Laser-micro-engraving process and laser-micro-engraving machine

A laser engraving and laser machine technology, applied in decorative arts, processing models, etc., can solve problems such as missing graphics, reduce contact probability and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, a laser engraving process, the steps are as follows:

[0053] The first step is to turn on the internal engraving machine, edit the pattern and text to be engraved, operate the counting software according to the pattern and text of the product, and then set the number of processing layers to 3 layers and the processing distance to 0.86;

[0054] If the number of processing layers is set below 3 layers, the fineness of the pattern will not be high, and the pattern density will be insufficient, which will make the continuity of the pattern lines poor; if the number of processing layers is higher than 3 layers, the processed pattern will be blurred.

[0055] If the processing distance is lower than 0.86, the fineness will not be high, and the pattern density will not be enough, which will make the continuity of the pattern lines poor; if the processing distance is higher than 0.86, the inner carving will rot.

[0056] The second step is to wipe the object to ...

Embodiment 2

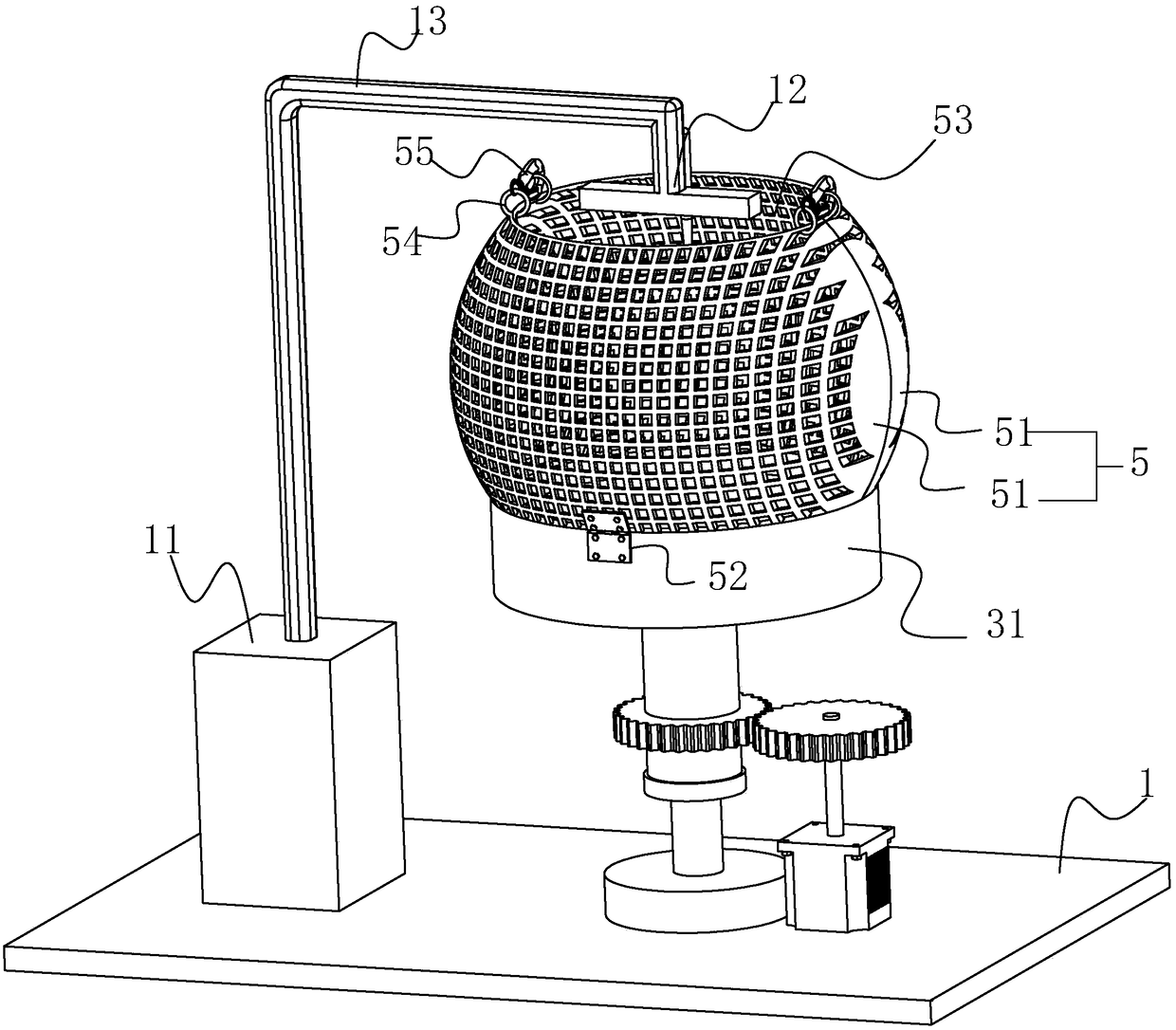

[0062] Embodiment 2, laser engraving machine, such as figure 1 As shown, it includes a machine base 1, which is a flat metal plate on which a laser machine 11 is fixed, and the laser machine 11 is provided with a laser head 12 for projecting laser light.

