Camera lens

A camera lens and image square technology, applied in the field of camera lenses, can solve the problem that the total optical length of the lens cannot be further reduced, and achieve the effect of reducing the total optical length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The camera lens in this embodiment includes a single silicone lens, and is mainly used in the field of application of the camera lens that requires ultra-thinness.

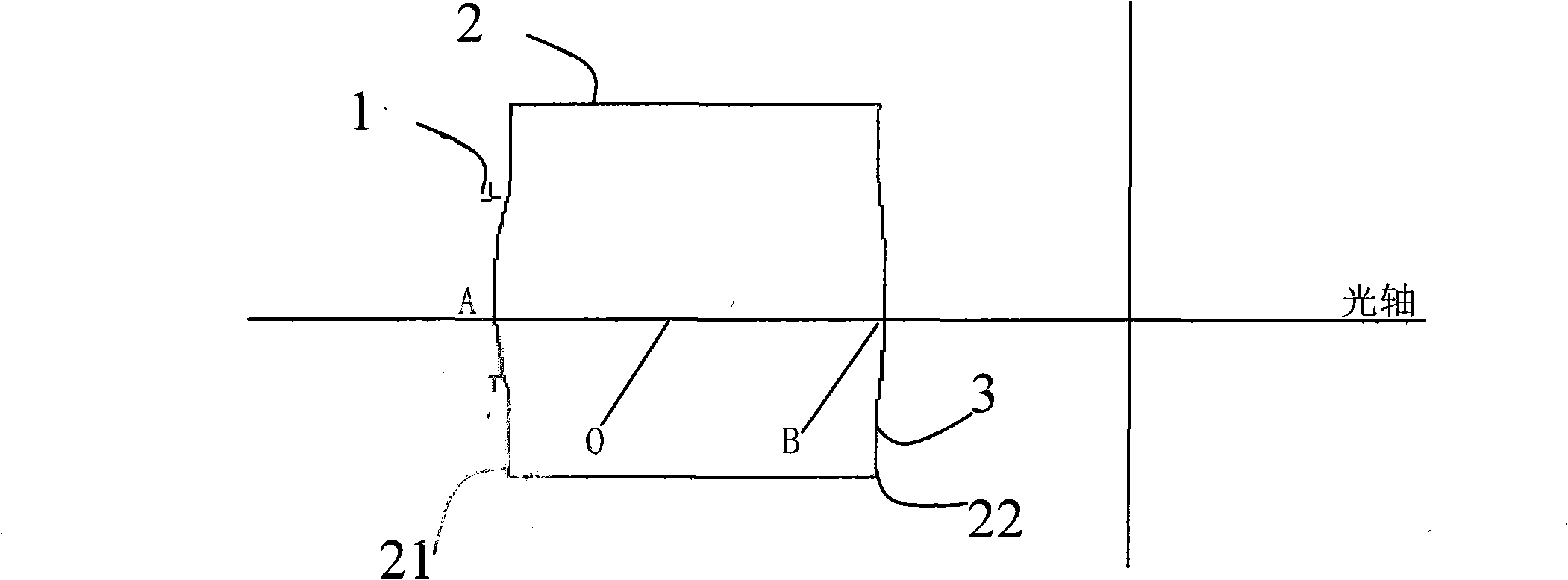

[0023] figure 1 It is a structural schematic diagram of the camera lens according to Embodiment 1 of the present invention. Please refer to figure 1 , the imaging lens provided by Embodiment 1 of the present invention includes a fixed diaphragm 1, a silicone lens 2 and an infrared filter film 3, and the silicone lens includes a first surface 21 and a second surface 22 in sequence from the object side to the image side, and the fixed The aperture 1 and the silicone lens 2 form a coaxial optical system. The first surface 21 is aspherical and convex to the object side, the second surface 22 is aspheric and convex to the image side, the first surface 21 and the second surface 22 are asymmetrical with respect to the lens centerline, therefore, the The silicone lens 2 is an asymmetrical drum type. The lens ce...

Embodiment 2

[0043] refer to Figure 5 , propose the second embodiment of the present invention, this embodiment is based on the first embodiment, and further proposes the relevant parameters of the camera lens as follows:

[0044] Table three

[0045]

[0046]

[0047] Table 4: Aspherical Coefficients

[0048] first surface

second surface

a1:0.015408005

a1:2.8169146

a2:1.0521064

a2:-0.61458389

a3:-22.564498

a3:66.460052

a4:112.23604

a4:-696.8954

a5:0

a5:3395.6174

a6:0

a6:-6242.5572

[0049] In Table 3, the thickness d is the distance between one surface and the next surface, the total length of the camera lens is L=1.7mm, the effective focal length is f=1.4mm, and L / f=1.21>1.2.

