System and method for real-time measurement of gas-solid two-phase flow field

A real-time measurement and flow field technology, applied in fluid velocity measurement, measurement device, velocity/acceleration/impact measurement, etc., can solve the problems of small number of effective discrete phase particle images, unrepresentative, poor real-time performance, etc. The effect of avoiding phase separation operations, increasing the number of effective samples, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

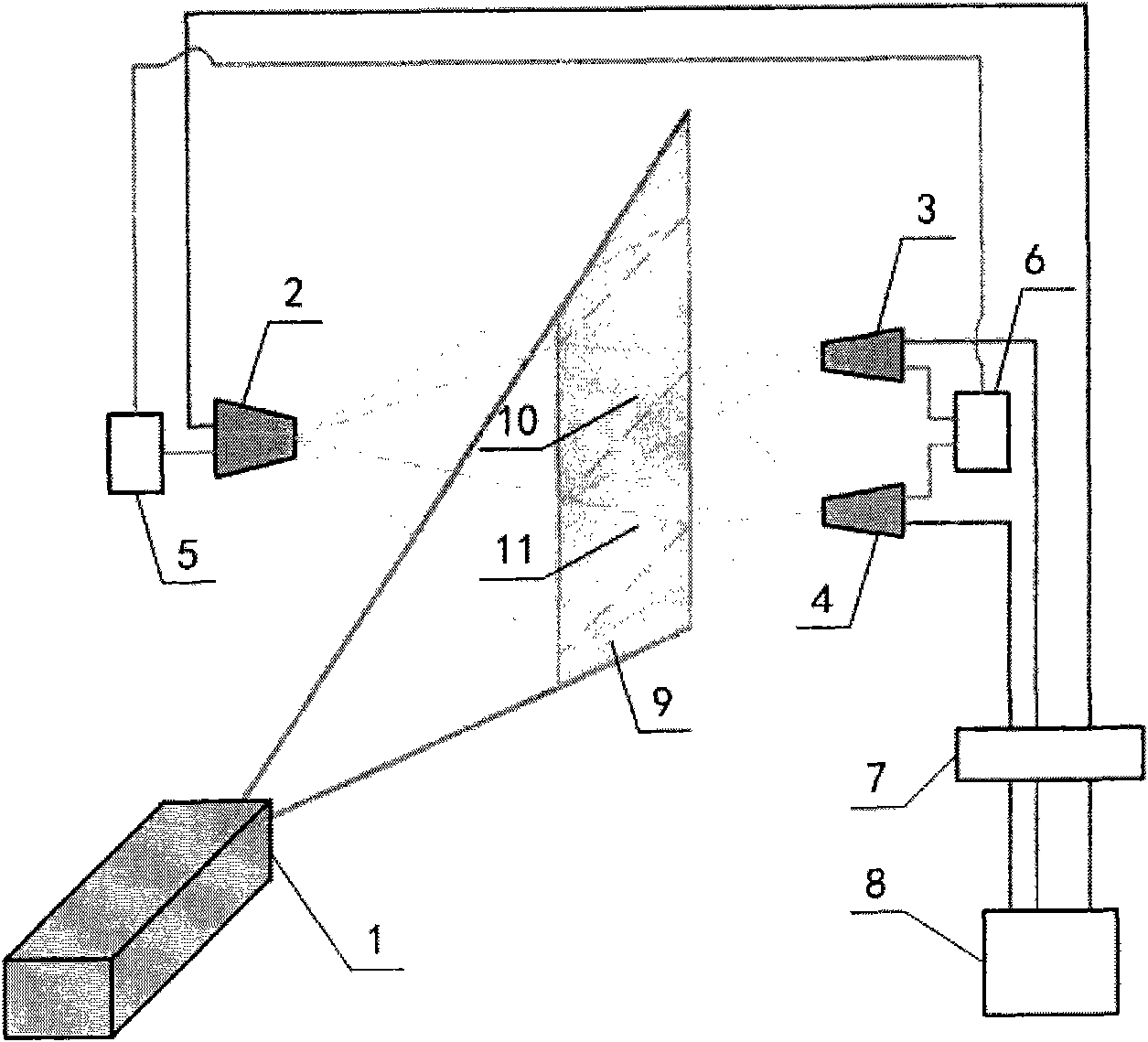

[0029] According to an embodiment of the present invention, a method for real-time measurement of a flow field of a gas-solid two-phase flow is provided. The method is based on figure 1 The real-time measurement system of the gas-solid two-phase flow field is realized. refer to figure 1 , the gas-solid two-phase flow field real-time measurement system in this embodiment includes: a high-energy laser sheet light source 1, a solid-phase digital high-speed camera 2 and corresponding auxiliary synchronization controller 5, two gas-phase digital high-speed cameras 3 and 4 and corresponding master synchronous controllers 6, a computer 7 loaded with one or more graphic processing units (GPUs), and a display screen or a display screen array 8 for real-time display of gas-solid two-phase motion vector images.

[0030] Among them, the solid-phase digital high-speed camera 2 is a low-resolution, high-frame transfer time digital high-speed camera for collecting motion trajectory images ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap