Method for predicting hot rolled steel austenite static recrystallization structure evolution

A static recrystallization, austenite technology, applied in the field of steel rolling, can solve the problems of large test workload, heavy workload, cumbersome process, etc., and achieve the effect of reducing the number of tests, optimizing the settings, and realizing the parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

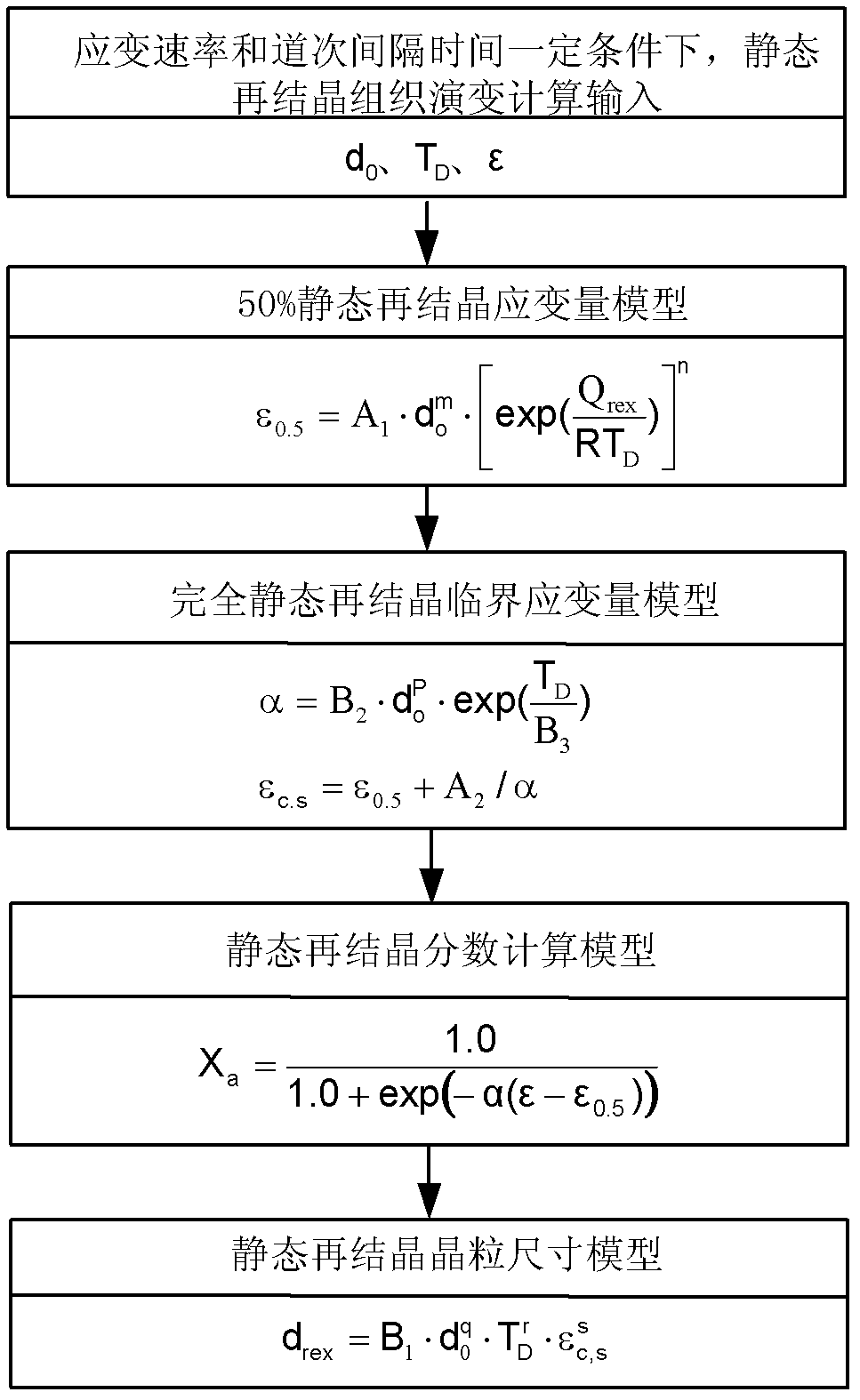

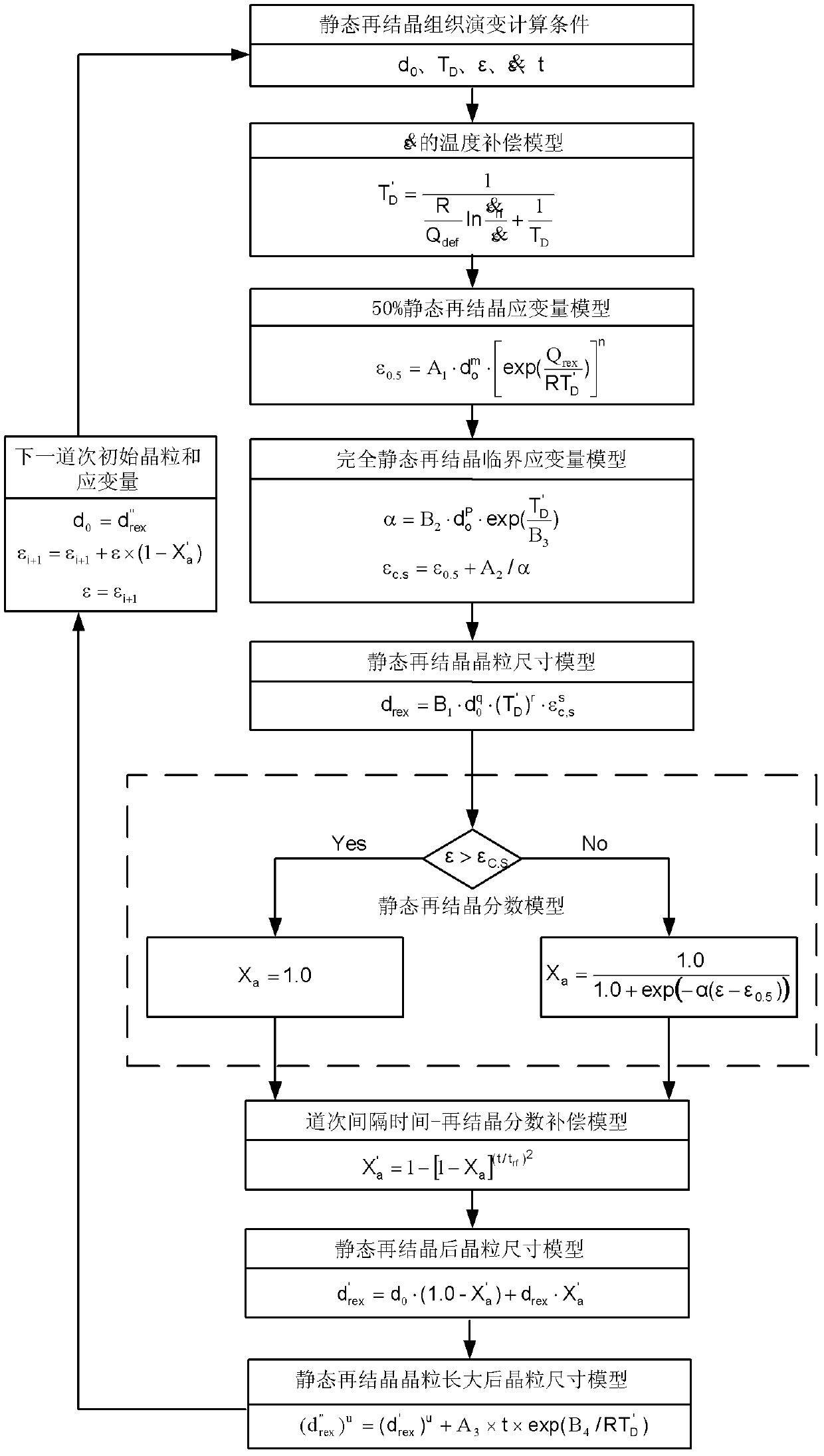

Method used

Image

Examples

