Lighting device with microstructured brightness enhancing film

A lighting device and brightness enhancement film technology, which is applied in the direction of lighting devices, lighting device components, lighting and heating equipment, etc., can solve the problems of reducing manufacturing costs, increasing manufacturing costs, and low central luminous intensity, so as to reduce manufacturing costs , Improve luminous efficiency, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

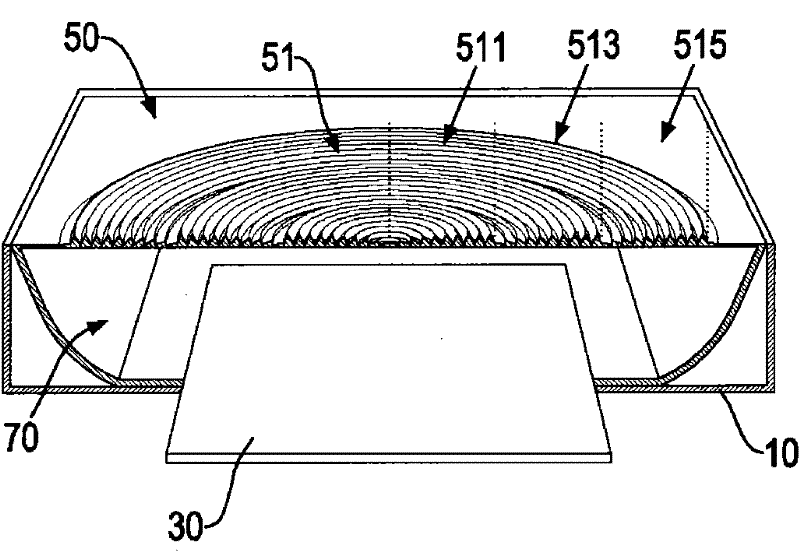

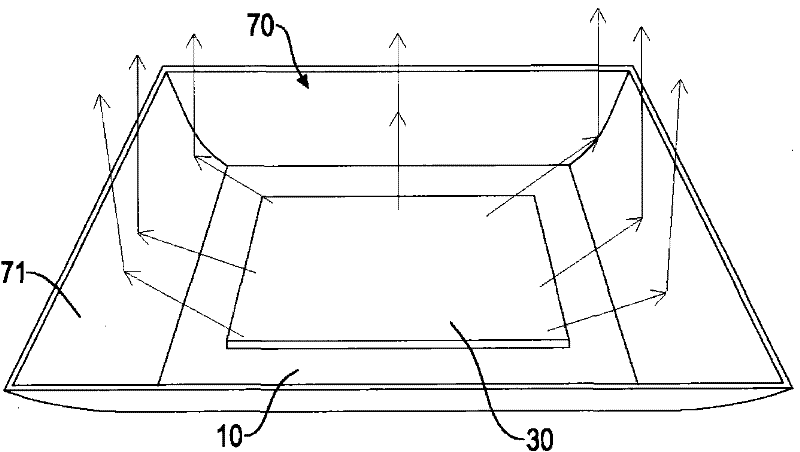

[0027] A first preferred embodiment of a lighting device with a microstructure brightness enhancing film provided by the present invention, such as figure 1 As shown, it includes: a casing 10, a planar light source 30, a microstructure brightness enhancement film 50, a reflector 70 and other components, wherein:

[0028] Such as figure 1 As shown, the housing 10 is hollow, and the housing 10 is a component of the prior art, and is not the focus of the present invention, and its detailed structure will not be repeated.

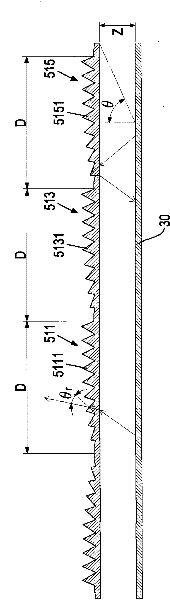

[0029] Such as figure 1 , 2 As shown, the planar light source 30 is horizontally fixed in the casing 10 and has a top surface. Preferably, the planar light source 30 is formed by a plurality of organic light emitting diodes arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com