Lithium-ion battery and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, applied in the field of lithium-ion batteries and their manufacturing, can solve the problems of long time, uneven internal structure of winding batteries, potential safety hazards, etc., and achieve good battery performance, interface stability and safety sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Combine below Attached picture The present invention is described further:

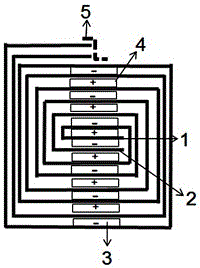

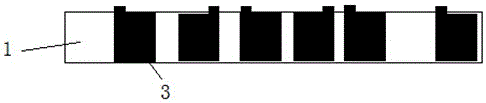

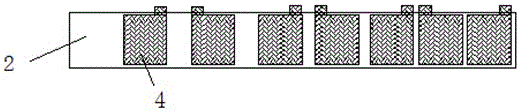

[0026] Such as figure 1 As shown, the lithium-ion battery of the present embodiment includes a battery cell assembly, and the battery cell assembly includes a plurality of positive electrode sheets 3 and a plurality of negative electrode sheets 4 alternately arranged with a plurality of positive electrode sheets 3, and the positive electrode sheets 3 and the negative electrode sheets 4 are at intervals Laminated arrangement, the positive electrode sheet 3 and the negative electrode sheet 4 are separated from each other by a separator. In this embodiment, the diaphragm is composed of the first diaphragm 1 and the second diaphragm 2, and the cell assembly is formed by sequentially stacking and winding the positive electrode sheet 3, the first diaphragm 1, the negative electrode sheet 4 and the second diaphragm 2, and the first diaphragm 1 and the outer ends of the second diaphragm 2 are fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com