Photoelectric oil smoke sensor

A lampblack sensor, photoelectric technology, applied in instruments, scientific instruments, material analysis by optical means, etc., can solve the problems of complex clean air production, and achieve the effect of reducing the possibility of head contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

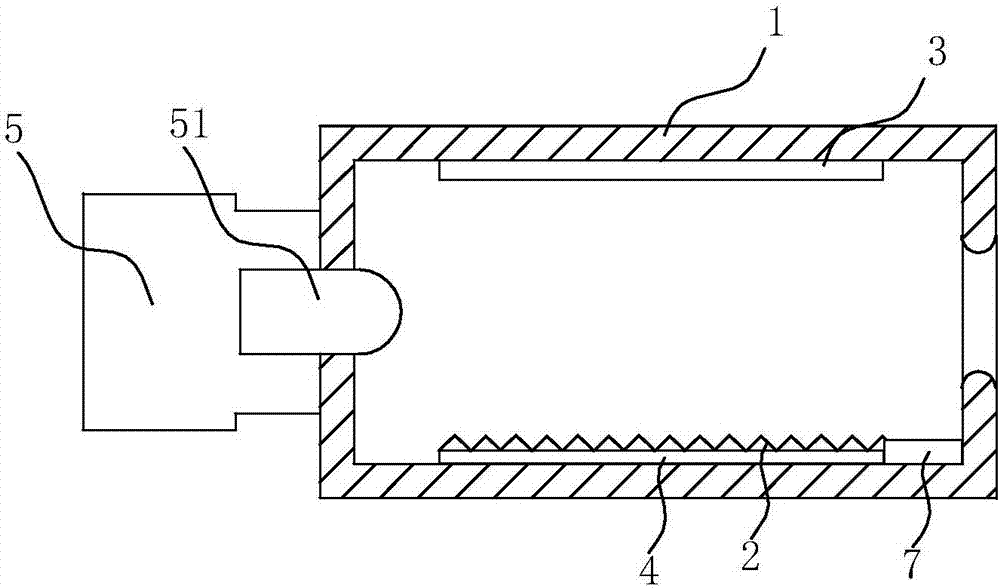

[0021] Such as figure 1 The photoelectric oil fume sensor shown includes a detection light emitting / receiving device 5, which has a head 51 capable of emitting or receiving detection light, the head is covered with a collimator tube 1 with a constant inner diameter, and the head 51 is sealed It is inserted into the opening at one end of the collimation tube 1 . The collimation tube 1 is provided with an electrostatic anti-oil pollution module, which includes a high-voltage pole 2 and a low-voltage pole 3, and the high-voltage pole 2 is attached to the insulating layer 4, and the insulating layer 4 is arranged on the lower part of the collimation tube 1; The low-voltage pole 3 is arranged on the upper part of the collimator tube 1 and placed opposite to the high-voltage pole 2; the high-voltage pole 2 is connected to the high-voltage generator 7, and the high-voltage generator 7 can be arranged inside the collimator tube or outside the collimator tube .

[0022] In this embod...

