Flow splitting system between ditches in two sides in water-rich tunnel provided with inclined shafts and flow splitting method of flow splitting system

A water-rich tunnel and diversion system technology, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve problems such as overflow, excessive water volume in drainage ditches, and threat to tunnel operation safety, so as to reduce drainage pressure, reduce water volume, and reduce The effect on the probability of disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in combination with specific embodiments.

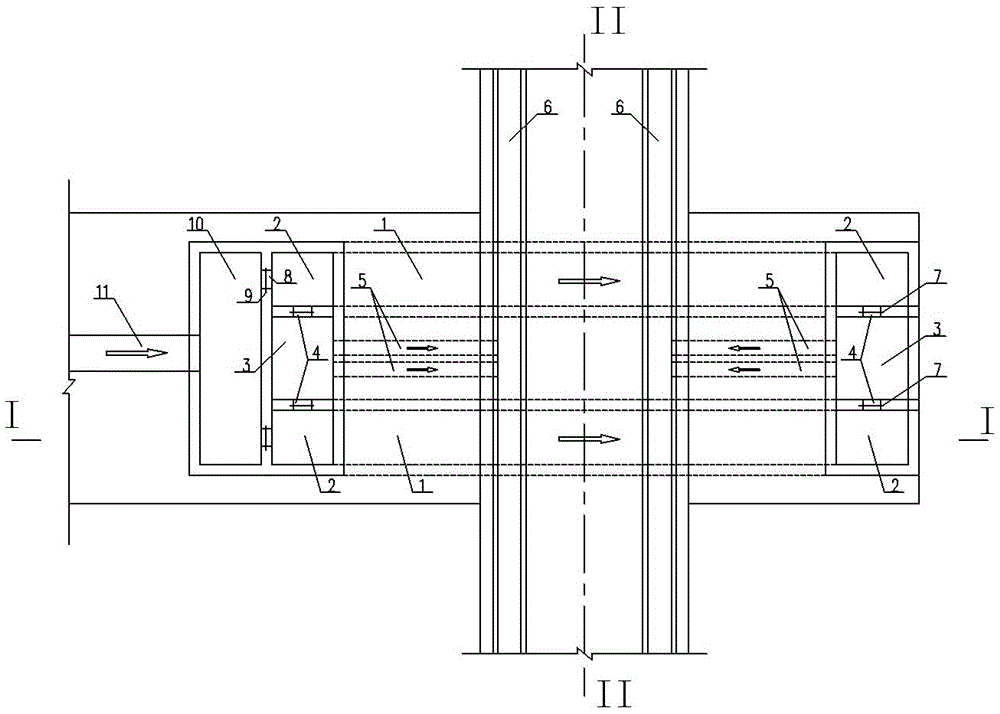

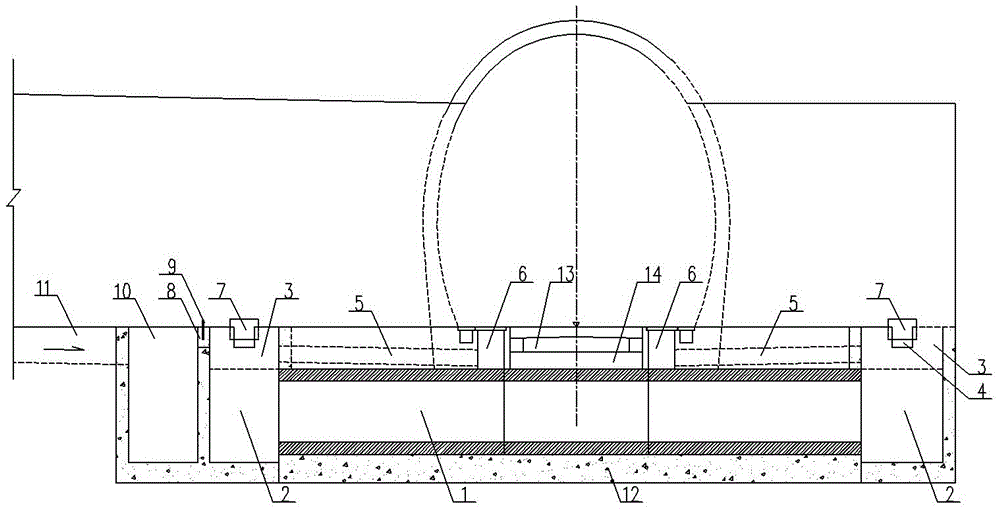

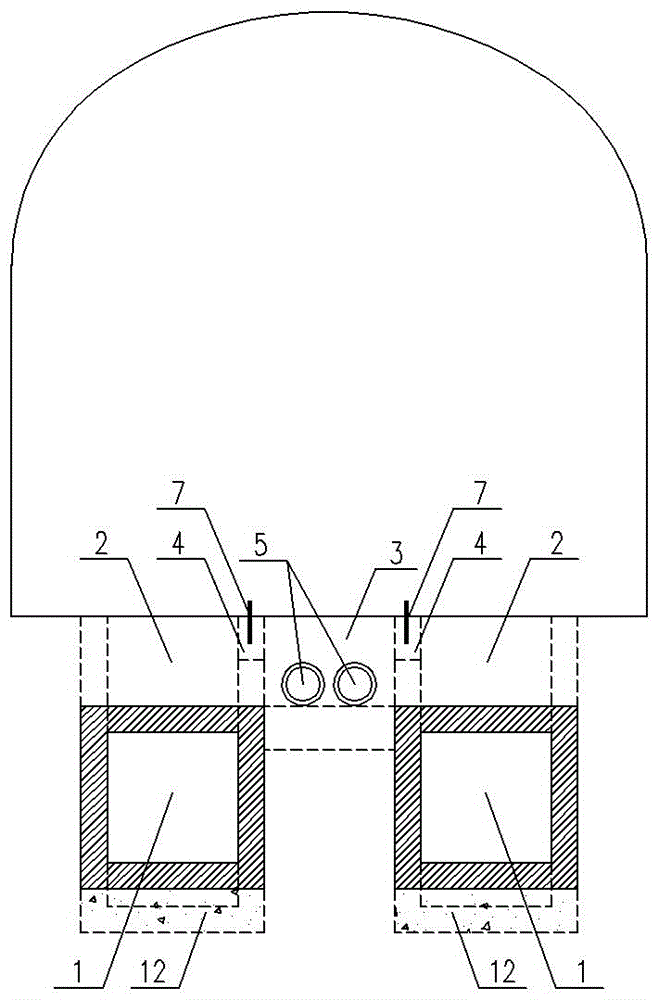

[0031] The diversion system between the ditches on both sides of the water-rich tunnel provided with an inclined shaft according to the present invention includes two connecting culverts 1 , four catchment pools 2 and two diversion bins 3 . Two connecting culverts 1 are horizontally arranged under the track bed bedding layer 14 of the tunnel, and both ends of each connecting culvert 1 are connected with the catchment pool 2 arranged at the bottom of the inclined shaft, and the two catchment pools 2 on the same side of the tunnel are arranged between There are diversion bins 3. Both sides of the integral ballast bed 13 in the tunnel are provided with side ditches 6 , and the distribution chambers 3 on both sides of the tunnel are respectively connected to the side ditches 6 on the same side of the tunnel through the pre-buried drainage pipes 5 . The drainage pipe 5 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com