Apparatus and method for controlling and/or regulating temperature of a heating device for preforms

一种加热装置、温度控制的技术,应用在预制件温度控制用加热装置领域,能够解决热增加等问题,达到防止过多偏离、精确温度调节、快速调节的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Identical or equivalent elements of the invention are marked with the same reference numerals. Also for the sake of clarity, only the reference numbers relevant to explaining the various figures are provided. It should be understood that the detailed description and specific examples, while indicating the preferred embodiment, of the apparatus and methods according to the invention are intended for purposes of illustration only and are not intended to limit the scope of the invention.

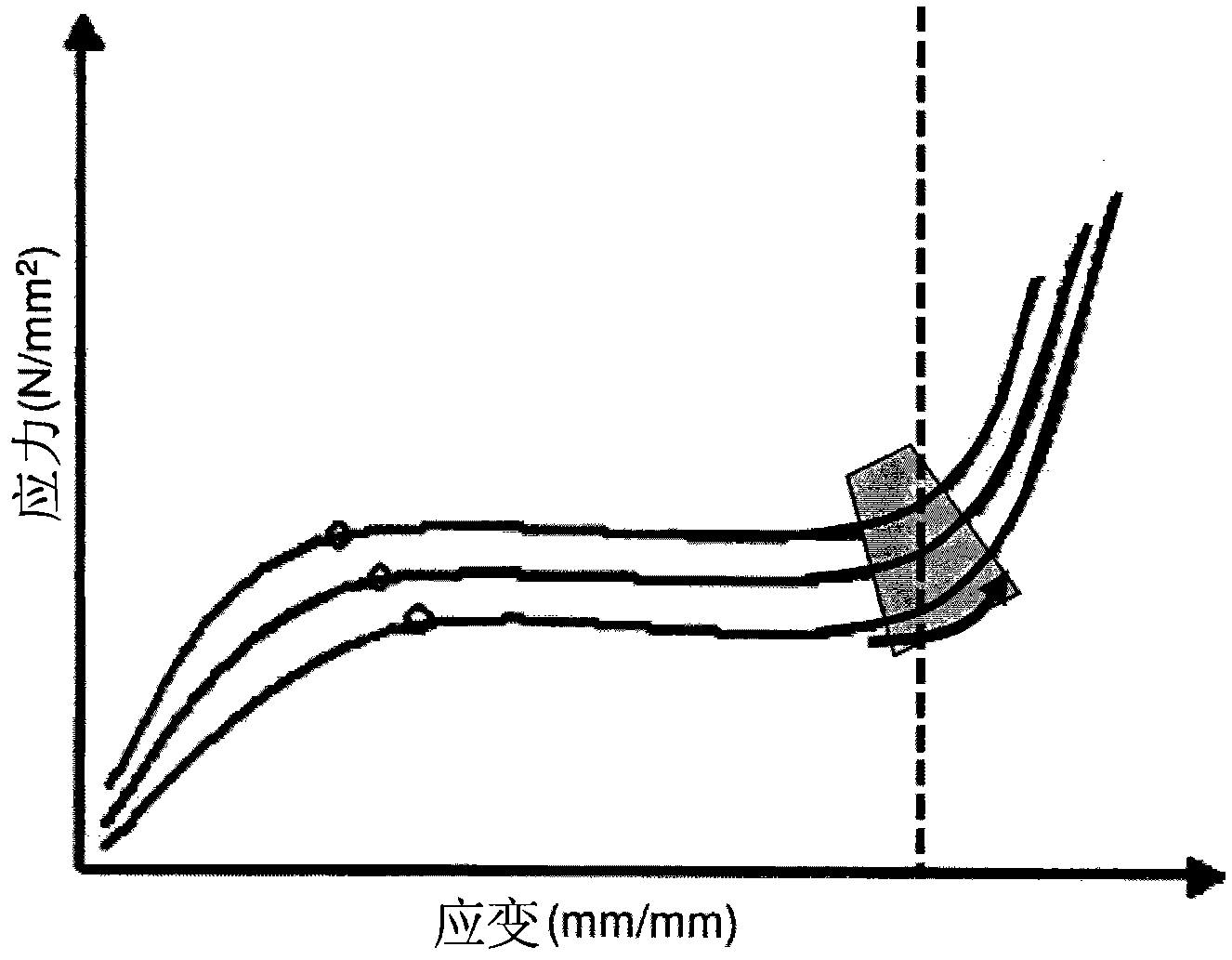

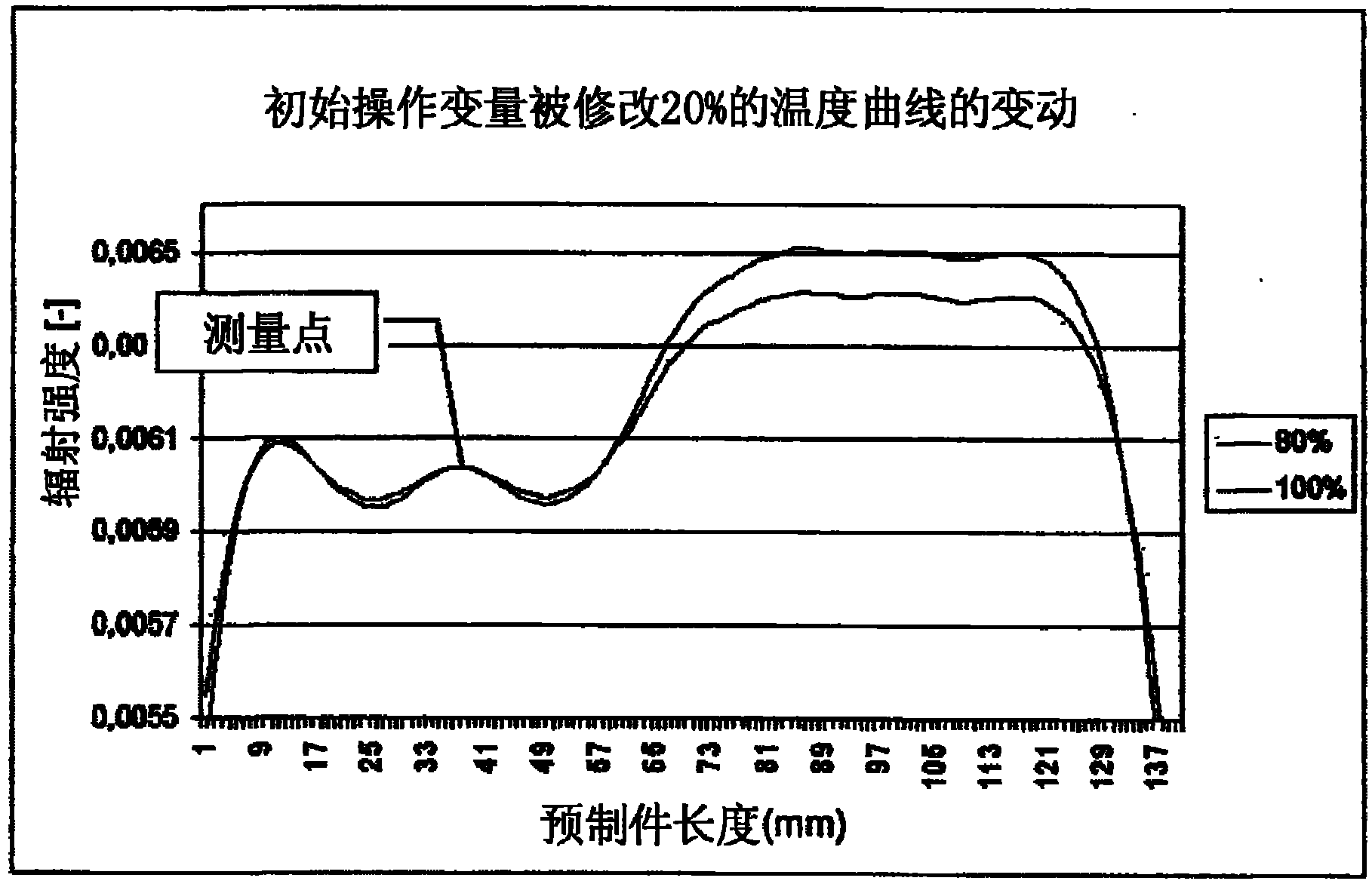

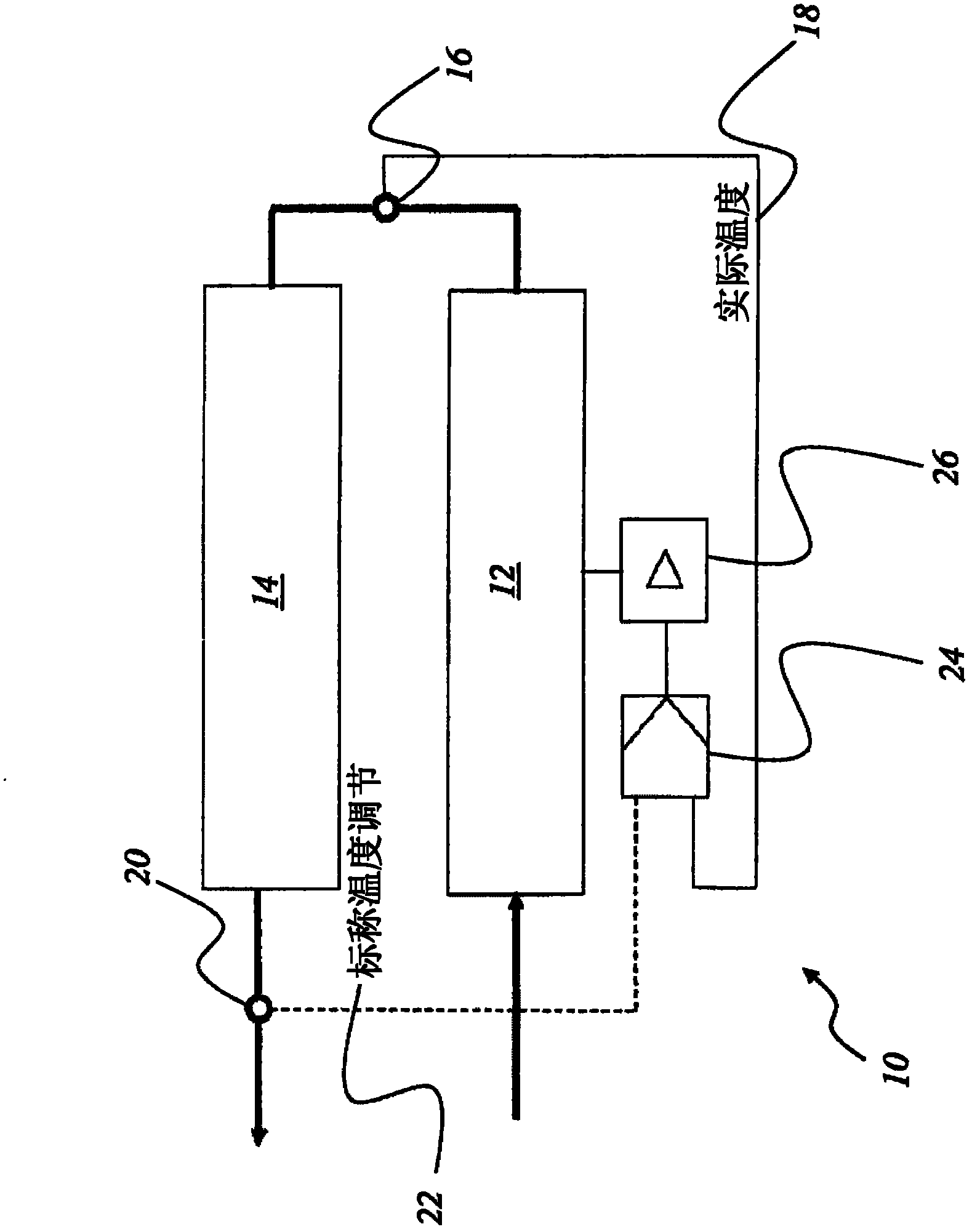

[0064] figure 1 The qualitative diagram given in shows the relationship between the strain and the resulting material stress when a PET material is deformed when it is used to stretch blow mold a beverage container. Here, the horizontal axis is the strain and the vertical axis is the resulting material stress. This graph is considered exemplary. At an initial low strain, they show an approximately linear rise curve of the stress, which then flattens out along a further section, result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com