A new type of notebook keyboard

A notebook and keyboard technology, applied in the field of new notebook keyboards, can solve the problems of increased production cost, complex printed circuit process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

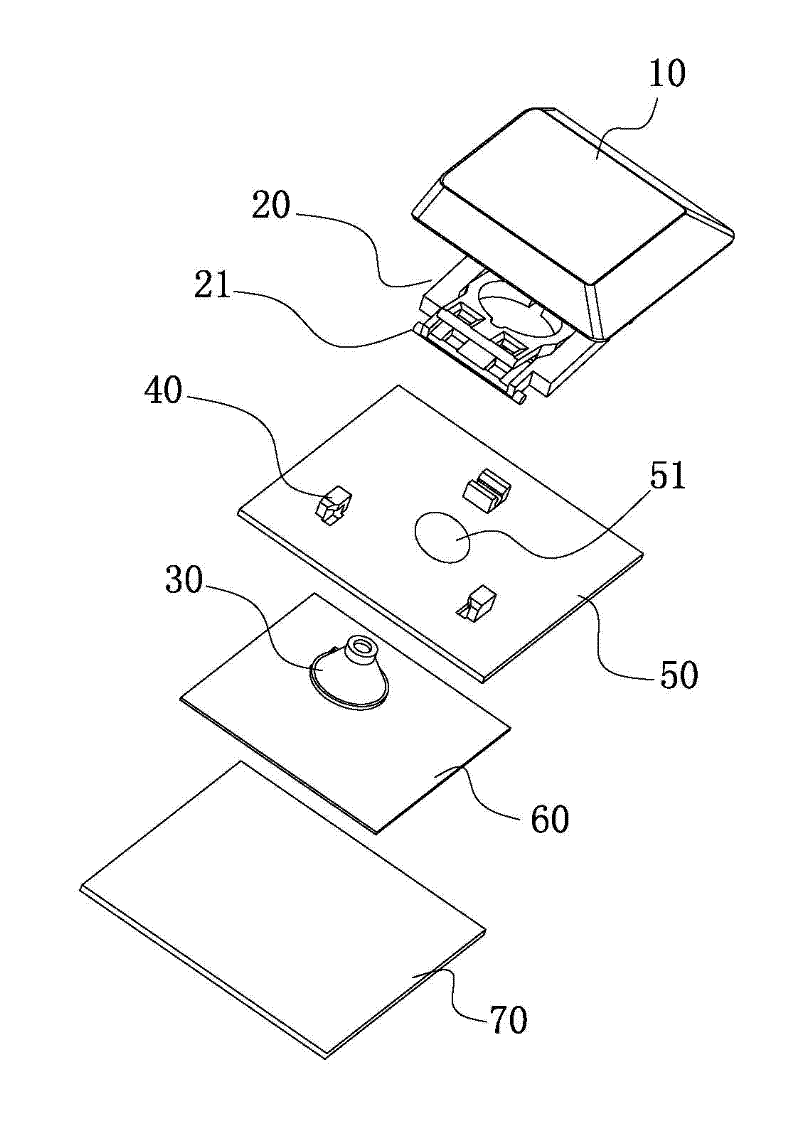

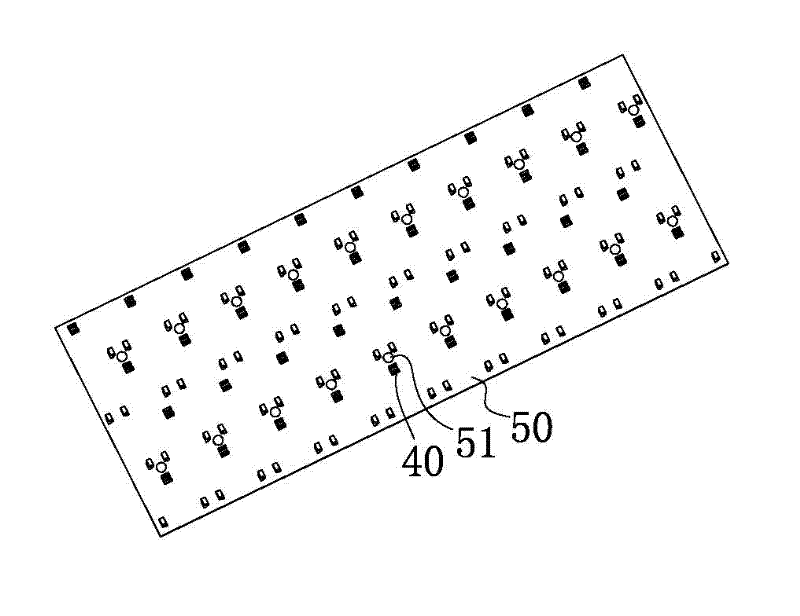

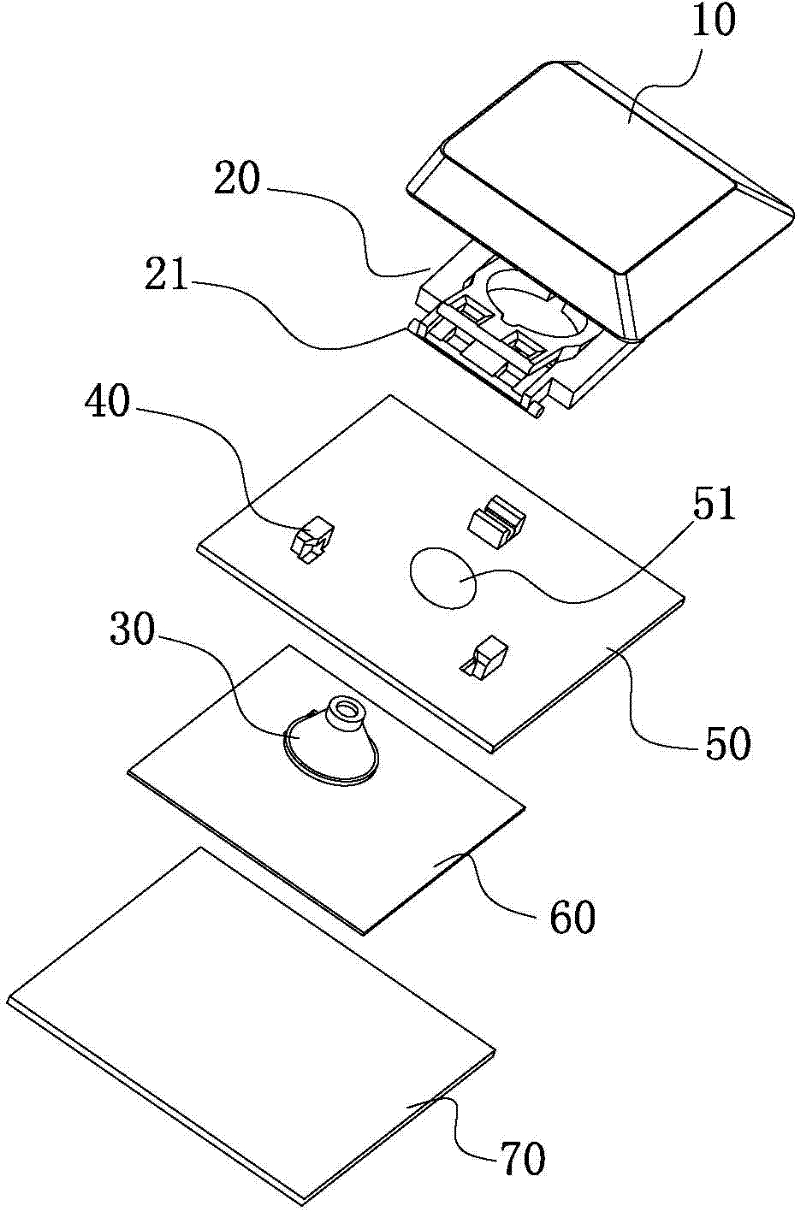

[0010] Such as Figure 1-2 As shown, a kind of novel notebook keyboard of the present invention comprises: some button caps 10 distributed at intervals, some scissor feet 20 corresponding to the button caps 10 one-to-one, and several elastic silicone bodies 30, and several scissor feet The lower pins 21 of 20 correspond to several lower pin holders 40, the keyboard middle plate 50, the printed circuit film 60 and the keyboard bottom plate 70, and the bottom surface of the keycap 10 is provided with an upper pin holder. After assembly, the scissors feet 20 The upper pins of the scissors feet 20 are plugged and fixed on the upper pin fixing seat, and the lower pins 21 of the scissors feet 20 are plugged and fixed on the lower pin fixing seat 40, and each of the lower pin fixing seats 40 and the keyboard middle plate 50 are made of plastic material. The same plastic part of injection molding; the printed circuit film 60 is arranged on the bottom of the keyboard middle plate 50, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com