Clamping device and clamping method for processing photoelectric components

A technology for optoelectronic components and clamping devices, applied in workpiece clamping devices, auxiliary devices, metal processing equipment, etc., can solve the problems of cost loss, loss of human and material resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

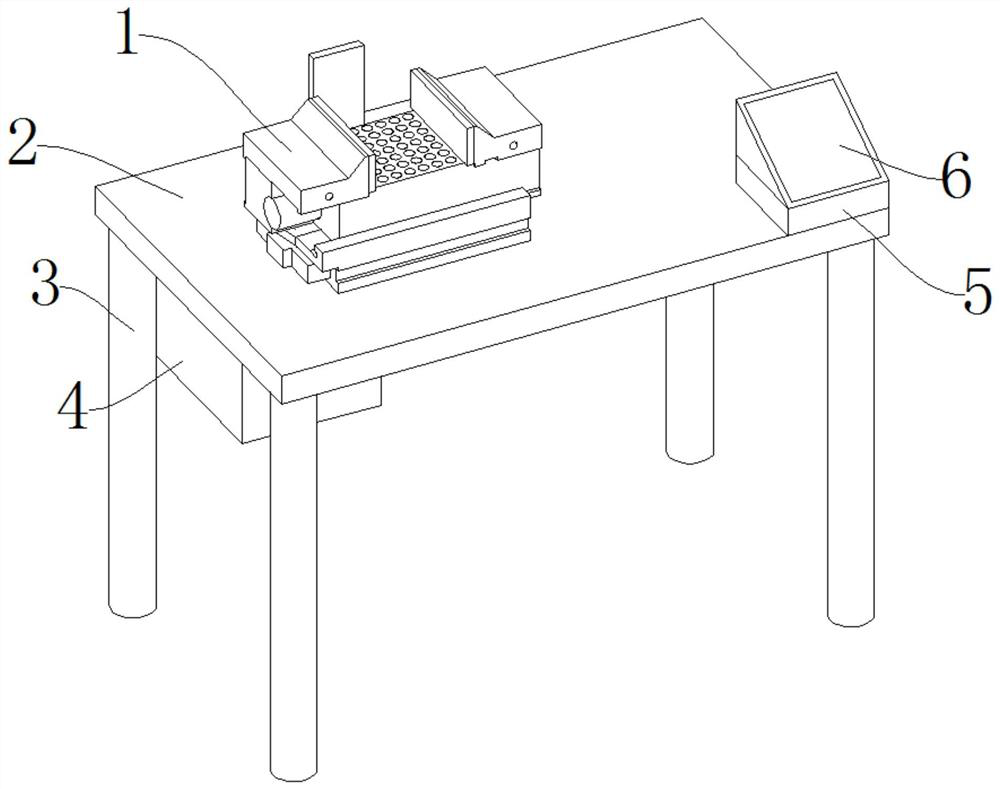

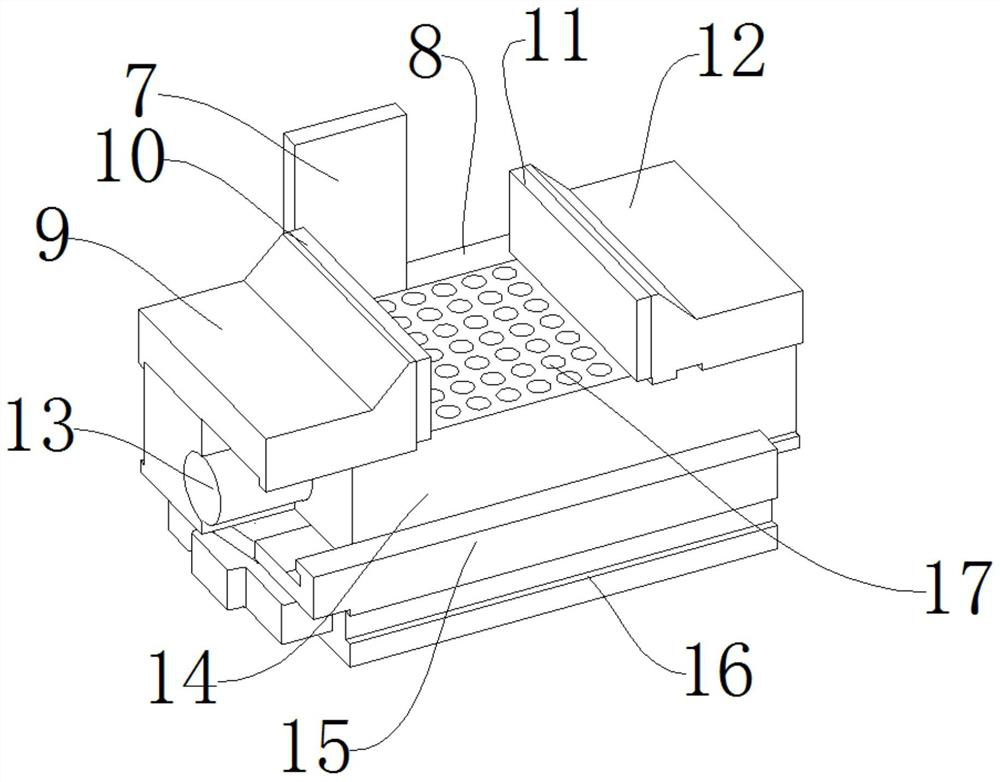

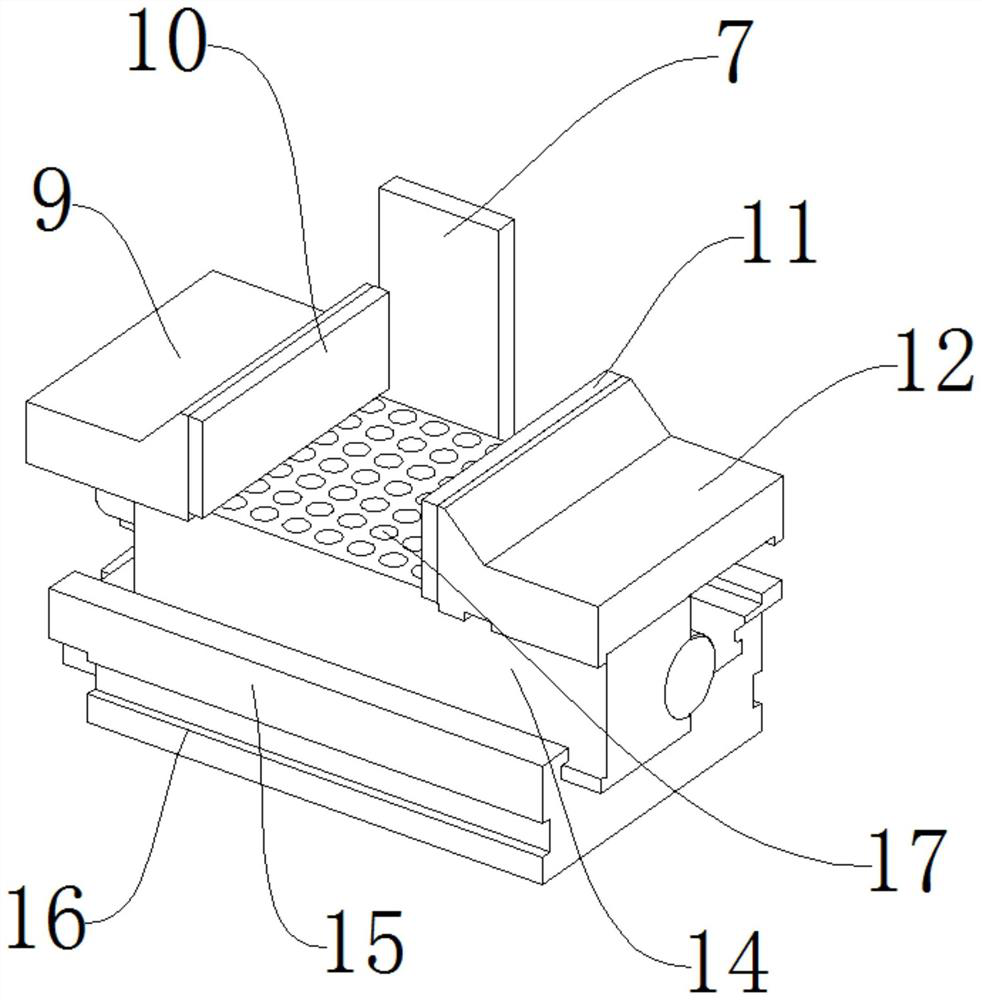

[0051] like Figure 1-Figure 12 As shown, a clamping device for processing photoelectric components includes a clamping mechanism 1, a workbench 2, a suction mechanism 22, and a center platform 14. The upper end of the workbench 2 is provided with a clamping mechanism 1, and the workbench 2 starts from Bearing function, the clamping mechanism 1 plays a clamping role. The clamping mechanism 1 is connected to the workbench 2 by bolts. The clamping mechanism 1 includes a first clamp 9, a first clamp 10, a second clamp 11, and a second clamp 12 , one side of the first clamp 9 is provided with a first clamping plate 10, the first clamping clamp 9 plays a clamping role, the first clamping plate 10 plays a protective role, the first clamping plate 10 is connected to the first clamping clamp 9 by bolts, and the first clamping plate 10 One side is provided with a second splint 11, the second splint 11 plays a protective role, and one side of the second splint 11 is provided with a seco...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is:

[0054] The electrical box 4 outside is provided with support leg 3, and support leg 3 is connected to workbench 2 by bolt, and support leg 3 plays a supporting role, and support leg 3 is connected with workbench 2 by bolt, has guaranteed the stability of equipment.

[0055] The present invention also provides a method for using a clamping device for processing photoelectric components, which is applied to the above-mentioned clamping device for processing photoelectric components. The specific waste recovery method is as follows:

[0056] a. First adjust the position of the baffle 7 on the baffle slide rail 8, then use the control panel 6 to control the controller 36 to turn on the equipment, and place the photoelectric components to be clamped on the center table 14.

[0057] b, the photoelectric component presses the sucker 23, the first pressure sensor 25 at the lower end of the sucker 23 feels the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com