Pressure reducing valve

A pressure reducing valve and valve body technology, which is applied in the field of pressure reducing valves, can solve the problems of not meeting the requirements of water flow, narrowness, etc., and achieve the solution of asymmetrical elastic decay, stable water outlet without vibration, and avoiding water hammer impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

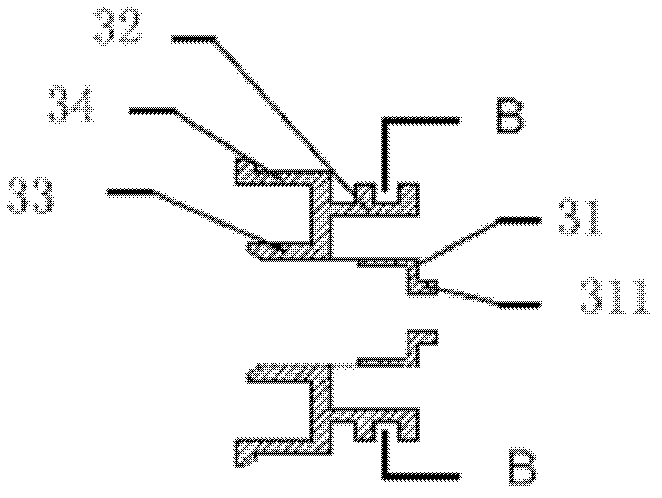

[0036] On the basis of the above-mentioned implementation, this embodiment provides another matching method for the connection structure between the valve core seat and the front cover, as follows:

[0037] see Figure 9 , the inner cavity of the front cover is provided with an internal thread, and the outer circular wall of the ring part 32 of the valve core seat is provided with an internal thread suitable for the thread of the inner cavity of the front cover, and an O-ring is arranged above the valve part of the valve core seat 5. The valve part of the valve core seat squeezes the O-ring 5 against the top of the inner cavity of the front cover, so that an end face seal is formed between the front valve cavity and the valve core seat. Due to the threaded connection structure, the valve core seat can cancel the outer base which plays a role of fixed installation, and correspondingly cancel the groove and clamping hole on the front cover.

[0038] Furthermore, since the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com