Method for measuring negative clearance of hub bearing unit

A wheel hub bearing and negative clearance technology, applied in the field of bearings, can solve the problems of early fatigue of balls and raceways, affect the performance of hub units, and affect the service life of hub bearings, etc., to adapt to continuous production, improve detection and The effect of high production efficiency and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

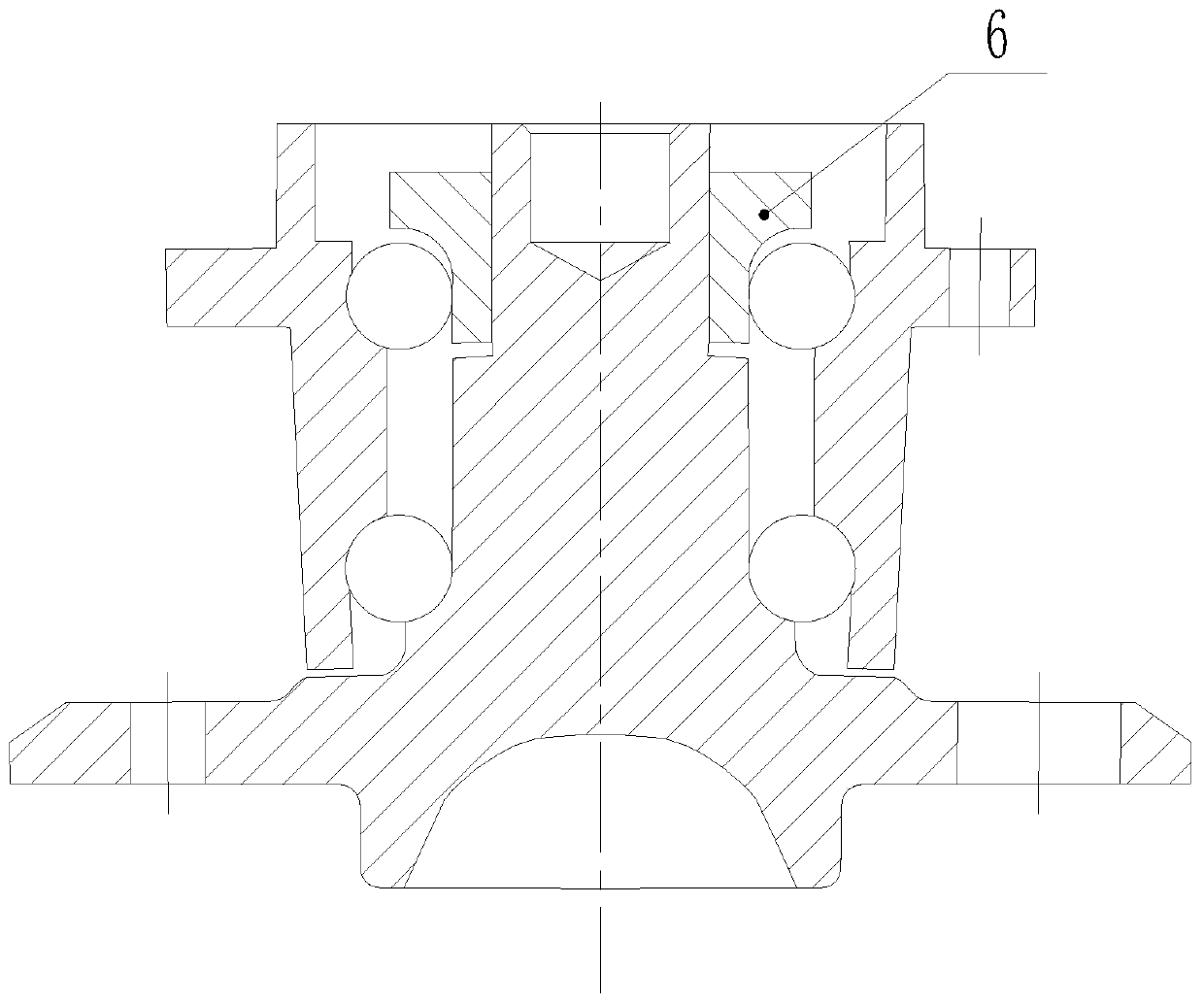

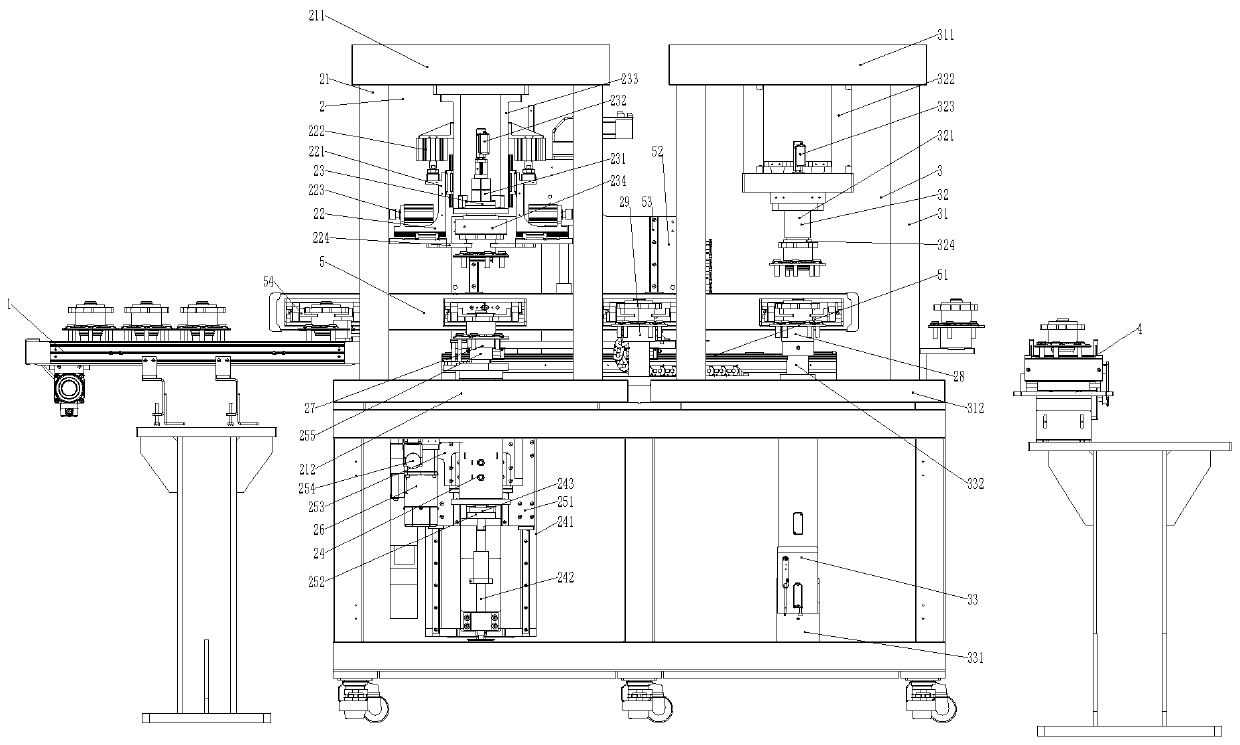

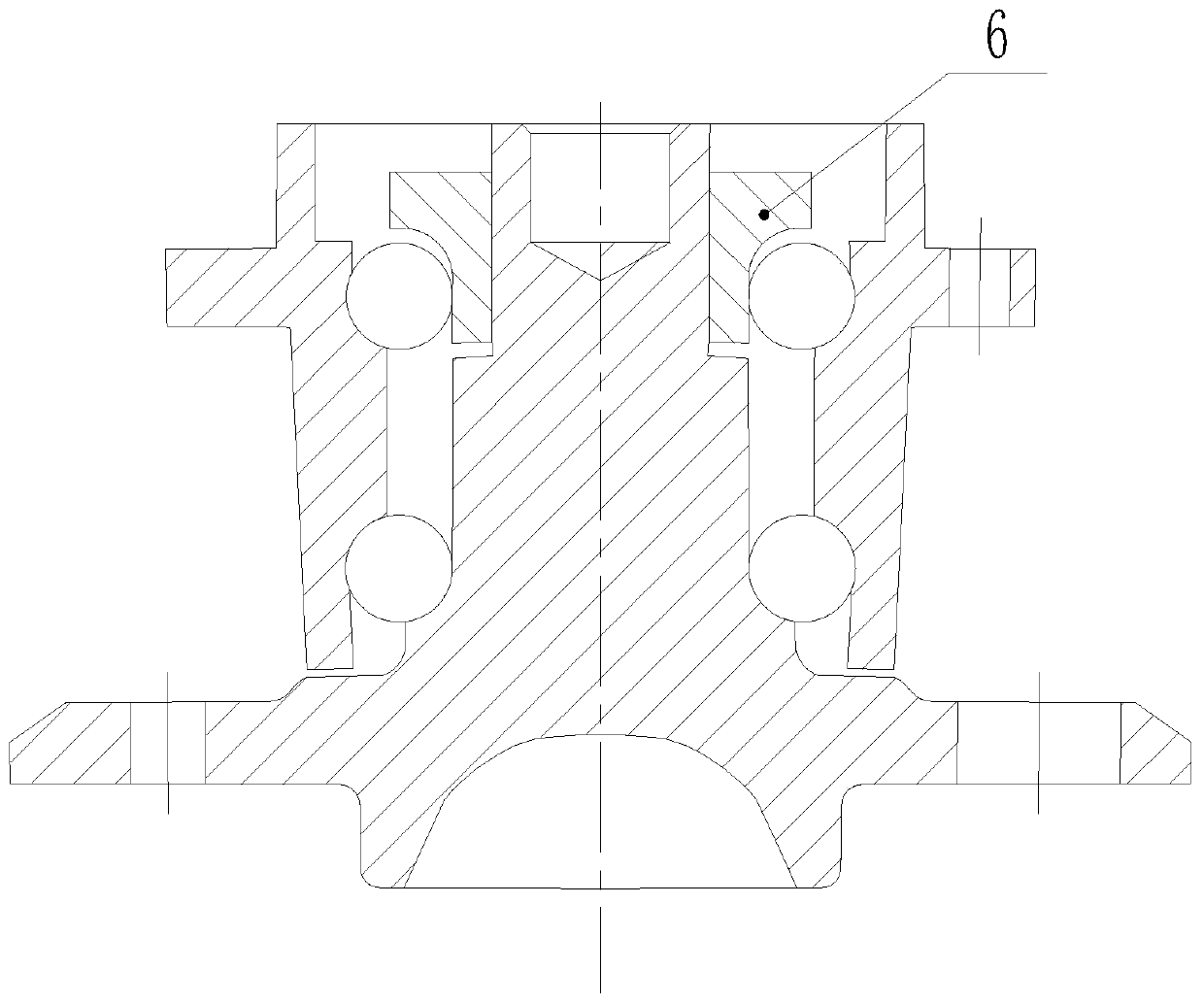

[0036] refer to figure 1 , the invention provides a method for measuring the negative clearance of a hub bearing unit, comprising the following steps:

[0037] S1: Feed the small circle 6 of the workpiece upwards into the positive clearance workpiece operating platform of the positive clearance and negative clearance press-fitting device of the hub bearing unit;

