Method for detecting smoothness of high-speed railway track

A high-speed railway and detection method technology, applied in the field of optical measurement, can solve problems such as uneven measurement accuracy, long-wave irregularity, and limited measurement accuracy, and achieve the effects of suppressing errors, high-stability measurement, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing

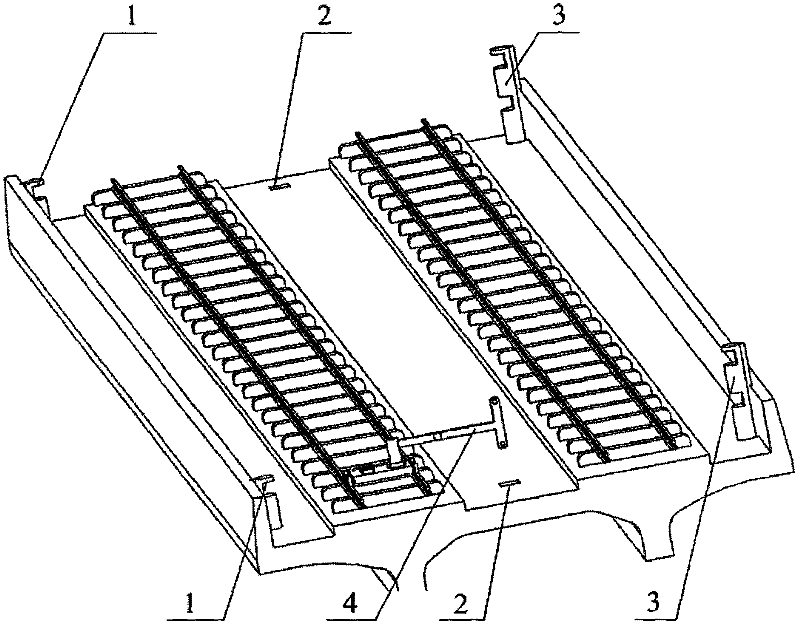

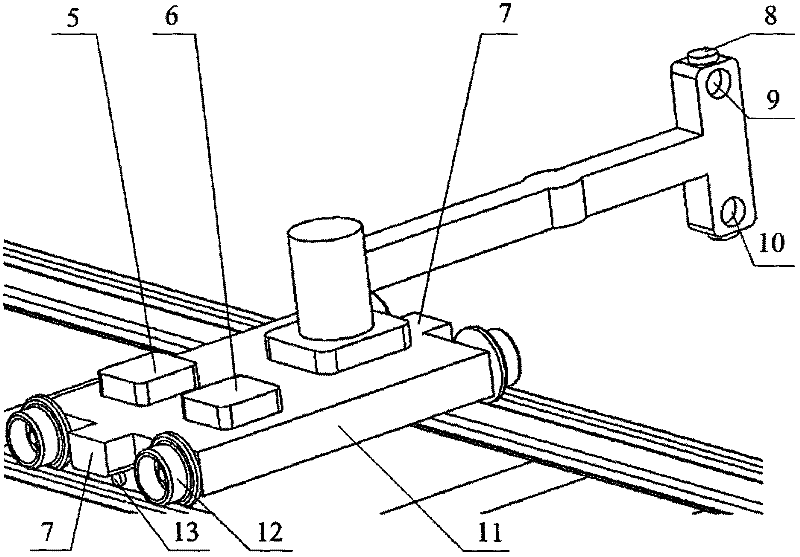

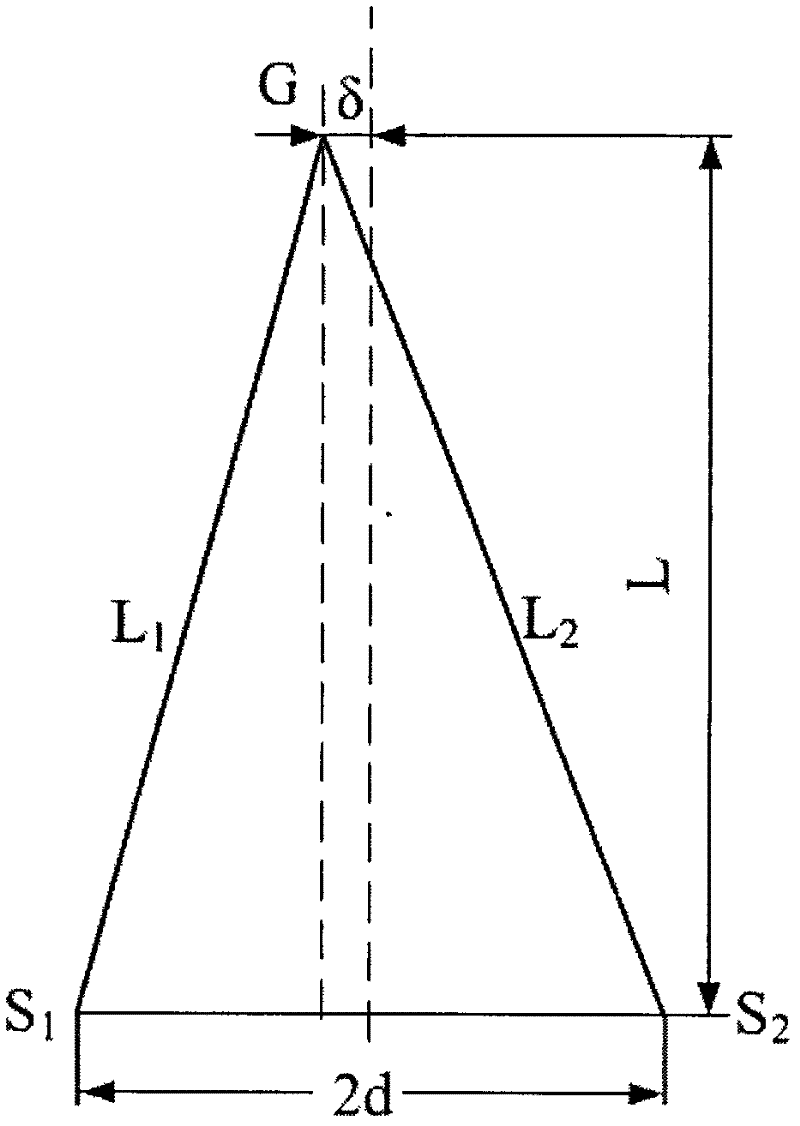

[0025] Such as figure 1 and figure 2 , a kind of detection method of track smoothness of high-speed railway involved in the present invention, mainly is made up of measuring trolley (4), optical reference station (2) and reference mark post, and wherein measuring trolley (4) mainly comprises lateral phase-locked measuring head ( 10), vertical phase-locked measuring head (9), automatic leveling plummet (8), gauge laser measuring device (13), horizontal laser distance measuring device (7), trolley body (11), trolley wheel rail (12), a power supply and drive module (5) and a data processing and storage module (6), and the benchmark includes a benchmark A type (1) and a benchmark B type (3).

[0026] The reference mark A type (1) has a spherical prism, the reference mark B type (3) has two vertically separated spherical prisms, and the spherical prism is used as a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com