Correction method for measuring luminous flux by using integral method

A technology of luminous flux and integral method, applied in the field of optical radiation measurement, which can solve the problem of low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of correction method of integral method measuring luminous flux, comprises the following steps:

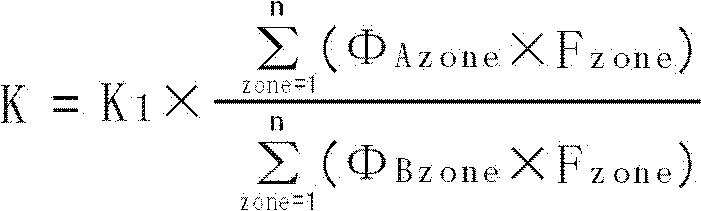

[0035] a) First, calculate the luminous flux correction coefficient K through the following formula (1):

[0036] K = K 1 × Σ zone = 1 n ( Φ Azone × F zone ) Σ zone = 1 n ( Φ Bzone × F z...

Embodiment 2

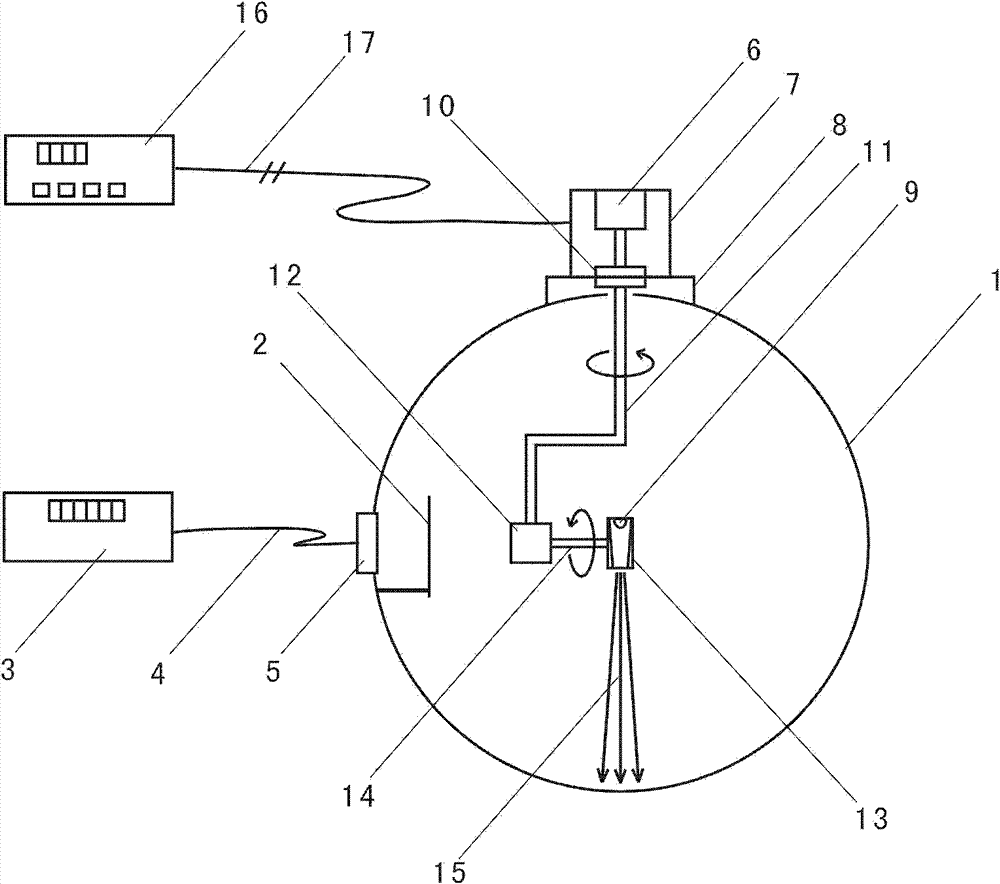

[0061] Embodiment 2: refer to figure 1 . A device for measuring relative reflection distribution parameters at various angles of an integrating sphere. Two holes are opened on the integrating sphere 1 to be measured: one hole is used to install the illuminance probe 5; 11 is slightly larger in diameter. The illuminance probe 5 calibrated by V(λ) is located on the wall of the integrating sphere behind the shading baffle 2 belonging to the attachment of the integrating sphere to be measured, and the signal of the illuminance probe 5 is transmitted to the display instrument 3 through the signal line 4 . The motor 6 is fixed on the case 7 , the case 7 is fixed on the interface seat 8 , the interface seat 8 is fixed on the integrating sphere 1 , and the bearing 10 is fixed on the interface seat 8 . The rotating shaft 11 is connected with the motor 6 through the bearing 10 , so that the power of the motor 6 is transmitted to the rotating shaft 11 . The rotating shaft 11 with cert...

Embodiment 3

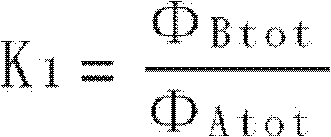

[0067] Embodiment 3: on the basis of embodiment 2, we can measure and obtain following three groups of data, are respectively: the relative light intensity distribution I of luminous flux standard lamp A (C, γ), the relative light intensity distribution I of the light source to be measured B (C, γ), the relative reflection distribution parameter E(C, γ) of each angle of the integrating sphere. Through the above three sets of data, the correction coefficient K can be calculated, and the luminous flux measured by the integration method of the measured light source can be corrected by the correction coefficient K, as follows:

[0068] 1) According to the total luminous flux calculation formula of C-γ system, there are:

[0069] Φ Atot = ∫ 0 2 π ∫ 0 π I A ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com