Wiper blade having connection component for linking to wiper arm

A technology of wiper blades and connectors, applied in the field of wiper blades with connectors for hinged on wiper arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

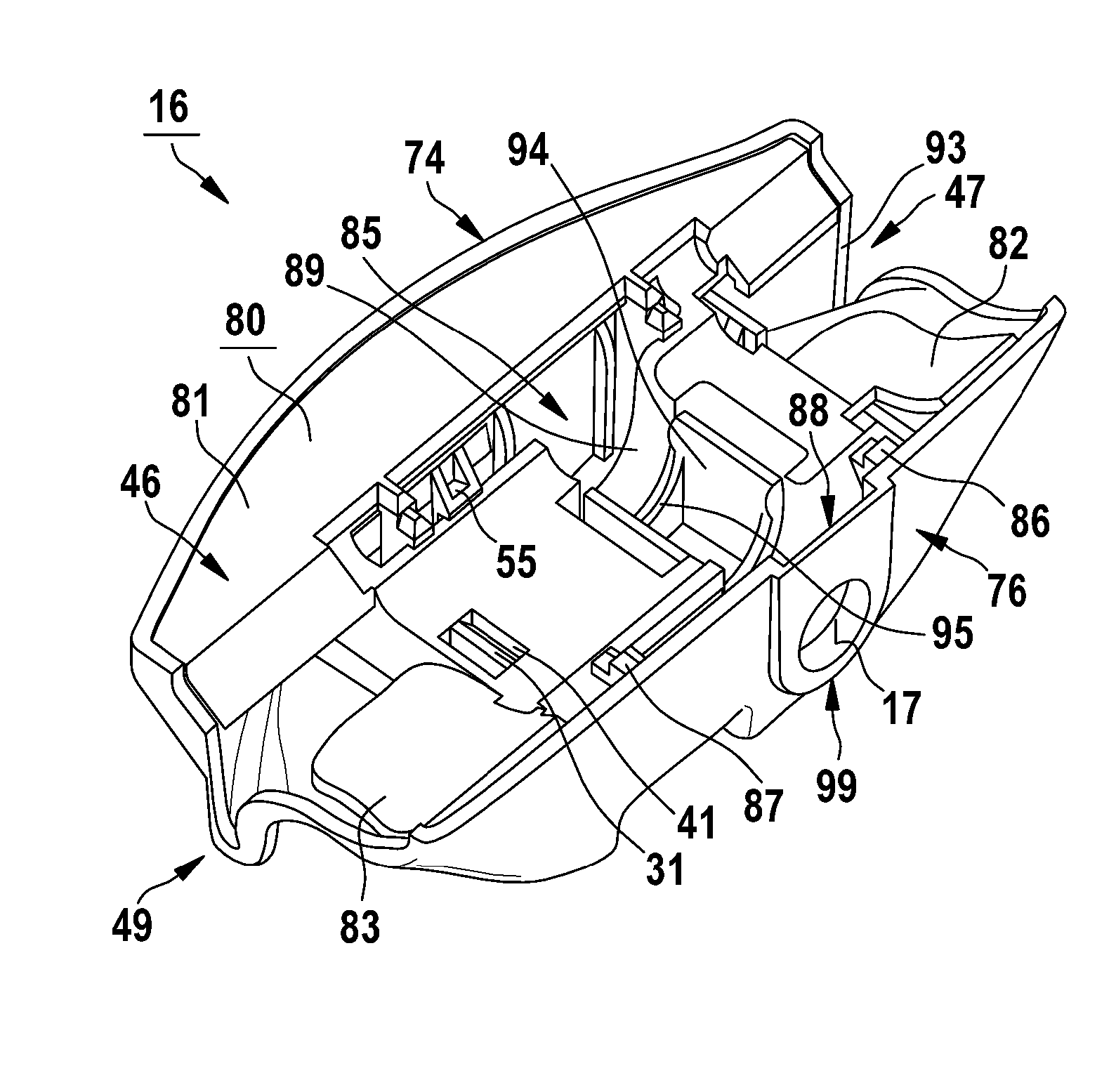

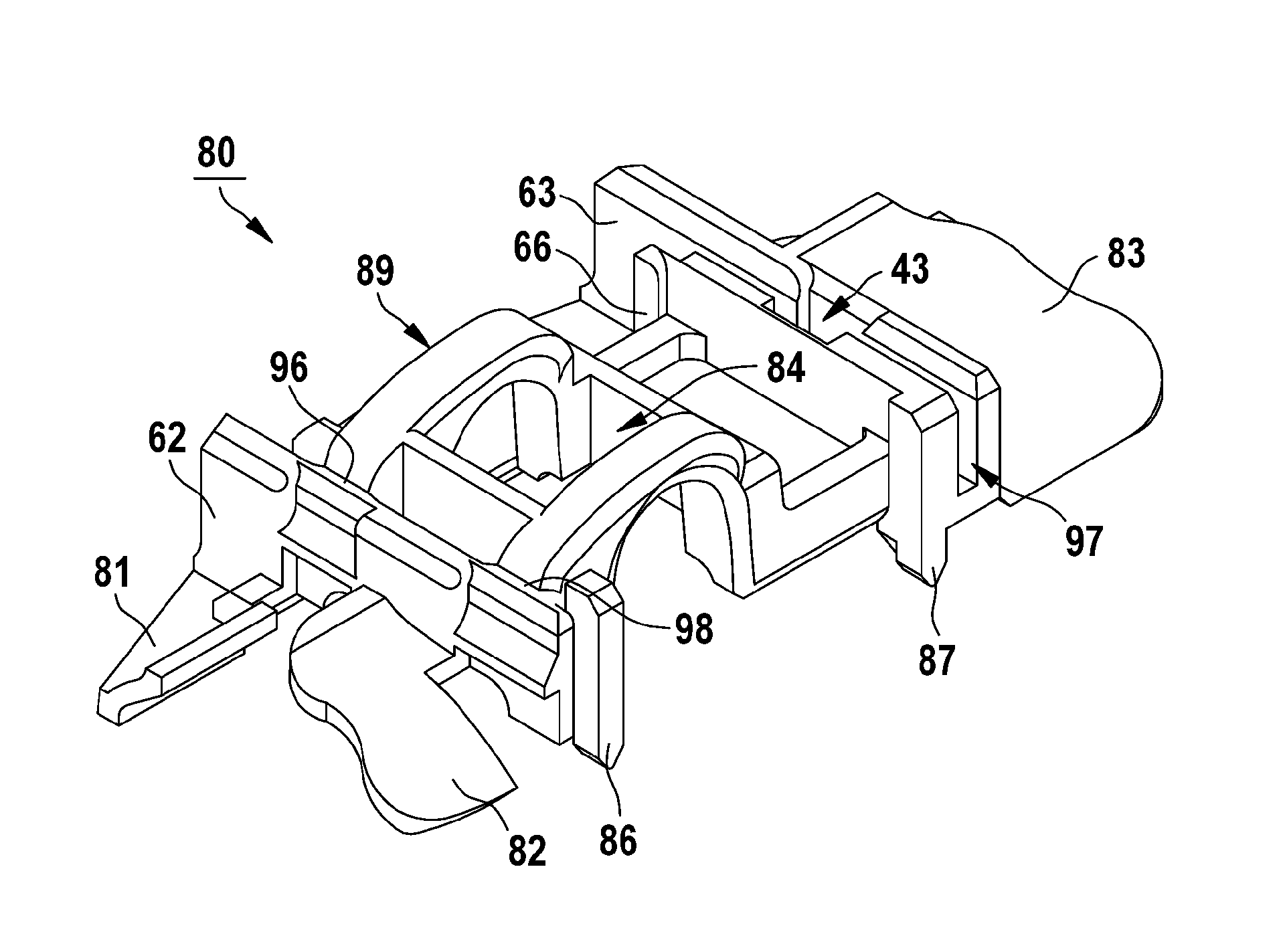

[0060] According to one specific embodiment, the cover 16 with the base element 80 forms the outflow opening 88 which is arranged in the region of the dome-like projection 99 . The bottom element 80 is preferably configured for figure 1 During the wiper operation of the wiper blade 12 , the water that has entered the cover 16 is discharged to the outflow opening 88 . as available from Figure 9 As seen in , the cover 16 and the base element 80 form a recess 85 in which the figure 1 The first connector 60 is fixed on the figure 1 The connecting element 50 on the wiper strip 20 ( Figure 10 ).