Embodiment Construction

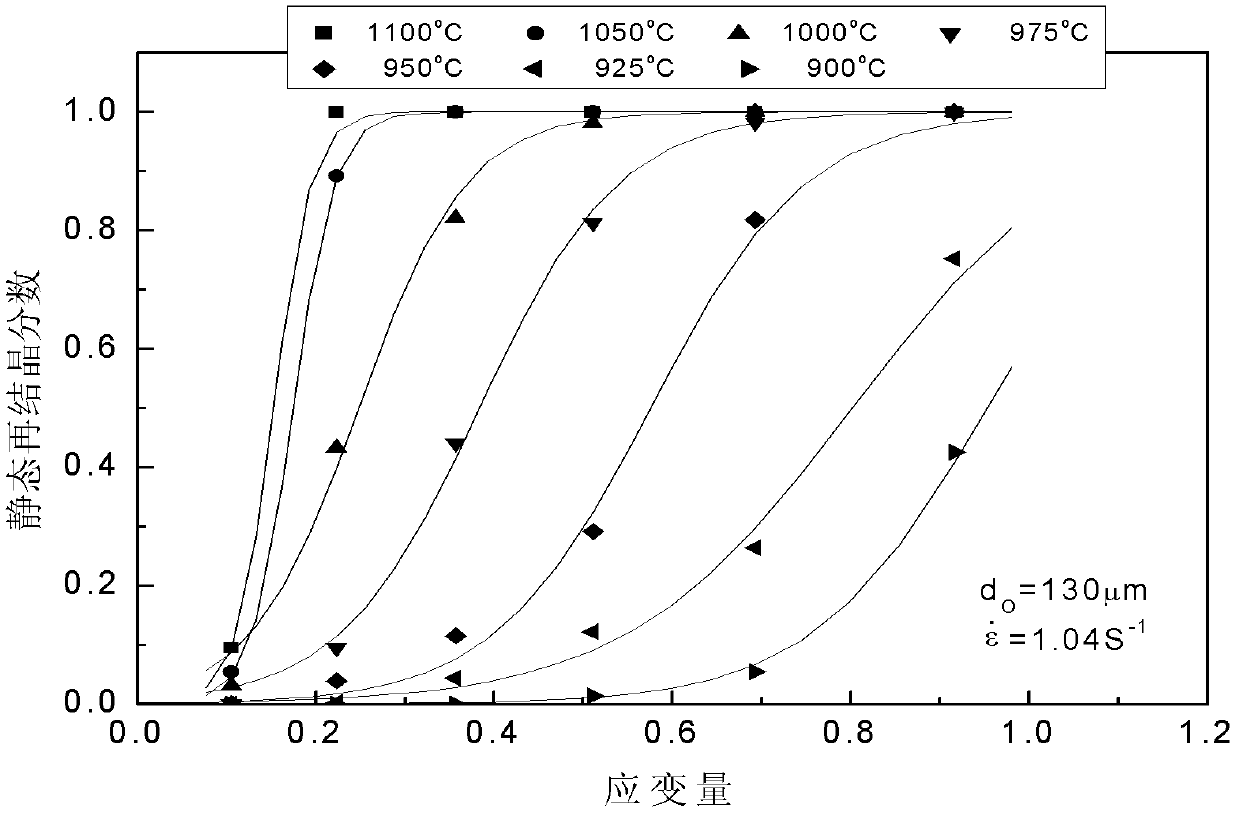

[0040] The method for predicting the evolution of austenite static recrystallization structure of hot-rolled steel provided by the invention can be widely used in the research on the evolution law of static recrystallization structure of steel types such as C-Mn steel and C-Mn-Nb steel that need to be controlled. Here, the test results of C-Mn-Nb steel with chemical composition of 0.16%C-0.30%Si-1.40%Mn-0.035%Nb are selected as the research data basis.

[0041] Test conditions: the pass interval time and strain rate are selected from the typical pass interval time and strain rate of rolling in the recrystallization zone, that is, the pass interval time is 3s and the strain rate is 1.04s -1 . Under these conditions, the effects of deformation temperature and strain on the austenite static recrystallization fraction and recrystallization grain size are studied in the range of deformation temperature 750-1100℃ and pass reduction rate 0-50%. The test results Such as image 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com