Power source device

A technology of a power supply device and a forward converter, which is applied to emergency protection circuit devices, electrical components, conversion equipment for intermediate conversion to DC conversion, etc., can solve the problems of device output stop and reduced operation reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

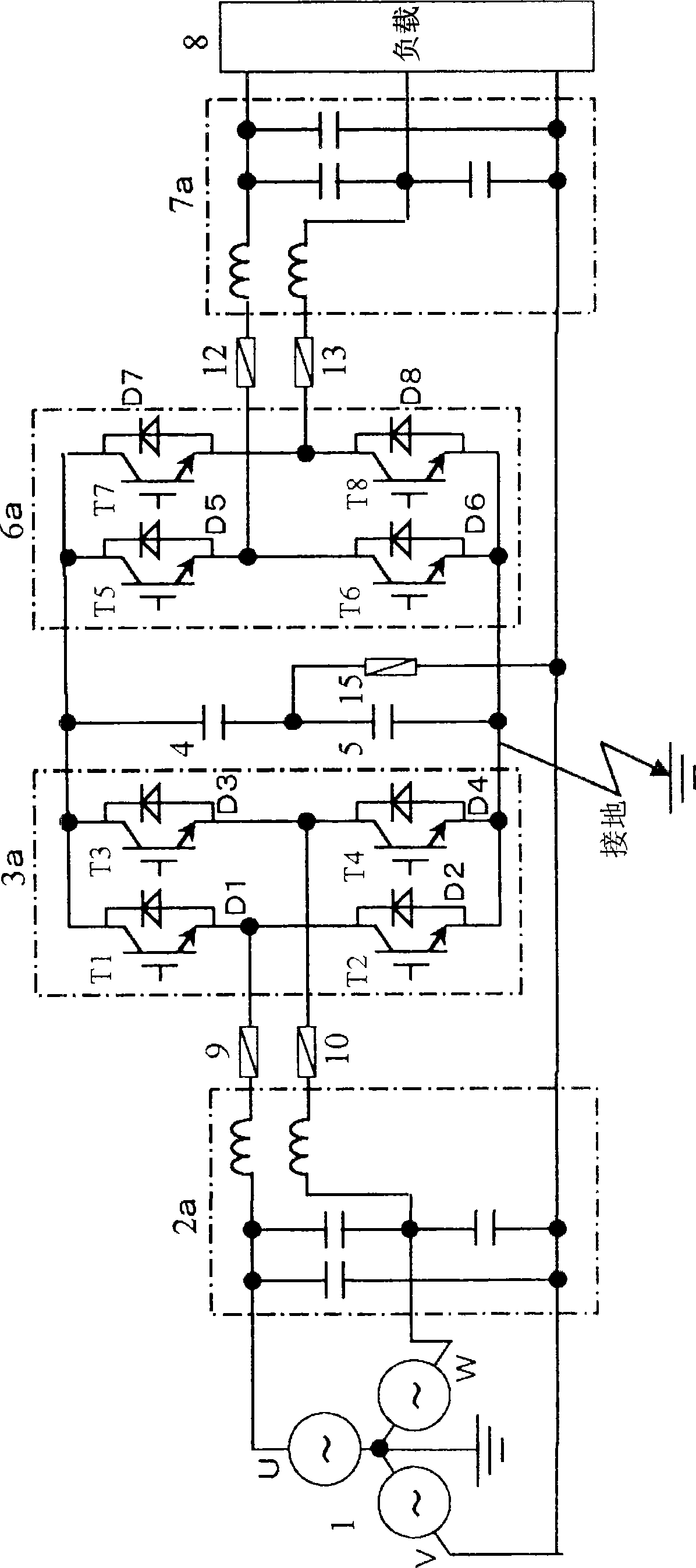

[0018] figure 2 shows the first embodiment of the present invention. The AC input of the forward converter 3a composed of IGBTT1-T4 and diodes D1-D4 is connected to the AC input filter 2a via fuses 9 and 10, and the input of the AC input filter 2a is connected to each of the three-phase AC power supply 1 respectively. connected. In addition, the output of inverter 6a composed of IGBT5-T8 and diodes D5-D8 is connected to AC output filter 7a via fuses 12 and 13, and the output of AC output filter 7a is connected to load 8, respectively. A series circuit of capacitors 4 and 5 is connected between the DC terminals of the forward converter 3a and the reverse converter 6a (between the positive pole and the negative pole), and the series connection point (neutral pole) of the capacitors 4 and 5 is connected to the 3-phase AC power supply The V-phase of 1 and the 1-phase of the load are connected via a fuse 15 .

