Plate loading device

A loading device and plate-shaped body technology, which is applied in the direction of packaging, transportation and packaging, and packaging of vulnerable items, can solve the problems of large lateral width of transport vehicles and violation of road traffic regulations, and achieve compact structure, reduce transportation costs, and load The effect of cheap installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

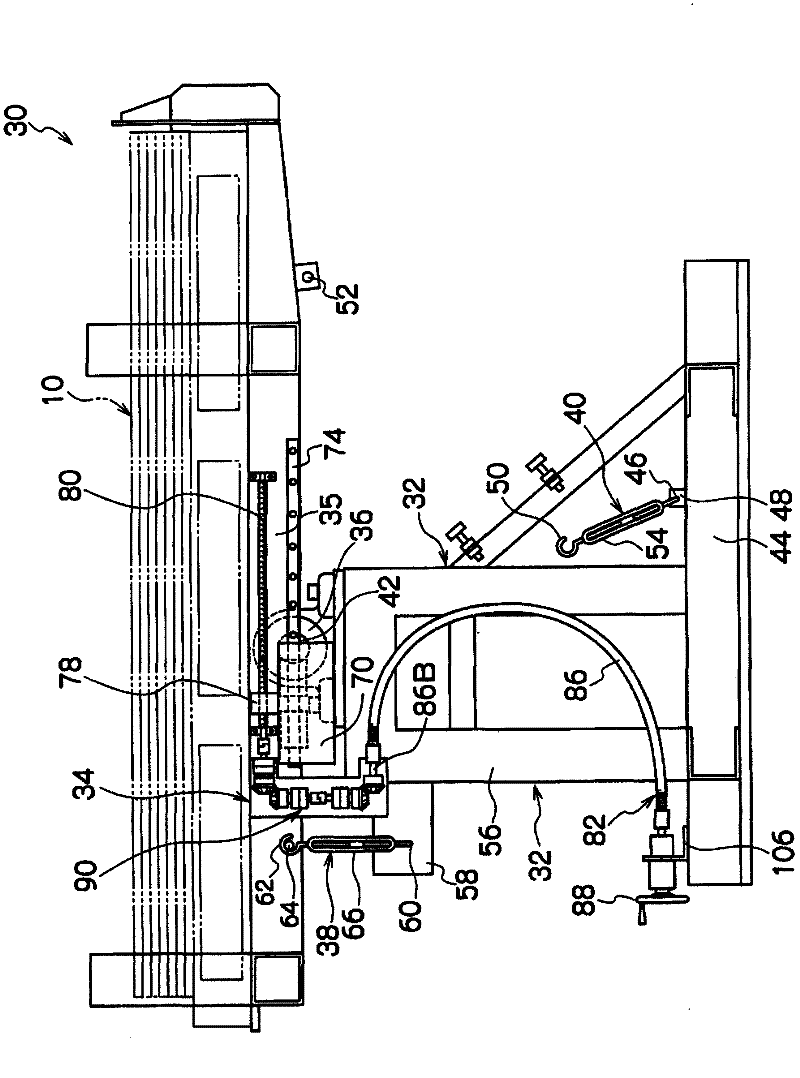

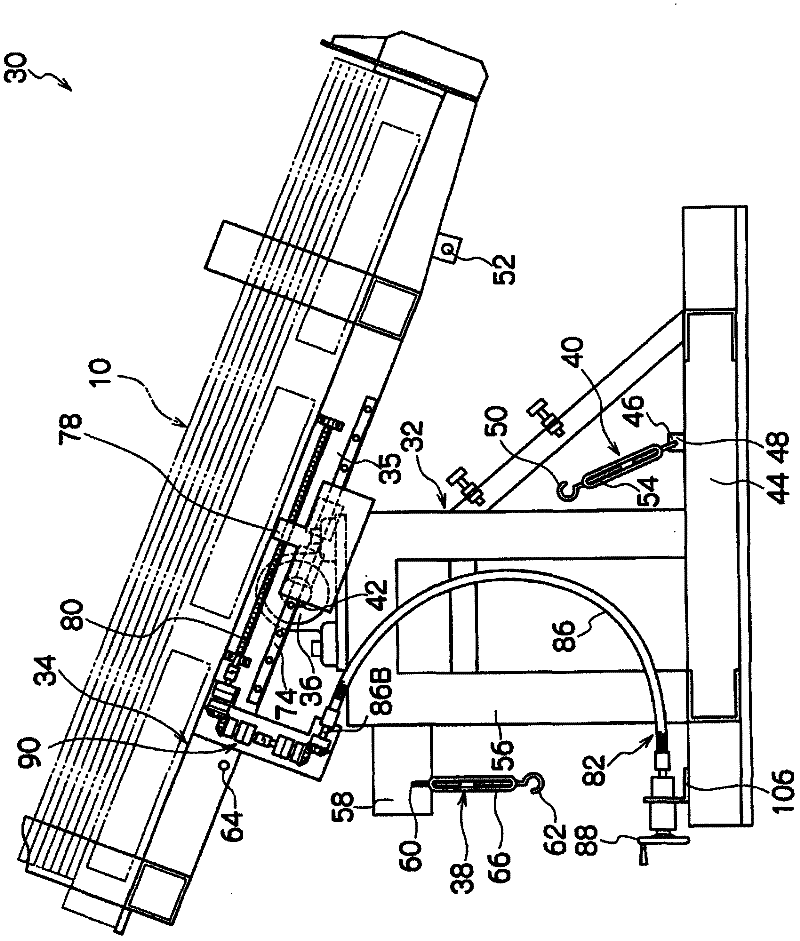

[0033] Hereinafter, preferred embodiments of a loading device for a plate-shaped object according to the present invention will be described with reference to the drawings.

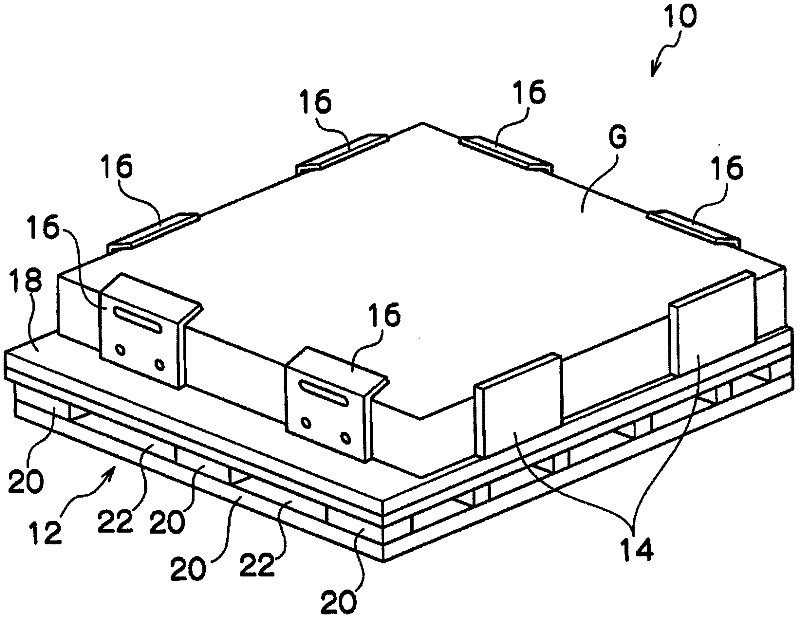

[0034] figure 1 It is an overall perspective view showing an example of the storage tray 10 loaded in the plate-shaped object loading device of the embodiment.

[0035] In the storage tray 10 shown in this figure, a plurality of, for example, 80 to 142 rectangular glass plates G are horizontally sandwiched between the glass plates G with rectangular papers ( not shown) and stored. The glass plate G shown in the embodiment is used for a flat panel display (FPD), and is a mother glass substrate with vertical and horizontal dimensions of about 3200×3000 (mm), and a plate thickness of 1 mm or less. In addition, the size of the glass plate G is not limited to this, and the loading apparatus of the plate-shaped object of embodiment is suitable for loading such a large glass plate as mentioned later.

[0036] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com