Part fixture used in drill press

A technology for fixing fixtures and parts, applied in metal processing machinery parts, clamping, positioning devices, etc., can solve the problems of deviation in processing, affecting dimensional accuracy, and unrestricted degrees of freedom, and achieve the effect of preventing deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

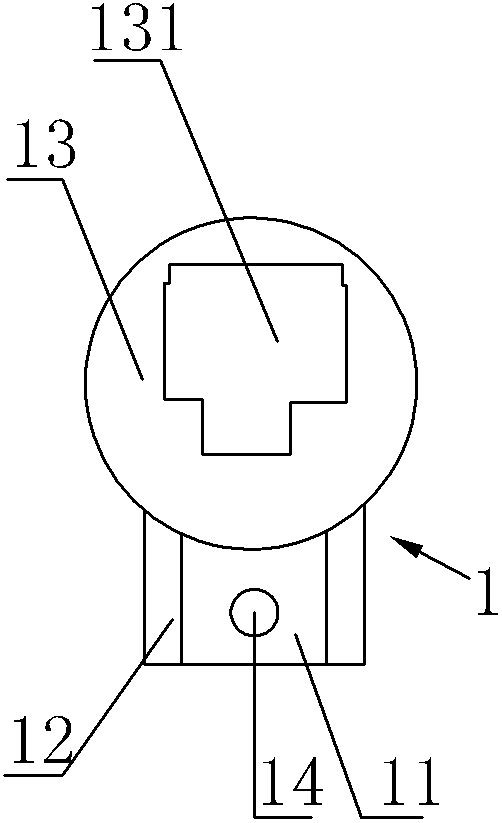

[0014] Such as image 3 , 4 As shown, a part 1 used on a sewing machine has a strip-shaped bottom plate 11, a wing plate 12 symmetrically arranged on both sides of the bottom plate 11, and a buckle 13 fixedly connected to the upper end surface of the bottom plate 11. The wing plate The upper surface of 12 is lower than the upper surface of bottom plate 11.