[0019] The protection operation in such a structure will be describ...

Embodiment 2

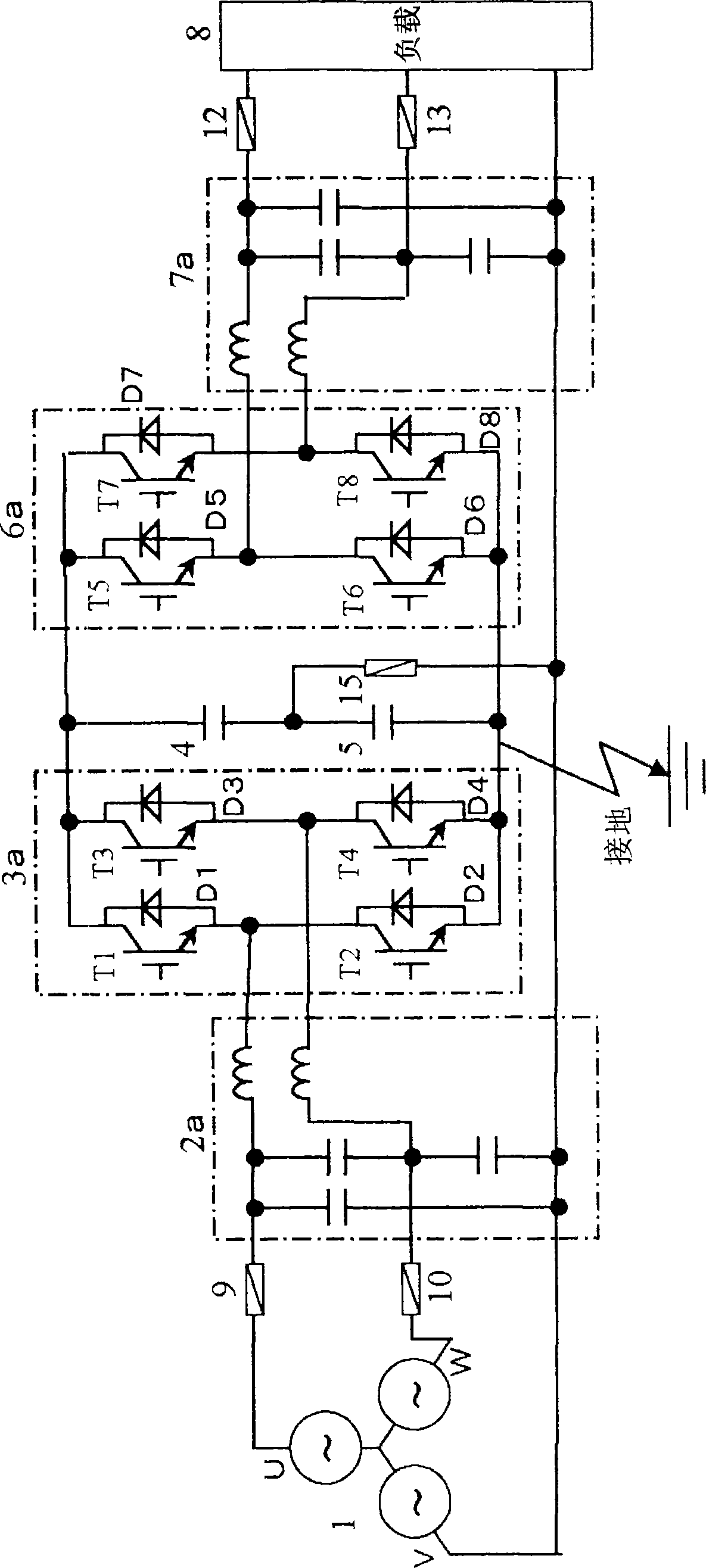

[0024] exist image 3 shows the second embodiment of the present invention. The difference from the first embodiment is the insertion positions of the fuses 9, 10 between the AC power source 1 and the forward converter 3a, and the fuses 12, 13 between the reverse converter 6a and the load 8. In Embodiment 1, fuses 9 and 10 are inserted between the AC input of the forward converter 3a and the AC input filter 2a on the side of the AC power supply 1, but in the second embodiment, fuses 9 and 10 are inserted between the AC input of the forward converter 3a and the AC input filter 2a. Between the input filter 2a and the AC power supply 1. In addition, on the AC output side of Embodiment 1, fuses 12 and 13 are inserted between the inverter 6a and the AC output filter 7a, but in the second embodiment, fuses 12 and 13 are inserted between the AC output filter 7a and load between 8. The protection action is the same as that of the first embodiment, so it is omitted.

[0025] In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com