Accumulated-oil-removing energy-saving device

A technology of oil collecting device and energy-saving device, which is applied in the field of energy saving and purification, and can solve problems such as fire hazards, and achieve the effects of avoiding fire, facilitating cleaning and maintenance, and protecting cleanliness and operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

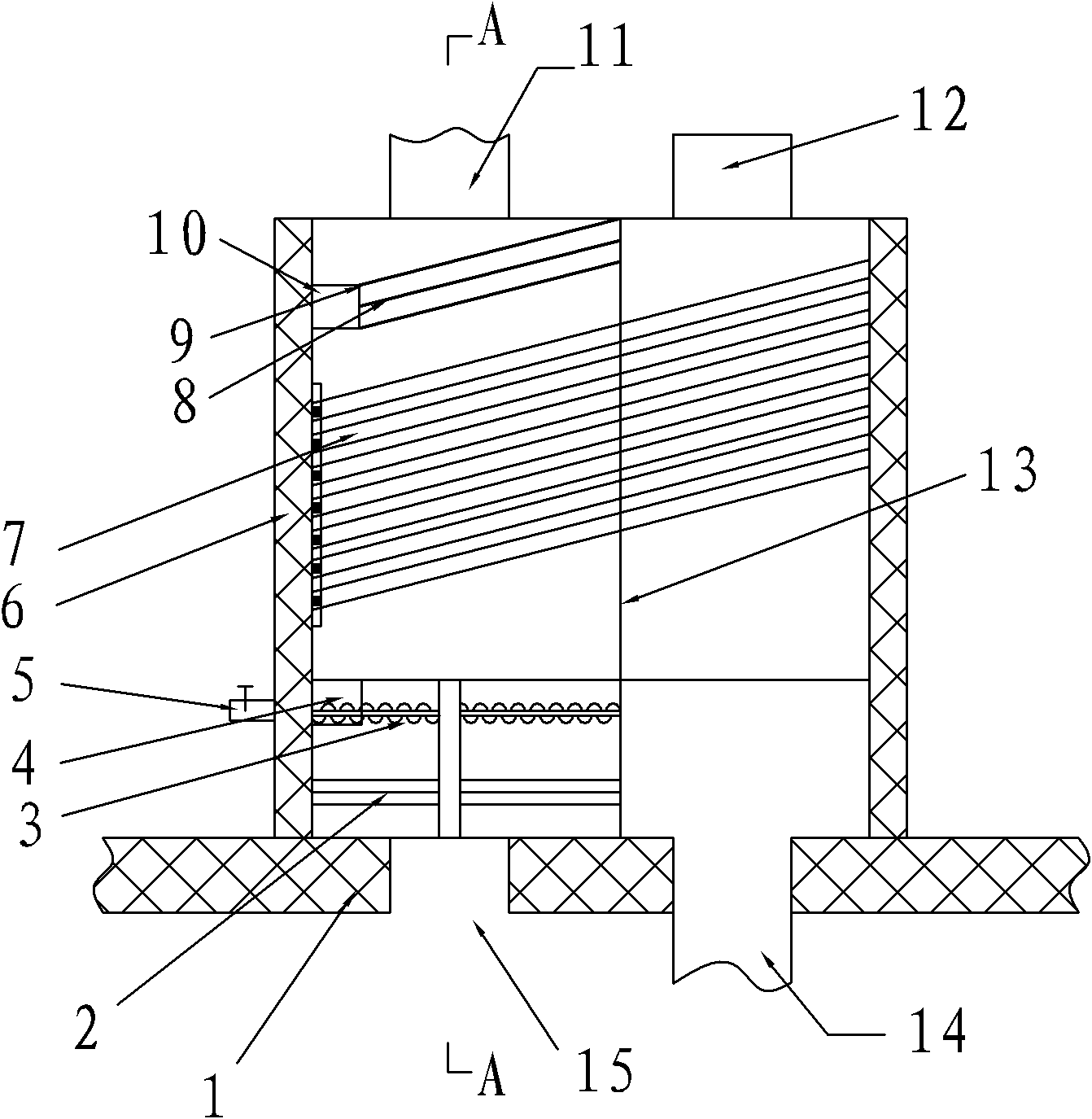

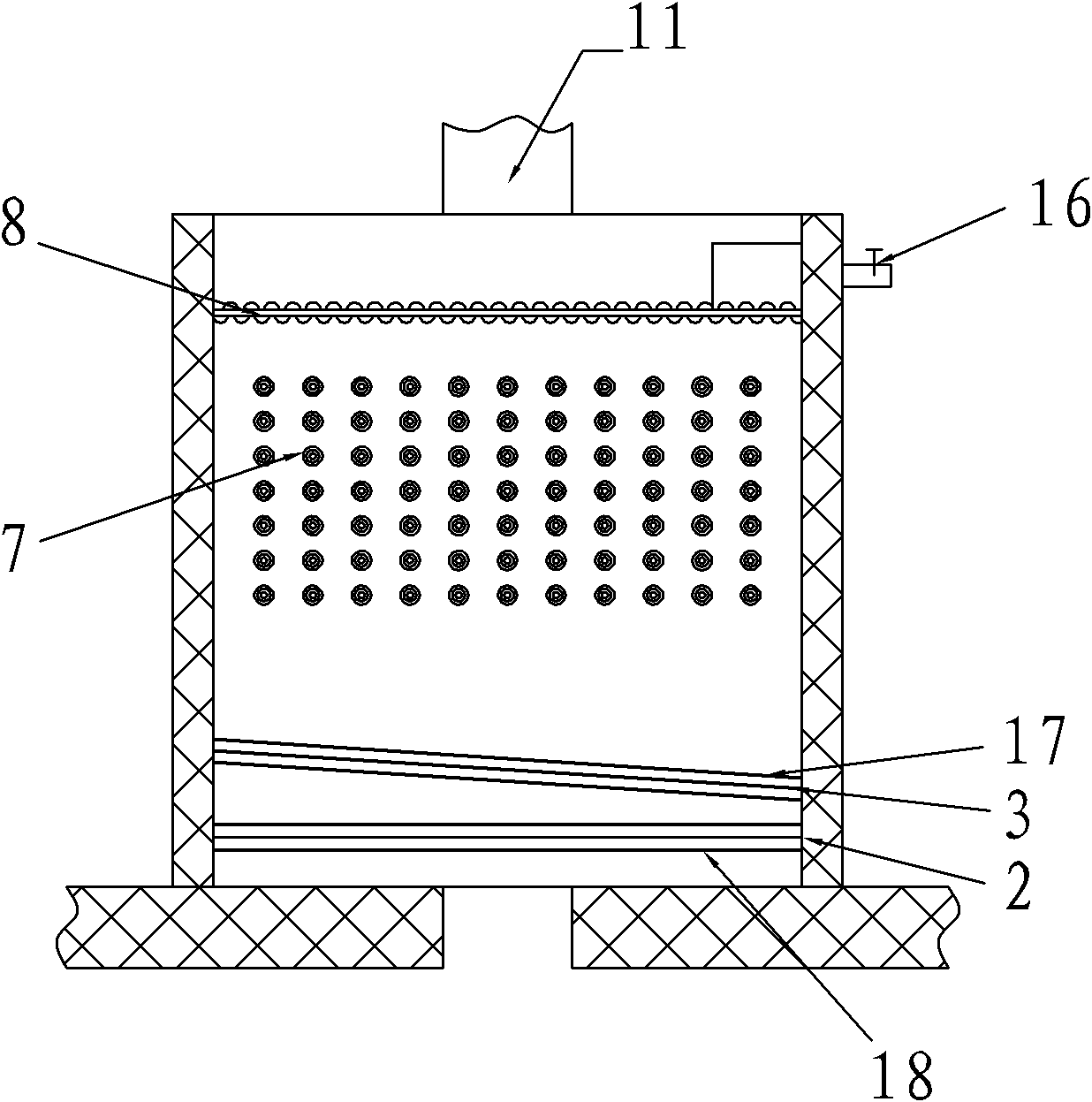

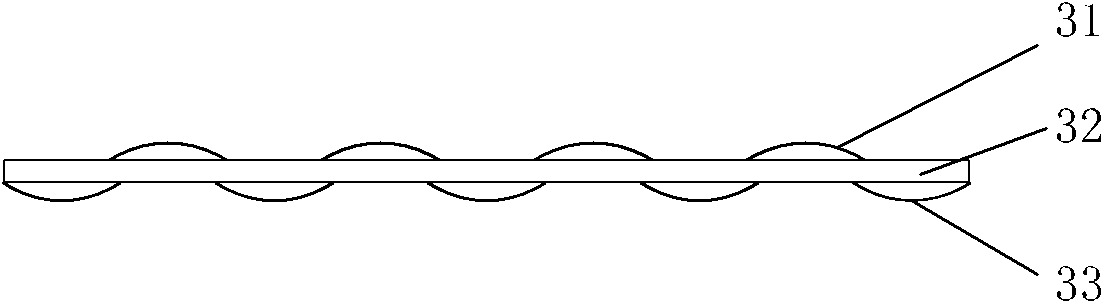

[0023] Such as figure 1 , figure 2 The shown oil-collecting and energy-saving device includes a box body 6, and the box body 6 is divided into two relatively independent spaces on the left and right by a sealing partition 13. The left part is an exhaust gas channel, and the right part is a fresh air channel; the box body 6 is in The bottom of the waste gas channel is provided with a waste gas inlet 15, and the top is provided with a waste gas discharge port 11. In the waste gas channel, a filter screen 2, a downward oil collecting device 3, a plurality of heat pipes 7 arranged in an array, and an upward collecting device are sequentially arranged in the waste gas channel. oil device 8, these heat pipes 7 enter the fresh air passage through the sealing partition 13; the box body 6 is provided with a fresh air inlet 12 above the fresh air passage, and a fresh air outlet 14 is provided below, and the above-mentioned multiple air outlets arranged in an array are arranged in the f...

Embodiment 2

[0027] A sizing machine, comprising the oil-removing and energy-saving device described in Embodiment 1, the waste gas inlet 15 of the oil-removing and energy-saving device communicates with the exhaust port of the sizing machine, and the fresh air outlet 14 of the oil-removing and energy-saving device is connected to the sizing machine The air inlet is connected.

Embodiment 3

[0029]A dryer, comprising the oil-removing and energy-saving device described in Embodiment 1, the waste gas inlet 15 of the oil-removing and energy-saving device communicates with the waste gas port of the dryer, and the fresh air outlet 14 of the oil-removing and energy-saving device is connected to the The air inlet of the dryer is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com