Air conditioner and air-conditioner indoor machine

A technology for indoor units and air conditioners, applied in the direction of airflow control components, etc., can solve the problems of greatly affecting the air volume, affecting the performance of the air conditioner, and reducing the air outlet area of the air outlet, etc., to achieve the effect of automatic air guiding and automatic sweeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

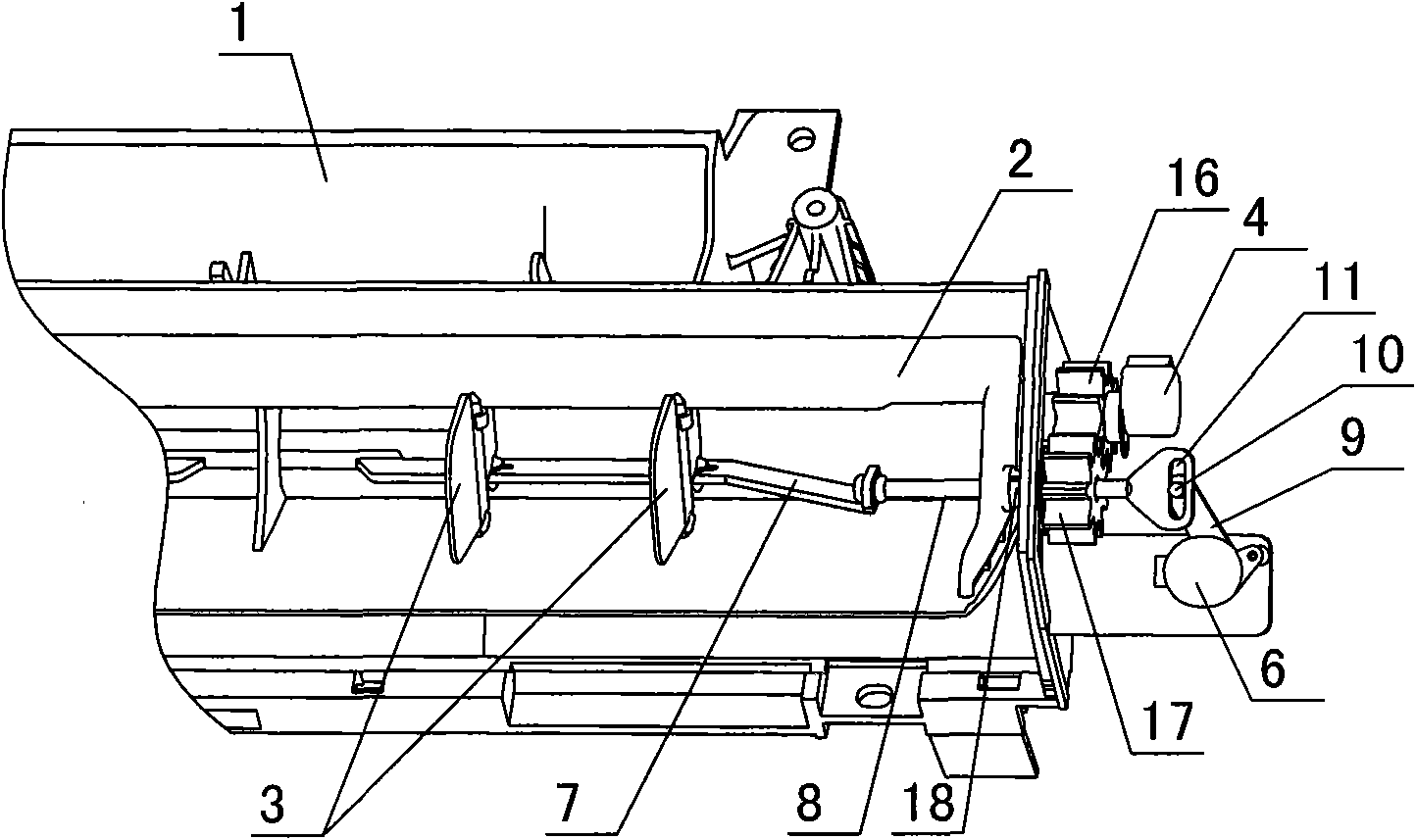

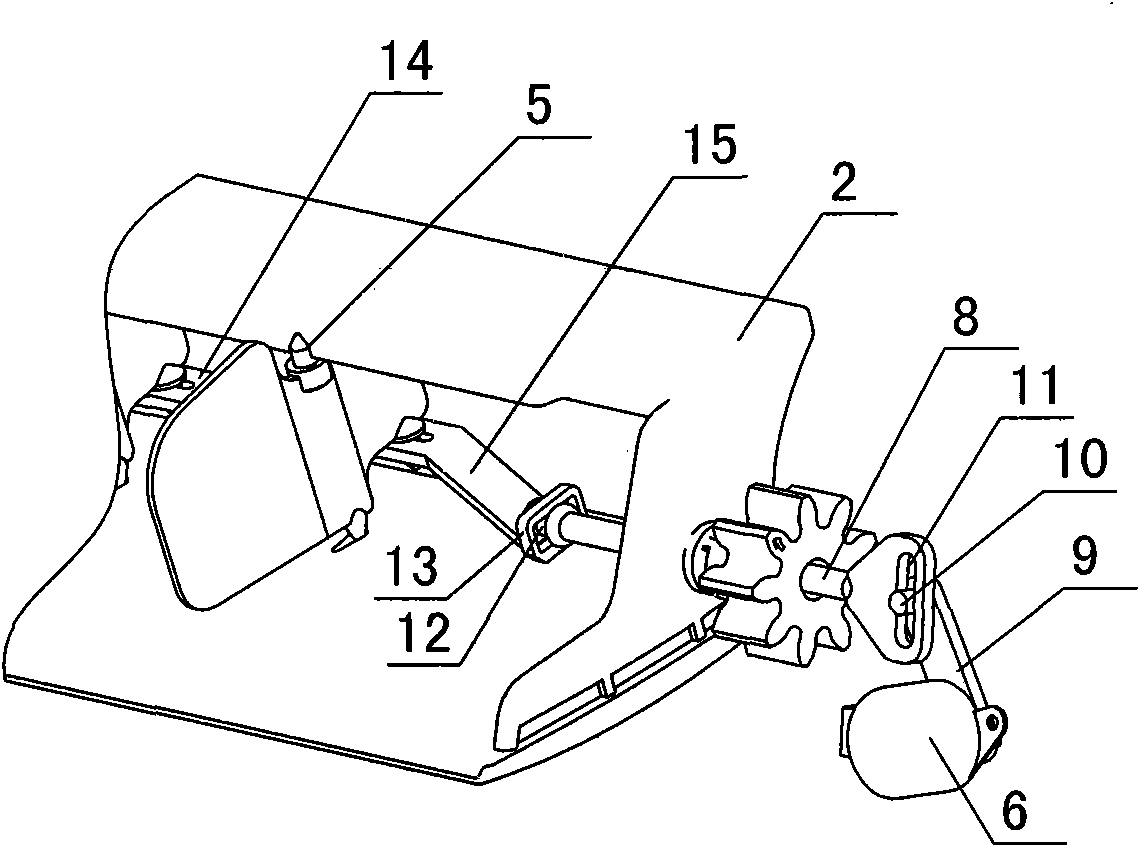

[0031] like figure 1 , figure 2 and image 3 As shown, an indoor unit of an air conditioner includes an indoor unit casing 1, an air deflector 2 and a sweeping vane 3, and the first end and the second end of the air deflector 2 are respectively connected to the indoor casing through a horizontal rotating shaft 18. On the first end and the second end of the body 1, the sweeping blades 3 are movably connected to the wind deflector 2 through the blade rotating shaft 5, and the wind deflector 2 guides the driving mechanism 4 (in this embodiment, the deflector The wind driving mechanism 4 is connected by the wind guide motor), and also includes a first connecting rod 7 and a second connecting rod 8 that are movably connected. After the second connecting rod 8 passes through the sliding hole, it is connected with the sweeping wind driving mechanism 6 (in this embodiment, the sweeping wind driving mechanism 6 is a sweeping wind motor).

[0032] In this embodiment, the wind deflec...

Embodiment 2

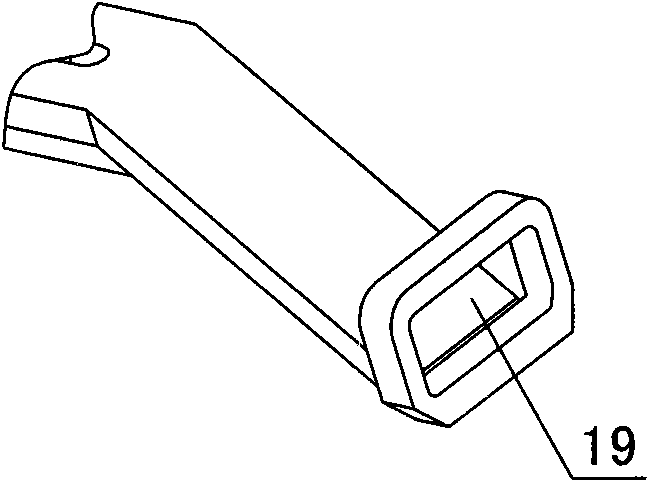