[0063] The laser machine 11 and the laser head 12 are connected by a connecting rod 13; the laser head 12 is on the upper end of the connecting rod 13, and the laser head 12 projects the laser line downward. The laser head 12 can be rotated by computer control to form the required laser line;

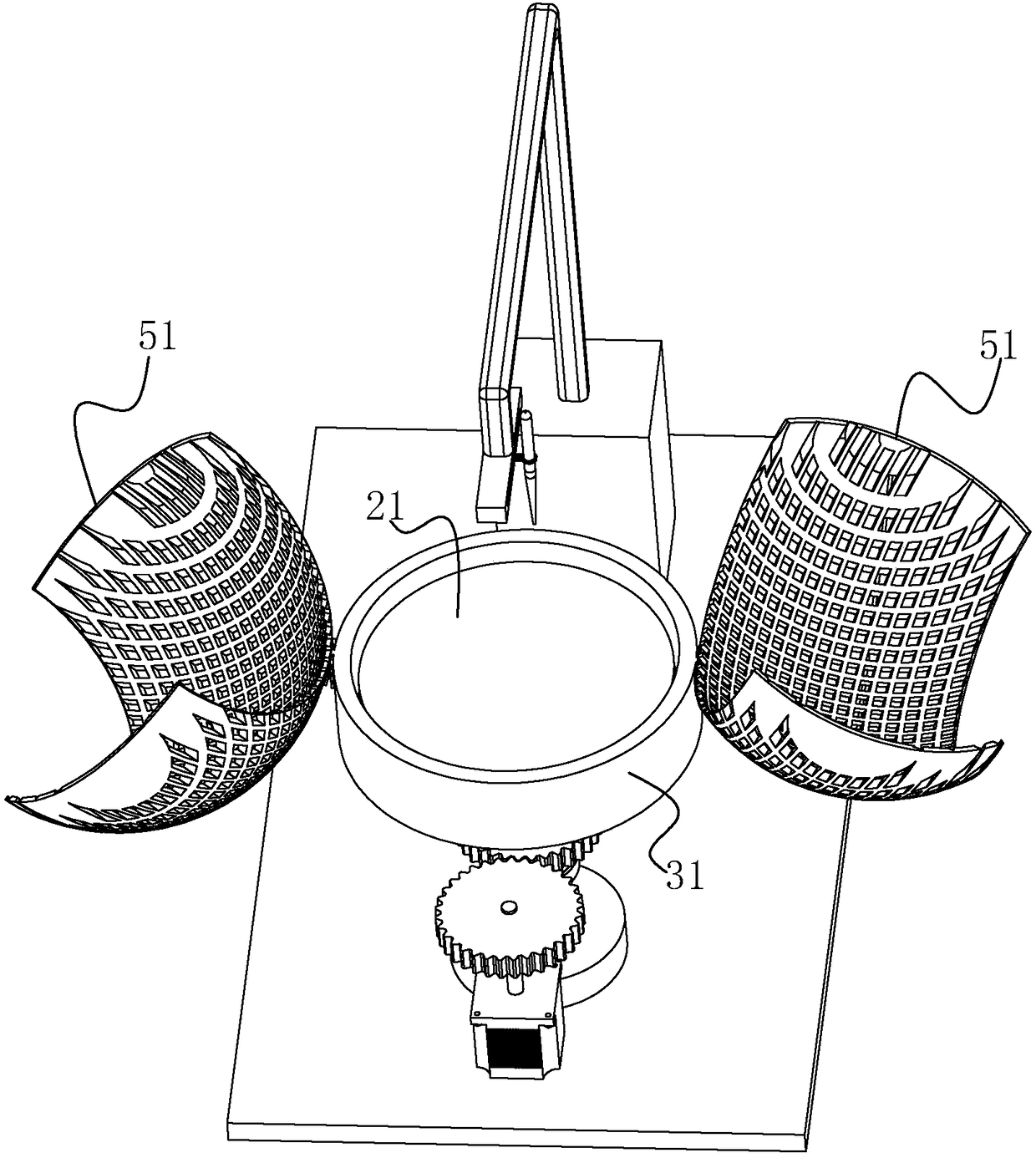

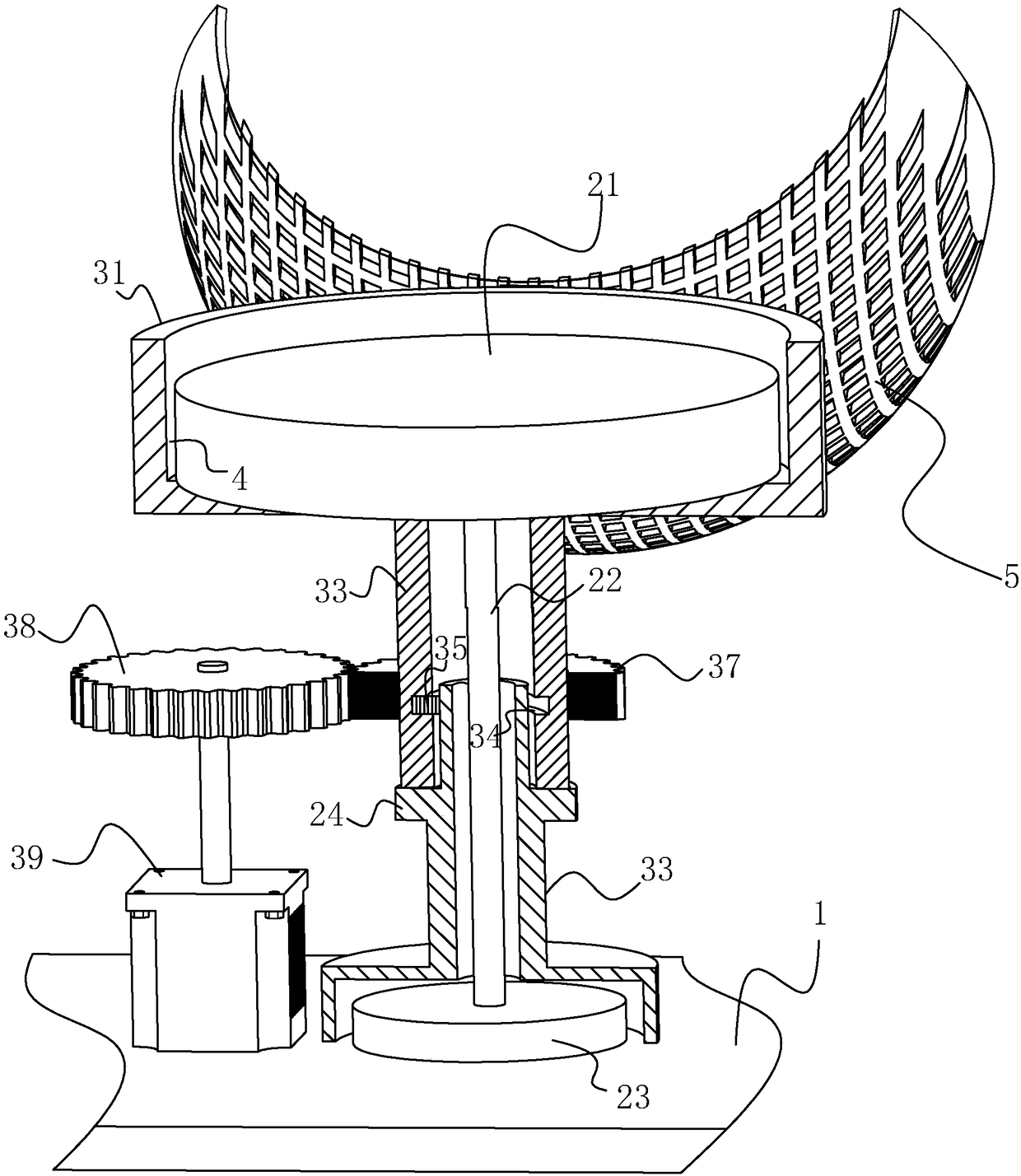

[0064] A metal mesh cover 5 is installed on the upper surface of the machine base 1, and the metal mesh cover 5 includes two hemispherical metal mesh sheets 51, and the two metal mesh sheets 51 are rotatably connected to both sides of the swivel 31 through hinges 52;

[0065] The metal mesh sheets 51 are folded together to form a spherical shape. At this time, the lower edges of the metal mesh sheets 51 collide with the swivel 31, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com