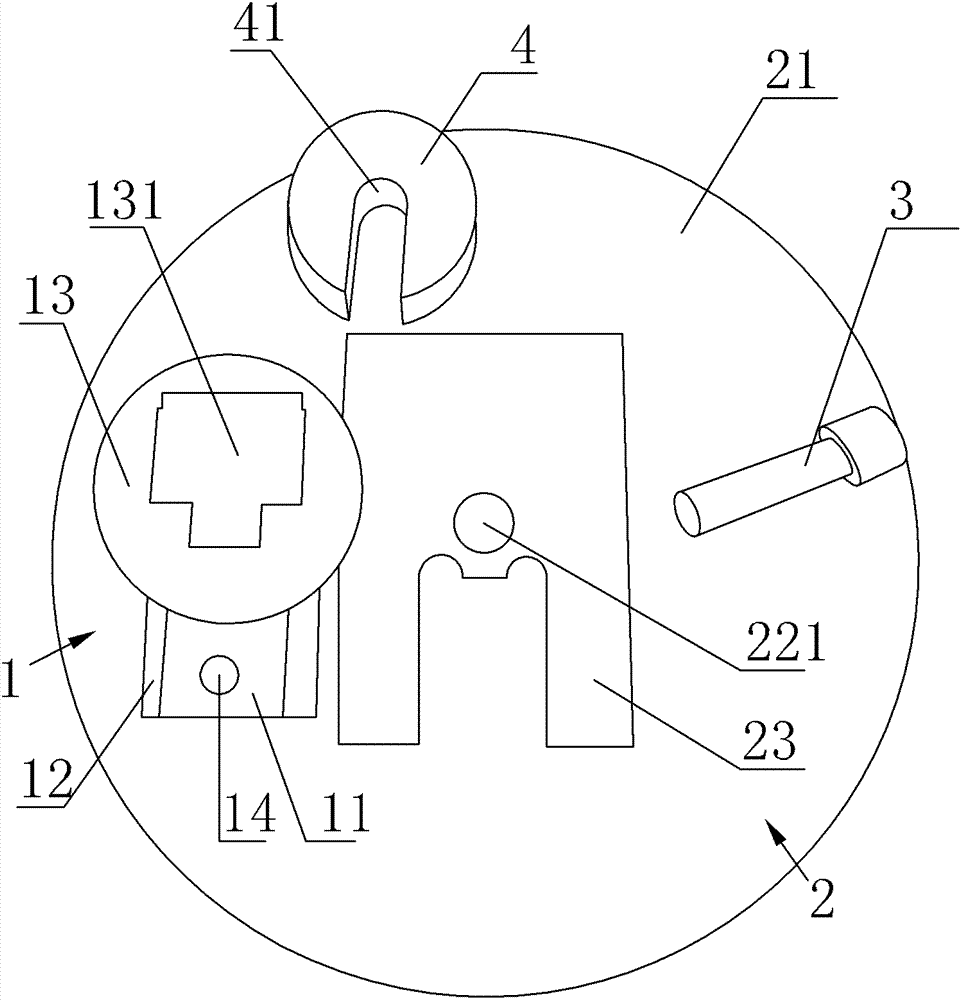

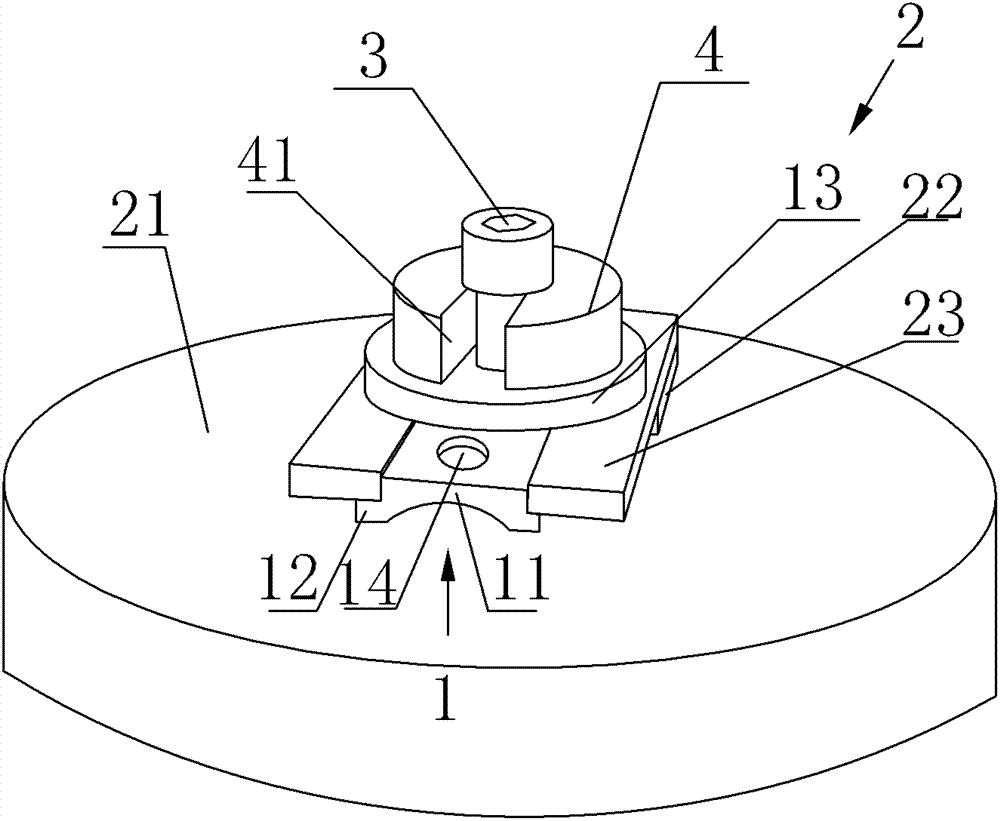

[0015] In order to fix the above parts 1, and drill a round hole 14 on the base plate 11, the present embodiment provides a clamp 2, such as figure 1 , 2 As shown, the clamp 2 includes a base 21, a pad 22 fixed on the base 21, a pressing block 23 fixed on the upper surface of the pad 22, one end of the pressing block 23 is fixed on the pad 22, and the other end is Out of the pad 22 and suspended on the base 21, the part of the pressure block 23 protruding from the pad 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com