Compact pressure relief valve

A technology of overpressure valve and matrix, applied in the field of overpressure valve, can solve the problem of lack of vacuum strength and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

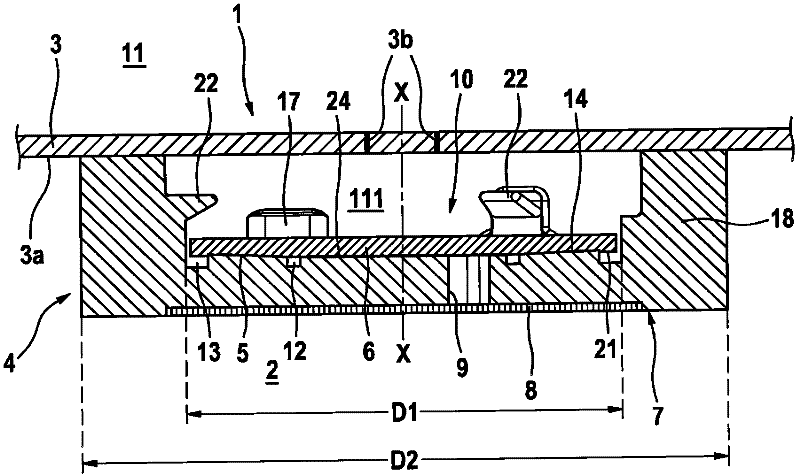

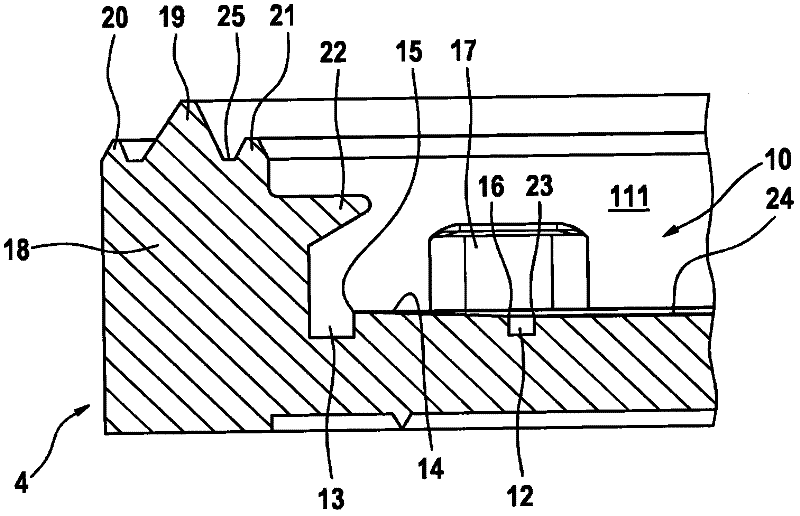

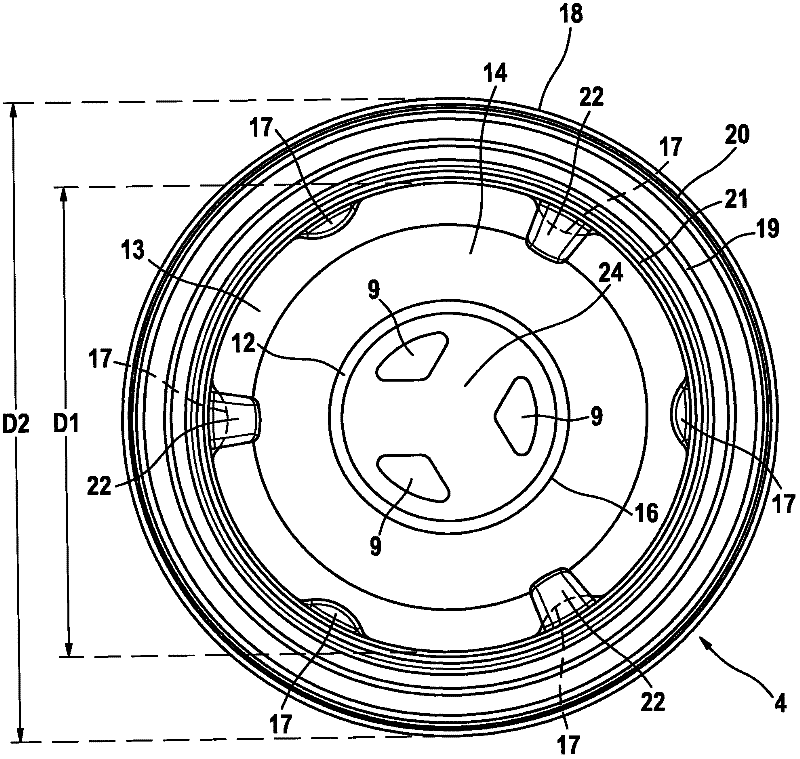

[0021] Refer below Figures 1 to 3 The pressure relief valve 1 according to a first preferred embodiment of the invention will be described in detail.

[0022] as by figure 1 It can be seen that the pressure relief valve 1 according to the invention comprises a base body 4 and a diaphragm 6 . The pressure relief valve 1 is fastened to the inner side 3 a of the packaging 3 by means of an encapsulation process. Openings 3b are provided in the packaging 3, below which openings the pressure relief valve 1 is fixed. exist figure 1 In , the inner space of the package 3 is marked with the reference number 2 , while the outer space (surrounding environment) of the package is marked with the reference number 11 . The pressure relief valve 1 here has the task of venting an excess pressure that may arise in the packaging 3 to the outside 11 and sealing a vacuum that may be present in the packaging 3 from the outside.

[0023] The base body 4 is cylindrical or slightly conical and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com