Embodiment 2

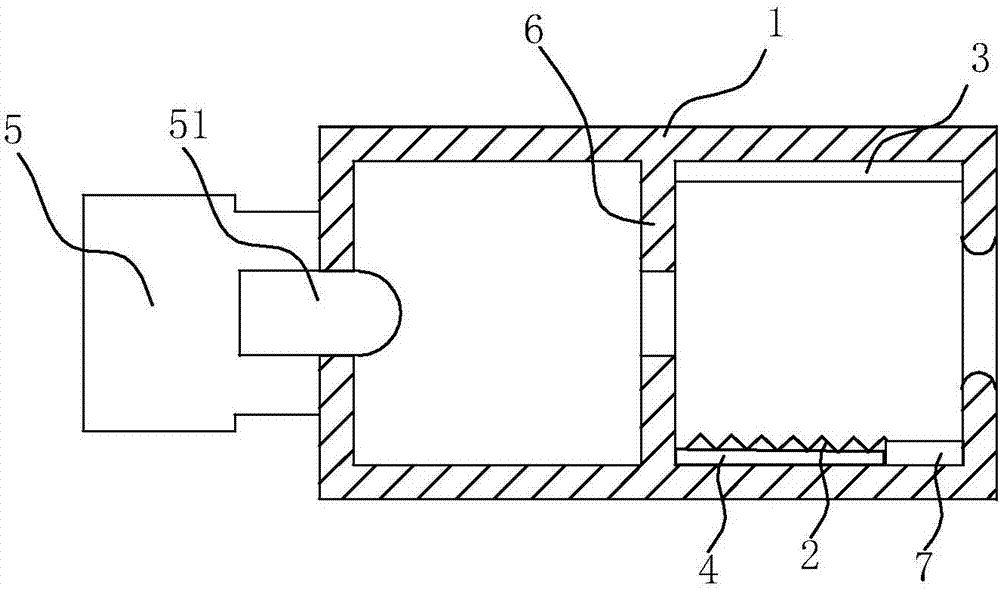

[0024] The difference from Embodiment 1 is that the inner diameter of the collimation tube is changed. In this embodiment, the change of the inner diameter is realized in the following way: a blocking plate 6 is provided in the middle of the collimating tube, and a hole is opened on the blocking plate. Through holes, the blocking plate 6 divides the interior of the collimation tube into two spaces. The electrostatic anti-oil pollution module can only be arranged in one of the spaces, and the electrostatic anti-oil pollution module can also be arranged in both spaces. In this embodiment, the electrostatic anti-oil pollution module is only arranged in a section of space away from the head 51. See figure 2 shown.

[0025] The above-mentioned collimation tube is designed with a deep cavity so that the head 51 of the detection light emitting / receiving device 5 will not be directly exposed to the oil fume flow, and the installation end of the head 51 is sealed so that the inside of...

Embodiment 3

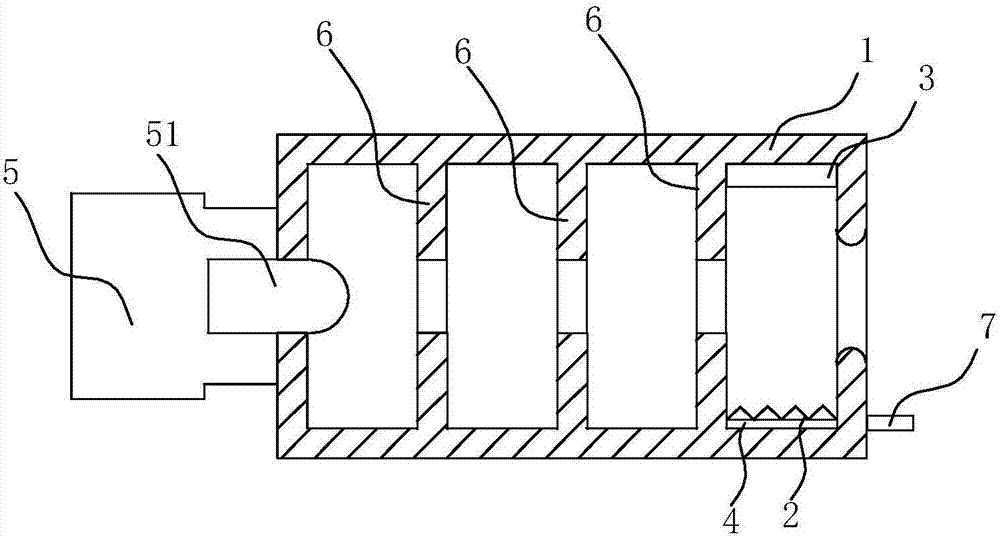

[0028] Different from Embodiment 2, there are multiple blocking plates 6 in the above-mentioned collimating tube, arranged at intervals, three in this embodiment, and the diameters of the through holes on two adjacent blocking plates 6 can be the same or not. Same, the diameters of the through holes are the same in this embodiment. Three blocking plates 6 arranged at intervals divide the interior of the collimation tube into four spaces, and the anti-static anti-oil module can be installed in only one or two or three spaces, or static electricity can be installed in all four spaces. Anti-oil pollution module, in this embodiment, the electrostatic anti-oil pollution module is only set in a section of space farthest from the head 51, see image 3 shown.

[0029] The design of this multiple variable-diameter labyrinth makes the inner diameter of the collimation tube expand and shrink multiple times. When expanding, the oil fume obtains a radial diffusion driving force, and most ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com