Small centrifugal water pump with impeller directly driven by internal rotor motor

An electric motor and centrifugal technology, applied in the direction of non-variable pumps, machines/engines, liquid fuel engines, etc., can solve the problems of complicated conduit connection structure, processing and installation, loose joints, and prone to water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are mainly improvements to the applicant's prior art products. Relevant designs of these prior art products can be found in the applicant's prior utility model patent specifications CN 200420047013, CN 200620054699 and CN 200720148584. For the relevant content of the prior art that needs to be applied in the embodiment of the present invention, which is not described in this application document, the above specification can be referred to.

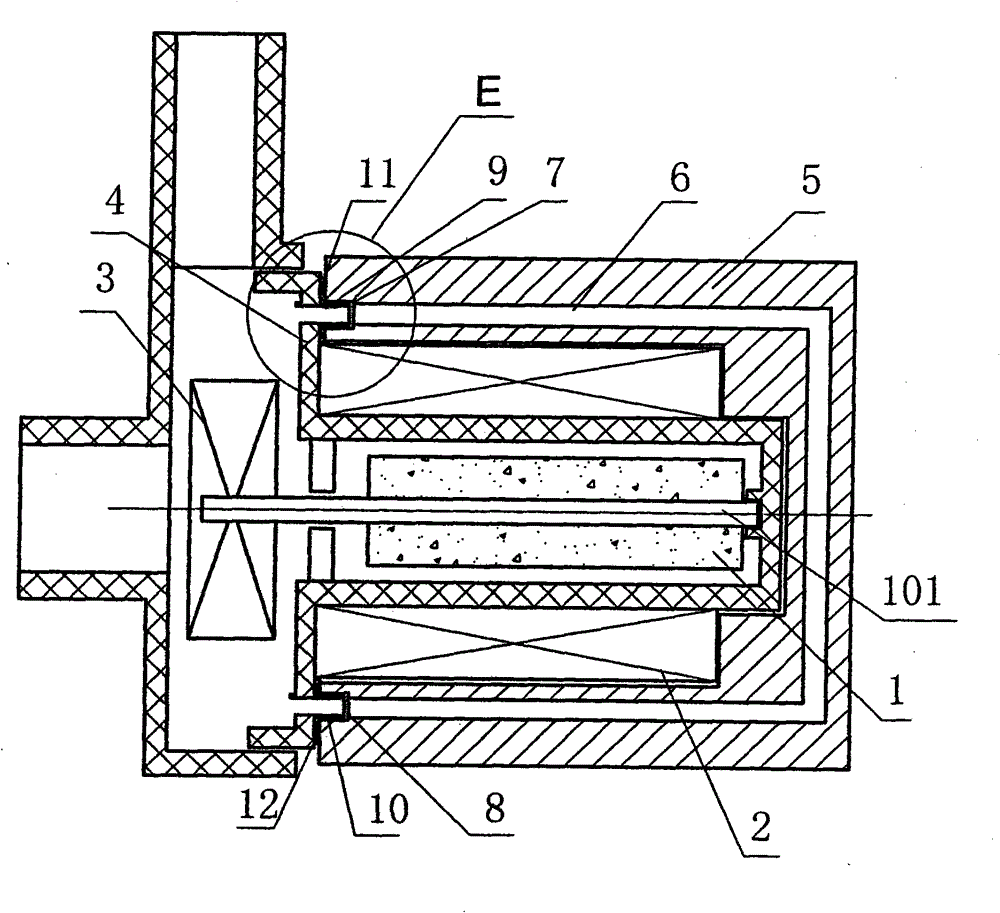

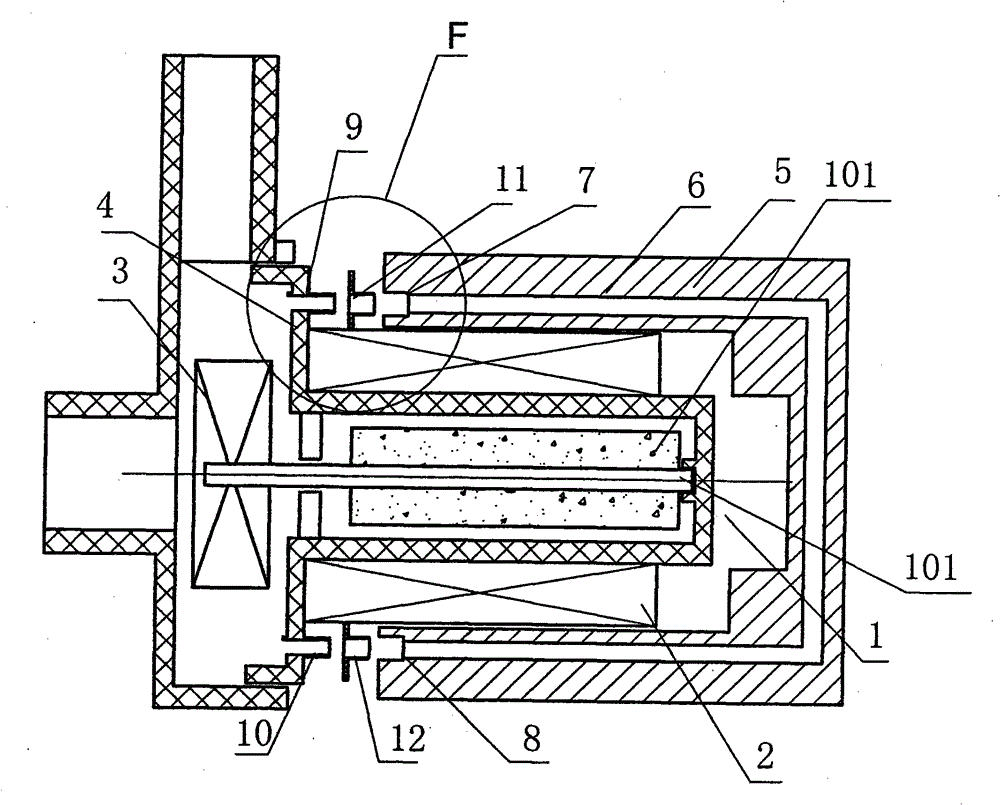

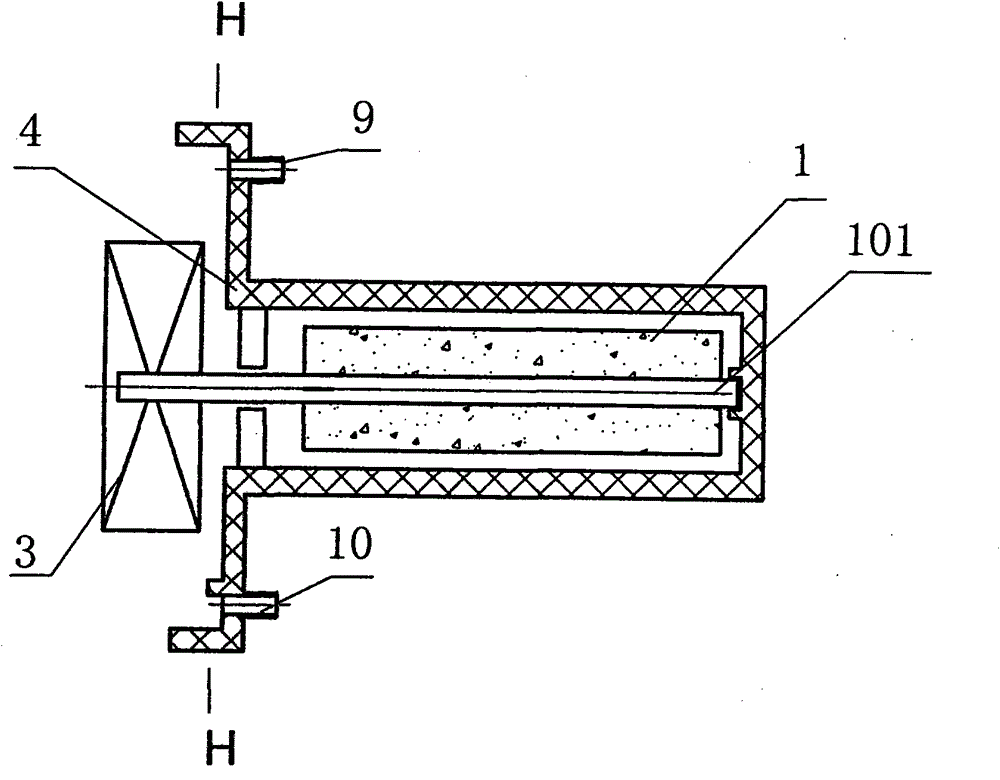

[0029] The structure of the small centrifugal water pump in the first embodiment of the present invention is as follows: figure 1 , figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 11 with Figure 12 As shown, it is mainly composed of three parts: motor, pump structure and water cooling structure.

[0030] Motors include:

[0031] - permanent magnet rotor 1;

[0032] - the stator core 2, the inner hole of which surrounds the rotor 1, and its shape is roughly cuboid;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com