaning devices, etc., can solve the problems of easy-to-break wire ropes, entanglement of traction pull ropes, and failure of gun wiping machines to be widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

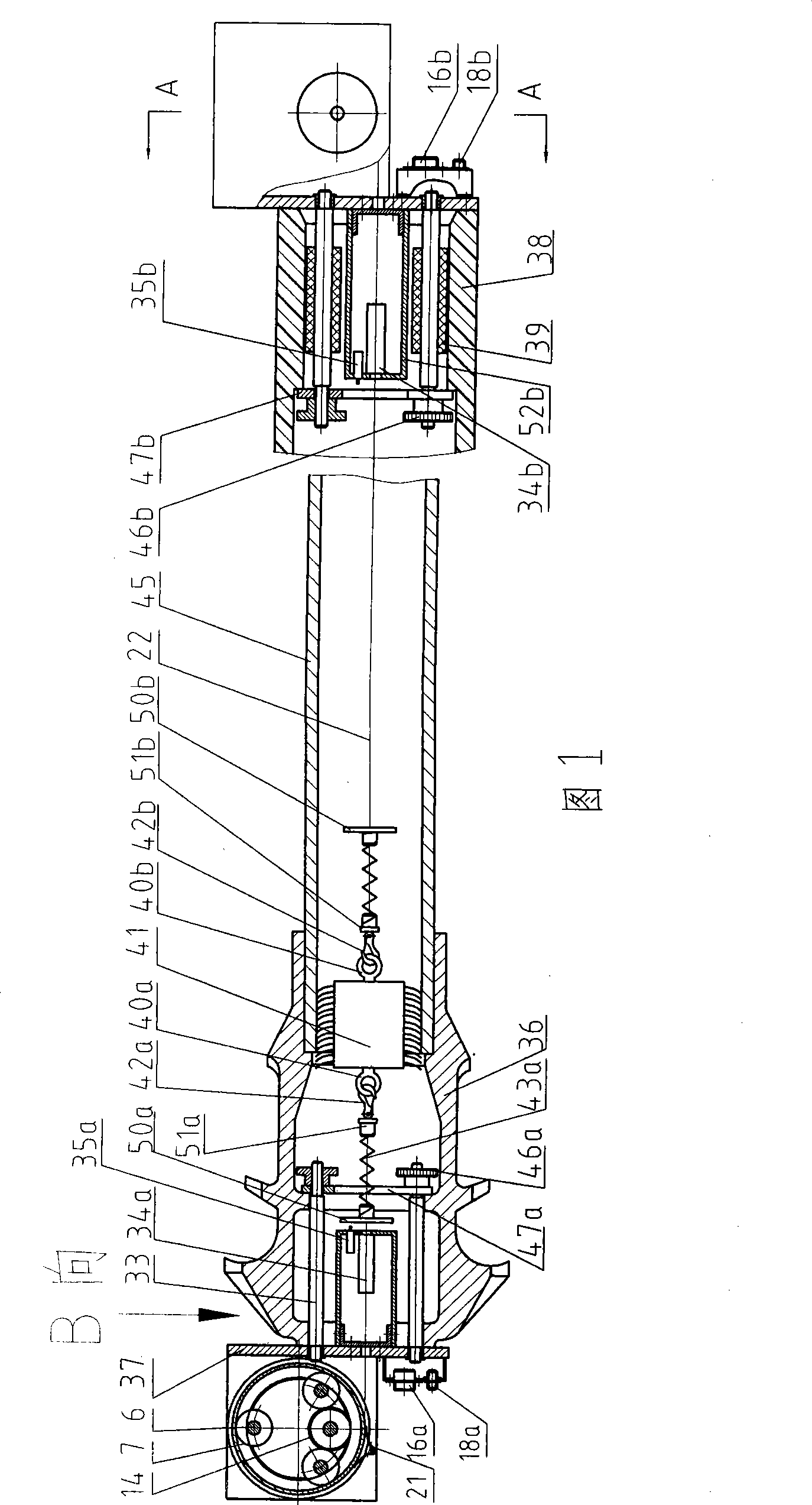

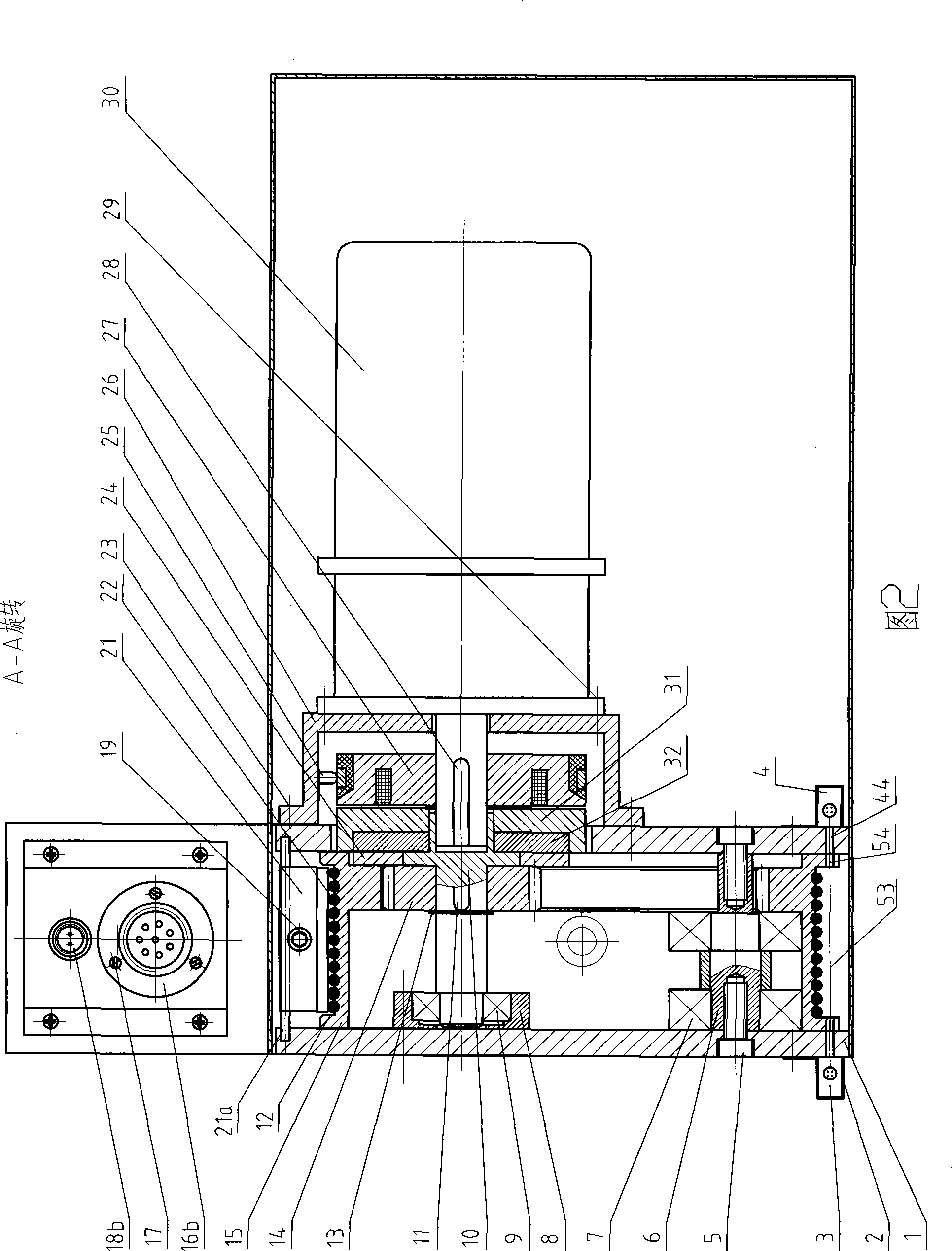

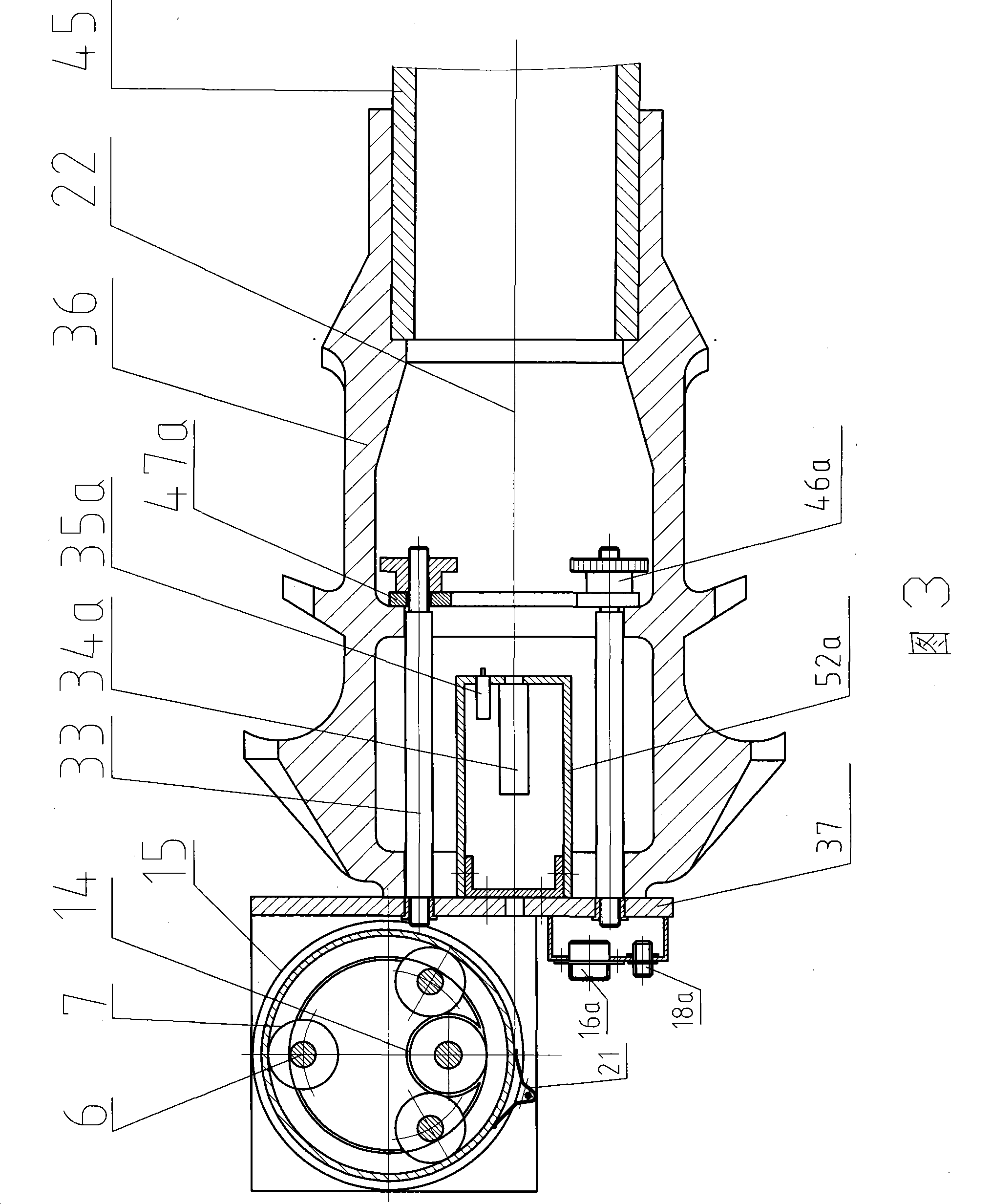

[0037] As shown in Figure 1-2, the present invention includes a driving motor 30, an automatic controller, and a wiping body 41. A transmission mechanism is arranged between the wiping body 41 and the driving motor 30, and two front and rear gun wiping machine brackets are also provided. The front end of the gun wiping machine bracket has a gun wiping machine bracket positioning structure matched with the two ports of the gun barrel, its rear end is fixed with a drive motor 30, and a transmission mechanism is arranged between the wiping body 41 and the two motors, and the transmission mechanism includes The drive motor 30 and the electromagnetic clutch and the gear reduction mechanism connected together by the rope winch, the electromagnetic clutch includes a suction end 27, a sliding end 31 and a fixed end 32, and the electromagnetic clutch suction end 27 is fixed on the motor output shaft 28 , the fixed end 32 of the electromagnetic clutch is fixedly connected to the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com