[0050] In this embodiment, the refractive index of the silica gel lens is n=1.52, and the dispersion value v=43.

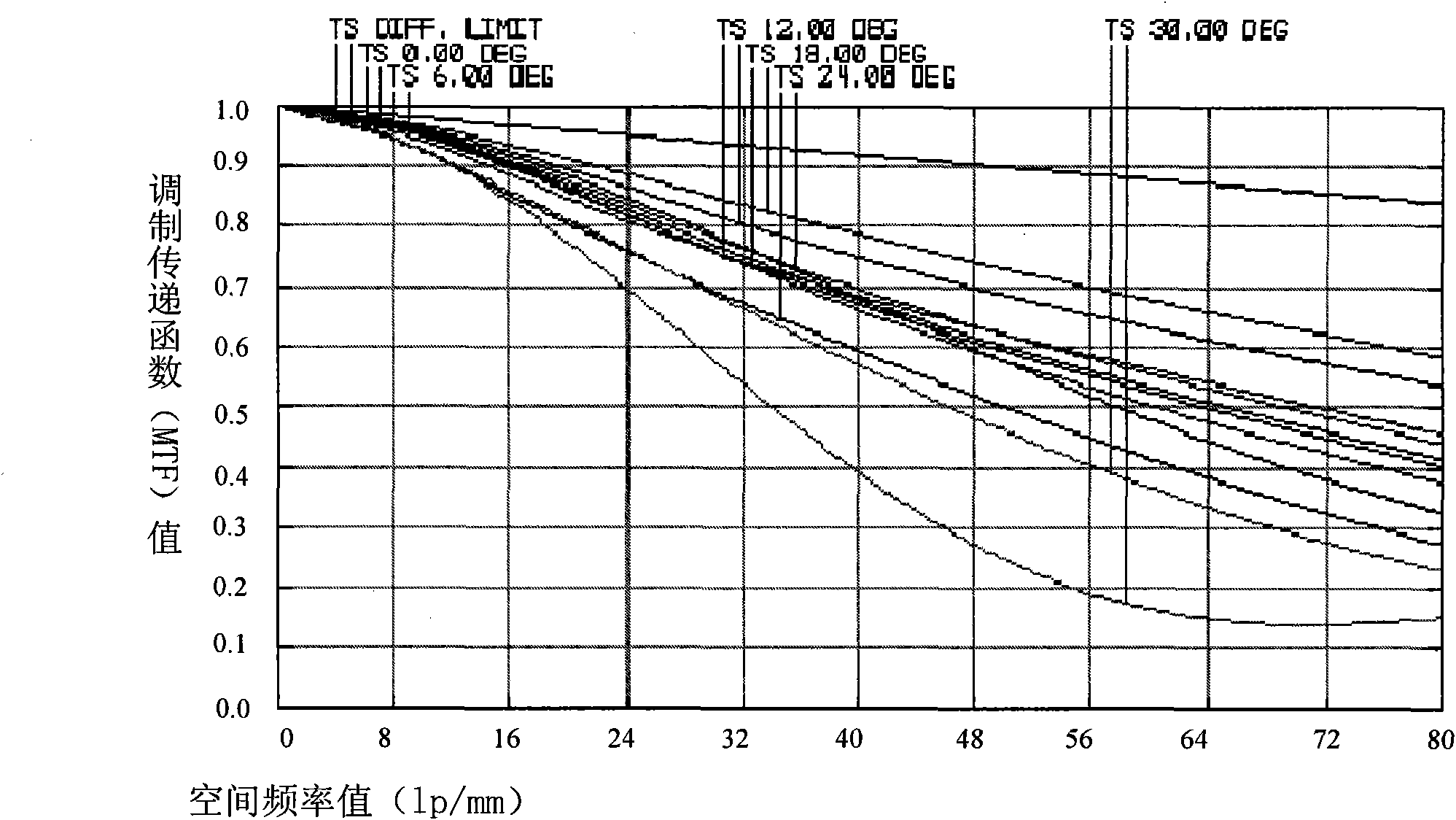

[0051] Figure 6 It is the modulation transfer function (Modulation Transfer Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com