Piston air leakage amount measurement system based on balanced flow meter

A technology of piston leakage and balanced flow, which is applied in directions such as measuring the rate of increase and deceleration of fluid, measuring fluid flow by measuring pressure difference, and volume/mass flow generated by mechanical effects, which can solve the low efficiency of piston leakage measurement , Piston leakage measurement error, measurement accuracy reduction and other problems, to achieve the effect of close theoretical calculation accuracy, close use accuracy, and reduce additional error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

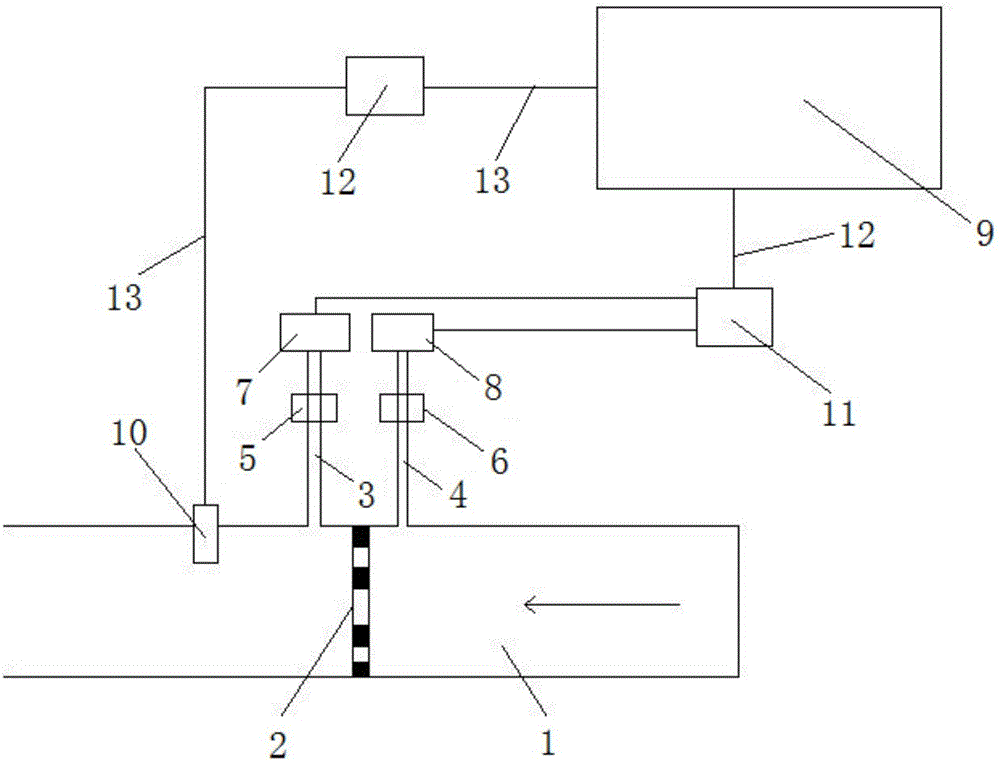

[0023] Such as figure 1 As shown, a piston air leakage measurement system based on a balance flowmeter includes an airflow pipeline 1, a balance flowmeter 2, a first pressure taking unit, a second pressure taking unit and a processor unit, and the airflow pipeline 1 is connected to Piston leakage port, the balance flowmeter 2 is set in the air flow pipeline 1, the first pressure-taking unit and the second pressure-taking unit are respectively set on both sides of the balance flowmeter 2 and communicate with the airflow pipeline 1, the Both the first pressure-taking unit and the second pressure-taking unit are connected to the processor unit;

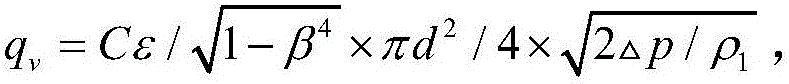

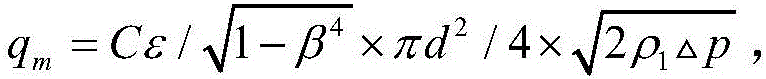

[0024] The first pressure measuring unit and the second pressure measuring unit obtain the pressure in the gas flow pipe 1 on both sides of the balance flow meter 2 and send it to the processor unit, and the processor unit performs processing to obtain the fluid volume flow q v and mass flow q m :

[0025] q ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com