[0039] like Figure 4As shown, the difference between this embodiment and Embodiment 1 is that the sliding hole is arranged in the horizontal shaft at the first end of the wind deflector 2, the first connecting rod 7 is connected with the sweeping blade 3, and the horizontal shaft The center of 18 is provided with a sliding hole, and the second connecting rod 8 passes through the sliding hole and is connected with the sweeping drive mechanism 6 for driving the sweeping blade 3, and the second end of the wind deflector 2 passes through the horizontal shaft 18 It is connected with the wind guide driving mechanism 4 for driving the wind guide plate 2 . In this embodiment, the wind sweeping driving mechanism 6 and the wind guiding driving mechanism 4 are installed at both ends of the wind deflecting plate 2 respectively, and its working principle is the same as that of the first embodiment.

Embodiment 3

[0041] like Figure 5 As shown, the difference between this embodiment and the second embodiment is that this embodiment also includes a gear 20, and a rack 21 meshing with the gear 20 is provided at the end of the second connecting rod 8, and the sweeping wind The driving mechanism 6 is a blower motor, and the output shaft of the blower motor is connected with the gear 20 . Through the gear 20 and the rack 21 , the rotational motion of the wind sweeping motor can also be converted into a left and right reciprocating motion, thereby driving the swing of the wind sweeping blades 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com