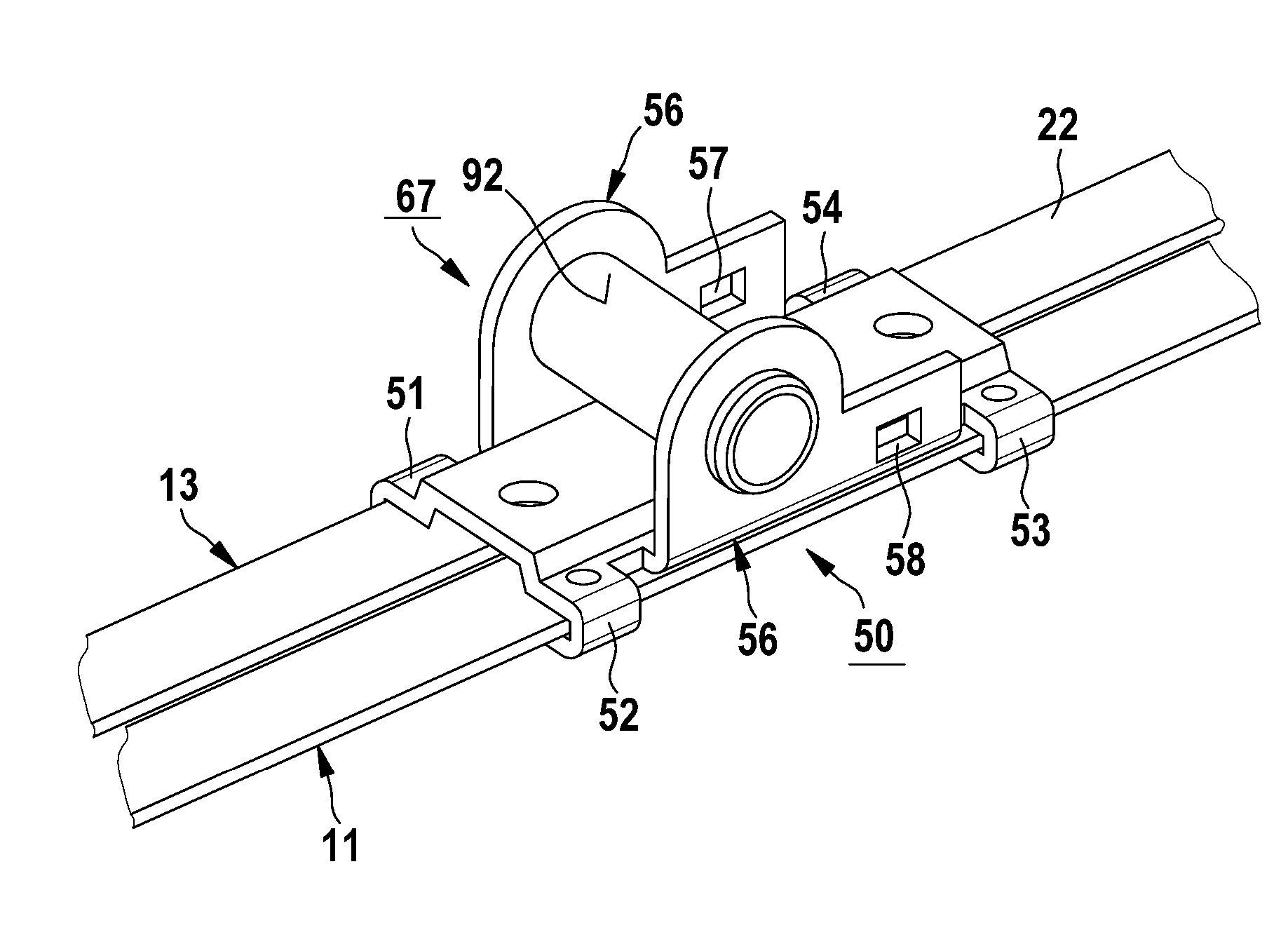

[0061] Figure 10 shows an exemplary assignment to figure 1 The connecting element 50 of the first connecting piece 60 is preferably configured as a metal adapter. The connection element 50 is for example via a collet-shaped figure 1 The holding elements 51 , 51 , 53 , 54 surrounding the spring rails 22 of the wiper blade 12 are fixedly connected to these spring rails 22 . On sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com