Screen flow equalization system

A screen and balanced technology, applied in the direction of production fluid, wellbore/well components, sealing/isolation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Pipe joints, as used herein, include but are not limited to threaded oil tubing (OCTG) along a body portion of a continuous coiled tubing string or other tubing string. Means the body portion of a fitting of a given length, but is not limited to any one particular size, length or configuration of such fittings. Apertured members include holes or other apertures, or slots or other openings of any size, shape or configuration designed to allow fluid to pass therethrough. Some examples of inflow control devices are tortuous channels, orifices or other openings or passages designed to restrict or moderate inflow flow to one section of the body portion more favorably than another section.

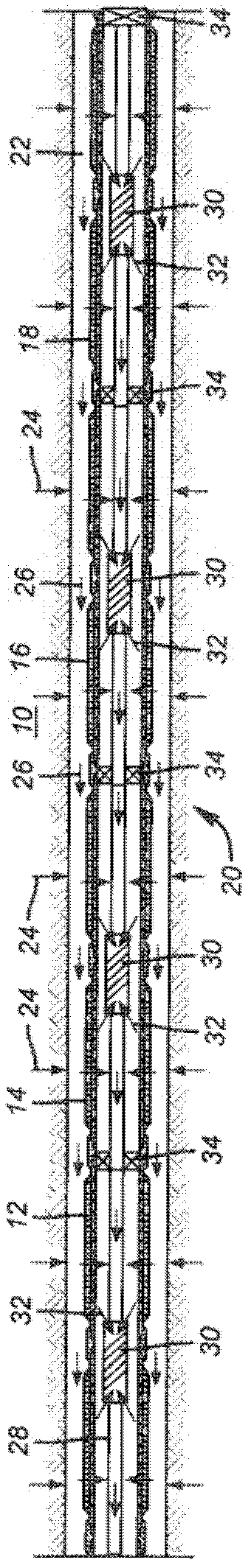

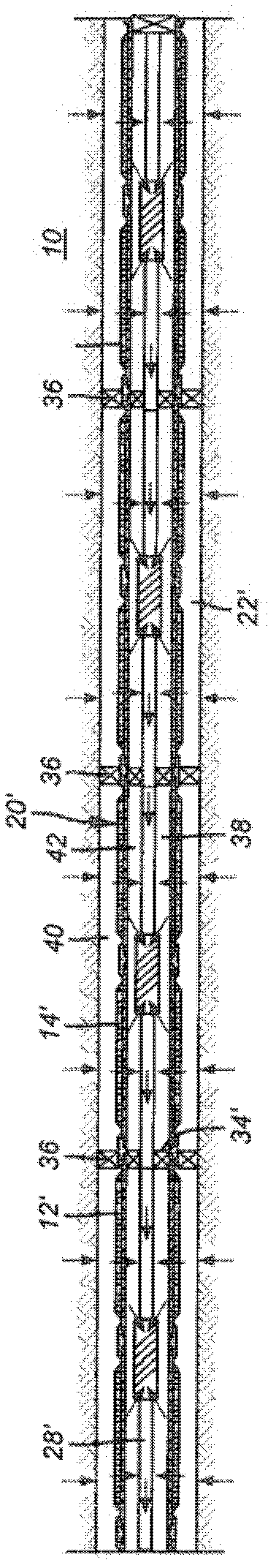

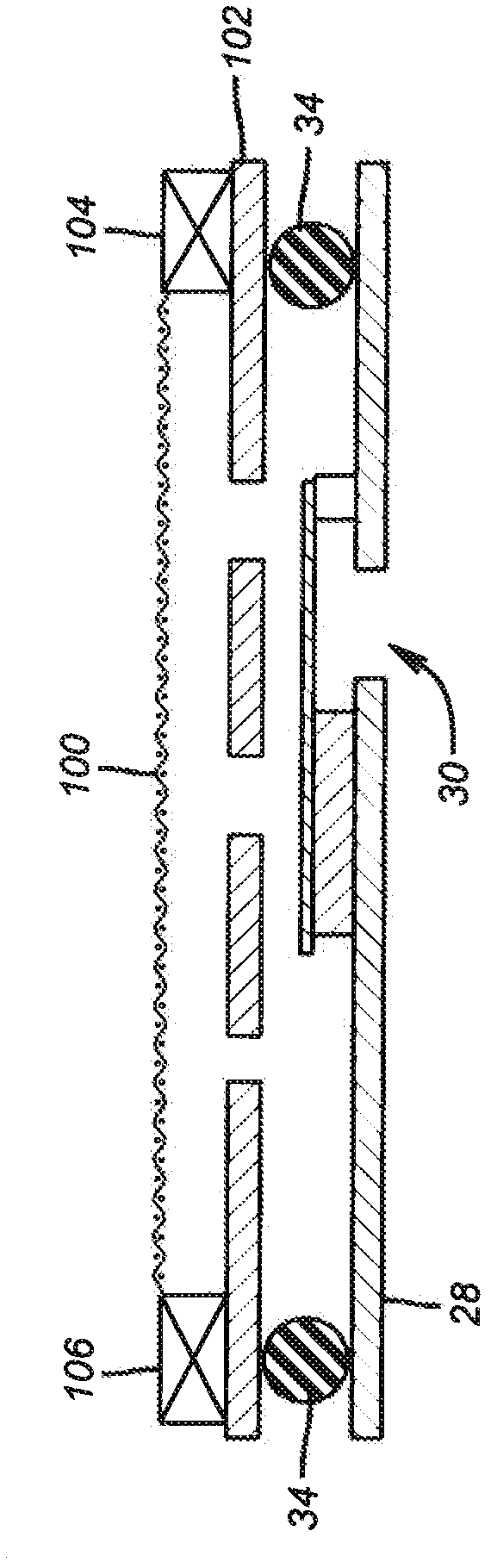

[0024] refer to figure 1Wellbore 10 , which may be an open hole or a cased hole, has a series of screen sections 12 , 14 , 16 and 18 that are connected together to form assembly 20 . Although the assembly 20 is not shown with empty pipe sections, the use of empty pipe sections still fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com