[0038] S2: The positive clearance measurement clamping mechanism clamps the outer flange of the workpiece, the small ring 6 is pressed by the lower top spring, and the workpiece is moved upwards from the positive clearance work table by the positive clearance measurement clamping mechanism, and the positive clearance displacement sensor The measurement data is a0;

[0039] S3: The inner flange lifting mechanism lifts the inner flange to a proper position;

[0040] S4: The rotating mechanism drives the inner and outer flanges of the workpiece to rotate relative to each other for 1-3 cycles, the measurement data of t...

Embodiment 2

[0045] refer to figure 1 , the invention provides a method for measuring the negative clearance of a hub bearing unit, comprising the following steps:

[0046] S1: Feed the small circle 6 of the workpiece upwards into the positive clearance workpiece operating platform of the positive clearance and negative clearance press-fitting device of the hub bearing unit with a translational manipulator;

[0047] S2: The positive clearance measurement clamping mechanism clamps the outer flange of the workpiece, the small ring 6 is pressed by the lower top spring, and the workpiece is moved upwards from the positive clearance work table by the positive clearance measurement clamping mechanism, and the positive clearance displacement sensor The measurement data is a0;

[0048] S3: The inner flange lifting mechanism lifts the inner flange to a proper position;

[0049] In this step, the servo motor drives the precision jacking mechanism mounted on the jacking mounting plate to move upward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com