Flatwise-mounted glass turnover table

A turntable and glass technology, applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low production efficiency and achieve the effects of low cost, space saving, and firm adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

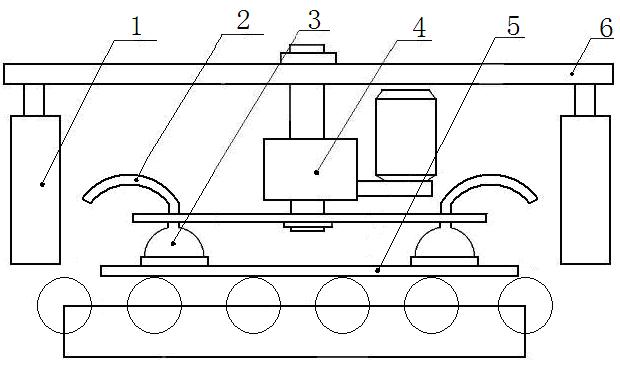

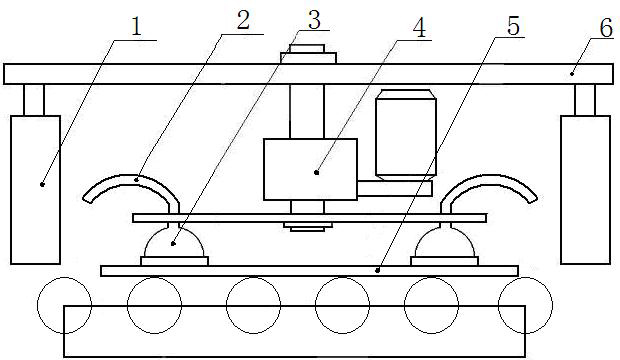

[0008] The present invention is described in detail below in conjunction with accompanying drawing:

[0009] Among the figure: 1, cylinder, 2, suction pipe, 3, sucker, 4, rotating head, 5, glass, 6, flat beam.

[0010] As shown in the drawings, it consists of a cylinder, a suction cup, a rotating head and a flat beam; the cylinder is placed at both ends of the flat beam, and the rotating head driven by a motor is set in the middle of the flat beam, and the rotating suction cup is fixed on the The two ends of the transverse arm fixedly connected with the rotating head.

[0011] In the middle process of conveying glass, after the glass is lifted by the suction cup, the glass is rotated 90° by the rotating head, and then the glass is continued to be conveyed, and the 90° turn of the glass is realized without stopping the glass conveying.

[0012] After starting up, the rollers convey the glass smoothly, at low speed and evenly. When the glass is close to the switch and it is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com